parking brake RENAULT TWINGO RS 2009 2.G Chasiss Owner's Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 281

Page 139 of 281

33A-41

REAR AXLE COMPONENTS

Complete rear axle system: Removal - Refitting

33A

aUnclip the end of the parking brake cables at (10) .

aUnclip the cable sleeve stops at (11) and extract the

parking brake cables from the rear drum flanges.

aRemove:

-the rear brake pads (see 33A, Rear axle compo-

nents, Rear brake lining: Removal - Refitting,

page 33A-14) ,

-the rear brake cylinders (see 33A, Rear axle com-

ponents, Rear brake cylinder: Removal - Refit-

ting, page 33A-17) ,

-the rear wheel speed sensors (see 38C, Anti-lock

braking system, Rear wheel speed sensor: Re-

moval - Refitting, page 38C-17) ,

-the rear rigid brake pipes from the rear axle,

-the rear rigid brake pipe clips from the rear axle,

-the rear stub axle carriers (see 33A, Rear axle

components, Rear stub axle carrier: Removal -

Refitting, page 33A-32) ,

-the rear brake drum flanges,

REFITTING

I - REFITTING PREPARATIONS OPERATION

aStrap the rear axle onto the (Mot. 1390).

aPosition the rear axle under the vehicle.II - REFITTING OPERATION FOR PART

CONCERNED

1 - Replacement

aRefit:

-the rear brake drum flanges,

-the rear stub axle carriers (see 33A, Rear axle

components, Rear stub axle carrier: Removal -

Refitting, page 33A-32) ,

-the rigid brake pipe clips on the rear axle,

-the rear rigid brake pipes from the rear axle,

-the rear wheel speed sensors (see 38C, Anti-lock

braking system, Rear wheel speed sensor: Re-

moval - Refitting, page 38C-17) ,

-the rear brake cylinders (see 33A, Rear axle com-

ponents, Rear brake cylinder: Removal - Refit-

ting, page 33A-17) ,

-the rear brake pads (see 33A, Rear axle compo-

nents, Rear brake lining: Removal - Refitting,

page 33A-14) .

-the parking brake cables (see 37A, Mechanical

component controls, Parking brake cables: Re-

moval - Refitting, page 37A-74) ,

-the rear brake drums (see 33A, Rear axle compo-

nents, Rear brake drum: Removal - Refitting,

page 33A-19) .

121331

Page 140 of 281

33A-42

REAR AXLE COMPONENTS

Complete rear axle system: Removal - Refitting

33A

2 - Refitting

aLower the lift.

aPosition the bearing centring devices (12) opposite

the centring holes.

aRefit the rear axle bearing bolts.

aTorque tighten the rear axle bearing bolts (62 Nm).

aRemove the safety strap(s).

aRaise the lift.

aRefit:

-the rear suspension springs (see 33A, Rear axle

components, Rear suspension spring: Remov-

al - Refitting, page 33A-28) ,

-the brake hose lower unions.

aTorque tighten the brake hose lower unions (17

Nm).

aConnect the ABS sensor connectors.

aClose the ABS sensor connector protective unit.

aClip the parking brake cables onto the reservoir.

aPosition the parking brake cables on the parking

brake compensator.

aCheck that the parking brake cable stops are proper-ly inserted in their housings.

III - FINAL OPERATION.

aAdjust the parking brake cables (see 37A, Mechan-

ical component controls, Parking brake lever:

Removal - Refitting, page 37A-46) .

aRefit the rear wheels (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) .

aRemove the pedal press.

aBleed the braking circuit (see 30A, General infor-

mation, Braking circuit: Bleed, page 30A-4) .

119651

Page 141 of 281

35A-1

WHEELS AND TYRES

Wheel: Removal - Refitting

35A

The removal - refitting procedure is the same for all

wheels.

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRelease the parking brake.

aRemove the trim.

aPosition the wheel so that the valve is at the top.

aMark the position of the wheel on the hub.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aLoosen the wheel bolts with the wheel on the

ground.

aRaise the lift.

aRemove:

-the wheel bolts,

-the wheel.

