RENAULT TWINGO RS 2009 2.G Air Conditioning Workshop Manual

Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 122

Page 101 of 122

62A-20

AIR CONDITIONING

Compressor: Removal - Refitting

AIR CONDITIONING or CLIMATE CONTROL

62A

aUse a compressed air nozzle to blow on the sur-

face and the seal of the connecting pipe.

aLubricate the surface of the connecting pipe and the

seal with air conditioning oil (see 62A, Air condi-

tioning, Air conditioning: Parts and consum-

ables for the repair, page 62A-2) .

aRemove the blanking plugs.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the compressor.

aConnect the compressor connector.

aPosition the compressor connecting pipes.

aRefit:

-the bolts of the connecting pipes on the compres-

sor,

-the bolt of the connecting pipe bracket on the com-

pressor.

III - FINAL OPERATION

aRefit:

-the accessories belt (see Accessories belt: Re-

moval - Refitting) (10A, Engine and peripherals),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres).

aConnect the battery (see ) (80A, Battery).

aConsult the amount of refrigerant and oil required

before filling the air conditioning circuit (see 62A, Air

conditioning, Air conditioning: Parts and con-

sumables for the repair, page 62A-2) .

aFill the refrigerant circuit using a refrigerant charg-

ing station (see 62A, Air conditioning, Refriger-

ant circuit: Draining - Filling, page 62A-8) .

aIn the event of replacement, apply the after repair

procedure:

-Switch on the ignition,

-Check that the air conditioning is off,

-Switch the ventilation to speed 2,

-Put the temperature setting at minimum,

-Select the air recirculation position,

-Start the engine.

-Run the air conditioning in manual mode (in the

case of climate control do not press auto),

-Run the engine at idle speed for 3 minutes with air

conditioning,

-Switch off the engine.

aCheck for leaks (see 62A, Air conditioning, Refrig-

erant circuit: Check, page 62A-7) .

aCheck that the air conditioning system is operating

correctly (see 62A, Air conditioning, Air condi-

tioning: Check, page 62A-4) .

143882

Page 102 of 122

62A-21

AIR CONDITIONING

Expansion valve: Removal - Refitting

AIR CONDITIONING or CLIMATE CONTROL

62A

REMOVAL

I - REMOVAL PREPARATION OPERATION

a

aDrain the refrigerant circuit using a refrigerant

charging station (see 62A, Air conditioning, Re-

frigerant circuit: Draining - Filling, page 62A-8) .

aDisconnect the battery (see ) (80A, Battery).

aRemove:

-the wiper arms (see Windscreen wiper arm: Re-

moval - Refitting) (85A, Wiping - Washing),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment).

aRemove:

-the air filter unit (see Air filter unit: Removal - Re-

fitting) (12A, Fuel mixture),

-the upstream oxygen sensor (see Oxygen sen-

sors: Removal - Refitting) (17B, Petrol injection). Equipment requiredrefrigerant charging station

compressed air nozzle

IMPORTANT

To avoid all risk of damage to the systems, apply

the safety and cleanliness instructions and opera-

tion recommendations before carrying out any

repair:

- (see 62A, Air conditioning, Air conditioning:

Precautions for the repair, page 62A-1) ,

- (see Vehicle: Precautions for the repair) (01D,

Mechanical introduction).

Note:

Use blanking plugs for the fuel circuits with part

numbers 77 01 208 229 or 77 01 476 857 to plug

any openings exposed to the open air. They must

be clean. Do not use any which have already been

used to plug a fuel circuit.

WARNING

To prevent moisture from entering the system,

place plugs on the cold loop components which are

open to the air.

WARNING

In order to avoid any refrigerant leaks, do not dam-

age (deform, twist, etc.) the pipe.

WARNING

To prevent the surrounding components from over-

heating, do not damage (tear, pierce, bend, etc.) a

heat shield.

Any damaged heat shields must be replaced.WARNING

Consult the device's operating manual to avoid

incorrect use.

