fuse box RENAULT TWINGO 2009 2.G Engine Diesel Injection Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 269

Page 67 of 269

13B-67

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V6 MR-413-X44-13B000$100.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 50, 58

DF032

PRESENT

OR

STOREDTHERMOPLUNGER 1 RELAY CONTROL CIRCUIT

NOTESConditions for applying the fault finding procedure to stored faults:

The fault is present when the ignition is switched on.

See the Technical Note Wiring Diagrams for the vehicle.

For New Twingo

Check the connection and condition of the additional heater 1 relay connector, component code 1067 and the 80 A

maxi fuse in the engine fuse and relay box.

Check the connection and condition of the injection computer connector, component code 120.

If the connector(s) is faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Run command AC250 Heating resistor 1 relay.

If the command does not run, check, with the ignition on, for earth on connection 3JA of component 1067.

Check for + 12 V on connection 3FB of component 1067.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

Check the insulation and continuity of the following connections:

–3JA between components 1067 and 120,

–3FB between components 1067 and 238,

–38LL between components 1067 and 1113,

–BP9 between components 1067 and 597.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

If the fault is still present, check the relay and replace it if necessary.

If the fault is still present, contact the Techline.

DCM1.2_V50_DF032/DCM1.2_V58_DF032

Page 69 of 269

13B-69

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V6 MR-413-X44-13B000$100.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 50, 58

DF033

PRESENT

OR

STOREDTHERMOPLUNGER 2 RELAY CONTROL CIRCUIT

NOTESConditions for applying the fault finding procedure to stored faults:

The fault is present when the ignition is switched on.

See the Technical Note Wiring Diagrams for the vehicle.

Check the connection and condition of the additional heater 2 relay connector, component code 1068

and the 80 A maxi fuse in the engine fuse and relay box.

Check the connection and condition of the injection computer connector, component code 120.

If the connector(s) are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Run command AC251 Heating resistor 2 relay.

If the command does not run, check, with the ignition on, for earth on connection 3JAA of component 1068.

Check for + 12 V on connection 3FB of component 1068.

If the connector is faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the insulation and continuity of the following connections:

–3JAA between components 1068 and 120,

–3FB between components 1068 and 238,

–38LM between components 1068 and 1113,

–BP9 between components 1068 and 597.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

If the fault is still present, check the relay and replace it if necessary.

If the fault is still present, contact the Techline.

DCM1.2_V50_DF033/DCM1.2_V58_DF033

Page 70 of 269

13B-70

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V6 MR-413-X44-13B000$100.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 50, 58

DF034

PRESENT

OR

STOREDTHERMOPLUNGER 3 RELAY CONTROL CIRCUIT

NOTESConditions for applying the fault finding procedure to stored faults:

The fault is present when the ignition is switched on.

See the Technical Note Wiring Diagrams for the vehicle.

Check the connection and condition of the additional heater 2 relay connector, component code 1068

and the 80 A maxi fuse in the engine fuse and relay box.

Check the connection and condition of the injection computer connector, component code 120.

If the connector(s) are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Run command AC251 Heating resistor 2 relay.

If the command does not run, check, with the ignition on, for earth on connection 3JAA of component 1068.

Check for + 12 V on connection 3FB of component 1068.

If the connector is faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the insulation and continuity of the following connections:

–3JAA between components 1068 and 120,

–3FB between components 1068 and 238,

–38LM between components 1068 and 1113,

–BP9 between components 1068 and 597.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

If the fault is still present, check the relay and replace it if necessary.

If the fault is still present, contact the Techline.

DCM1.2_V50_DF034/DCM1.2_V58_DF034

Page 132 of 269

13B-132

AFTER REPAIRDeal with any faults. Clear the faults from the computer memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

V6 MR-413-X44-13B000$150.mif

DIESEL INJECTION

Fault finding – Interpretation of statuses13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

ET007PRE-POSTHEATING UNIT CONTROL

STATUS DEFINITIONACTIVE: the status is active when the heater plugs are activated according to the

engine coolant temperature.

INACTIVE: the status is inactive after the engine has been running for a certain period.

In the event of a fault, consult the interpretation of fault DF017 Preheating unit control

circuit.

Conformity check: Engine running and the engine coolant temperature > 80˚C

ACTIVEWhen the ignition is switched on, status ET007 should be ACTIVE for a time that varies

according to the engine coolant temperature. Both the relay and the heater plugs are

supplied.

After starting the status should remain ACTIVE for a time that varies depending on the

engine coolant temperature. This is postheating.

If ET007 is INACTIVE when the ignition is switched on, check:

–The supply fuse FB1 (70A) of the engine fuse and relay box or F2 (70A) on the power

feed fuse board, according to the vehicle.

–The feed to the heater plugs following relay actuation, and the heater plugs

connections.

–The continuity and the absence of interference resistance between the following

connections:

●Connection code 37Z between components 257 (or 980) and 680.

●Connection code 37AA between components 257 (or 980) and 681.

●Connection code 37AB between components 257 (or 980) and 682.

●Connection code 37AC between components 257 (or 980) and 683.

–That the contacts of the pre-postheating unit connector are in good condition and

connected correctly.

If the vehicle starts, preheating is completed and status ET007 remains ACTIVE during

the engine operating phase, consult the interpretation of faults DF017 Preheating unit

control circuit and DF025 Preheating unit fault finding connection.

INACTIVEIf the vehicle does not start, the status remains INACTIVE and the preheating was not

executed when the ignition was switched on or during the starting phase, check the

following connections:

●connection code 3FY and 3FF between components 120 and 257 (or 980).