If the wheel cannot be removed after the bolt has

been undone:

aPosition all the wheel bolts.

aTighten the wheel bolts to bring all the bolt heads

into contact with the wheel.

aUndo the wheel bolts by one turn.aStrike around the edge of the tyre walls (1) several

times using a mallet on the inner and outer surfaces

of the wheel to detach the wheel.

aRemove:

-the wheel bolts,

-the wheel. Note:

This mark is required in order to:

-Note the original position of the wheel on the

hub,

-perform the balancing operation.

Note:

Use sockets with protective sheaths in order to

avoid scratching the alloy wheel rims.

100682

Page 144 of 281

35A-4

WHEELS AND TYRES

Wheel: Balancing

35A

I - PREREQUISITES FOR WHEEL BALANCING

aWheel balancing is a measurement operation.

Several conditions must be met to achieve a reliable

result in a single operation.

The wheel balancer must be installed in accordance

with the manufacturer's instructions.

It is essential to calibrate the balancer according to

the frequency recommended by the manufacturer.

Do not grease the threaded shaft.

Check the condition of the supports, centring com-

ponents and mountings.

Replace any faulty parts (see manufacturer's in-

structions).

The wheel and the wheel balancer must be clean.

Driver's perception

aIf the wheels are not correctly balanced this causes

the steering wheel and/or the vehicle floor to vibrate.

These vibrations appear between 54 mph (90 km/h)

and 90 mph (150 km/h).

II - BALANCING PREPARATION OPERATION

aAdjust the tyre pressure (see 35A, Wheels and ty-

res, Tyre pressure: Identification, page 35A-10) .

aAlways carry out a road test for a minimum distance

of 1 mile (2 km) before balancing the wheels, in or-

der to remove any flat spots on the tread caused by

the vehicle being immobilised.

aActions to be carried out immediately after the test

drive:

-Position the vehicle on a two-post vehicle lift (see

Vehicle: Towing and lifting) ,

-raise the vehicle,

-leave the four wheels hanging free,

-release the parking brake.a

To reproduce the exact vehicle wheel assembly, use

a ring (1) of diameter:

a60 mm

aThere are three types of weight:

105870

Note:

The ring is available from the supplier of the

equipment used.