D4F, and 780 – K4M, and 854

Page 103 of 122

62A-22

AIR CONDITIONING

Expansion valve: Removal - Refitting

AIR CONDITIONING or CLIMATE CONTROL

62A

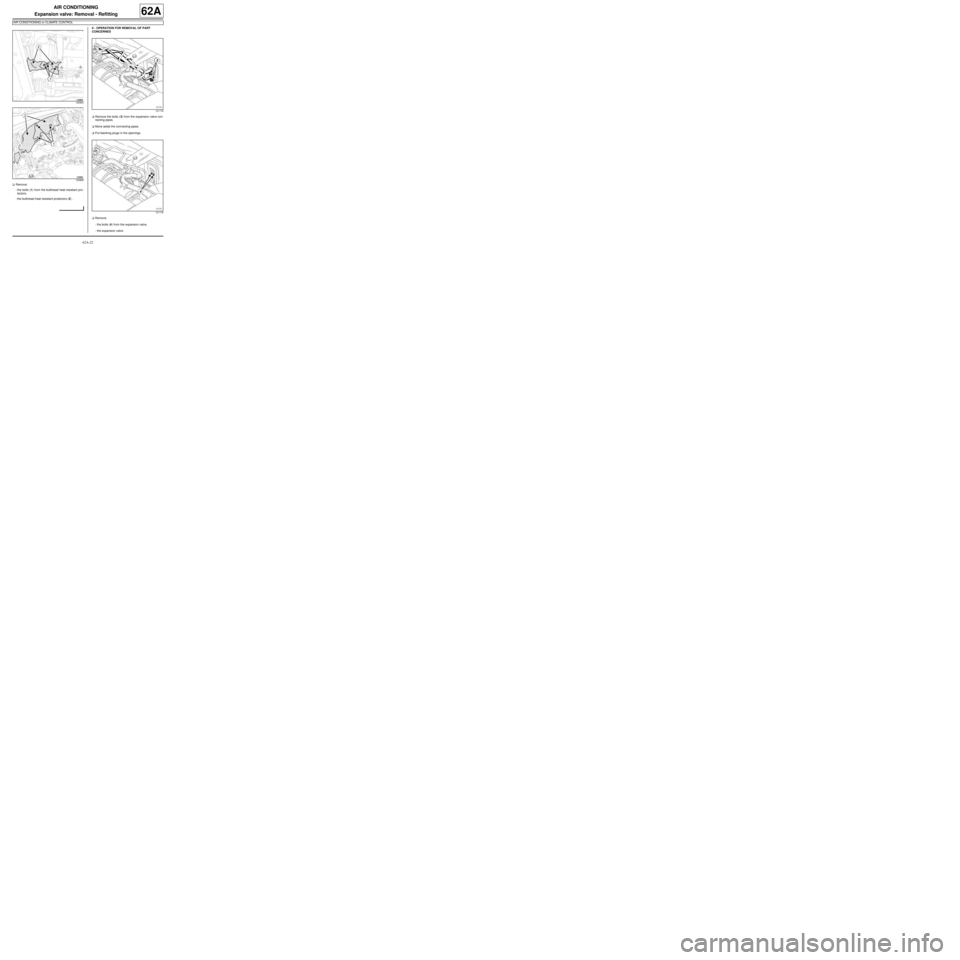

aRemove:

-the bolts (1) from the bulkhead heat-resistant pro-

tectors,

-the bulkhead heat-resistant protectors (2) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the bolts (3) from the expansion valve con-

necting pipes.

aMove aside the connecting pipes.

aPut blanking plugs in the openings.

aRemove:

-the bolts (4) from the expansion valve,

-the expansion valve.

