tow RENAULT TWINGO RS 2009 2.G Chasiss Owner's Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 281

Page 112 of 281

33A-14

REAR AXLE COMPONENTS

Rear brake lining: Removal - Refitting

33A

Replace all the brake pads on one axle at the same

time. Never mix brake pads of different brands or qual-

ities.

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift ( (see Vehicle:

Towing and lifting) ).

aRelease the parking brake.

aRemove:

-the rear wheels (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) ,

-the rear brake drums (see 33A, Rear axle compo-

nents, Rear brake drum: Removal - Refitting,

page 33A-19) .

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the lower return spring (1) , then the upper

return spring (2) using brake shoe pliers.aFit pliers (3) onto the slave cylinder pistons.

aRemove:

-the side retainer springs (4) of the segments, keep-

ing the connecting rod (5) in contact with the brake

backing plate (6) ,

-the leading shoe (7) ,

-the link rod (8) ,

-the trailing shoe (9) .

aUncouple the parking brake cable from the parking

brake lever.

86561

86560

Page 115 of 281

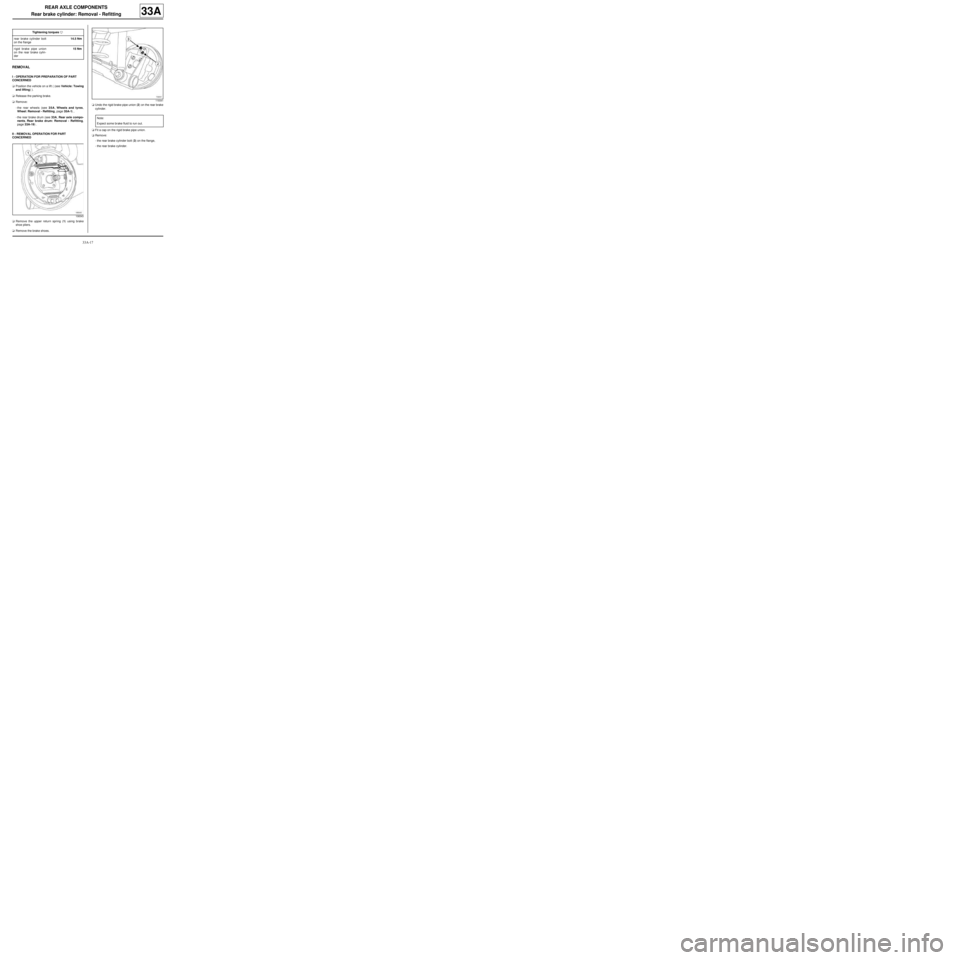

33A-17

REAR AXLE COMPONENTS

Rear brake cylinder: Removal - Refitting

33A

REMOVAL

I - OPERATION FOR PREPARATION OF PART

CONCERNED

aPosition the vehicle on a lift ( (see Vehicle: Towing

and lifting) ).

aRelease the parking brake.

aRemove:

-the rear wheels (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) ,

-the rear brake drum (see 33A, Rear axle compo-

nents, Rear brake drum: Removal - Refitting,

page 33A-19) .