Page 225 of 281

37A-46

MECHANICAL COMPONENT CONTROLS

Parking brake lever: Removal - Refitting

37A

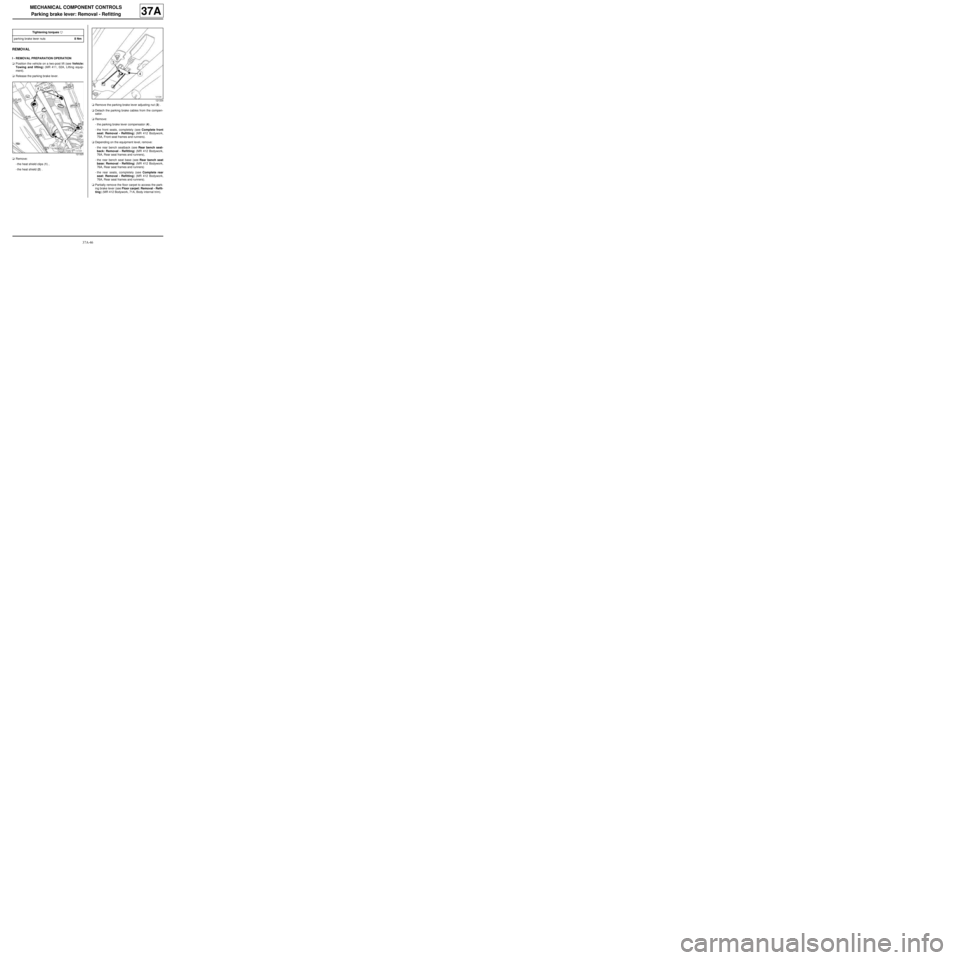

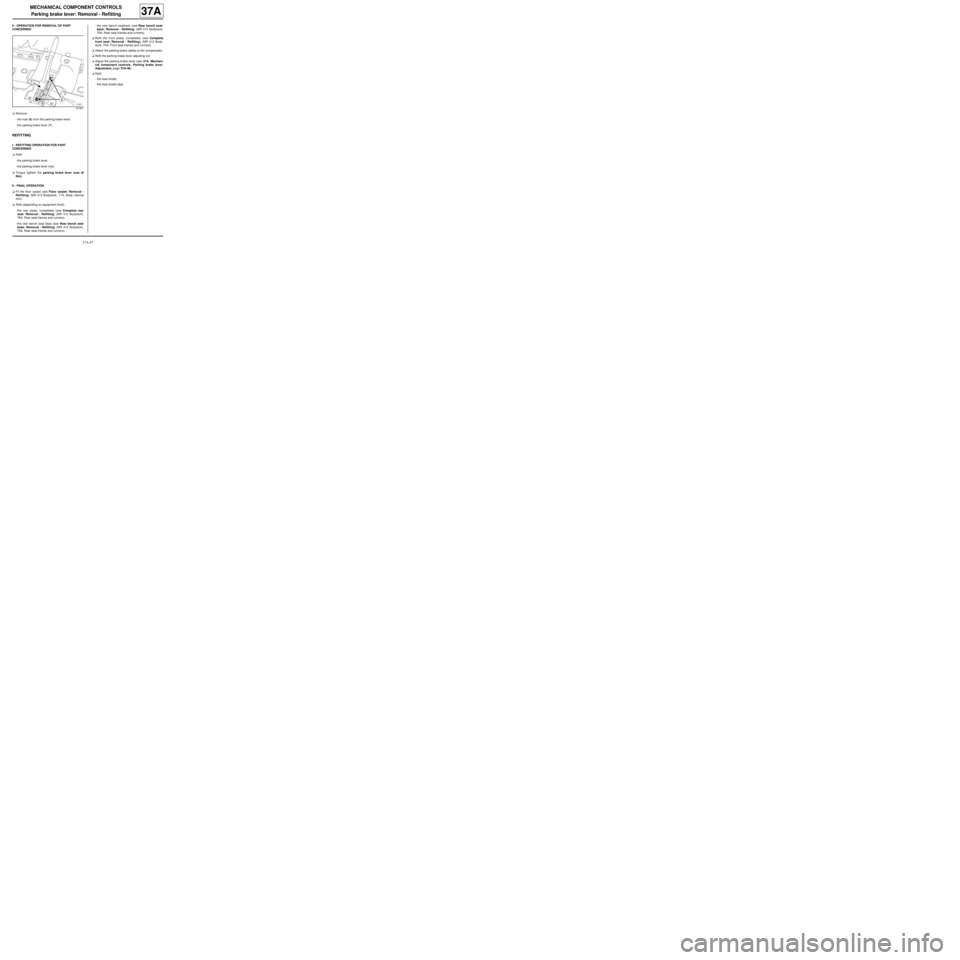

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aRelease the parking brake lever.

