ESP RENAULT TWINGO RS 2009 2.G Chasiss ESP Owner's Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 101

Page 21 of 101

38C-21

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool

If the fault is still present, contact the Techline.

V3 MR-413-X44-38C050$101.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Interpretation of faults38C

Bosch 8.1 ESP

Vdiag No.: 05

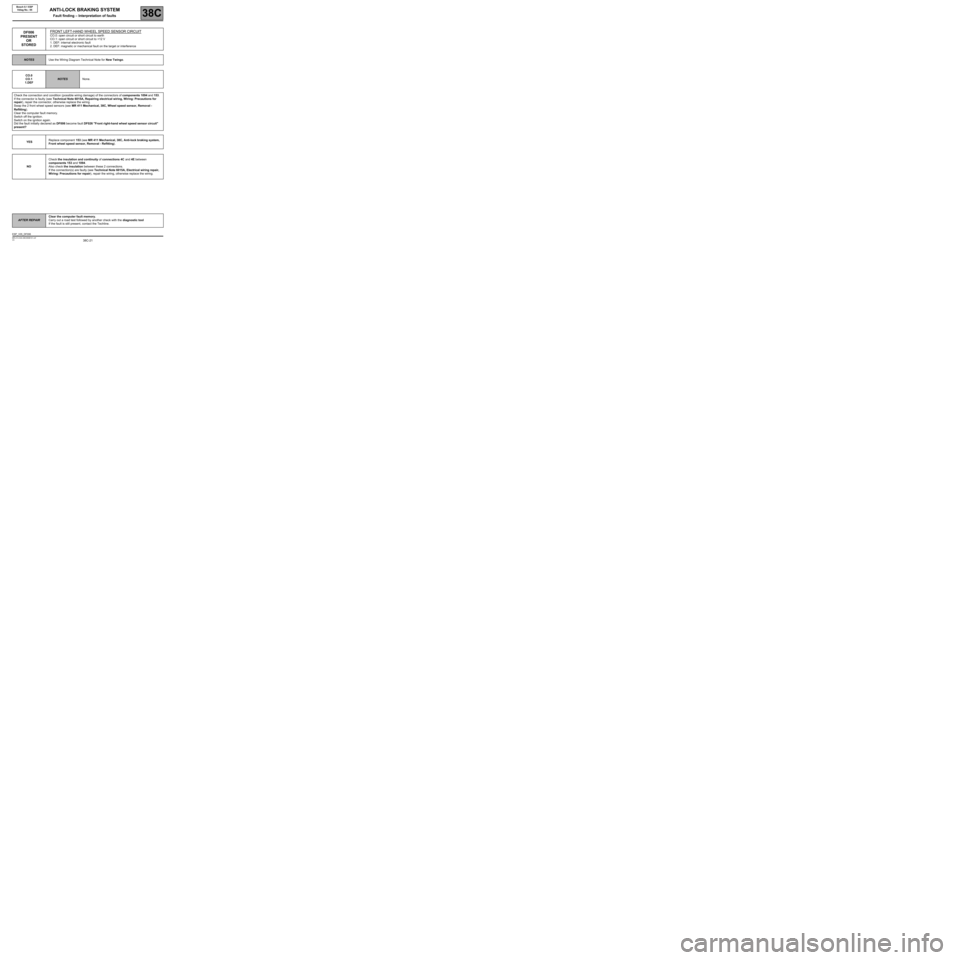

DF006

PRESENT

OR

STOREDFRONT LEFT-HAND WHEEL SPEED SENSOR CIRCUITCO.0: open circuit or short circuit to earth

CO.1: open circuit or short circuit to +12 V

1. DEF: internal electronic fault

2. DEF: magnetic or mechanical fault on the target or interference

NOTESUse the Wiring Diagram Technical Note for New Twingo.

CO.0

CO.1

1.DEF

NOTESNone.

Check the connection and condition (possible wiring damage) of the connectors of components 1094 and 153.

If the connector is faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the connector, otherwise replace the wiring.

Swap the 2 front wheel speed sensors (see MR 411 Mechanical, 38C, Wheel speed sensor, Removal -

Refitting).

Clear the computer fault memory.

Switch off the ignition.

Switch on the ignition again.

Did the fault initially declared as DF006 become fault DF026 "Front right-hand wheel speed sensor circuit"

present?

