sensor RENAULT TWINGO 2009 2.G Heating And Air Conditioning - Manual Air Conditioning Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 63

Page 2 of 63

62C-2

MR-413-X44-62C000$091_eng.mif

V1

62C

MANUAL AIR CONDITIONING

Fault finding - Introduction

1. SCOPE OF THIS DOCUMENT

This document presents the fault finding procedure applicable to all computers with the following specifications:

2. PREREQUISITES FOR FAULT FINDING

Documentation type

Fault finding procedures (this document and the Technical Notes concerning the injection system

fitted to the vehicle, and the UCH):

–Assisted fault finding (integrated into the diagnostic tool), Dialogys.

Wiring Diagrams:

–Visu Schéma (CD-ROM), paper.

Type of diagnostic tools

–CLIP + multiplex line sensor

Special tooling required

3. REMINDERS

Procedure

To run fault finding on the vehicle computers, proceed as follows:

–turn the ignition key to APC,

–Connect the diagnostic tool and carry out the required operations,

To cut off the + after ignition feed, proceed as follows:

–disconnect the diagnostic tool,

–turn the ignition key to OFF,

–switch off the ignition. Vehicle(s): New Twingo

Function concerned: Manual air conditioning

Special tooling required

Multimeter

Elé. 1681 Universal bornier

MR-413-X44-62C000$091_eng.mif

Page 11 of 63

62C-11

MR-413-X44-62C000$273_eng.mif

V1

MANUAL AIR CONDITIONING

Fault finding - Role of components62C

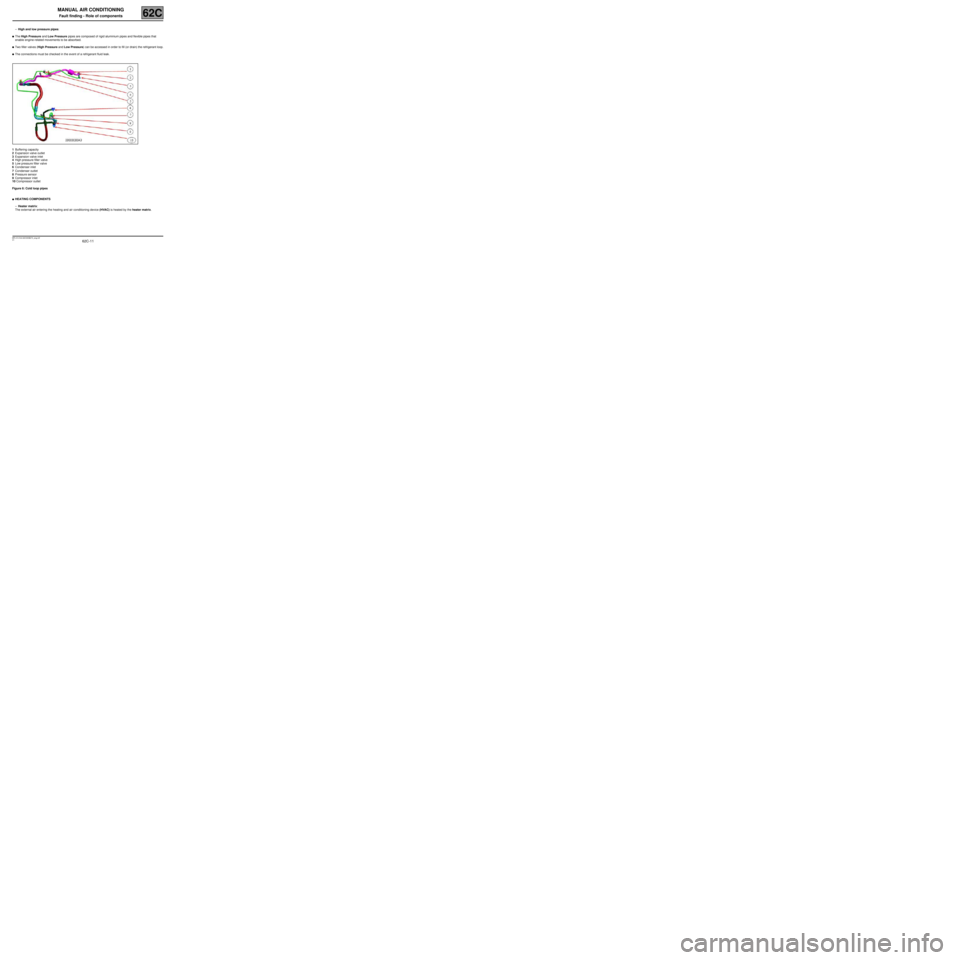

–High and low pressure pipes:

●The High Pressure and Low Pressure pipes are composed of rigid aluminium pipes and flexible pipes that

enable engine-related movements to be absorbed.

●Two filler valves (High Pressure and Low Pressure) can be accessed in order to fill (or drain) the refrigerant loop.

●The connections must be checked in the event of a refrigerant fluid leak.

1Buffering capacity

2Expansion valve outlet

3Expansion valve inlet

4High pressure filler valve

5Low pressure filler valve

6Condenser inlet

7Condenser outlet

8Pressure sensor

9Compressor inlet

10 Compressor outlet

Figure 6: Cold loop pipes

●HEATING COMPONENTS

–Heater matrix:

The external air entering the heating and air conditioning device (HVAC) is heated by the heater matrix.