aRemove:

-the heat shield clips (1) ,

-the heat shield (2) .aRemove the parking brake lever adjusting nut (3) .

aDetach the parking brake cables from the compen-

sator.

aRemove:

-the parking brake lever compensator (4) ,

-the front seats, completely (see Complete front

seat: Removal - Refitting) (MR 412 Bodywork,

75A, Front seat frames and runners).

aDepending on the equipment level, remove:

-the rear bench seatback (see Rear bench seat-

back: Removal - Refitting) (MR 412 Bodywork,

76A, Rear seat frames and runners),

-the rear bench seat base (see Rear bench seat

base: Removal - Refitting) (MR 412 Bodywork,

76A, Rear seat frames and runners)

-the rear seats, completely (see Complete rear

seat: Removal - Refitting) (MR 412 Bodywork,

76A, Rear seat frames and runners).

aPartially remove the floor carpet to access the park-

ing brake lever (see Floor carpet: Removal - Refit-

ting) (MR 412 Bodywork, 71A, Body internal trim). Tightening torquesm

par king brake lever nuts8 Nm

121325

121334

Page 226 of 281

37A-47

MECHANICAL COMPONENT CONTROLS

Parking brake lever: Removal - Refitting

37A

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the nuts (6) from the parking brake lever,

-the parking brake lever (7) .

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the parking brake lever,

-the parking brake lever nuts.

aTorque tighten the parking brake lever nuts (8

Nm).

II - FINAL OPERATION.

aFit the floor carpet (see Floor carpet: Removal -

Refitting) (MR 412 Bodywork, 71A, Body internal

trim).

aRefit (depending on equipment level):

-the rear seats, completely (see Complete rear

seat: Removal - Refitting) (MR 412 Bodywork,

76A, Rear seat frames and runners),

-the rear bench seat base (see Rear bench seat

base: Removal - Refitting) (MR 412 Bodywork,

76A, Rear seat frames and runners),-the rear bench seatback (see Rear bench seat-

back: Removal - Refitting) (MR 412 Bodywork,

76A, Rear seat frames and runners).

aRefit the front seats, completely (see Complete

front seat: Removal - Refitting) (MR 412 Body-

work, 75A, Front seat frames and runners).

aAttach the parking brake cables to the compensator.

aRefit the parking brake lever adjusting nut.

aAdjust the parking brake lever (see 37A, Mechani-

cal component controls, Parking brake lever:

Adjustment, page 37A-48) .

aRefit:

-the heat shield,

-the heat shield clips.