123903

123908

121178

121179

Page 104 of 122

62A-23

AIR CONDITIONING

Expansion valve: Removal - Refitting

AIR CONDITIONING or CLIMATE CONTROL

62A

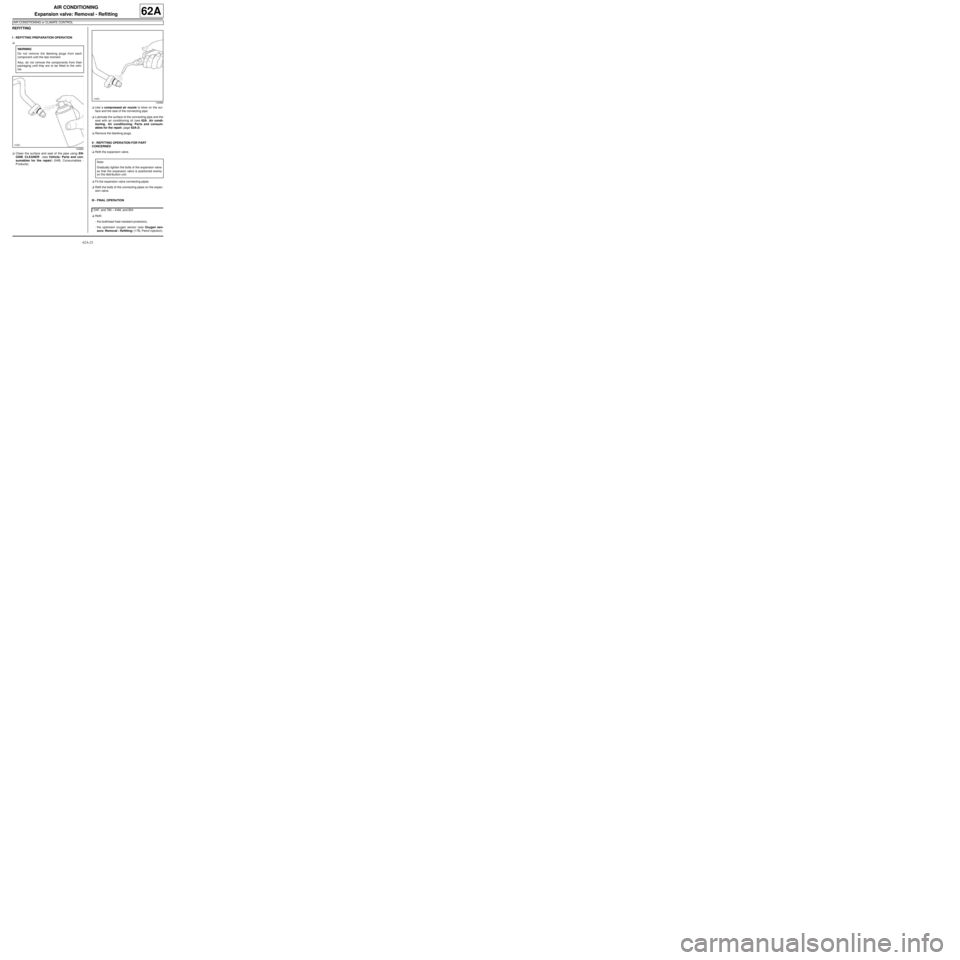

REFITTING

I - REFITTING PREPARATION OPERATION

a

aClean the surface and seal of the pipe using EN-

GINE CLEANER (see Vehicle: Parts and con-

sumables for the repair) (04B, Consumables -

Products).aUse a compressed air nozzle to blow on the sur-

face and the seal of the connecting pipe.

aLubricate the surface of the connecting pipe and the

seal with air conditioning oil (see 62A, Air condi-

tioning, Air conditioning: Parts and consum-

ables for the repair, page 62A-2) .

aRemove the blanking plugs.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the expansion valve.

aFit the expansion valve connecting pipes.

aRefit the bolts of the connecting pipes on the expan-

sion valve.

III - FINAL OPERATION

aRefit:

-the bulkhead heat-resistant protectors,

-the upstream oxygen sensor (see Oxygen sen-

sors: Removal - Refitting) (17B, Petrol injection), WARNING

Do not remove the blanking plugs from each

component until the last moment.

Also, do not remove the components from their

packaging until they are to be fitted to the vehi-

cle.

143880

143882

Note:

Gradually tighten the bolts of the expansion valve

so that the expansion valve is positioned evenly

on the distr ibution unit.