Page 14 of 63

62C-14

MR-413-X44-62C000$364_eng.mif

V1

62C

MANUAL AIR CONDITIONING

Fault finding - Operating diagram

Summary diagram of all the components of the air conditioning system

1Evaporator

2Temperature sensor

3Compressor

4Condenser

5Fan assembly

6Pressure switch

7Dehydration canister

8Expansion valve

MR-413-X44-62C000$364_eng.mif

Page 19 of 63

62C-19

MR-413-X44-62C000$455_eng.mif

V1

MANUAL AIR CONDITIONING

Fault finding - Function62C

Vehicle

multiplex

network

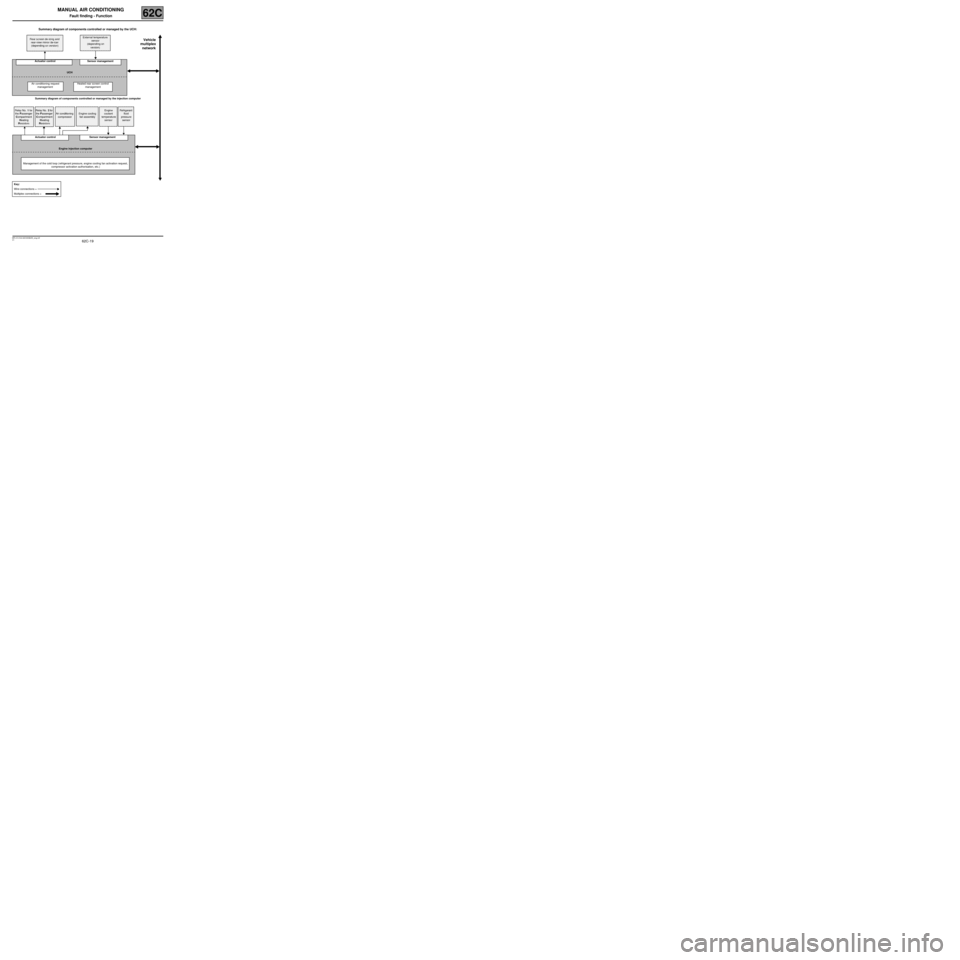

Summary diagram of components controlled or managed by the UCH:

Summary diagram of components controlled or managed by the injection computer Rear screen de-icing and

rear-view mirror de-icer

(depending on version)External temperature

sensor

(depending on

version)

Actuator control Sensor management

UCH

Air conditioning request

managementHeated rear screen control

management

Relay No. 1 for

the Passenger

Compartment

Heating

ResistorsRelay No. 2 for

the Passenger

Compartment

Heating

ResistorsAir conditioning

compressorEngine cooling

fan assemblyEngine

coolant

temperature

sensorRefrigerant

fluid

pressure

sensor

Actuator control Sensor management

Engine injection computer

Management of the cold loop (refrigerant pressure, engine cooling fan activation request,

compressor activation authorisation, etc.)

Key:

Wire connections =

Multiplex connections =

Page 21 of 63

62C-21

MR-413-X44-62C000$546_eng.mif

V1

62C

MANUAL AIR CONDITIONING

Diagnostics - Configuration and programming

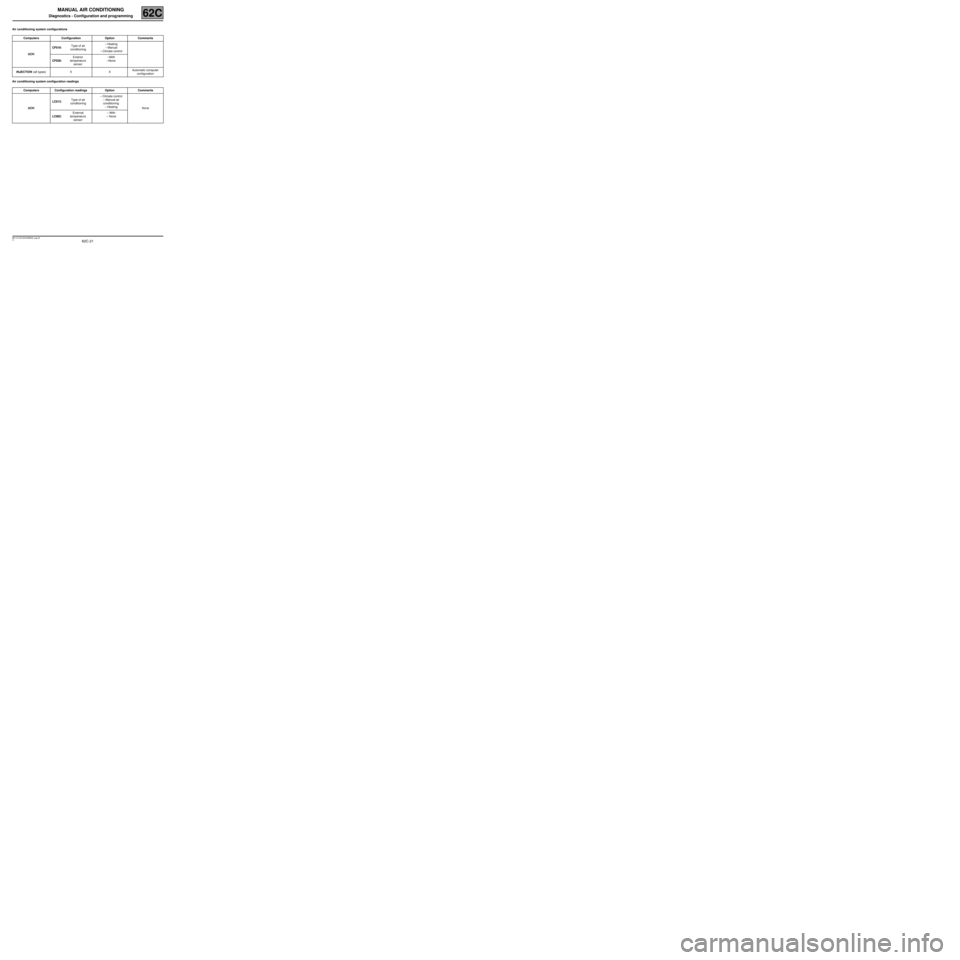

Air conditioning system configurations

Air conditioning system configuration readingsComputers Configuration Option Comments