YESReplace component 153 (see MR 411 Mechanical, 38C, Anti-lock braking system,

Front wheel speed sensor, Removal - Refitting).

NOCheck the insulation and continuity of connections 4C and 4E between

components 153 and 1094.

Also check the insulation between these 2 connections.

If the connection(s) are faulty (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

ESP_V05_DF006

Page 22 of 101

38C-22

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool

If the fault is still present, contact the Techline.

V3 MR-413-X44-38C050$101.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Interpretation of faults38C

Bosch 8.1 ESP

Vdiag No.: 05

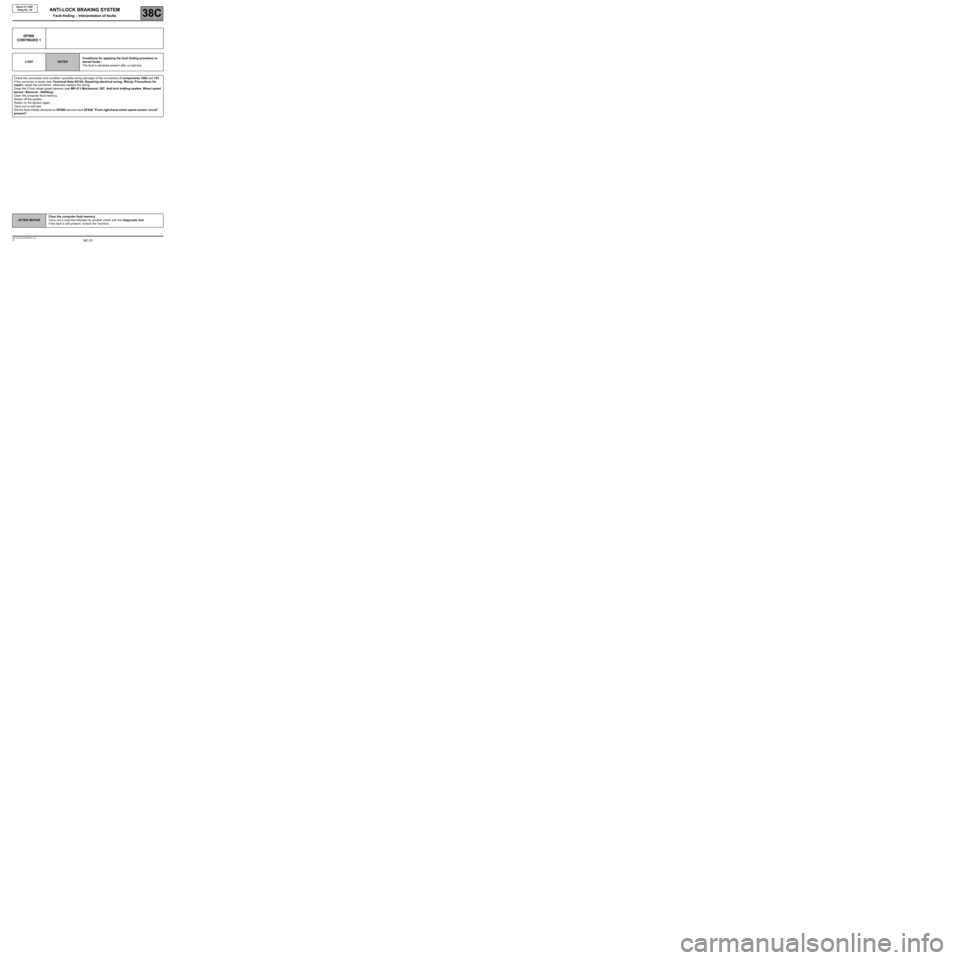

DF006

CONTINUED 1

2.DEFNOTESConditions for applying the fault finding procedure to

stored faults:

The fault is declared present after a road test.

Check the connection and condition (possible wiring damage) of the connectors of components 1094 and 153.

If the connector is faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the connector, otherwise replace the wiring.

Swap the 2 front wheel speed sensors (see MR 411 Mechanical, 38C, Anti-lock braking system, Wheel speed

sensor: Removal - Refitting).

Clear the computer fault memory.

Switch off the ignition.

Switch on the ignition again.

Carry out a road test.

Did the fault initially declared as DF006 become fault DF026 "Front right-hand wheel speed sensor circuit"

present?