D4F, and 780 – K4M, and 854

Page 105 of 122

62A-24

AIR CONDITIONING

Expansion valve: Removal - Refitting

AIR CONDITIONING or CLIMATE CONTROL

62A

-the air filter box (see Air filter unit: Removal - Re-

fitting) (12A, Fuel mixture).

aRefit:

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the wiper arms (see Windscreen wiper arm: Re-

moval - Refitting) (85A, Wiping - Washing).

aConnect the battery (see ) (80A, Battery).

aConsult the amount of refrigerant and oil required

before filling the air conditioning circuit (see 62A, Air

conditioning, Air conditioning: Parts and con-

sumables for the repair, page 62A-2) .

aFill the refrigerant circuit using a refrigerant charg-

ing station (see 62A, Air conditioning, Refriger-

ant circuit: Draining - Filling, page 62A-8) .

aCheck for leaks (see 62A, Air conditioning, Refrig-

erant circuit: Check, page 62A-7) .

aCheck that the air conditioning system is operating

correctly (see 62A, Air conditioning, Air condi-

tioning: Check, page 62A-4) .

Page 106 of 122

62A-25

AIR CONDITIONING

Evaporator: Removal - Refitting

AIR CONDITIONING or CLIMATE CONTROL

62A

REMOVAL

OPERATION FOR REMOVAL OF PART

CONCERNED

a

aRemove the distribution unit (see 61A, Heating,

Distribution unit: Removal - Refitting, page 61A-

27) .

REFITTING

REFITTING OPERATION FOR PART CONCERNED

aRefit the distribution unit (see 61A, Heating, Distri-

bution unit: Removal - Refitting, page 61A-27) . Note:

The evaporator is supplied already assembled in

the distribution unit.

Page 107 of 122

62A-26

AIR CONDITIONING

Evaporator: Cleaning

AIR CONDITIONING or CLIMATE CONTROL

62A

CLEANING

I - CLEANING PREPARATION OPERATION

aRemove the cabin filter (see 61A, Heating, Cabin

filter: Removal - Refitting, page 61A-6) .

II - OPERATION FOR CLEANING PART

CONCERNED

aRemove any foreign matter (leaves, insects, etc.)

from the cabin filter housing.

a

Apply AIR CONDITIONING CLEANER using an ex-

tension piece. The end of the extension piece must

be positioned at the base of the evaporator.

aSpray the entire contents of the can.

aLeave the product to work for 15 minutes.

aRun the fan assembly very slowly for 5 minutes.

III - FINAL OPERATION.

aRefit the cabin filter (see 61A, Heating, Cabin filter:

Removal - Refitting, page 61A-6) . Note:

For the part number for the air conditioning

cleaner (see Vehicle: Parts and consumables

for the repair) (MR 411, 04B, Consumables -

Products).

WARNING

Do not spray the cleaner via the air inlet, as this

could damage the fan assembly.

Page 108 of 122

62A-27

AIR CONDITIONING

Expansion valve - intermediate pipe connecting pipe at the expansion valve outlet: Removal - Refitting

AIR CONDITIONING or CLIMATE CONTROL

62A

REMOVAL

I - PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aDrain the coolant circuit using a refrigerant charg-

ing station (see 62A, Air conditioning, Refriger-

ant circuit: Draining - Filling, page 62A-8) .

aDisconnect the battery (see ) (MR 411, 80A, Bat-

tery).

aRemove:

-the wiper arms (see Windscreen wiper arm: Re-

moval - Refitting) (MR 411, 85A, Wipers - Wash-

ers),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (MR 412, 56A, Exterior

equipment),-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (MR 412, 56A, Exterior equipment).

II - REMOVAL OPERATION FOR PART

CONCERNED

aRemove the « dehydrator reservoir - expansion

valve » and « expansion valve intermediate pipe »

(see 62A, Air conditioning, Dehydrator reservoir

- expansion valve connecting pipe: Removal -

Refitting, page 62A-28) connecting pipe assembly.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit the « expansion valve - intermediate pipe » -

« expansion valve - dehydrator reservoir » (see

62A, Air conditioning, Dehydrator reservoir - ex-

pansion valve connecting pipe: Removal - Refit-

ting, page 62A-28) connecting pipe assembly.