II - REMOVAL OPERATION FOR PART

CONCERNED

aRemove the upper return spring (1) using brake

shoe pliers.

aRemove the brake shoes.aUndo the rigid brake pipe union (2) on the rear brake

cylinder.

aFit a cap on the rigid brake pipe union.

aRemove:

-the rear brake cylinder bolt (3) on the flange,

-the rear brake cylinder. Tightening torquesm

rear brake cylinder bolt

on the flange14.5 Nm

rigid brake pipe union

on the rear brake cylin-

der15 Nm

108343

119341

Note:

Expect some br ake fluid to run out.

Page 117 of 281

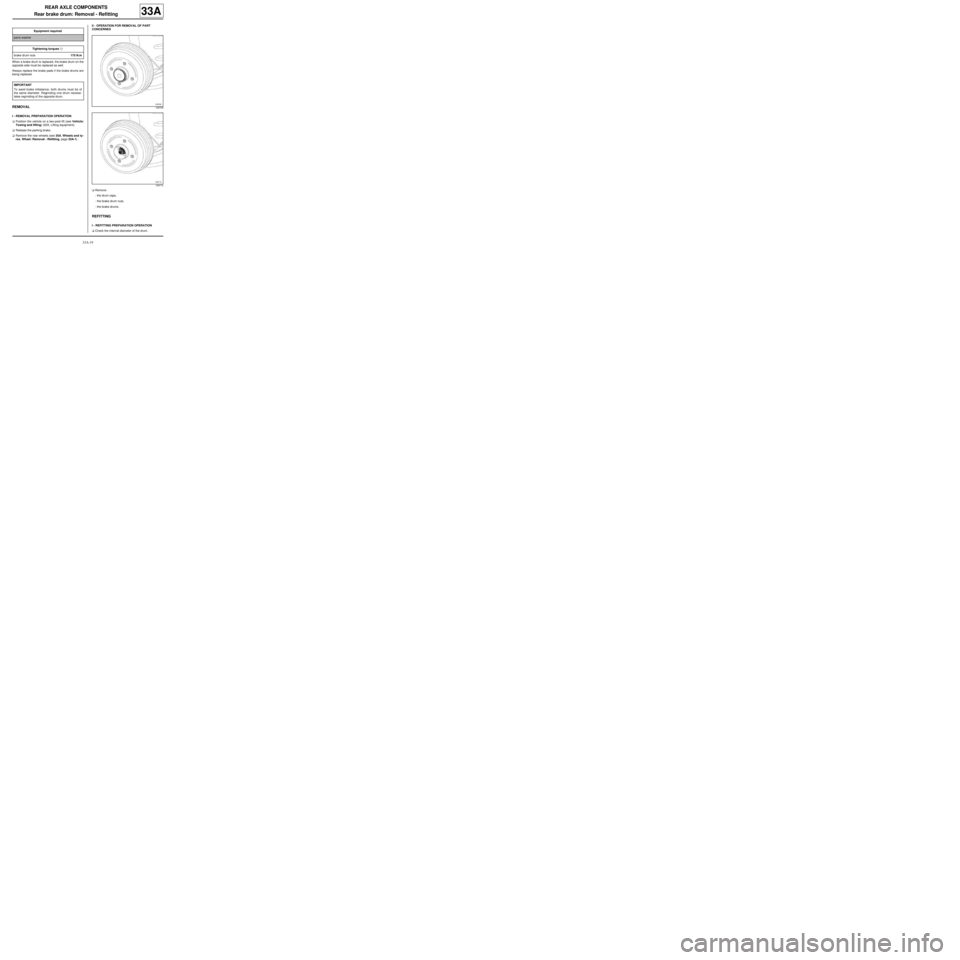

33A-19

REAR AXLE COMPONENTS

Rear brake drum: Removal - Refitting

33A

When a brake drum is replaced, the brake drum on the

opposite side must be replaced as well.