Page 23 of 101

38C-23

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool

If the fault is still present, contact the Techline.

V3 MR-413-X44-38C050$101.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Interpretation of faults38C

Bosch 8.1 ESP

Vdiag No.: 05

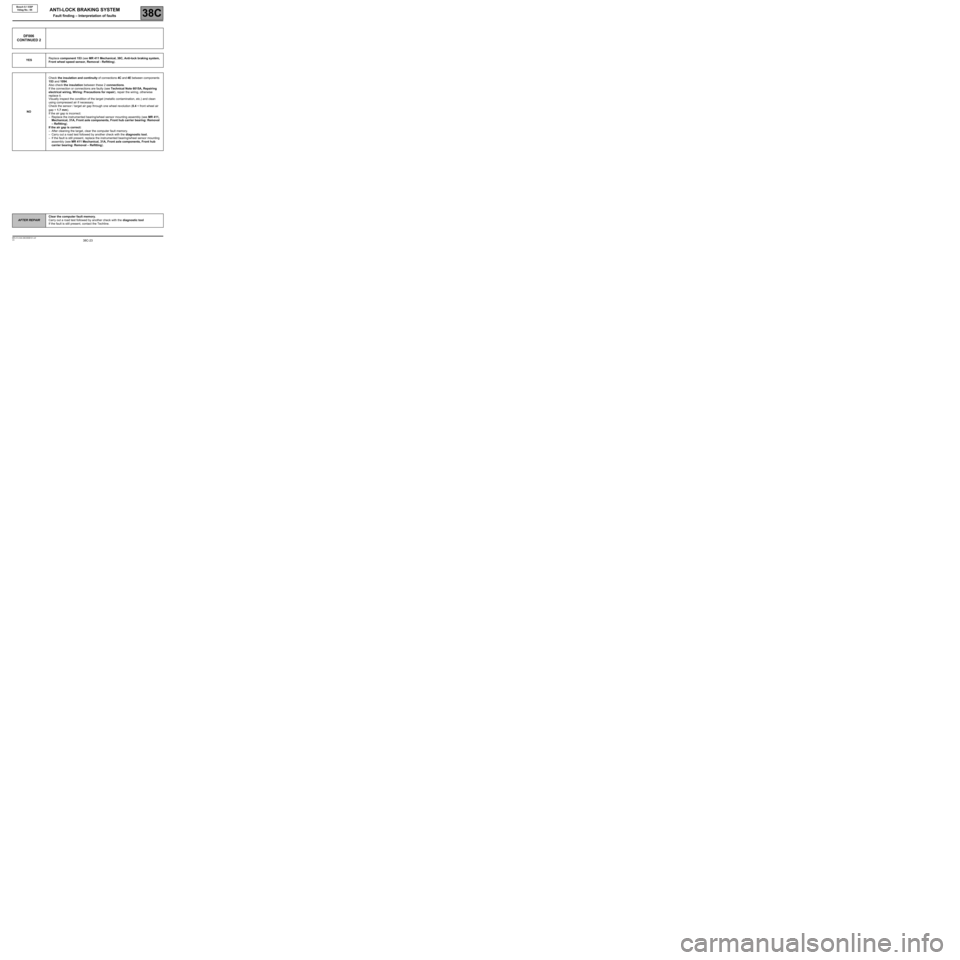

DF006

CONTINUED 2

YESReplace component 153 (see MR 411 Mechanical, 38C, Anti-lock braking system,

Front wheel speed sensor, Removal - Refitting).

NOCheck the insulation and continuity of connections 4C and 4E between components

153 and 1094.

Also check the insulation between these 2 connections.

If the connection or connections are faulty (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the wiring, otherwise

replace it.

Visually inspect the condition of the target (metallic contamination, etc.) and clean

using compressed air if necessary.

Check the sensor / target air gap through one wheel revolution (0.4 < front wheel air

gap < 1.7 mm).

If the air gap is incorrect:

–Replace the instrumented bearing/wheel sensor mounting assembly (see MR 411,

Mechanical, 31A, Front axle components, Front hub carrier bearing: Removal

– Refitting).

If the air gap is correct:

–After cleaning the target, clear the computer fault memory.

–Carry out a road test followed by another check with the diagnostic tool.

–If the fault is still present, replace the instrumented bearing/wheel sensor mounting

assembly (see MR 411 Mechanical, 31A, Front axle components, Front hub

carrier bearing: Removal – Refitting).

