wheel bolts RENAULT TWINGO RS 2009 2.G Chasiss Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 281

Page 25 of 281

30A-21

GENERAL INFORMATION

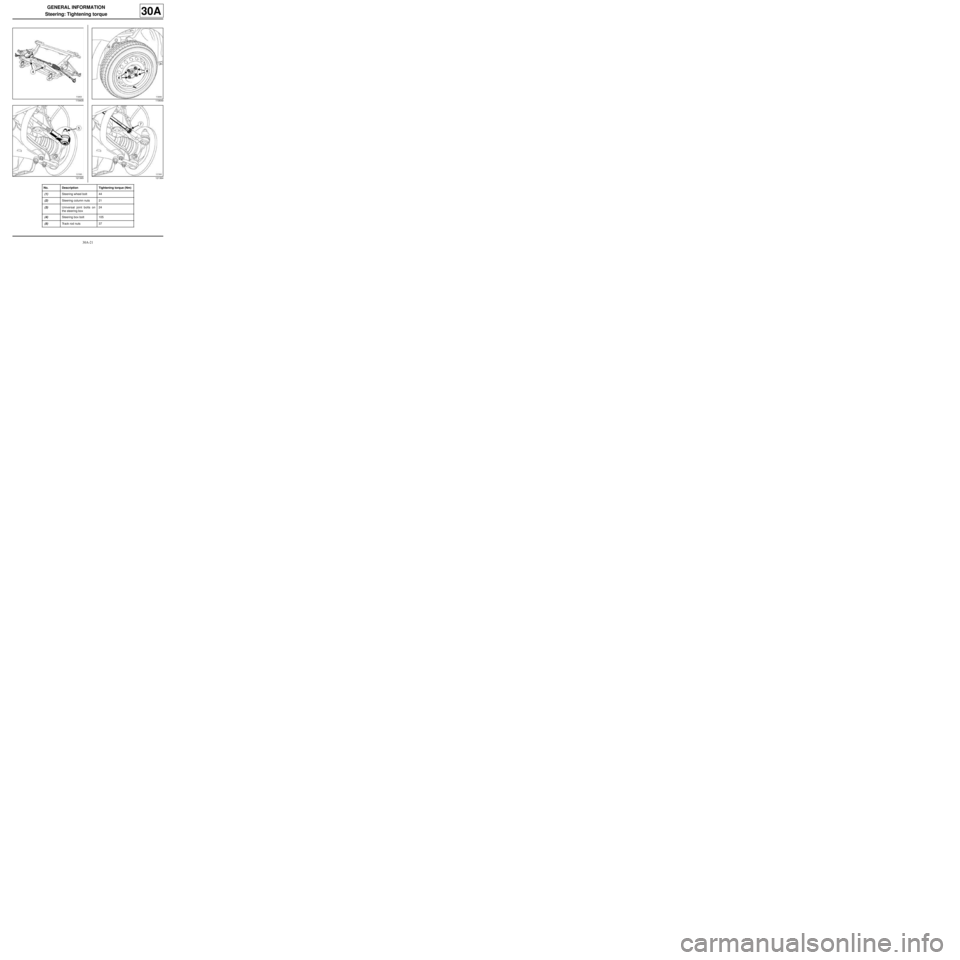

Steering: Tightening torque

30A

119405

121365119649

121364

No. Description Tightening torque (Nm)

