wheel RENAULT TWINGO RS 2009 2.G Chasiss Owners Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 281

Page 139 of 281

33A-41

REAR AXLE COMPONENTS

Complete rear axle system: Removal - Refitting

33A

aUnclip the end of the parking brake cables at (10) .

aUnclip the cable sleeve stops at (11) and extract the

parking brake cables from the rear drum flanges.

aRemove:

-the rear brake pads (see 33A, Rear axle compo-

nents, Rear brake lining: Removal - Refitting,

page 33A-14) ,

-the rear brake cylinders (see 33A, Rear axle com-

ponents, Rear brake cylinder: Removal - Refit-

ting, page 33A-17) ,

-the rear wheel speed sensors (see 38C, Anti-lock

braking system, Rear wheel speed sensor: Re-

moval - Refitting, page 38C-17) ,

-the rear rigid brake pipes from the rear axle,

-the rear rigid brake pipe clips from the rear axle,

-the rear stub axle carriers (see 33A, Rear axle

components, Rear stub axle carrier: Removal -

Refitting, page 33A-32) ,

-the rear brake drum flanges,

REFITTING

I - REFITTING PREPARATIONS OPERATION

aStrap the rear axle onto the (Mot. 1390).

aPosition the rear axle under the vehicle.II - REFITTING OPERATION FOR PART

CONCERNED

1 - Replacement

aRefit:

-the rear brake drum flanges,

-the rear stub axle carriers (see 33A, Rear axle

components, Rear stub axle carrier: Removal -

Refitting, page 33A-32) ,

-the rigid brake pipe clips on the rear axle,

-the rear rigid brake pipes from the rear axle,

-the rear wheel speed sensors (see 38C, Anti-lock

braking system, Rear wheel speed sensor: Re-

moval - Refitting, page 38C-17) ,

-the rear brake cylinders (see 33A, Rear axle com-

ponents, Rear brake cylinder: Removal - Refit-

ting, page 33A-17) ,

-the rear brake pads (see 33A, Rear axle compo-

nents, Rear brake lining: Removal - Refitting,

page 33A-14) .

-the parking brake cables (see 37A, Mechanical

component controls, Parking brake cables: Re-

moval - Refitting, page 37A-74) ,

-the rear brake drums (see 33A, Rear axle compo-

nents, Rear brake drum: Removal - Refitting,

page 33A-19) .

121331

Page 140 of 281

33A-42

REAR AXLE COMPONENTS

Complete rear axle system: Removal - Refitting

33A

2 - Refitting

aLower the lift.

aPosition the bearing centring devices (12) opposite

the centring holes.

aRefit the rear axle bearing bolts.

aTorque tighten the rear axle bearing bolts (62 Nm).

aRemove the safety strap(s).

aRaise the lift.

aRefit:

-the rear suspension springs (see 33A, Rear axle

components, Rear suspension spring: Remov-

al - Refitting, page 33A-28) ,

-the brake hose lower unions.

aTorque tighten the brake hose lower unions (17

Nm).

aConnect the ABS sensor connectors.

aClose the ABS sensor connector protective unit.

aClip the parking brake cables onto the reservoir.

aPosition the parking brake cables on the parking

brake compensator.

aCheck that the parking brake cable stops are proper-ly inserted in their housings.

III - FINAL OPERATION.

aAdjust the parking brake cables (see 37A, Mechan-

ical component controls, Parking brake lever:

Removal - Refitting, page 37A-46) .

aRefit the rear wheels (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) .

aRemove the pedal press.

aBleed the braking circuit (see 30A, General infor-

mation, Braking circuit: Bleed, page 30A-4) .

119651

Page 141 of 281

35A-1

WHEELS AND TYRES

Wheel: Removal - Refitting

35A

The removal - refitting procedure is the same for all

wheels.

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRelease the parking brake.

aRemove the trim.

aPosition the wheel so that the valve is at the top.

aMark the position of the wheel on the hub.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aLoosen the wheel bolts with the wheel on the

ground.

aRaise the lift.

aRemove:

-the wheel bolts,

-the wheel.

If the wheel cannot be removed after the bolt has

been undone:

aPosition all the wheel bolts.

aTighten the wheel bolts to bring all the bolt heads

into contact with the wheel.

aUndo the wheel bolts by one turn.aStrike around the edge of the tyre walls (1) several

times using a mallet on the inner and outer surfaces

of the wheel to detach the wheel.

aRemove:

-the wheel bolts,

-the wheel. Note:

This mark is required in order to:

-Note the original position of the wheel on the

hub,

-perform the balancing operation.