UCHCF019: Type of air

conditioning– Heating

– Manual

– Climate control

CF029: Exterior

temperature

sensor–With

–None

INJECTION (all types) X XAutomatic computer

configuration

Computers Configuration readings Option Comments

UCHLC013: Type of air

conditioning– Climate control

– Manual air

conditioning

– Heating

None

LC002: External

temperature

sensor– With

– None

MR-413-X44-62C000$546_eng.mif

Page 39 of 63

62C-39

MR-413-X44-62C000$819_eng.mif

V1

MANUAL AIR CONDITIONING

Fault finding - Fault finding charts62C

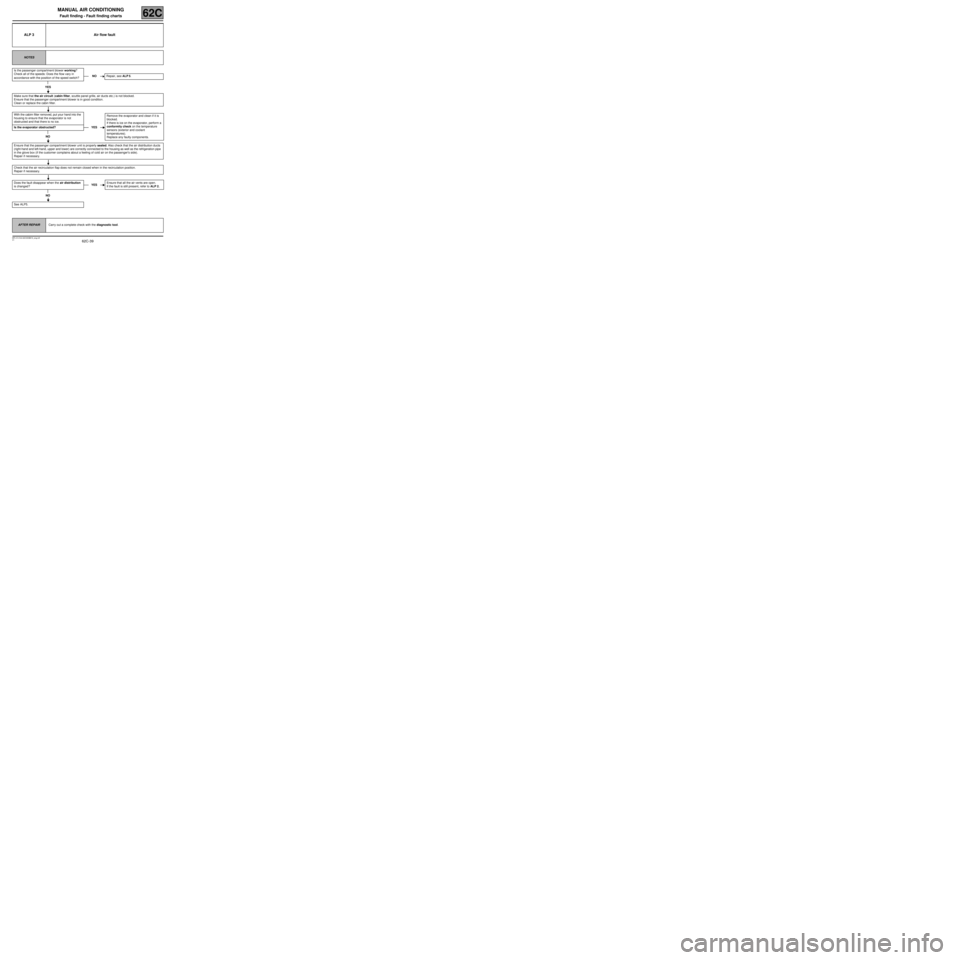

ALP 3 Air flow fault

NOTES

Is the passenger compartment blower working?

Check all of the speeds: Does the flow vary in

accordance with the position of the speed switch?

YES

Make sure that the air circuit (cabin filter, scuttle panel grille, air ducts etc.) is not blocked.

Ensure that the passenger compartment blower is in good condition.

Clean or replace the cabin filter.

With the cabim filter removed, put your hand into the

housing to ensure that the evaporator is not

obstructed and that there is no ice.

Is the evaporator obstructed?

NO

Ensure that the passenger compartment blower unit is properly sealed. Also check that the air distribution ducts

(right-hand and left-hand, upper and lower) are correctly connected to the housing as well as the refrigeration pipe

in the glove box (if the customer complains about a feeling of cold air on the passenger's side).

Repair if necessary.

Check that the air recirculation flap does not remain closed when in the recirculation position.

Repair if necessary.

Does the fault disappear when the air distribution

is changed ?

NO

See ALP5.

AFTER REPAIRCarry out a complete check with the diagnostic tool.

NORepair, see ALP 5.

YESRemove the evaporator and clean if it is

blocked.

If there is ice on the evaporator, perform a

conformity check on the temperature

sensors (exterior and coolant

temperatures).

Replace any faulty components.

YESEnsure that all the air vents are open.

If the fault is still present, refer to ALP 2.