(1) Steering wheel bolt 44

(2) Steering column nuts 21

(3) Universal joint bolts on

the steering box24

(4) Steering box bolt 105

(5) Track rod nuts 37

Page 34 of 281

30A-30

GENERAL INFORMATION

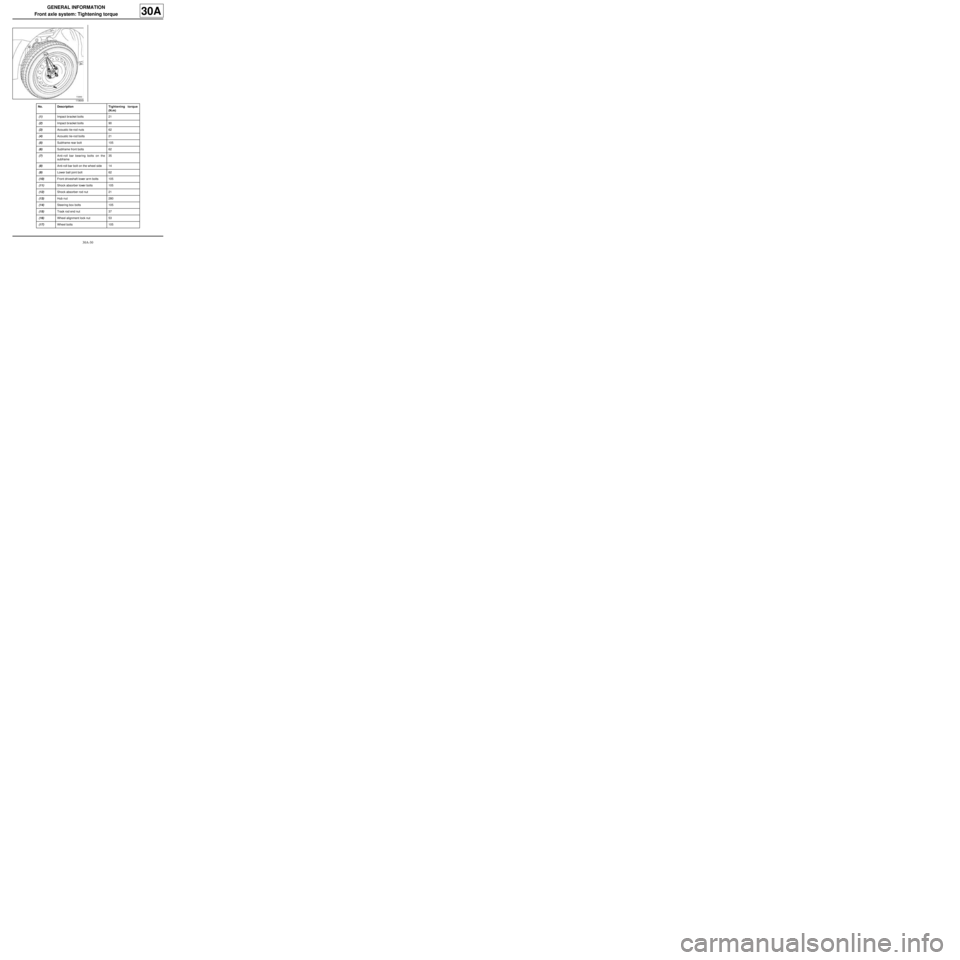

Front axle system: Tightening torque

30A

119649

No. DescriptionTightening torque

(N.m)