121607

Page 227 of 281

37A-48

MECHANICAL COMPONENT CONTROLS

Parking brake lever: Adjustment

37A

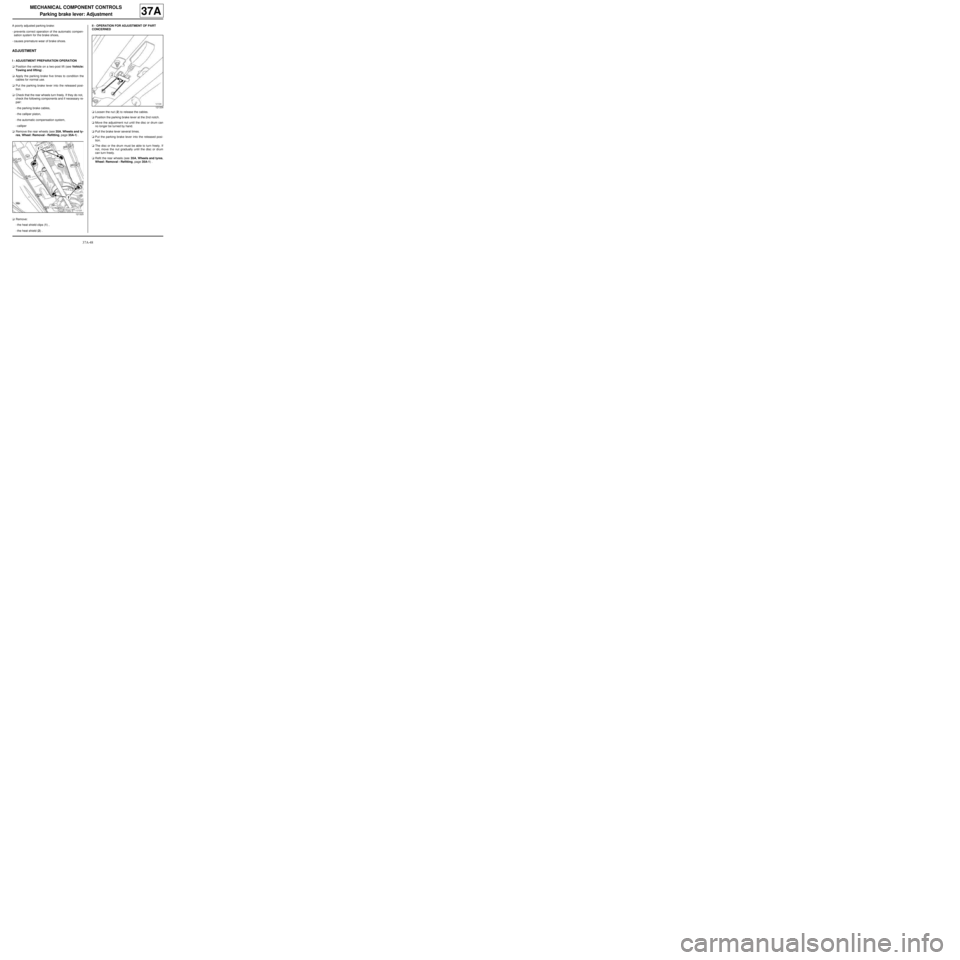

A poorly adjusted parking brake:

-prevents correct operation of the automatic compen-

sation system for the brake shoes,

-causes premature wear of brake shoes.

ADJUSTMENT

I - ADJUSTMENT PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) .

aApply the parking brake five times to condition the

cables for normal use.

aPut the parking brake lever into the released posi-

tion.

aCheck that the rear wheels turn freely. If they do not,

check the following components and if necessary re-

pair:

-the parking brake cables,

-the calliper piston,

-the automatic compensation system,

-calliper

aRemove the rear wheels (see 35A, Wheels and ty-

res, Wheel: Removal - Refitting, page 35A-1) .

aRemove:

-the heat shield clips (1) ,

-the heat shield (2) .II - OPERATION FOR ADJUSTMENT OF PART

CONCERNED

aLoosen the nut (2) to release the cables.

aPosition the parking brake lever at the 2nd notch.

aMove the adjustment nut until the disc or drum can

no longer be turned by hand.

aPull the brake lever several times.

aPut the parking brake lever into the released posi-

tion.

aThe disc or the drum must be able to turn freely. If

not, move the nut gradually until the disc or drum

can turn freely.

aRefit the rear wheels (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) .

121325

121334

Page 253 of 281

37A-74

MECHANICAL COMPONENT CONTROLS

Parking brake cables: Removal - Refitting

EQ UIPMENT LEVEL EA0 or EQUIPMENT LEVEL EA1 or EQUIPMENT LEVEL EA3 or EQUIPMENT LEVEL EA5

or EQUIPMENT LEVEL EAG or EQUIPMENT LEVEL EZ2 or EQUIPMENT LEVEL EZ4

37A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aFit:

-the vehicle on a two-post lift (see Vehicle: Towing

and lifting) (02A, Lifting equipment),

-the parking brake lever in the released position.

aRemove:

-the rear wheels (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) ,

-the rear brake drums (see 33A, Rear axle compo-

nents, Rear brake drum: Removal - Refitting,

page 33A-19) .

aRemoval:

-the clips (1) ,

-the heat shield (2) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aLoosen nut (3) .

aUnclip the left-hand (5) and right-hand (6) parking

brake cable sleeve stops.