Page 24 of 101

38C-24

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool

If the fault is still present, contact the Techline.

V3 MR-413-X44-38C050$101.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Interpretation of faults38C

Bosch 8.1 ESP

Vdiag No.: 05

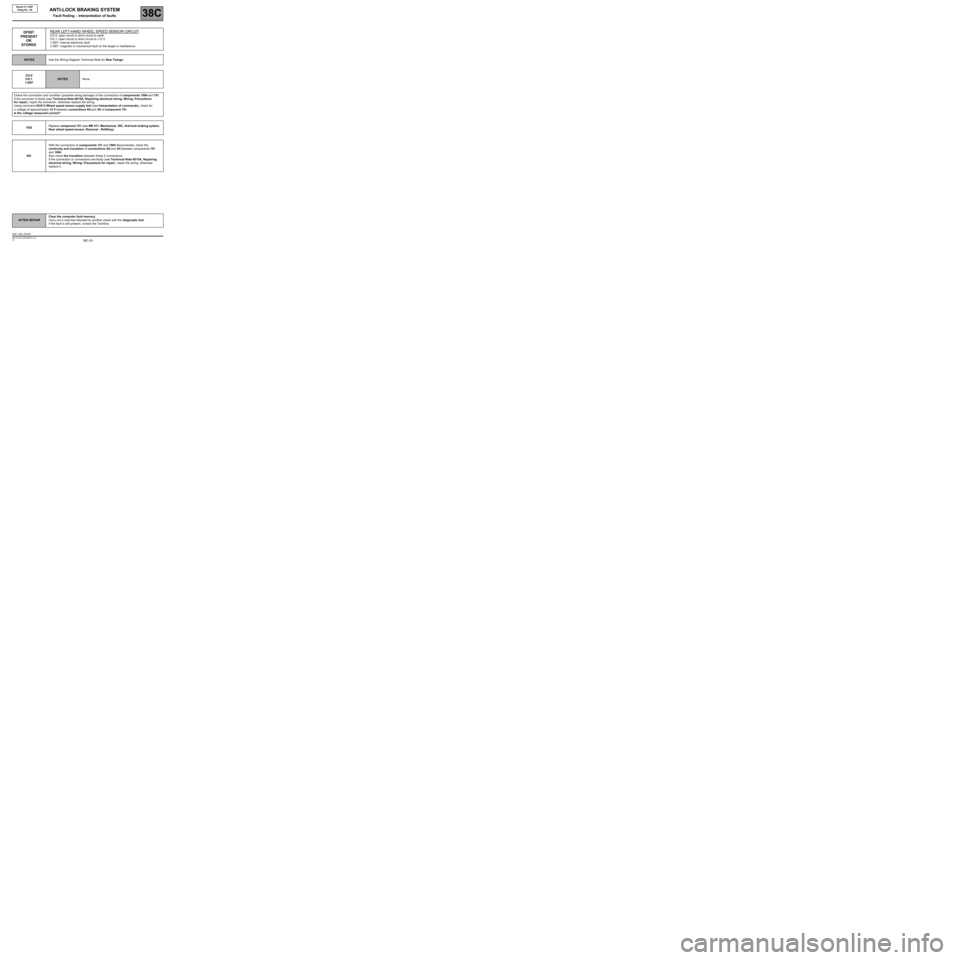

DF007

PRESENT

OR

STOREDREAR LEFT-HAND WHEEL SPEED SENSOR CIRCUITCO.0: open circuit or short circuit to earth

CO.1: open circuit or short circuit to +12 V

1.DEF: internal electronic fault

2 DEF: magnetic or mechanical fault on the target or interference

NOTESUse the Wiring Diagram Technical Note for New Twingo.

CO.0

CO.1

1.DEF

NOTESNone.

Check the connection and condition (possible wiring damage) of the connectors of components 1094 and 151.

If the connector is faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions

for repair), repair the connector, otherwise replace the wiring.

Using command AC013 Wheel speed sensor supply test (see Interpretation of commands), check for

a voltage of approximately 12 V between connections 4G and 4H of component 151.

Is the voltage measured correct?

YESReplace component 151 (see MR 411, Mechanical, 38C, Anti-lock braking system,

Rear wheel speed sensor, Removal - Refitting).