(1) Impact bracket bolts 21

(2) Impact bracket bolts 90

(3) Acoustic tie-rod nuts 62

(4) Acoustic tie-rod bolts 21

(5) Subframe rear bolt 105

(6) Subframe front bolts 62

(7) Anti-roll bar bearing bolts on the

subframe35

(8) Anti-roll bar bolt on the wheel side 14

(9) Lower ball joint bolt 62

(10) Front driveshaft lower arm bolts 105

(11) Shock absorber lower bolts 105

(12) Shock absorber rod nut 21

(13) Hub nut 280

(14) Steering box bolts 105

(15) Track rod end nut 37

(16) Wheel alignment lock nut 53

(17) Wheel bolts 105

Page 46 of 281

31A-3

FRONT AXLE COMPONENTS

Front brake pads: Removal - Refitting

EQ UIPMENT LEVEL SPORT

31A

REMOVAL

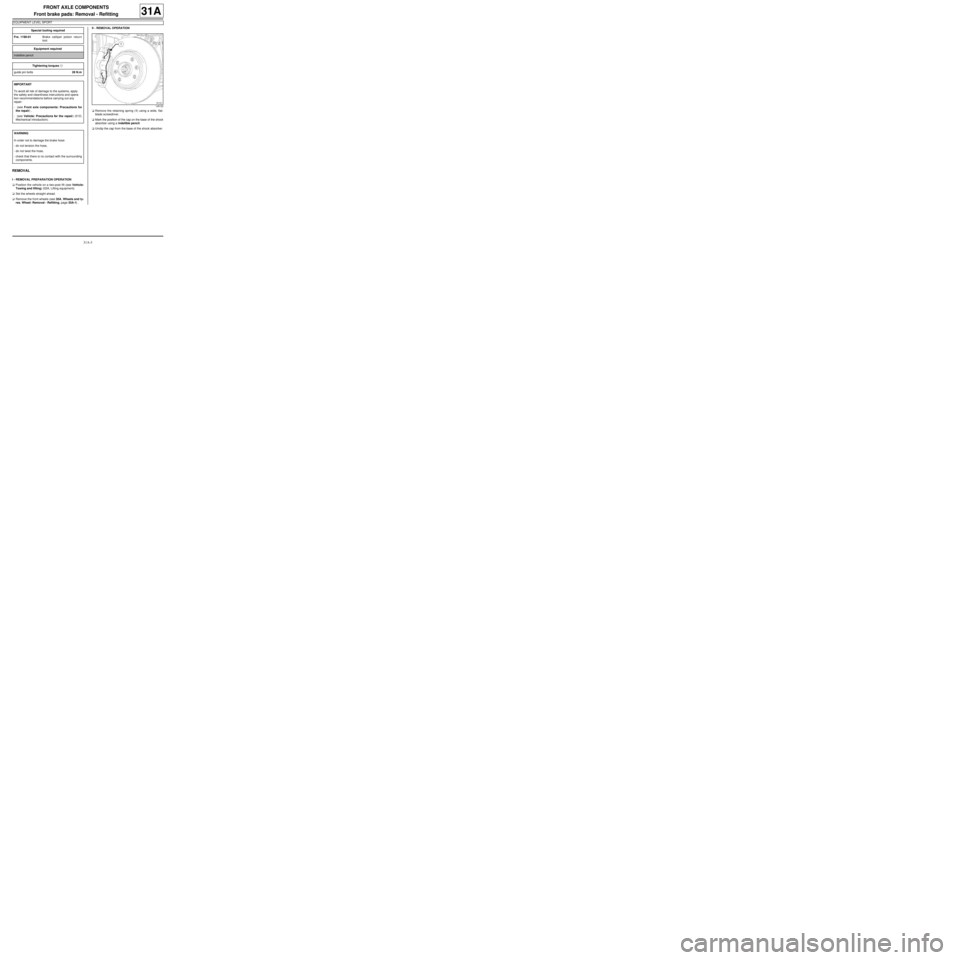

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aSet the wheels straight ahead.

aRemove the front wheels (see 35A, Wheels and ty-

res, Wheel: Removal - Refitting, page 35A-1) .II - REMOVAL OPERATION

aRemove the retaining spring (1) using a wide, flat-

blade screwdriver.

aMark the position of the cap on the base of the shock

absorber using a indelible pencil.

aUnclip the cap from the base of the shock absorber. Special tooling required

Fre. 1190-01Brake calliper piston return

tool.

Equipment required

indelible pencil

Tightening torquesm

guide pin bolts28 N.m

IMPORTANT

To avoid all risk of damage to the systems, apply

the safety and cleanliness instructions and opera-

tion recommendations before carrying out any

repair:

- (see Front axle components: Precautions for

the repair) ,

- (see Vehicle: Precautions for the repair) (01D,

Mechanical introduction).

WARNING

In order not to damage the brake hose:

-do not tension the hose,

-do not twist the hose,

-check that there is no contact with the surrounding

components.