Page 49 of 63

62C-49

MR-413-X44-62C000$819_eng.mif

V1

MANUAL AIR CONDITIONING

Fault finding - Fault finding charts62C

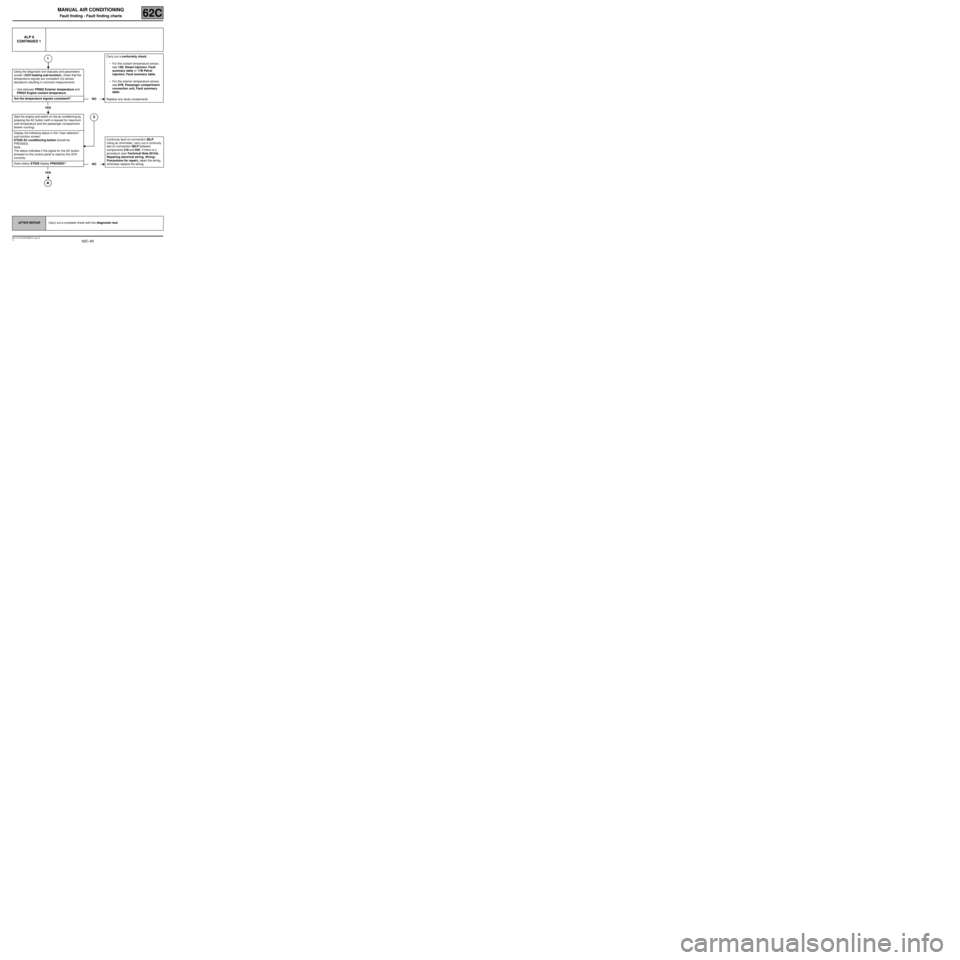

ALP 8

CONTINUED 1

1

Using the diagnostic tool statuses and parameters

screen (UCH heating sub-function), check that the

temperature signals are consistent (no sensor

deviations resulting in incorrect measurement).

–Use statuses PR002 Exterior temperature and

PR024 Engine coolant temperature.

Are the temperature signals consistent?

YES

Start the engine and switch on the air conditioning by

pressing the AC button (with a request for maximum

cold temperature and the passenger compartment

blower running).

2

Display the following status in the “User selection”

sub-function screen:

ET029 Air conditioning button should be

PRESSED.

Note:

The status indicates if the signal for the AC button

pressed on the control panel is read by the UCH

correctly.

Does status ET029 display PRESSED?

YES

NOCarry out a conformity check:

–For the coolant temperature sensor,

see 13B, Diesel injection, Fault

summary table or 17B Petrol

injection, Fault summary table.

–For the exterior temperature sensor,

see 87B, Passenger compartment

connection unit, Fault summary

table.

Replace any faulty components.

NOContinuity fault on connection 38LP.

Using an ohmmeter, carry out a continuity

test on connection 38LP between

components 319 and 645. If there is a

procedure (see Technical Note 6015A,

Repairing electrical wiring, Wiring:

Precautions for repair), repair the wiring,

otherwise replace the wiring.

AFTER REPAIRCarry out a complete check with the diagnostic tool.

