ESP RENAULT TWINGO RS 2009 2.G Chasiss ESP Owner's Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 101

Page 31 of 101

38C-31

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool

If the fault is still present, contact the Techline.

V3 MR-413-X44-38C050$101.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Interpretation of faults38C

Bosch 8.1 ESP

Vdiag No.: 05

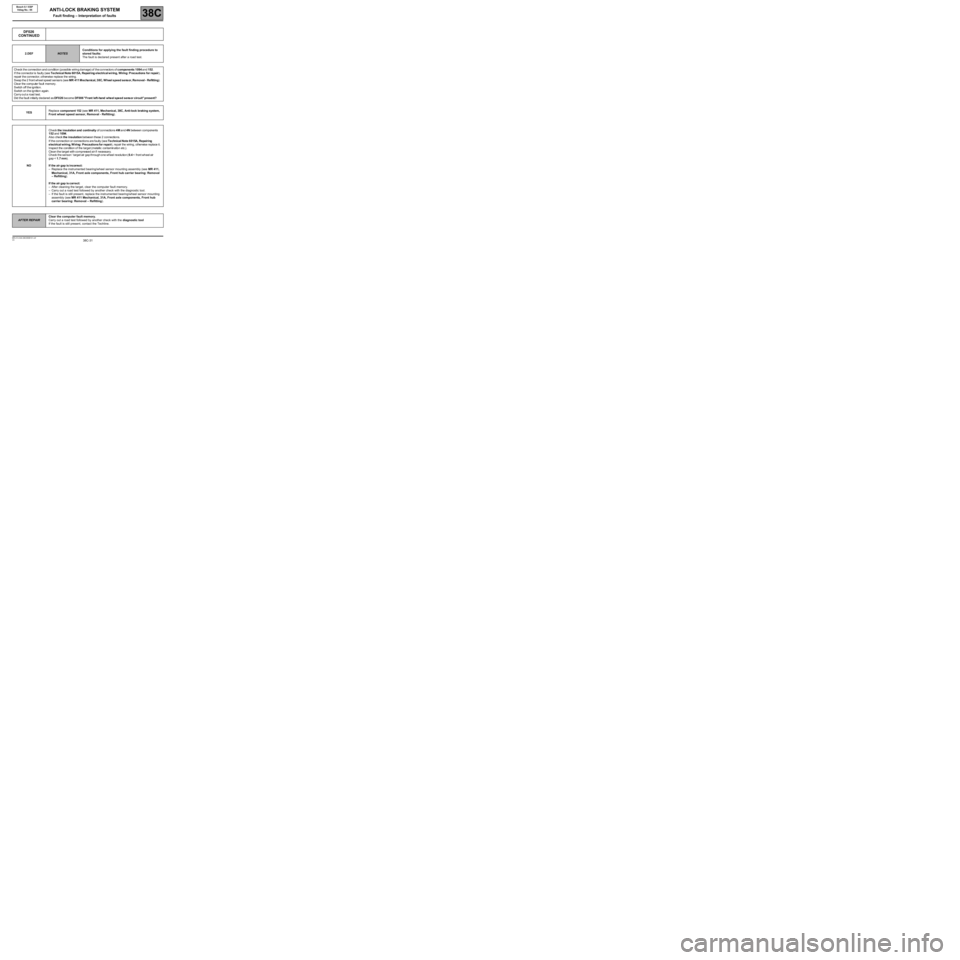

DF026

CONTINUED

2.DEFNOTESConditions for applying the fault finding procedure to

stored faults:

The fault is declared present after a road test.

Check the connection and condition (possible wiring damage) of the connectors ofcomponents 1 094and152.

Iftheconnector is faulty (seeTe chnical Note 6015A, Repairing e lectrical wiring, Wiring: Precautions for repair),

repair the connector, otherwise replace the wiring.

Swap the 2 front wheel speed sensors (seeMR 411 M echanical, 38C, W heel speed sensor, Removal - Refitting).

Clearthecomputer fault memory.

Switch offtheignition.