145122

Page 48 of 281

31A-5

FRONT AXLE COMPONENTS

Front brake pads: Removal - Refitting

EQ UIPMENT LEVEL SPORT

31A

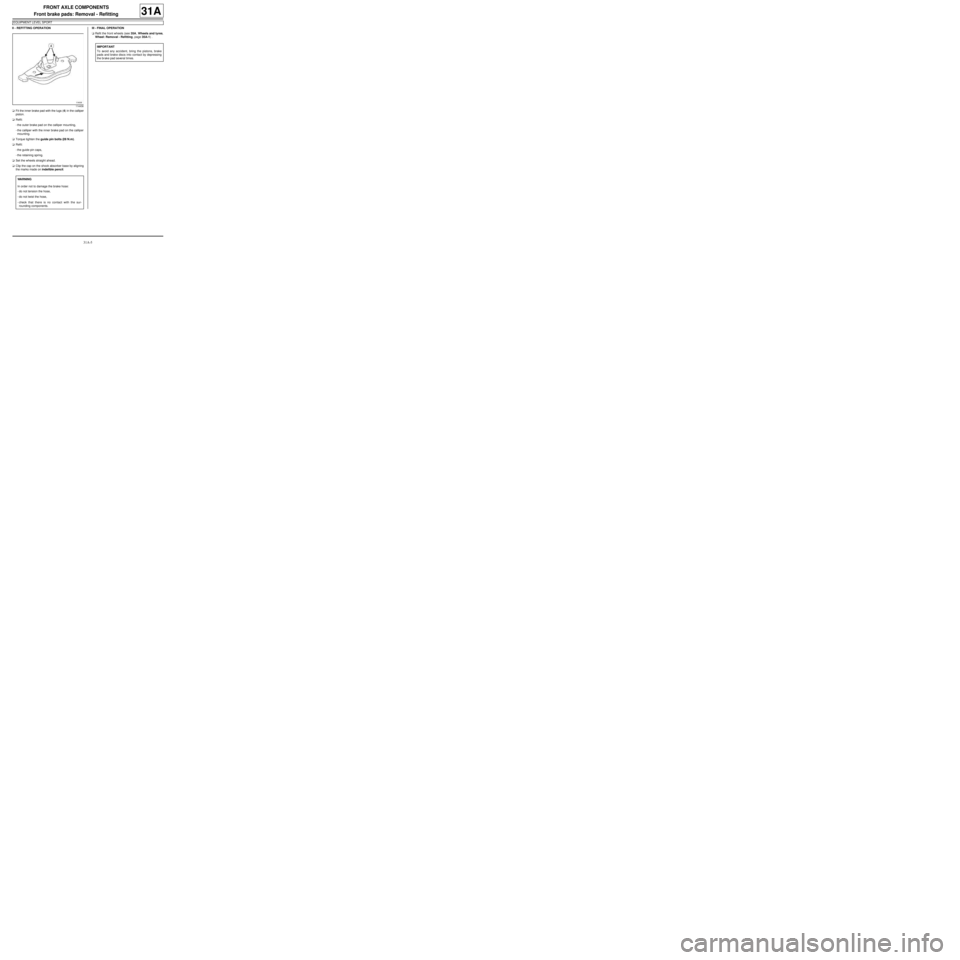

II - REFITTING OPERATION

aFit the inner brake pad with the lugs (4) in the calliper

piston.

aRefit:

-the outer brake pad on the calliper mounting,

-the calliper with the inner brake pad on the calliper

mounting.

aTorque tighten the guide pin bolts (28 N.m).

aRefit:

-the guide pin caps,

-the retaining spring.

aSet the wheels straight ahead.

aClip the cap on the shock absorber base by aligning

the marks made on indelible pencil.III - FINAL OPERATION

aRefit the front wheels (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) .

114436

WARNING

In order not to damage the brake hose:

-do not tension the hose,

-do not twist the hose,

-check that there is no contact with the sur-

rounding components.

IMPORTANT

To avoid any accident, bring the pistons, brake

pads and brake discs into contact by depressing

the brake pad several times.

Page 51 of 281

31A-8

FRONT AXLE COMPONENTS

Front brake calliper: Removal - Refitting

EQ UIPMENT LEVEL EA0 or EQUIPMENT LEVEL EA1 or EQUIPMENT LEVEL EA3 or EQUIPMENT LEVEL EA5

or EQUIPMENT LEVEL EAG or EQUIPMENT LEVEL EZ2 or EQUIPMENT LEVEL EZ4

31A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) .

aFit the pedal press to the brake pedal to limit the

outflow of brake fluid.

aUnlock the steering column.

aRemove the front wheel on the side concerned (see

35A, Wheels and tyres, Wheel: Removal - Refit-

ting, page 35A-1) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aUnlock the brake hose (1) on the brake calliper.

aRemove the brake pads (see 31A, Front axle com-

ponents, Front brake pads: Removal - Refitting,

page 31A-1) . Equipment required

pedal press

Tightening torquesm

guide pin bolts34 N.m

brake hose17 N.m

Note:

The callipers supplied as spare par ts are pre-filled

with br ake fluid.

WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

119214

WARNING

In order not to damage the brake hose:

-do not tension the hose,

-do not twist the hose,

-check that there is no contact with the sur-

rounding components.

Page 52 of 281

31A-9

FRONT AXLE COMPONENTS

Front brake calliper: Removal - Refitting

EQ UIPMENT LEVEL EA0 or EQUIPMENT LEVEL EA1 or EQUIPMENT LEVEL EA3 or EQUIPMENT LEVEL EA5

or EQUIPMENT LEVEL EAG or EQUIPMENT LEVEL EZ2 or EQUIPMENT LEVEL EZ4

31A

aRemove:

-the bolts from the guide pins (2) while holding the

nut (3) ,

-the brake calliper from the hose,

-the brake calliper.

REFITTING

I - REFITTING PREPARATION OPERATION

aCheck the condition of the gaiter and calliper piston

(replace defective parts).

aPush the piston back until it is at the end of its bore.

aUsing the cleaning station, clean:

-the calliper mounting,

-the calliper.II - REFITTING OPERATION FOR PART

CONCERNED

aSet the front wheels straight.

aWithout using a tool, screw the calliper to the brake

hose as tightly as possible.

aRefit:

-the brake pads (see 31A, Front axle compo-

nents, Front brake pads: Removal - Refitting,

page 31A-1) ,

-the calliper,

-the new guide pin bolts.

aTorque tighten:

-the guide pin bolts (34 N.m),

-the brake hose (17 N.m).

III - FINAL OPERATION

aRemove the pedal press from the brake pedal.

aBleed the brake circuit (see 30A, General informa-

tion, Braking circuit: Bleed, page 30A-4) .

aRefit the front wheel on the side concerned (see

35A, Wheels and tyres, Wheel: Removal - Refit-

ting, page 35A-1) .

119218

WARNING

In order not to damage the brake hose:

-do not tension the hose,

-do not twist the hose,

-check that there is no contact with the sur-

rounding components.

IMPORTANT

To avoid any accident, bring the pistons, brake

pads and brake discs into contact by depressing

the brake pad several times.

Page 57 of 281

31A-14

FRONT AXLE COMPONENTS

Front brake calliper mounting: Removal - Refitting

EQ UIPMENT LEVEL EA0 or EQUIPMENT LEVEL EA1 or EQUIPMENT LEVEL EA3 or EQUIPMENT LEVEL EA5

or EQUIPMENT LEVEL EAG or EQUIPMENT LEVEL EZ2 or EQUIPMENT LEVEL EZ4

31A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the front wheel (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) ,

-the front brake pads (see 31A, Front axle compo-

nents, Front brake pads: Removal - Refitting,

page 31A-1) .aRemove the guide pin upper bolt (1) while holding

the nut (2) .

aHang the brake calliper on the shock absorber

spring using a safety strap(s). Equipment required

safety strap(s)

Tightening torquesm

brake calliper mounting

bolts100 N.m

guide pin upper bolt29 N.m

119218

WARNING

In order not to damage the brake hose:

-do not tension the hose,

-do not twist the hose,

-check that there is no contact with the sur-

rounding components.

Page 58 of 281

31A-15

FRONT AXLE COMPONENTS

Front brake calliper mounting: Removal - Refitting

EQ UIPMENT LEVEL EA0 or EQUIPMENT LEVEL EA1 or EQUIPMENT LEVEL EA3 or EQUIPMENT LEVEL EA5

or EQUIPMENT LEVEL EAG or EQUIPMENT LEVEL EZ2 or EQUIPMENT LEVEL EZ4

31A

II - REMOVAL OPERATION

aRemove:

-the brake calliper mounting bolts (3) ,

-the brake calliper mounting.

REFITTING

I - REFITTING PREPARATION OPERATION

aAlways replace the guide pin upper bolt.

aUsing the cleaning station, clean:

-the brake calliper mounting,

-the brake calliper.

aCoat the brake calliper mounting bolts with HIGH

STRENGTH THREAD LOCK (see Vehicle: Parts

and consumables for the repair) (04B, Consum-

ables - Products) before refitting them.