Note:

Use sockets with protective sheaths in order to

avoid scratching the alloy wheel rims.

100682

Page 142 of 281

35A-2

WHEELS AND TYRES

Wheel: Removal - Refitting

35A

If this procedure does not work:

aStrike the inner surface of the wheel (2) using a mal-

let and a wooden block to detach it.

aRemove:

-the wheel bolts,

-the wheel.

REFITTING

I - REFITTING PREPARATION OPERATION

aClean the hub carrier using a wire brush.

aCheck the condition of the tyre.

aDo not move or remove the balance weights.

II - REFITTING OPERATION FOR PART

CONCERNED

aClean the mating surfaces between the wheel and

the hub carrier using a wire brush.aCoat the wheel-mating face (3) with COPPER ANTI-

SEIZE AGENT (see Vehicle: Parts and consum-

ables for the repair) (04B, Consumables - Prod-

ucts).

aAlign the mark on the wheel with the mark made on

the hub when it was removed.

aFit the wheel to the vehicle, positioning the valve at

the top.

aInsert the wheel bolts.

aTighten the wheel bolts to bring all the bolt heads

into contact with the wheel.

106089

Note:

Do not strike the surface of the wheel using

excessive force as this may damage it.

Note:

there are two types of wheel bolts for alloy and

steel wheel rims; do not swap them.

124750

113180

Page 143 of 281

35A-3

WHEELS AND TYRES

Wheel: Removal - Refitting

35A

aPretighten the wheel bolts to 30 N.m, with the wheel

suspended, starting with the bolts at the bottom.

aRotate the wheel through 180˚ to bring the valve into

the bottom position.

aPosition the vehicle on its wheels.

aTorque tighten the wheel bolts in order (see 30A,

General information, Front axle system: Tighten-

ing torque, page 30A-27) (30A, General informa-

tion).

aRefit the trim piece.Note:

Use sockets with protective sheaths in order to

avoid scratching the alloy wheel rims.

Page 144 of 281

35A-4

WHEELS AND TYRES

Wheel: Balancing

35A

I - PREREQUISITES FOR WHEEL BALANCING

aWheel balancing is a measurement operation.

Several conditions must be met to achieve a reliable

result in a single operation.

The wheel balancer must be installed in accordance

with the manufacturer's instructions.

It is essential to calibrate the balancer according to

the frequency recommended by the manufacturer.

Do not grease the threaded shaft.

Check the condition of the supports, centring com-

ponents and mountings.

Replace any faulty parts (see manufacturer's in-

structions).

The wheel and the wheel balancer must be clean.

Driver's perception

aIf the wheels are not correctly balanced this causes

the steering wheel and/or the vehicle floor to vibrate.

These vibrations appear between 54 mph (90 km/h)

and 90 mph (150 km/h).

II - BALANCING PREPARATION OPERATION

aAdjust the tyre pressure (see 35A, Wheels and ty-

res, Tyre pressure: Identification, page 35A-10) .

aAlways carry out a road test for a minimum distance

of 1 mile (2 km) before balancing the wheels, in or-

der to remove any flat spots on the tread caused by

the vehicle being immobilised.

aActions to be carried out immediately after the test

drive:

-Position the vehicle on a two-post vehicle lift (see

Vehicle: Towing and lifting) ,

-raise the vehicle,

-leave the four wheels hanging free,

-release the parking brake.a

To reproduce the exact vehicle wheel assembly, use

a ring (1) of diameter:

a60 mm

aThere are three types of weight:

105870

Note:

The ring is available from the supplier of the

equipment used.

Page 145 of 281

35A-5

WHEELS AND TYRES

Wheel: Balancing

35A

aIn some countries, the use of lead weights is forbid-

den; in this case it is recommended to use ZAMAK

weights instead.

Only use weights provided by the Parts Department.

aRemove the wheels (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) .

aAlways clean the wheel, disc, and hub bearing sur-

faces.