Switch on the ignit io nagain.

Carry out a road test.

Did the fault i nitially declared asDF0 26becomeDF006 "Front left-hand wheel speed sensor circuit" present?

YESReplace component 152 (see MR 411, Mechanical, 38C, Anti-lock braking system,

Front wheel speed sensor, Removal - Refitting).

NOCh eckthe insulatio n a nd c on t i n ui t yof connections4Mand4Nbetween components

152and1094.

Alsocheckthe insulationbetween these 2 connections.

Iftheconnection or connections are faulty (seeTe chnical Note 6 015A, Repairing

electrical wiring, W iring: Precautions for repair), repair the wiring, otherwise replace it.

Inspect the condition of the target (metallic contamination etc.).

Cle an the target with compressed air if necessary.

Ch eck the sensor / target air gap through one wheel revolution (0.4

If the air gap isincorrect:

–Replace the instrumented bearing/wheel sensor mounting assembly (see MR 411,

Mechanical, 31A, Front axle components, Front hub carrier bearing: Removal

– Refitting).

If the air gap iscorrect:

–After cleaning the target, clear the computer fault memory.

–Carry out a road test followed by another check with the diagnostic tool.

–If the fault is still present, replace the instrumented bearing/wheel sensor mounting

assembly (see MR 411 Mechanical, 31A, Front axle components, Front hub

carrier bearing: Removal – Refitting).

Page 32 of 101

38C-32

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool

If the fault is still present, contact the Techline.

V3 MR-413-X44-38C050$101.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Interpretation of faults38C