Always replace the brake pads if the brake drums are

being replaced.

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRelease the parking brake.

aRemove the rear wheels (see 35A, Wheels and ty-

res, Wheel: Removal - Refitting, page 35A-1) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the drum caps,

-the brake drum nuts,

-the brake drums.

REFITTING

I - REFITTING PREPARATION OPERATION

aCheck the internal diameter of the drum. Equipment required

par ts washer

Tightening torquesm

brake drum nuts175 N.m

IMPORTANT

To avoid brake imbalance, both drums must be of

the same diameter. Regrinding one drum necessi-

tates regrinding of the opposite drum.

109709

109710

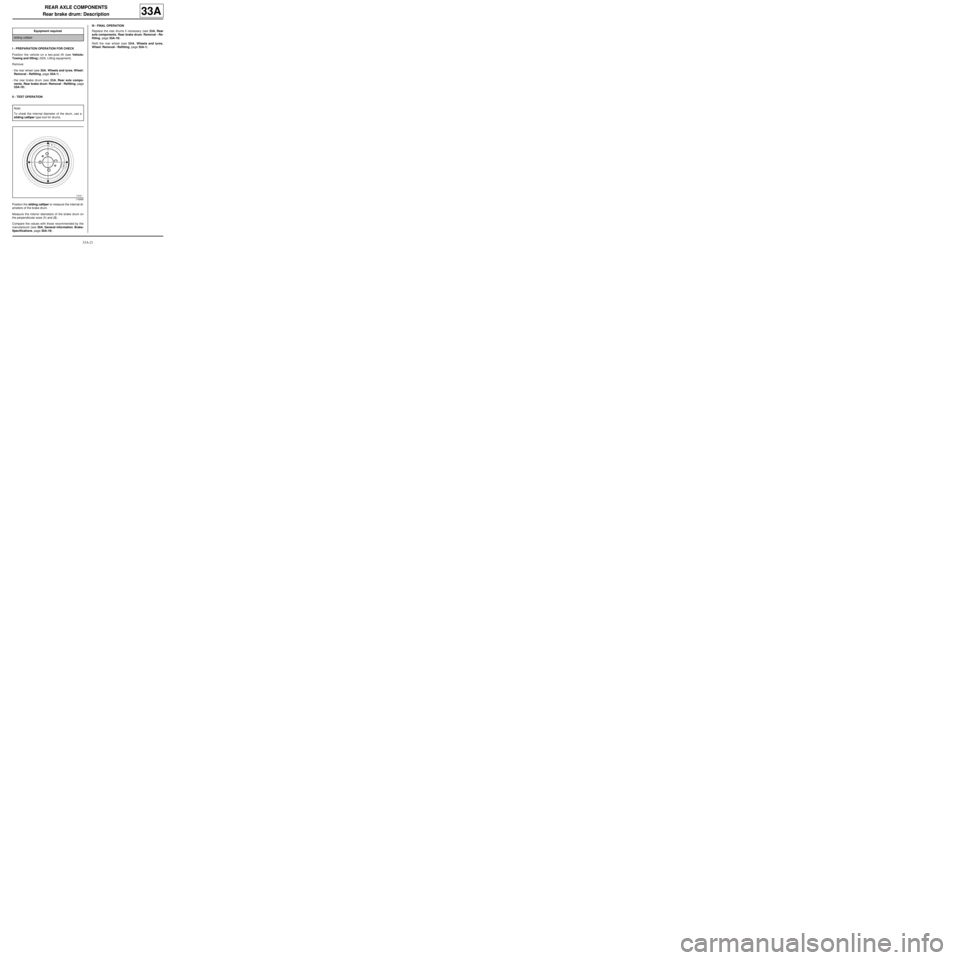

Page 119 of 281

33A-21

REAR AXLE COMPONENTS

Rear brake drum: Description

33A

I - PREPARATION OPERATION FOR CHECK

Position the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

Remove:

-the rear wheel (see 35A, Wheels and tyres, Wheel:

Removal - Refitting, page 35A-1) ,

-the rear brake drum (see 33A, Rear axle compo-

nents, Rear brake drum: Removal - Refitting, page

33A-19) .