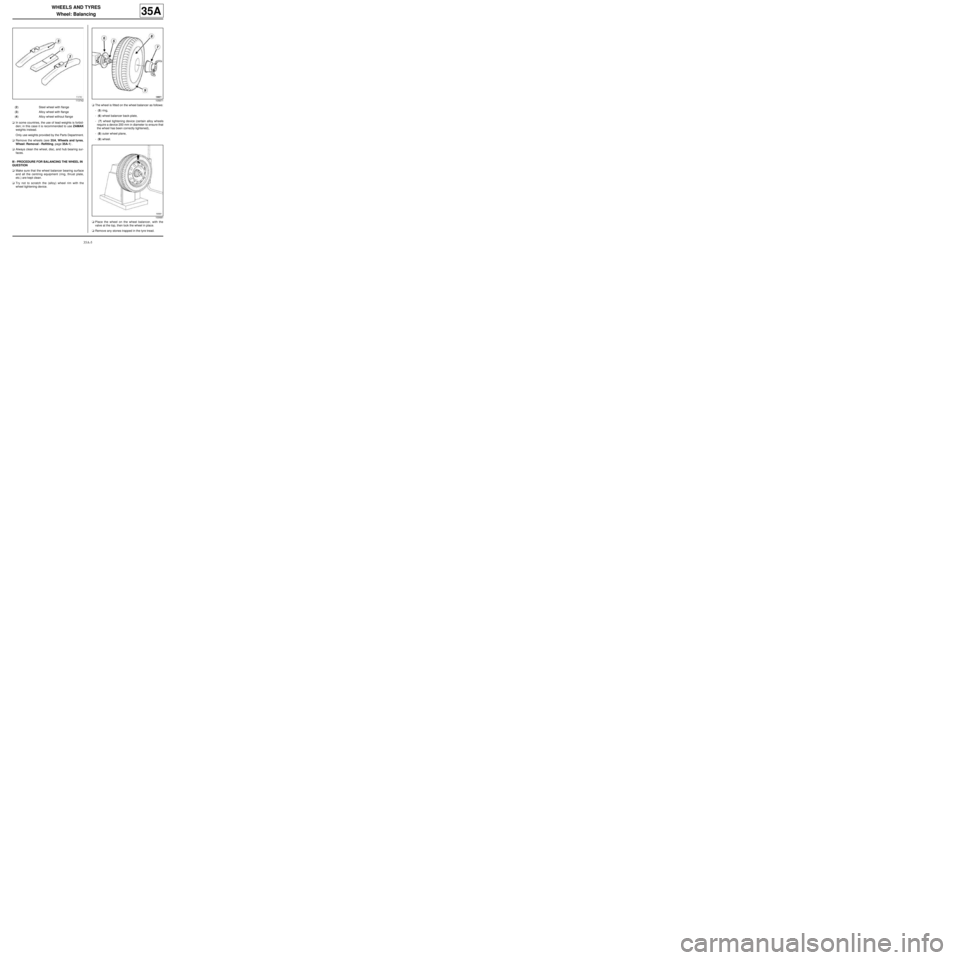

III - PROCEDURE FOR BALANCING THE WHEEL IN

QUESTION

aMake sure that the wheel balancer bearing surface

and all the centring equipment (ring, thrust plate,

etc.) are kept clean.

aTry not to scratch the (alloy) wheel rim with the

wheel tightening device.aThe wheel is fitted on the wheel balancer as follows:

- (5) ring,

- (6) wheel balancer back-plate,

- (7) wheel tightening device (certain alloy wheels

require a device 200 mm in diameter to ensure that

the wheel has been correctly tightened),

- (8) outer wheel plane,

- (9) wheel.

aPlace the wheel on the wheel balancer, with the

valve at the top, then lock the wheel in place.

aRemove any stones trapped in the tyre tread.

113742

(2) Steel wheel with flange

(3) Alloy wheel with flange

(4) Alloy wheel without flange

105871

100681

Page 146 of 281

35A-6

WHEELS AND TYRES

Wheel: Balancing

35A

aEnter the specific wheel parameters when starting

the wheel balancer.

aStart the wheel balancer and check the wheel bal-

ance, which should be 0 g on each plane of the

wheel.

aIf this is not the case, remove the old wheel balanc-

ing weights and repeat the wheel balancing proce-

dure, checking that the wheel balance equals 0 on

each wheel plane.

IV - FINAL OPERATION

aRefit the wheel (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) . WARNING

To avoid detachment of the balance weights, use

only weights which correspond to the vehicle

wheel rims.

Page 147 of 281

35A-7

WHEELS AND TYRES

Tyres: Identification

35A

Example of a tyre identification mark: 205/65 R 15 91

V.Speed code table:

101008

123448

205 Tyre width in mm (L)

65 Height/width ratio

RRadial structure

15 Internal diameter in inches (c)

91 Load index

VSpeed code

Code Maximum

speed in

mph (km/h)

R170

S180

T190

U200

H210

V240

ZR above 240

W270

Y300

Page 148 of 281

35A-8

WHEELS AND TYRES

Tyres: Removal - Refitting

35A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the wheel in question (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) ,

-the balance weights,

-the valve mechanism.