Bosch 8.1 ESP

Vdiag No.: 05

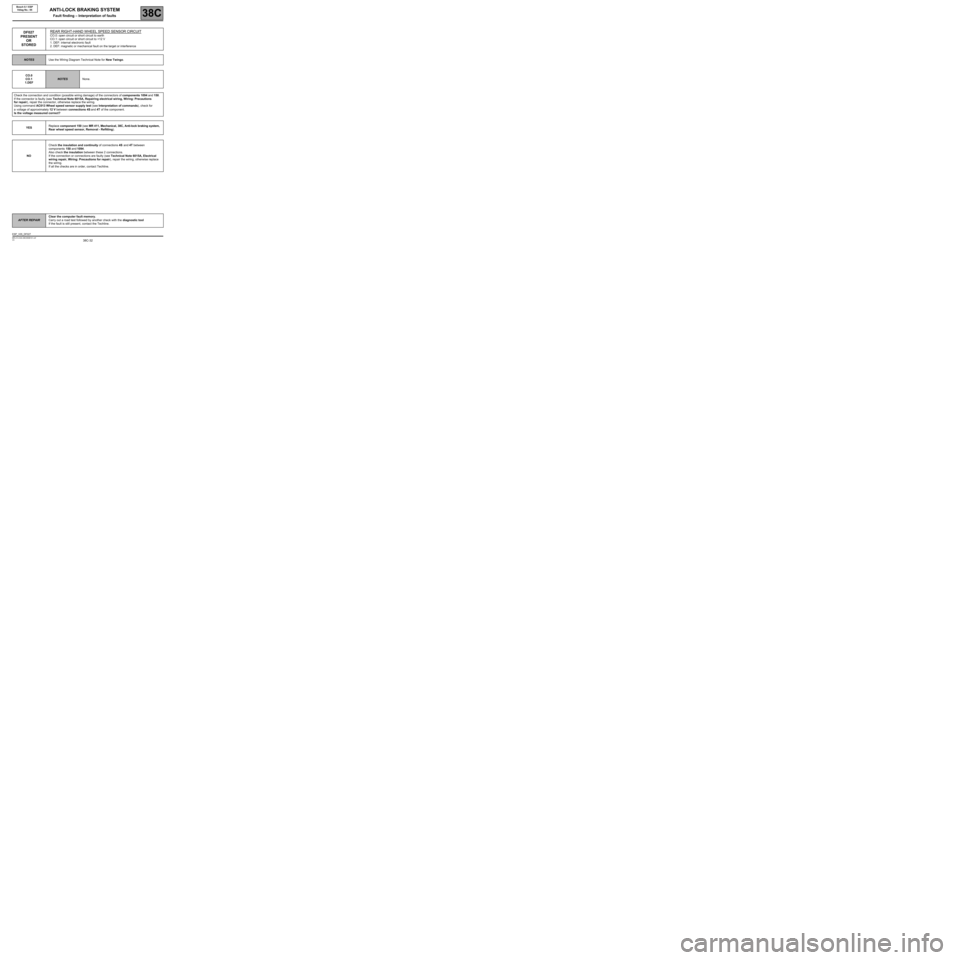

DF027

PRESENT

OR

STOREDREAR RIGHT-HAND WHEEL SPEED SENSOR CIRCUITCO.0: open circuit or short circuit to earth

CO.1: open circuit or short circuit to +12 V

1. DEF: internal electronic fault

2. DEF: magnetic or mechanical fault on the target or interference

NOTESUse the Wiring Diagram Technical Note for New Twingo.

CO.0

CO.1

1.DEF

NOTESNone.

Check the connection and condition (possible wiring damage) of the connectors of components 1094 and 150.

If the connector is faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions

for repair), repair the connector, otherwise replace the wiring.

Using command AC013 Wheel speed sensor supply test (see Interpretation of commands), check for

a voltage of approximately 12 V between connections 4S and 4T of the component.

Is the voltage measured correct?

YESReplace component 150 (see MR 411, Mechanical, 38C, Anti-lock braking system,

Rear wheel speed sensor, Removal - Refitting).

NOCheck the insulation and continuity of connections 4S and 4T between

components 150 and 1094.

Also check the insulation between these 2 connections.

If the connection or connections are faulty (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace

the wiring.

If all the checks are in order, contact Techline.

ESP_V05_DF027

Page 33 of 101

38C-33

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool

If the fault is still present, contact the Techline.

V3 MR-413-X44-38C050$101.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Interpretation of faults38C