II - REFITTING OPERATION

aRefit:

-the brake calliper mounting,

-the brake calliper mounting bolts.

aTorque tighten the brake calliper mounting bolts

(100 N.m).

III - FINAL OPERATION

aFit the front brake calliper.aRefit the upper bolt on the guide pin while holding

the nut.

aTorque tighten the guide pin upper bolt (29 N.m)

while holding the nut.

aRefit:

-the front brake pads (see 31A, Front axle compo-

nents, Front brake pads: Removal - Refitting,

page 31A-1) ,

-the front wheel (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) .

119219

Page 59 of 281

31A-16

FRONT AXLE COMPONENTS

Front brake calliper mounting: Removal - Refitting

EQ UIPMENT LEVEL SPORT

31A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the front wheel (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) ,

-the front brake pads (see 31A, Front axle compo-

nents, Front brake pads: Removal - Refitting,

page 31A-1) .II - REMOVAL OPERATION

aRemove:

-the calliper mounting bolts (1) ,

-the calliper mounting.

REFITTING

I - REFITTING PREPARATION OPERATION

aClean using a wire brush and BRAKE CLEANER

(see Vehicle: Parts and consumables for the re-

pair) (04B, Consumables - Products):

-the calliper mounting,

-the calliper,

-the hub carrier.

aparts always to be replaced: Front brake calliper

mounting bolt.

II - REFITTING OPERATION

aRefit the calliper mounting.

aTorque tighten the calliper mounting bolts (100

N.m).

III - FINAL OPERATION

aRefit:

-the front brake pads (see 31A, Front axle compo-

nents, Front brake pads: Removal - Refitting,

page 31A-1) , Tightening torquesm

calliper mounting bolts100 N.m

IMPORTANT

To avoid all risk of damage to the systems, apply

the safety and cleanliness instructions and opera-

tion recommendations before carrying out any

repair:

- (see Front axle components: Precautions for

the repair) ,

- (see Vehicle: Precautions for the repair) (01D,

Mechanical introduction).

145125

Page 61 of 281

31A-18

FRONT AXLE COMPONENTS

Front brake disc protector: Removal - Refitting

31A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aRemove:

-the front wheel (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) ,

-the front brake pads (see 31A, Front axle compo-

nents, Front brake pads: Removal - Refitting,

page 31A-1) ,

-the calliper mounting (see 31A, Front axle com-

ponents, Front brake calliper mounting: Re-

moval - Refitting, page 31A-14) ,

-the front brake disc (see 31A, Front axle compo-

nents, Front brake disc: Removal - Refitting,

page 31A-19) ,

-the hub carrier (see 31A, Front axle components,

Front driveshaft hub carrier: Removal - Refit-

ting, page 31A-23) ,

-the hub carrier bearing (see 31A, Front axle com-

ponents, Front hub carrier bearing: Removal -

Refitting, page 31A-26) .

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the brake disc protector bolts (1) ,-the brake disc protector (2) .

REFITTING

I - REFITTING PREPARATIONS OPERATION

aAlways replace the hub carrier bearing when a hub

is removed (see 31A, Front axle components,

Front hub carrier bearing: Removal - Refitting,

page 31A-26) .

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the brake disc protector,

-the brake disc protector bolts.

aTorque tighten the brake disc protector bolts (8

Nm ).

III - FINAL OPERATION.

aRefit:

-the hub carrier bearing (see 31A, Front axle com-

ponents, Front hub carrier bearing: Removal -

Refitting, page 31A-26) ,

-the hub carrier (see 31A, Front axle components,

Front driveshaft hub carrier: Removal - Refit-

ting, page 31A-23) ,

-the front brake disc (see 31A, Front axle compo-

nents, Front brake disc: Removal - Refitting,

page 31A-19) ,

-the calliper mounting (see 31A, Front axle com-

ponents, Front brake calliper mounting: Re-

moval - Refitting, page 31A-14) ,

-the front brake pads (see 31A, Front axle compo-

nents, Front brake pads: Removal - Refitting,

page 31A-1) ,

-the front wheel (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) . Tightening torquesm

brake disc protector

bolts8 Nm

121610