121325

121334

121334

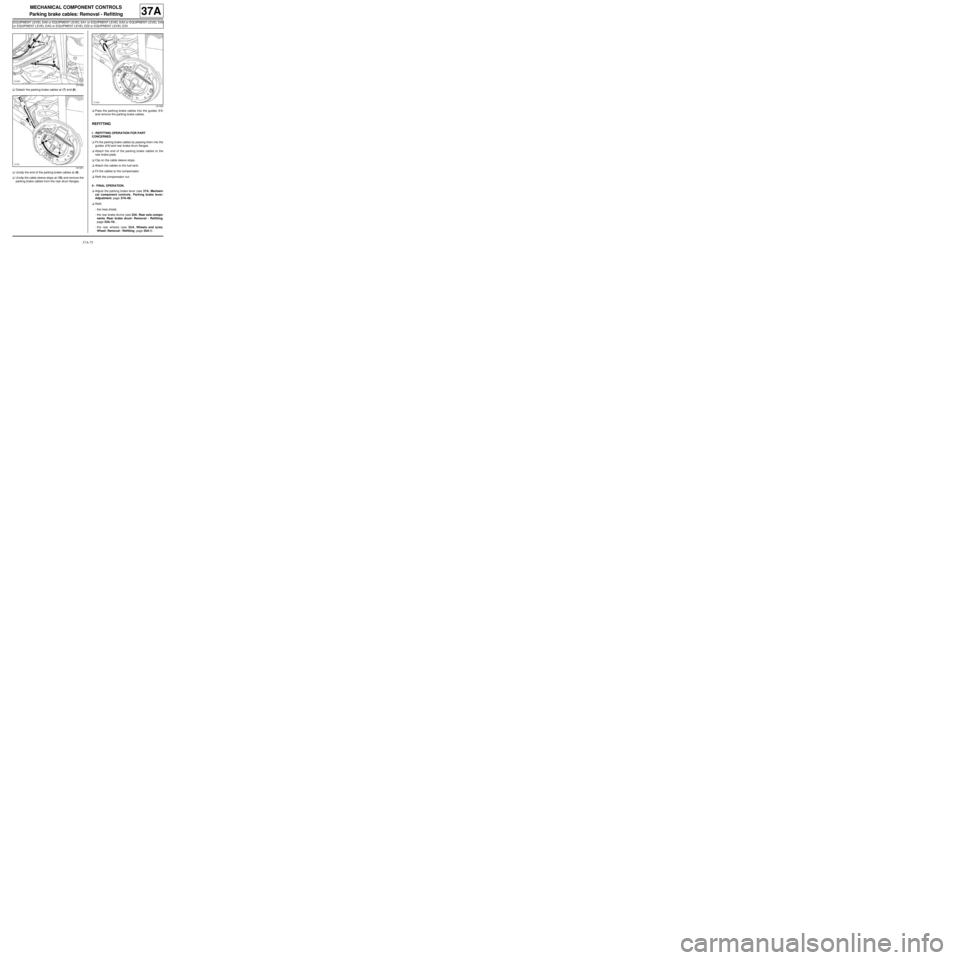

Page 254 of 281

37A-75

MECHANICAL COMPONENT CONTROLS

Parking brake cables: Removal - Refitting

EQ UIPMENT LEVEL EA0 or EQUIPMENT LEVEL EA1 or EQUIPMENT LEVEL EA3 or EQUIPMENT LEVEL EA5

or EQUIPMENT LEVEL EAG or EQUIPMENT LEVEL EZ2 or EQUIPMENT LEVEL EZ4

37A

aDetach the parking brake cables at (7) and (8) .

aUnclip the end of the parking brake cables at (9) .

aUnclip the cable sleeve stops at (10) and remove the

parking brake cables from the rear drum flanges.aPass the parking brake cables into the guides (11)

and remove the parking brake cables.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aFit the parking brake cables by passing them into the

guides (11) and rear brake drum flanges.

aAttach the end of the parking brake cables to the

rear brake pads.

aClip on the cable sleeve stops.

aAttach the cables to the fuel tank.

aFit the cables to the compensator.

aRefit the compensator nut.