NOWith the connectors of components 151 and 1094 disconnected, check the

continuity and insulation of connections 4G and 4H between components 151

and 1094.

Also check the insulation between these 2 connections.

If the connection or connections are faulty (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the wiring, otherwise

replace it.

ESP_V05_DF007

Page 25 of 101

38C-25

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool

If the fault is still present, contact the Techline.

V3 MR-413-X44-38C050$101.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Interpretation of faults38C

Bosch 8.1 ESP

Vdiag No.: 05

DF007

CONTINUED 1

2.DEFNOTESConditions for applying the fault finding procedure to

stored faults:

The fault is declared present after a road test.

Check the connection and condition (possible wiring damage) of the connectors of components 1094 and 151.

If the connector is faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions

for repair), repair the connector, otherwise replace the wiring.

Check the insulation and continuity of connections 4G and 4H between components 151 and 1094.

Also check the insulation between these 2 connections.

If the connection or connections are faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring:

Precautions for repair), repair the wiring, otherwise replace it.

Inspect the condition of the target (metallic contamination etc.).

Clean the target with compressed air if necessary.

For versions equipped with disc brakes:

Check the sensor / target air gap through one wheel revolution (0.1 < rear wheel air gap < 0.9 mm).

If the air gap is incorrect:

–Replace the instrumented bearing/wheel sensor mounting assembly (see MR 411, Mechanical, 33A, Rear axle

components, Rear hub carrier bearing: Removal - Refitting).

Page 26 of 101

38C-26

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool

If the fault is still present, contact the Techline.

V3 MR-413-X44-38C050$101.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Interpretation of faults38C

Bosch 8.1 ESP

Vdiag No.: 05

DF007

CONTINUED 2

If the air gap is correct:

–Swap both rear wheel brake discs as well as the brake pads.

–Clear the computer fault memory.

–Carry out a road test followed by another check with the diagnostic tool.

–If the fault initially declared as DF007 has become DF027 Rear right-hand wheel speed sensor circuit,

replace the instrumented bearing/wheel sensor mounting assembly (see MR 411, Mechanical, 33A, Rear axle

components, Rear hub carrier bearing: Removal - Refitting).

–If the fault remains on the same side, replace component 151 (see MR 411, Mechanical, 38C, Anti-lock

braking system, Rear wheel speed sensor, Removal - Refitting).

For versions equipped with drum brakes:

–Swap both rear wheel brake drums.

–Clear the computer fault memory.

–Carry out a road test followed by another check with the diagnostic tool.

–If the fault initially declared as DF007 has become DF027 Rear right-hand wheel speed sensor circuit, replace

the target (see MR 411, Mechanical, 33A, Rear axle components, Rear brake drums, Removal - Refitting).

–If the fault remains on the same side, replace component 151 (see MR 411, Mechanical, 38C, Anti-lock

braking system, Rear wheel speed sensor, Removal - Refitting).

Page 27 of 101

38C-27

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool

If the fault is still present, contact the Techline.

V3 MR-413-X44-38C050$101.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Interpretation of faults38C

Bosch 8.1 ESP

Vdiag No.: 05

DF011

PRESENT

OR

STOREDSOLENOID VALVE SUPPLY

DEF: Abnormal voltage

NOTESConditions for applying the fault finding procedure to stored faults:

Apply the fault finding procedure whether the fault is present or stored.

Use the Wiring Diagram Technical Note for New Twingo.

Check the tightness and condition of the battery terminals (see 80A, Battery).

Check the charging circuit (see 16A, Starting - Charging).

Check the condition and position of fuse F2 (30A) in the engine fuse box.

Check the connection and condition (possible wiring damage) of the connector of component 1094.

If the connector is faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions

for repair), repair the connector, otherwise replace the wiring.

With the connector of component 1094 disconnected, check the insulation and continuity of connections MAH

of component 1094 (tightness, oxidation, etc.).

With the connectors of components 1094 and 1834 disconnected, check the continuity and insulation

of connection BP8 between components 1094 and 1834.

If the connection or connections are faulty (see Technical Note 6015A, Electrical wiring repair, Wiring:

Precautions for repair), repair the connectors or wiring, otherwise replace the wiring.

ESP_V05_DF011

Page 28 of 101

38C-28

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool

If the fault is still present, contact the Techline.