Bosch 8.1 ESP

Vdiag No.: 05

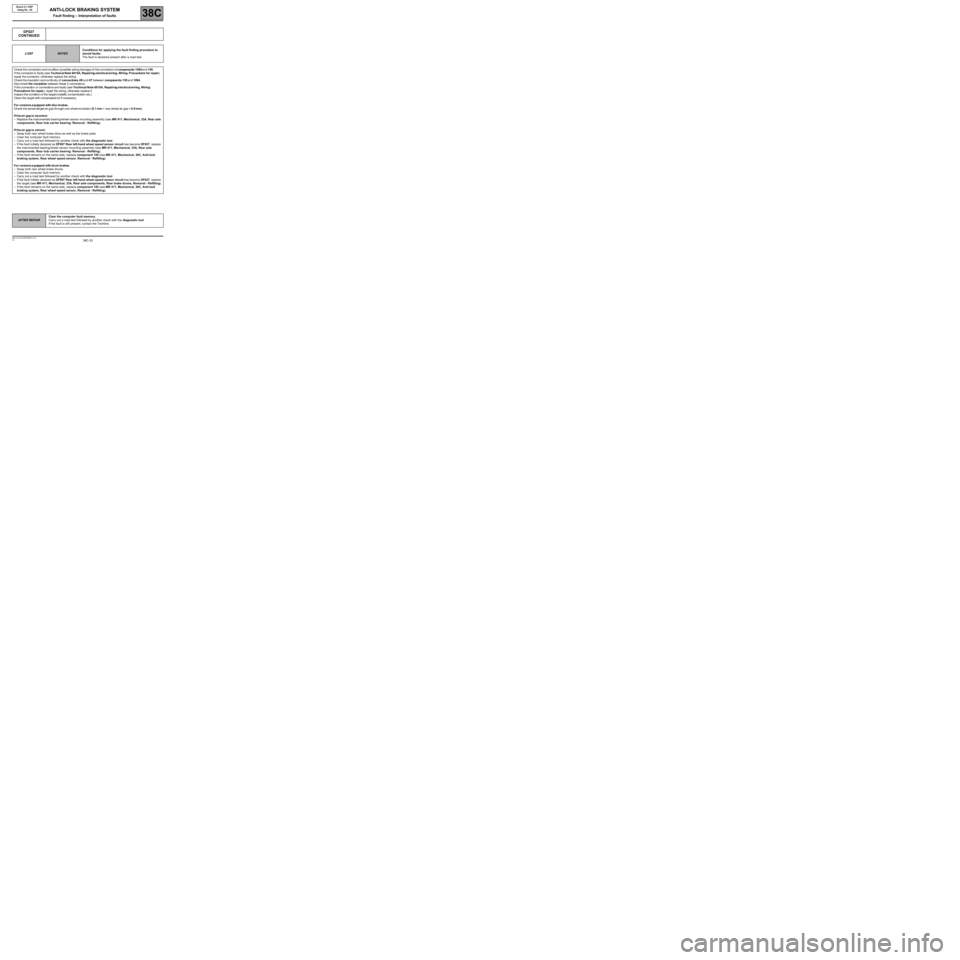

DF027

CONTINUED

2.DEFNOTESConditions for applying the fault finding procedure to

stored faults:

The fault is declared present after a road test.

Check the connection and condition (possible wiring damage) of the connectors ofcomponents 1 094and150.

Iftheconnector is faulty (seeTe chnical Note 6015A, Repairing e lectrical wiring, Wiring: Precautions for repair),

repair the connector, otherwise replace the wiring.

Ch eck the insulation and continuity ofconnections 4Sand4Tbetweencomponents 150and1094.

Alsocheckthe insulationbetween these 2 connections.

Iftheconnection or connections are faulty (seeTe chnical Note 6015A, Repairing e lectrical wiring, Wiring:

Precautions for repair), repair the wiring, otherwise replace it.

Inspect the condition of the target ( metallic contamination etc.).

Cleanthetarget with compressed air if necessary.

For v ersions e quippedwithdiscbrakes:

Check the sensor/target air gap through one wheel revolution (0.1 mm

–Replace the instrumented bearing/wheel sensor mounting assembly (see MR 411, Mechanical, 33A, Rear axle

components, Rear hub carrier bearing: Removal - Refitting).

If the air gap iscorrect:

–Swap both rear wheel brake discs as well as the brake pads.

–Clear the computer fault memory.

–Carry out a road test followed by another check with the diagnostic tool.

–If the fault initially declared as DF007 Rear left-hand wheel speed sensor circuit has become DF027, replace

the instrumented bearing/wheel sensor mounting assembly (see MR 411, Mechanical, 33A, Rear axle

components, Rear hub carrier bearing: Removal - Refitting).

–If the fault remains on the same side, replace component 150 (see MR 411, Mechanical, 38C, Anti-lock

braking system, Rear wheel speed sensor, Removal - Refitting).

For v ersions e quippedwithdrumbrakes:

–Swap both rear wheel brake drums.

–Clear the computer fault memory.

–Carry out a road test followed by another check with the diagnostic tool.

–If the fault initially declared as DF007 Rear left-hand wheel speed sensor circuit has become DF027, replace

the target (see MR 411, Mechanical, 33A, Rear axle components, Rear brake drums, Removal - Refitting).

–If the fault remains on the same side, replace component 150 (see MR 411, Mechanical, 38C, Anti-lock

braking system, Rear wheel speed sensor, Removal - Refitting).

Page 34 of 101

38C-34

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool

If the fault is still present, contact the Techline.

V3 MR-413-X44-38C050$101.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Interpretation of faults38C

Bosch 8.1 ESP

Vdiag No.: 05

DF055

PRESENTVEHICLE PARAMETER PROGRAMMINGDEF: configuration absent or incorrect

NOTESNone.

Configure the vehicle parameters using command VP004 Vehicle parameters (see help table in clip).

Clear the fault memory, and initialise the computer (switch the + after ignition feed off and on again).