II - FINAL OPERATION.

aAdjust the parking brake lever (see 37A, Mechani-

cal component controls, Parking brake lever:

Adjustment, page 37A-48) .

aRefit:

-the heat shield,

-the rear brake drums (see 33A, Rear axle compo-

nents, Rear brake drum: Removal - Refitting,

page 33A-19) ,

-the rear wheels (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) .

121329

121331

121330

Page 255 of 281

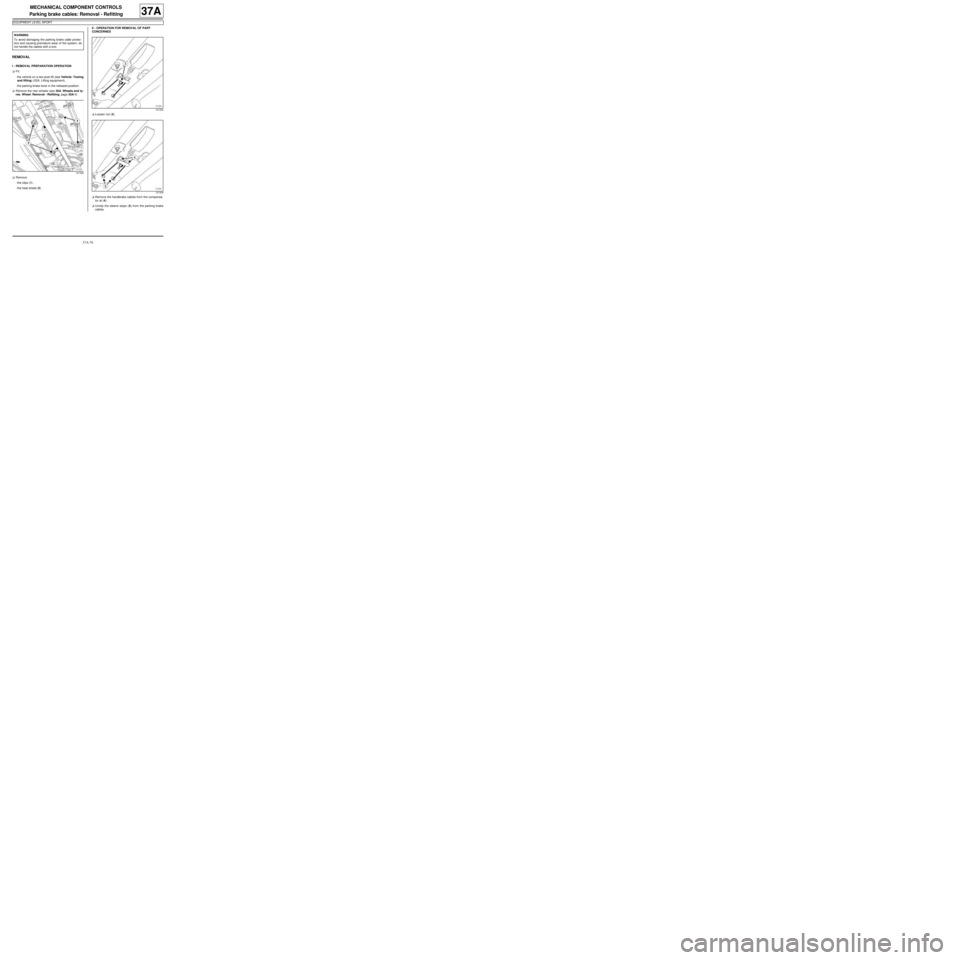

37A-76

MECHANICAL COMPONENT CONTROLS

Parking brake cables: Removal - Refitting

EQ UIPMENT LEVEL SPORT

37A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aFit:

-the vehicle on a two-post lift (see Vehicle: Towing

and lifting) (02A, Lifting equipment),

-the parking brake lever in the released position.

aRemove the rear wheels (see 35A, Wheels and ty-

res, Wheel: Removal - Refitting, page 35A-1) .

aRemove:

-the clips (1) ,

-the heat shield (2) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aLoosen nut (3) .

aRemove the handbrake cables from the compensa-

tor at (4) .

aUnclip the sleeve stops (5) from the parking brake

cables. WARNING

To avoid damaging the parking brake cable protec-

tors and causing premature wear of the system, do

not handle the cables with a tool.

121326

121334

121334