Gearbox RENAULT TWINGO 2009 2.G Transmission Repair Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 135

Page 53 of 135

21A-38

MANUAL GEARBOX

Differential output seal: Removal - Refitting

JB1 or JH1 or JH3 or JR5

21A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the front right-hand wheel driveshaft (see 29A,

Driveshafts, Front right-hand driveshaft: Re-

moval - Refitting, page 29A-8) .

aDrain the gearbox (see 21A, Manual gearbox,

Manual gearbox oils: Draining - Filling, page

21A-2) .

aRemove:

-the wheel on the side concerned (see Wheel: Re-

moval - Refitting) (35A, Wheels and tyres),

-the front wheel driveshaft for the side in question

(see 29A, Driveshafts, Front left-hand drive-

shaft: Removal - Refitting, page 29A-2) or (see

29A, Driveshafts, Front right-hand driveshaft:

Removal - Refitting, page 29A-8) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aTap the base of the differential output seal using a

roll pin punch and a small hammer to rotate it in its

housing.

aRemove the differential output seal using pliers, tak-

ing care not to damage the splines on the sunwheel. Special tooling required

Bvi. 945Mandrel for fitting the sun-

wheel seal.

Bvi. 1666Tool for fitting differential

seals .

Equipment required

roll pin punch

JB1 or JH1

JH3 or JR5

JB1 or JH1

86031

Page 54 of 135

21A-39

MANUAL GEARBOX

Differential output seal: Removal - Refitting

JB1 or JH1 or JH3 or JR5

21A

aTap the base of the differential output seal using a

roll pin punch and a small hammer to detach it and

rotate it in its housing.

aRemove the differential output seal using a large

screwdriver, taking care not to damage the differen-

tial housing.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

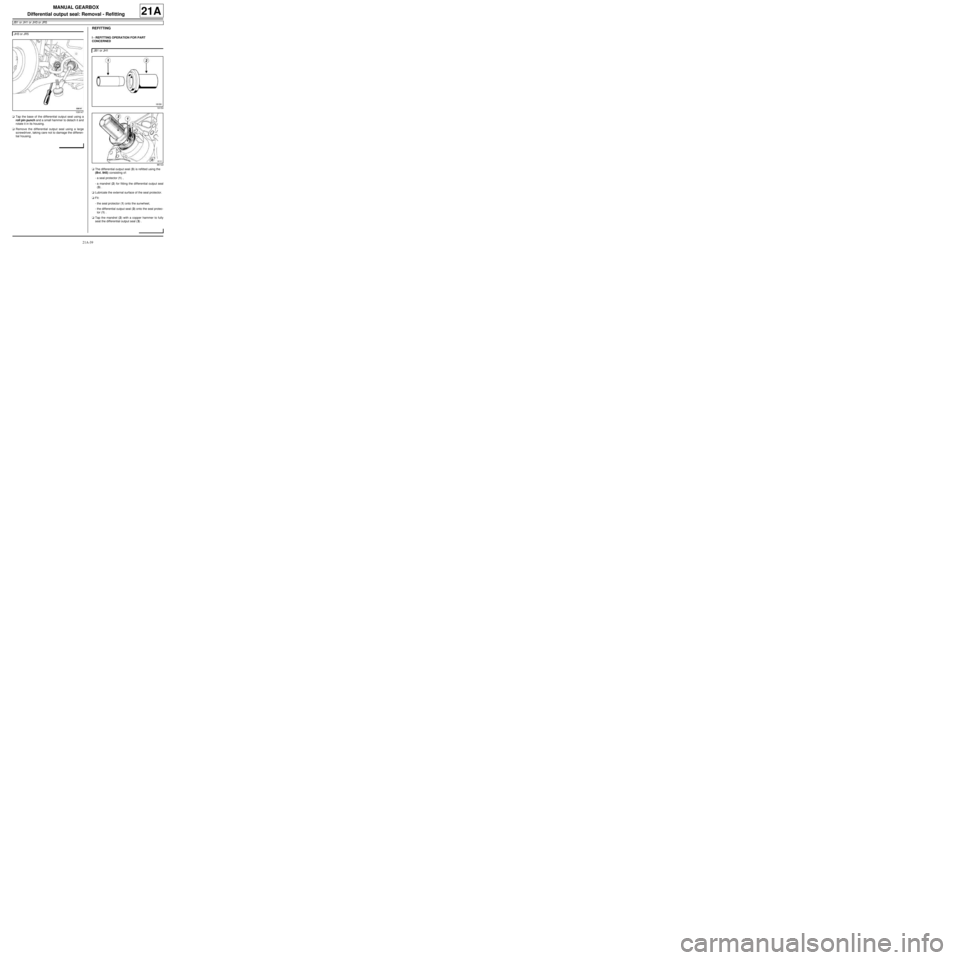

aThe differential output seal (3) is refitted using the

(Bvi. 945) consisting of:

-a seal protector (1) ,

-a mandrel (2) for fitting the differential output seal

(3) .

aLubricate the external surface of the seal protector.

aFit:

-the seal protector (1) onto the sunwheel,

-the differential output seal (3) onto the seal protec-

tor (1) .

aTap the mandrel (2) with a copper hammer to fully

seat the differential output seal (3) . JH3 or JR5

109147

JB1 or JH1

18150

86122

Page 55 of 135

21A-40

MANUAL GEARBOX

Differential output seal: Removal - Refitting

JB1 or JH1 or JH3 or JR5

21A

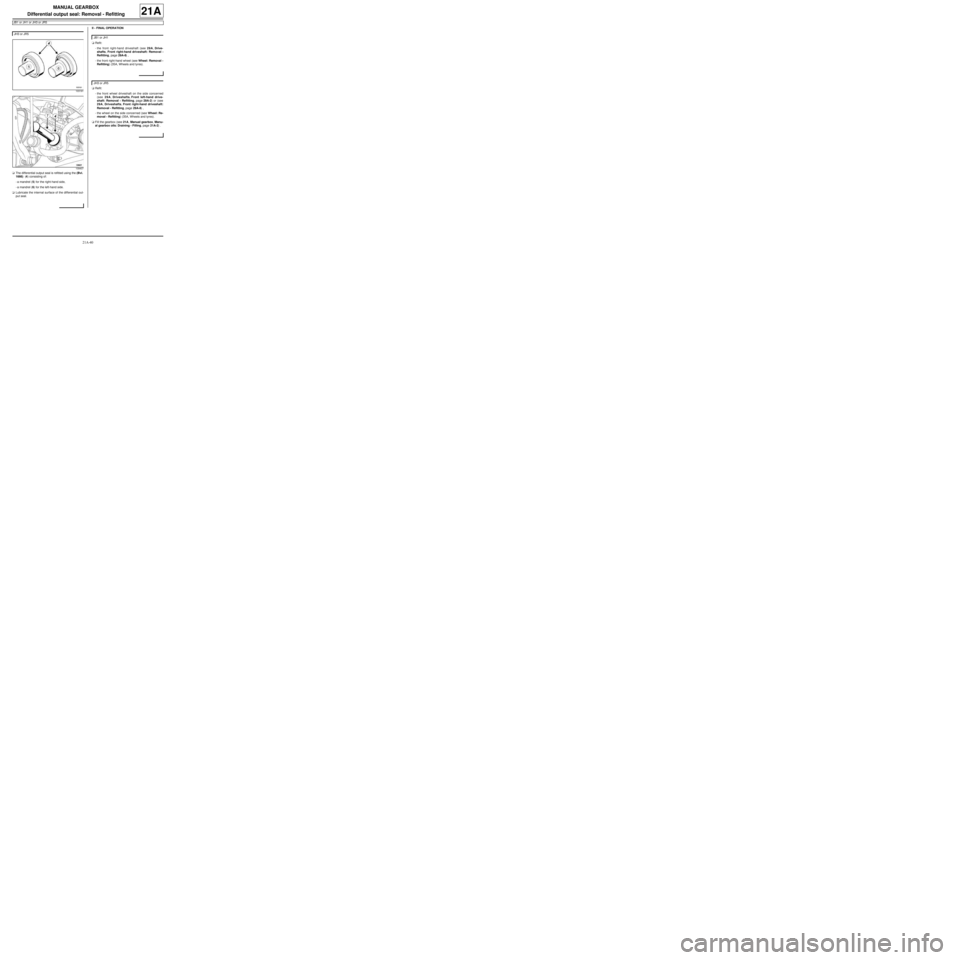

aThe differential output seal is refitted using the (Bvi.