Page 57 of 63

62C-57

MR-413-X44-62C000$910_eng.mif

V1

MANUAL AIR CONDITIONING

Fault finding - Fault finding charts62C

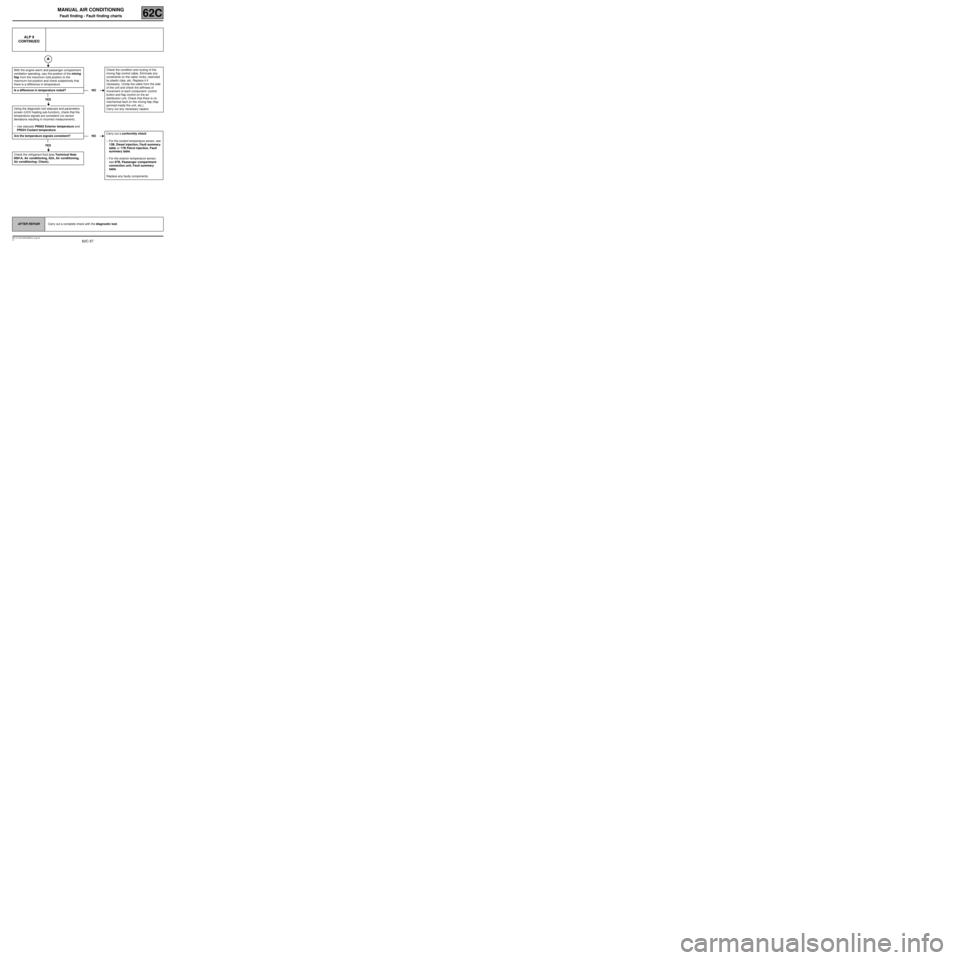

ALP 9

CONTINUED

With the engine warm and passenger compartment

ventilation operating, vary the position of the mixing

flap from the maximum cold position to the

maximum hot position and check subjectively that

there is a difference in temperature.

Is a difference in temperature noted?

YES

Using the diagnostic tool statuses and parameters

screen (UCH heating sub-function), check that the

temperature signals are consistent (no sensor

deviations resulting in incorrect measurement).

–Use statuses PR002 Exterior temperature and

PR024 Coolant temperature.

Are the temperature signals consistent?

YES

Check the refrigerant fluid (see Technical Note

6001A, Air conditioning, 62A, Air conditioning,

Air conditioning: Check).

NOCheck the condition and routing of the

mixing flap control cable. Eliminate any

constraints on the cable: kinks, restricted

by plastic clips, etc. Replace it if

necessary. Unclip the cable from the side

of the unit and check the stiffness of

movement of each component: control

button and flap control on the air

distribution unit. Check that there is no

mechanical fault on the mixing flap (flap

jammed inside the unit, etc.).

Carry out any necessary repairs.

NOCarry out a conformity check:

–For the coolant temperature sensor, see

13B, Diesel injection, Fault summary

table or 17B Petrol injection, Fault

summary table.

–For the exterior temperature sensor,

see 87B, Passenger compartment

connection unit, Fault summary

table.

Replace any faulty components.

AFTER REPAIRCarry out a complete check with the diagnostic tool.