Check for any possible faults.

ESP_V05_DF055

Page 35 of 101

38C-35

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool

If the fault is still present, contact the Techline.

V3 MR-413-X44-38C050$101.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Interpretation of faults38C

Bosch 8.1 ESP

Vdiag No.: 05

DF063

PRESENT

OR

STOREDWHEEL SPEED CONSISTENCY

DEF: inconsistency

CC.1: short-circuit to +12 volts

NOTESSpecial notes:

This fault indicates that the wheel speeds are inconsistent with each other.

The computer does not know how to determine which one is faulty.

Priorities when dealing with a number of faults:

Deal first with faults DF090 Front right-hand wheel target, DF091 Front left-hand

wheel target, DF092 Rear right-hand wheel target and DF093 Rear left-hand wheel

target even if they are stored.

Use the Wiring Diagram Technical Note for New Twingo.

DEF

NOTESConditions for applying the fault finding procedure to

stored faults:

The fault is declared present after a road test.

Check the quality of the mounting of the wheel speed sensors (correct clipping without excessive play).

Check the conformity of the targets (condition, number of teeth = 48) using the specific command SC001 Check

target teeth for each wheel.

Are the numbers of teeth correct?

YESVisually inspect the condition of the axles (impacts, deformations, etc.) and check that

the tyre mountings conform and are in good condition (see MR 411, Mechanical, 35A,

Wheels and tyres, Identification).

Ensure that the braking system is in good condition (condition of the linings, tightness,

grip, bleeding, bearing play, lubricant on the targets, etc.).

NOApply the target fault procedure for the wheel(s) concerned:

–DF090 Front right-hand wheel target

–DF091 Front left-hand wheel target

–DF092 Rear right-hand wheel target

–DF093 Rear left-hand wheel target

ESP_V05_DF063

Page 36 of 101

38C-36

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool

If the fault is still present, contact the Techline.

V3 MR-413-X44-38C050$101.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Interpretation of faults38C

Bosch 8.1 ESP

Vdiag No.: 05

DF063

CONTINUED

2.DEFNOTESNone.

Check the connection and condition (possible wiring damage) of the connectors:

–of component 1094,

–of component 150,

–of component 151,

–of component 152,

–of component 153.

Iftheconnector is faulty (seeTe chnical Note 6015A, Repairing e lectrical wiring, Wiring: Precautions for repair),

repair the connector, otherwise replace the wiring.

Ch eckthe insulation and continuityofconnections 4Mand4Nbetweencomponents 152and1094.

Alsocheckthe insulationbetween these 2 connections.

Ch eckthe insulation and continuityofconnections 4Sand4Tbetweencomponents 1 50and1094.

Alsocheckthe insulationbetween these 2 connections.

Ch eckthe insulation and continuityofconnections 4Cand4Ebetweencomponents 1 53and1094.

Alsocheckthe insulationbetween these 2 connections.

Ch eckthe insulation and continuityofconnections 4Gand4Hbetweencomponents 151and1094.

Alsocheckthe insulationbetween these 2 connections.

If theconnection(s) are faulty (seeTechnical Note 6 015A, Electrical wiring repair, Wiring: Precautions for repair),

repair the wiring, otherwise replace the wiring.

Perform the procedure of counting the poles for each wheel (number of teeth =48)usingspecial command

SC001 Check target teethtoconfirm the disappearance of the fault.

Page 37 of 101

38C-37

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool

If the fault is still present, contact the Techline.

V3 MR-413-X44-38C050$101.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Interpretation of faults38C

Bosch 8.1 ESP

Vdiag No.: 05

DF066

PRESENT

OR

STOREDINJECTION MULTIPLEX SIGNAL ABSENT

NOTESSpecial notes:

The injection does not always store these transient faults as quickly as the ESP

system.

If no fault is stored in the injection computer, start the engine; if there is no fault present,

contact the Techline.

Once the fault in the injection system has been repaired, clear the ESP computer

fault memory.