1666) (4) consisting of:

-a mandrel (5) for the right-hand side,

-a mandrel (6) for the left-hand side.

aLubricate the internal surface of the differential out-

put seal.II - FINAL OPERATION

aRefit:

-the front right-hand driveshaft (see 29A, Drive-

shafts, Front right-hand driveshaft: Removal -

Refitting, page 29A-8) ,

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres).

aRefit:

-the front wheel driveshaft on the side concerned

(see 29A, Driveshafts, Front left-hand drive-

shaft: Removal - Refitting, page 29A-2) or (see

29A, Driveshafts, Front right-hand driveshaft:

Removal - Refitting, page 29A-8) ,

-the wheel on the side concerned (see Wheel: Re-

moval - Refitting) (35A, Wheels and tyres).

aFill the gearbox (see 21A, Manual gearbox, Manu-

al gearbox oils: Draining - Filling, page 21A-2) . JH3 or JR5

103191

109407

JB1 or JH1

JH3 or JR5

Page 56 of 135

21A-41

MANUAL GEARBOX

Input shaft lip seal: Removal - Refitting

JB1

21A

Detailed view of the Bvi tool components. 1445

aThe gearbox must be removed.

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (MR 411, 80A, Battery).aRemove the gearbox (see 21A, Manual gearbox,

Manual gearbox: Removal - Refitting, page 21A-

24) .

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aPosition the gearbox on the mounting (1) adjusting

the adjustable support (2) .

aGently remove the guide tube with a press using the

(Bvi. 1828).

aDegrease the guide tube. Special tooling required

Bvi. 1828Snap r ivet and pressure plate

for removal and refitting of the

guide tube (JH1 gearbo x)

Note:

The lip seal and the primary shaft bearing are built

into the thr ust pad guide tube.

It is lubricated via an aperture into the housing

bore.

99057

(1) tightening clamp

(2) sleeve

(3) Sender

(4) key

(5) split ring

98934

98936

Page 57 of 135

21A-42

MANUAL GEARBOX

Input shaft lip seal: Removal - Refitting

JB1

21A

aPlace the tightening clamp (3) onto the tube.

aLock the tightening clamp using the spanner (4) .

aTighten the nut firmly (5) .

aPosition the sleeve (6) and the split ring (7) .

aTurn the upper nut (8) .

aGently extract the guide tube.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aPosition the new guide tube on the clutch housing.

aGently remove the guide tube with a press and the

(Bvi. 1828).

II - FINAL OPERATION.

aRefit the gearbox (see 21A, Manual gearbox, Man-

ual gearbox: Removal - Refitting, page 21A-24)

(MR 411, 21A, Manual gearbox).

aConnect the battery (see Battery: Removal - Refit-

ting) (MR 411, 80A, Battery).

98937

98938

98939

98935-1

Page 58 of 135

21A-43

MANUAL GEARBOX

Input shaft lip seal: Removal - Refitting

JH1 or JH3 or JR5

21A

aReplace the lip seal after having opened the gear-

box (see Clutch housing bearing: Removal - Re-

fitting) (Technical Note 6029A, 21A, Manual

gearbox).

Page 59 of 135

21A-44

MANUAL GEARBOX

Reverse gear switch: Removal - Refitting

JB1 or JH1 or JH3 or JR5

21A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the front left-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the front left-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection).

aRemove the engine undertray.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the connector (1) from the reverse gear

switch.aRemove the reverse gear switch using the tool (Bvi.

1934) (2) .

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aApply some SILICONE ADHESIVE SEALANT (see

Vehicle: Parts and consumables for the repair)

(04B, Consumables - Products) to the threading of

the reverse gear switch.

aRefit the reverse gear switch using the (Bvi. 1934).

aTorque tighten the reverse gear switch (23 N.m).

aConnect the reverse gear switch connector.

II - FINAL OPERATION

aFill the gearbox (see 21A, Manual gearbox, Manu-

al gearbox oils: Draining - Filling, page 21A-2) .

aRefit the engine undertray.

aRefit:

-the front left-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection), Special tooling required

Bvi. 1934Socket for removing/refitting

reverse gear switch

Tightening torquesm

reverse gear switch23 N.m

132082

144801

Note:

Seal the housing of the reverse gear switch while

replacing the par t.

Page 60 of 135

21A-45

MANUAL GEARBOX

Reverse gear switch: Removal - Refitting

JB1 or JH1 or JH3 or JR5

21A

-the front left-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres).

Page 61 of 135

21B-1

SEQUENTIAL GEARBOX

Sequential gearbox: Precautions for the repair

D4F, and JH1

21B

I - SEQUENTIAL GEARBOX

II - SEQUENTIAL GEARBOX COMPUTER

To disconnect the computer, switch off the ignition and

wait for 1 minute.

III - ELECTRO-HYDRAULIC UNIT

Discharge the pressure accumulator using the Diag-

nostic tool before any operation on the electro-hy-

draulic unit.