Check for + 12 V on the preheating unit.

●Connection code BP35 of component 257 (or 980).

If the connection or connections are faulty and there is a repair procedure (see

Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for repair),

repair the wiring, otherwise replace it.

DCM1.2_V48_ET007/DCM1.2_V4C_ET007/DCM1.2_V50_ET007/DCM1.2_V54_ET007/DCM1.2_V58_ET007/DCM1.2_V5C_ET007

Page 236 of 269

13B-236V6 MR-413-X44-13B000$210.mif

13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

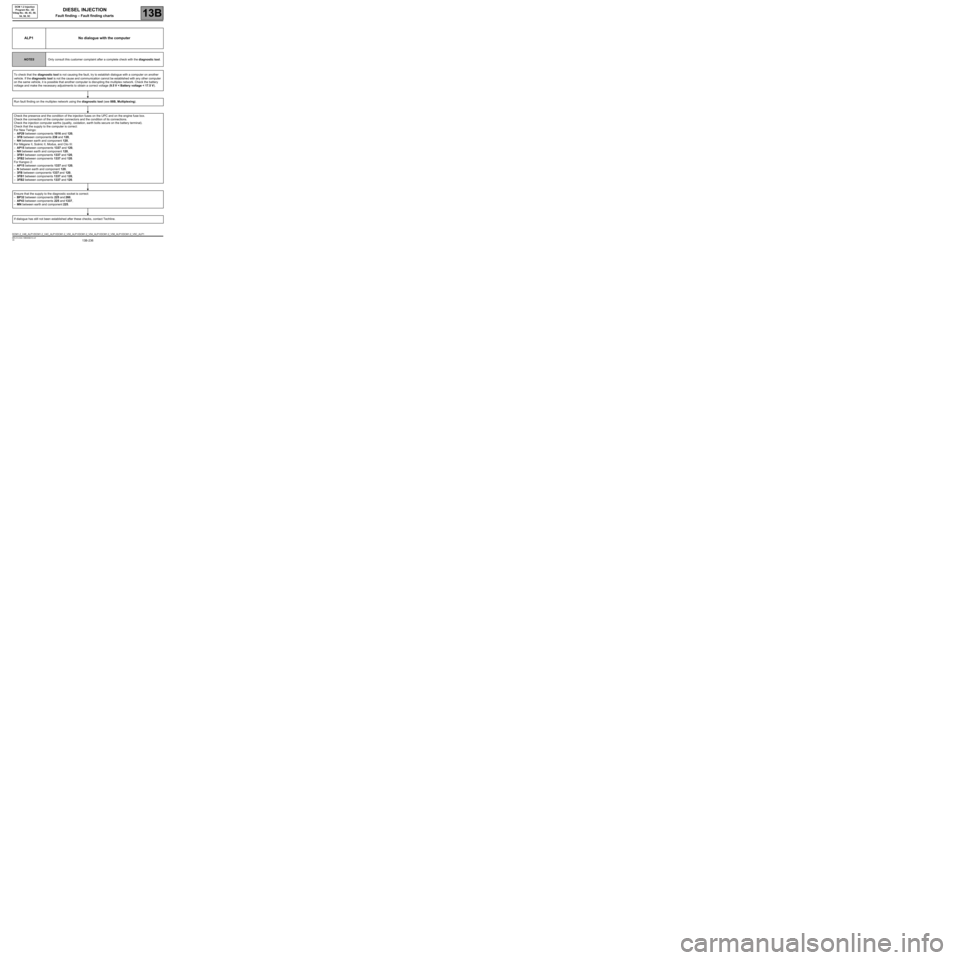

ALP1 No dialogue with the computer

NOTESOnly consult this customer complaint after a complete check with the diagnostic tool.

To check that the diagnostic tool is not causing the fault, try to establish dialogue with a computer on another

vehicle. If the diagnostic tool is not the cause and communication cannot be established with any other computer

on the same vehicle, it is possible that another computer is disrupting the multiplex network. Check the battery

voltage and make the necessary adjustments to obtain a correct voltage (9.5 V < Battery voltage < 17.5 V).

Run fault finding on the multiplex network using the diagnostic tool (see 88B, Multiplexing).

Check the presence and the condition of the injection fuses on the UPC and on the engine fuse box.

Check the connection of the computer connectors and the condition of its connections.

Check the injection computer earths (quality, oxidation, earth bolts secure on the battery terminal).

Check that the supply to the computer is correct:

For New Twingo:

–AP29 between components 1016 and 120,

–3FB between components 238 and 120,

–NH between earth and component 120,

For Mégane II, Scénic II, Modus, and Clio III:

–AP15 between components 1337 and 120,

–NH between earth and component 120,

–3FB1 between components 1337 and 120,

–3FB2 between components 1337 and 120.

For Kangoo 2:

–AP15 between components 1337 and 120,

–N between earth and component 120,

–3FB between components 1337 and 120,

–3FB1 between components 1337 and 120,

–3FB2 between components 1337 and 120.

Ensure that the supply to the diagnostic socket is correct:

–BP32 between components 225 and 260,

–AP43 between components 225 and 1337,

–MN between earth and component 225.

If dialogue has still not been established after these checks, contact Techline.

DCM1.2_V48_ALP1/DCM1.2_V4C_ALP1/DCM1.2_V50_ALP1/DCM1.2_V54_ALP1/DCM1.2_V58_ALP1/DCM1.2_V5C_ALP1

DIESEL INJECTION

Fault finding – Fault finding charts