II - FINAL OPERATION.

aRefit:

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (MR 412, 56A, Exterior equipment),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (MR 412, 56A, Exterior

equipment),

-the wiper arms (see Windscreen wiper arm: Re-

moval - Refitting) (MR 411, 85A, Washing - wip-

ing).

aConnect the battery (see ) (MR 411, 80A, Battery).

aConsult the refrigerant and oil quantity values before

filling the circuit (see 62A, Air conditioning, Air

conditioning: Parts and consumables for the re-

pair, page 62A-2) .

aFill the refrigerant circuit using a refrigerant charg-

ing station (see 62A, Air conditioning, Refriger-

ant circuit: Draining - Filling, page 62A-8) .

aCheck that the air conditioning system is operating

correctly (see 62A, Air conditioning, Air condi-

tioning: Check, page 62A-4) .

aCheck for leaks (see 62A, Air conditioning, Refrig-

erant circuit: Check, page 62A-7) . Equipment required

refrigerant charging station

IMPORTANT

Consult the safety and cleanliness advice and oper-

ation recommendations before carrying out any

repair (see 62A, Air conditioning, Air condition-

ing: Precautions for the repair, page 62A-1) .

Note:

Use blanking plugs for the fuel circuits with part

numbers 77 01 208 229 or 77 01 476 857 to plug

any openings exposed to the open air. They must

be clean. Do not use plugs which have already

been used to plug a fuel circuit.

Note:

The « expansion valve - intermediate pipe » and

« expansion valve - dehydrator reservoir » connect-

ing pipes cannot be separated.

WARNING

Consult the device's operating manual to avoid

incorrect use.

Page 109 of 122

62A-28

AIR CONDITIONING

Dehydrator reservoir - expansion valve connecting pipe: Removal - Refitting

AIR CONDITIONING or CLIMATE CONTROL

62A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDrain the refrigerant circuit using a refrigerant

charging station (see 62A, Air conditioning, Re-

frigerant circuit: Draining - Filling, page 62A-8) .

aDisconnect the battery (see ) (80A, Battery).

aRemove:

-the wiper arms (see Windscreen wiper arm: Re-

moval - Refitting) (85A, Wiping - Washing),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment). Special tooling required

Mot. 1410Set of refrigerant pipe union

disconnection sockets.

(dimensions in inches): 5/16,

3/8, 1/2, 5/8, 3/4, 7/8.

Equipment required

refrigerant charging station

compressed air nozzle

IMPORTANT

To avoid all risk of damage to the systems, apply

the safety and cleanliness instructions and opera-

tion recommendations before carrying out any

repair:

- (see 62A, Air conditioning, Air conditioning:

Precautions for the repair, page 62A-1) ,

- (see Vehicle: Precautions for the repair) (01D,

Mechanical introduction).

WARNING

To prevent moisture from entering the system,

place plugs on the cold loop components which are

open to the air.

WARNING

In order to avoid any refrigerant leaks, do not dam-

age (deform, twist, etc.) the pipe.

Note:

Use blanking plugs for the fuel circuits with part

numbers 77 01 2008 229 or 77 01 476 857 to plug

any openings exposed to the open air. They must

be clean. Do not use any which have already been

used to plug a fuel circuit.

WARNING

To prevent the surrounding components from over-

heating, do not damage (tear, pierce, bend, etc.) a

heat shield.

Any damaged heat shields must be replaced.

Note:

The « expansion valve - intermediate pipe » and

« expansion valve - dehydrator reservoir » connect-

ing pipes cannot be separated.

WARNING

Consult the device's operating manual to avoid

incorrect use.

Page 110 of 122

62A-29

AIR CONDITIONING

Dehydrator reservoir - expansion valve connecting pipe: Removal - Refitting

AIR CONDITIONING or CLIMATE CONTROL

62A

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the nuts (1) from the connecting pipe brack-

et.

aMove aside the connecting pipes on the body.

aUncouple the « expansion valve - intermediate

pipe » connecting pipe from the « compressor - in-

termediate pipe » connecting pipe using tool (Mot.

1410) at (2) .aRemove the bolts (3) from the expansion valve con-

necting pipes.

aRemove the connecting pipes from the expansion

valve.

aInsert the blanking plugs.

aRemove:

-the air filter unit (see Air filter unit: Removal - Re-

fitting) (12A, Fuel mixture),

-the upstream oxygen sensor (see Oxygen sen-

sors: Removal - Refitting) (17B, Petrol injection).

aDisconnect the air temperature sensor.

121180

121178

D4F, and 780

K4M