Be careful not to twist the high pressure pipes when re-

moving the electro-hydraulic unit.

IV - GEAR SELECTION SENSOREquipment required

Diagnostic tool

IMPORTANT

Before any operation on the sequential system, dis-

charge the accumulator using the Diagnostic tool.

WARNING

If any operation is carried out on the electro-hydrau-

lic unit, it is essential to clean the unit using a clean-

ing product and compressed air.

Never leave the circuit open and never use a high

pressure cleaner.

WARNING

After the accumulator has been fully filled (15 sec-

onds after the ignition has been switched on): the

oil level is at the MINIMUM mark.

WARNING

To remove the gear selection sensor it is essential

that you shift to first gear before removal.

Page 62 of 135

21B-2

SEQUENTIAL GEARBOX

Sequential gearbox: List and location of components

D4F, and JH1

21B

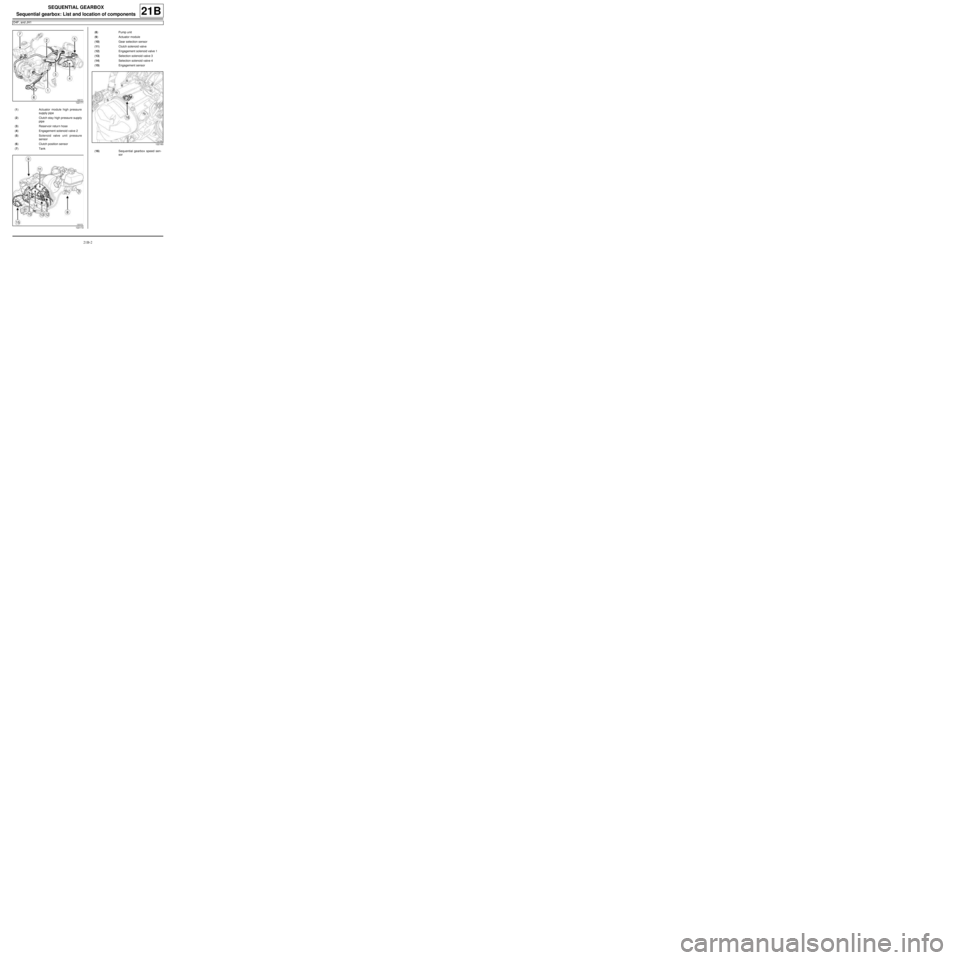

122171

(1) Actuator module high pressure

supply pipe

(2) Clutch stay high pressure supply

pipe

(3) Reservoir retur n hose

(4) Engagement solenoid v alve 2

(5) Solenoid valve unit pressure

sensor

(6) Clutch position sensor

(7) Tank

122172

(8) Pump unit

(9) Actuator module

(10) Gear selection sensor

(11) Clutch solenoid valve

(12) Engagement solenoid valve 1

(13) Selection solenoid valve 3

(14) Selection solenoid valve 4

(15) Engagement sensor

122160

(16) Sequential gearbox speed sen-

sor