Priority in the event of a number of faults:

Deal with fault DF152 Multiplex network first if it is present or stored.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present when the engine is started.

Check the injection computer (see13B, Diesel injection or 17B, Petrol injection)usingthe diagnostic tool.

Ru n a m ultiple xnetwork test (see88B, Multiplex).

ESP_V05_DF066

Page 38 of 101

38C-38

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool

If the fault is still present, contact the Techline.

V3 MR-413-X44-38C050$101.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Interpretation of faults38C

Bosch 8.1 ESP

Vdiag No.: 05

DF075

PRESENT

OR

STOREDSTEERING WHEEL ANGLE SENSOR SIGNAL

1. DEF: inconsistency

2. DEF: constant signal

NOTESConditions for applying the fault finding procedure to stored faults:

The fault is declared present after a road test.

1.DEF

NOTESSpecial notes:

Question the customer to find out if he regularly drives on

a speed track. If this is the case, follow the procedure below

but never replace component 583.

Clear the ESP offsets using command RZ011 Sensor offset.

Position the steering wheel straight ahead (the wheels must be directly in line with the vehicle) and read the value

of the steering wheel angle using the parameter PR033 "Steering wheel angle".

If the value is not close to 0 ± 5˚, calibrate component 583 using command VP003 Steering wheel angle sensor

(see Configurations and programming).

Clear the ESP sensor offsets using command RZ011 Sensor offset.

With the steering wheel horizontal and the front wheels set straight ahead, turn the steering wheel a quarter of

a turn to the left.

Using parameter PR033 Steering wheel angle, check that the steering wheel angle value is close to - 90.

With the steering wheel horizontal and the front wheels set straight ahead, turn the steering wheel a quarter of

a turn to the right.

Using parameter PR033 Steering wheel angle, check that the steering wheel angle value is close to + 90.

If the steering wheel angle values are not correct, replace component 583 (see MR 411, Mechanical, 36A,

Steering assembly, Steering column, Removal - Refitting).

Drive in a straight line.

If the steering wheel is not horizontal when the vehicle is driving in a straight line (the vehicle "pulls" to the left

or right):

Check the conformity of the tyres, pressures, wear and dimensions (see MR 411, 35A, Wheels and tyres, Tyres,

Identification and tyre pressure, Identification).

Replace the tyre(s) if necessary (see MR 411, 35A, Wheels and tyres, Tyres, Removal - Refitting).

Adjust the wheel alignment (see MR 411, Mechanical, 30A, General information, Front axle: Adjustment).

Calibrate component 583 using command VP003 Steering wheel angle sensor (see Configurations

and programming).

Clear the ESP sensor offsets using command RZ011 Sensor offsets.

ESP_V05_DF075

Page 39 of 101

38C-39

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool

If the fault is still present, contact the Techline.

V3 MR-413-X44-38C050$101.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Interpretation of faults38C

Bosch 8.1 ESP

Vdiag No.: 05

DF075

CONTINUED

2.DEFNOTESNone.

Clear the ESP offsets using command RZ011 Sensor offset.

When stationary, turn the steering wheel from left to right and check that the value changes using parameter PR033

Steering wheel angle.

If the value is inconsistent, replace component 583 (see MR 411, Mechanical, 36A, Steering assembly,

Steering column, Removal - Refitting).

Page 40 of 101

38C-40

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool

If the fault is still present, contact the Techline.

V3 MR-413-X44-38C050$101.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Interpretation of faults38C

Bosch 8.1 ESP

Vdiag No.: 05

DF086

PRESENT

OR

STOREDCOMPUTER CONFIGURATION

DEF: incorrect vehicle configuration

NOTESNone.

Configure the inhibition or authorisation of the automatic brake lights (according to the legislation of the country).

Using command VP021 Automatic brake light inhibition:

Configure the inhibition of the automatic brake lights using command VP021 Automatic brake light inhibition

Using command VP022 Automatic brake light authorisation:

Configure the authorisation of the automatic brake lights using command VP022 Automatic brake light

authorisation.

ESP_V05_DF086