V3 MR-413-X44-38C050$101.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Interpretation of faults38C

Bosch 8.1 ESP

Vdiag No.: 05

DF017

PRESENT

OR

STOREDCOMPUTER

1. DEF: Supply fault or internal electronic fault

NOTESConditions for applying the fault finding procedure to stored faults:

Apply the fault finding procedure whether the fault is present or stored.

Use the Wiring Diagram Technical Note for New Twingo.

Check the tightness and condition of the battery terminals (see 80A, Battery).

Check the charging circuit (see 16A, Starting - Charging).

Check the condition and position of fuses F1 and F2 (40A and 30A) in the engine fuse box and fuse F10 (5A) in

the passenger compartment fuse box (see MR413, Fault finding, 81C, Fuse box).

Check the connection and condition (possible wiring damage) of the connector of component 1094.

If the connector is faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions

for repair), repair the connector, otherwise replace the wiring.

With the connector of component 1094 disconnected, check the insulation and continuity of connections MAH

of component 1094 (tightness, oxidation etc.).

With the connectors of component 1094, 1175, 583 and intermediate connector R107 disconnected, check

the insulation and continuity of connection AP5 between component 1094 and intermediate connector R107.

Check the insulation and continuity of connection AP5 between intermediate connector R107 and

component 1016.

With the connectors of components 1094 and 1834 disconnected, check the continuity and insulation

of connection BP14 between components 1094 and 1834.

With the connectors of components 1094 and 1834 disconnected, check the continuity and insulation

of connection BP8 between components 1094 and 1834.

If the connection(s) are faulty (see Technical Note 6015A, Electrical wiring repair, Wiring: Precautions

for repair), repair the wiring, otherwise replace the wiring.

ESP_V05_DF017

Page 29 of 101

38C-29

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool

If the fault is still present, contact the Techline.

V3 MR-413-X44-38C050$101.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Interpretation of faults38C

Bosch 8.1 ESP

Vdiag No.: 05

DF020

PRESENTTACHOMETRIC INDEX PROGRAMMING1. DEF: tachometric index not programmed

NOTESNone.

The ESP computer with the tachometric function supplies the vehicle speed signal to all areas where this

information is needed (instrument panel, engine management, etc.).

This vehicle speed signal replaces the one supplied by the speed sensor located on the gearbox.

The ESP computer calculates the vehicle speed from the wheel speed and the tyre circumference.

The tyre circumference must be programmed into the memory of a new computer. This consists

of entering an X index using command VP007 Tachometric index on the diagnostic tool.

Once the index has been entered using command VP007 Tachometric index, clear the computer fault memory

and then switch off the ignition.

Use parameter PR030 Tachometric index to check that the index entered is being used correctly by the system.

ESP_V05_DF020

Page 30 of 101

38C-30

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool

If the fault is still present, contact the Techline.

V3 MR-413-X44-38C050$101.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Interpretation of faults38C

Bosch 8.1 ESP

Vdiag No.: 05

DF026

PRESENT

OR

STOREDFRONT RIGHT-HAND WHEEL SPEED SENSOR CIRCUITCO.0: open circuit or short circuit to earth

CO.1: open circuit or short circuit to +12 V

1. DEF: internal electronic fault

2. DEF: magnetic or mechanical fault on the target or interference

NOTESUse the Wiring Diagram Technical Note for New Twingo.

CO.0

CO.1

1.DEF

NOTESNone.

Check the connection and condition (possible wiring damage) of the connectors of components 1094 and 152.

If the connector is faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions

for repair), repair the connector, otherwise replace the wiring.

Swap the 2 front wheel speed sensors (see MR 411 Mechanical, 38C, Wheel speed sensor, Removal -

Refitting).

Clear the computer fault memory.

Switch off the ignition.

Switch on the ignition again.

Did the fault initially declared as DF026 become fault DF006 "Front left-hand wheel speed sensor circuit"

present?

YESReplace the wheel speed sensor (see MR 411 Mechanical, 38C, Anti-lock braking

system, Front wheel speed sensor, Removal - Refitting).

NOCheck the insulation and continuity of connections 4M and 4N between

components 152 and 1094.

Also check the insulation between these 2 connections.

If the connection or connections are faulty (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the wiring, otherwise

replace it.

If all the checks are in order, contact Techline.

ESP_V05_DF026