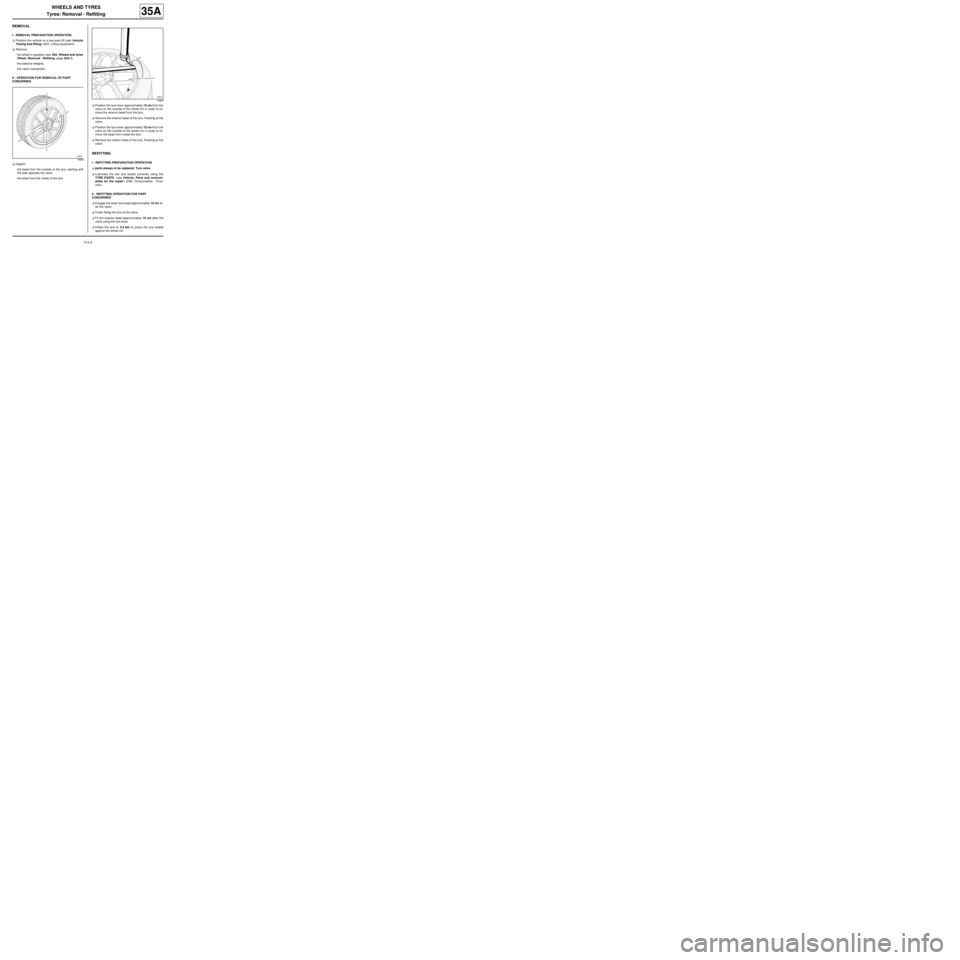

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDetach:

-the bead from the outside of the tyre, starting with

the side opposite the valve,

-the bead from the inside of the tyre.aPosition the tyre lever approximately 15 cm from the

valve on the outside of the wheel rim in order to re-

move the exterior bead from the tyre.

aRemove the exterior bead of the tyre, finishing at the

valve.

aPosition the tyre lever approximately 15 cm from the

valve on the outside of the wheel rim in order to re-

move the bead from inside the tyre.

aRemove the interior bead of the tyre, finishing at the

valve.

REFITTING

I - REFITTING PREPARATION OPERATION

aparts always to be replaced: Tyre valve

aLubricate the two tyre beads correctly using the

TYRE PASTE (see Vehicle: Parts and consum-

ables for the repair) (04B, Consumables - Prod-

ucts).

II - REFITTING OPERATION FOR PART

CONCERNED

aEngage the lower tyre bead approximately 15 cm af-

ter the valve.

aFinish fitting the tyre at the valve.

aFit the exterior bead approximately 15 cm after the

valve using the tyre lever.

aInflate the tyre to 3.5 bar to press the tyre beads

against the wheel rim.

18884

18885