II - TEST OPERATION

Position the sliding calliper to measure the internal di-

ameters of the brake drum.

Measure the interior diameters of the brake drum on

the perpendicular axes (1) and (2) .

Compare the values with those recommended by the

manufacturer (see 30A, General information, Brake:

Specifications, page 30A-19) .III - FINAL OPERATION

Replace the rear drums if necessary (see 33A, Rear

axle components, Rear brake drum: Removal - Re-

fitting, page 33A-19) .

Refit the rear wheel (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) . Equipment required

sliding calliper

Note:

To check the internal diameter of the drum, use a

sliding calliper type tool for drums.

116995

Page 120 of 281

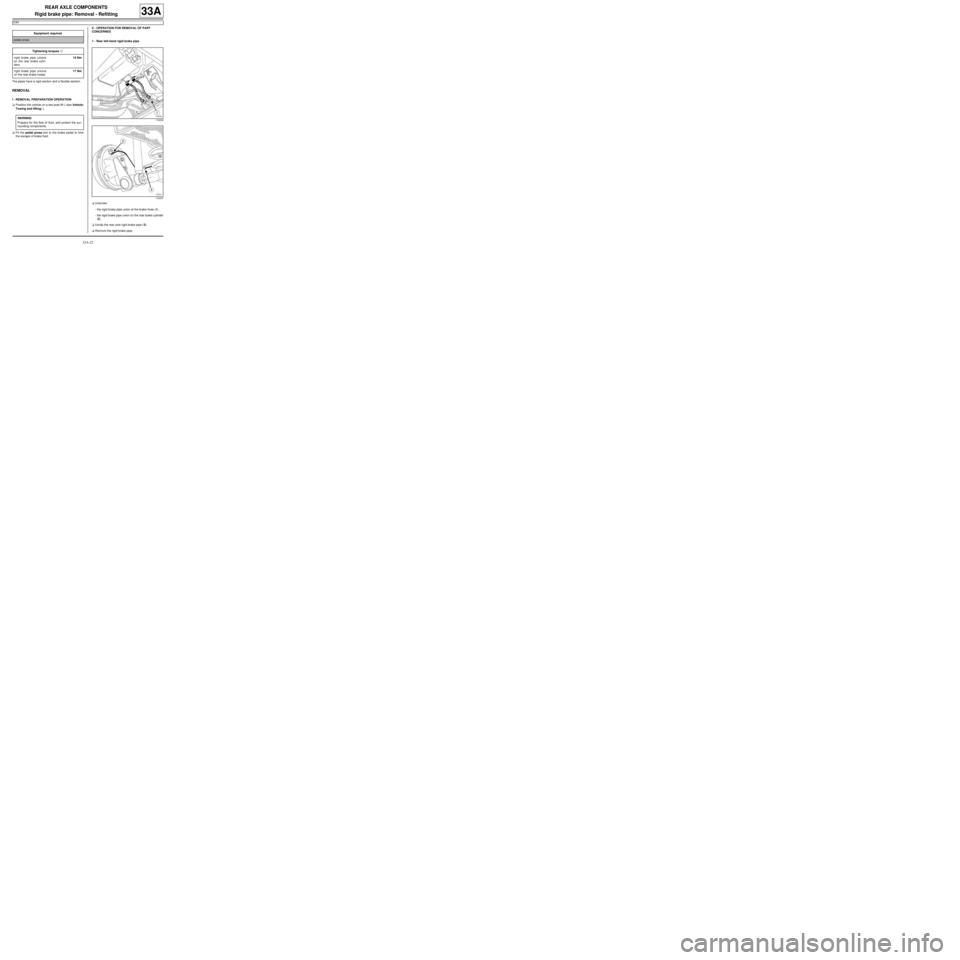

33A-22

REAR AXLE COMPONENTS

Rigid brake pipe: Removal - Refitting

C44

33A

The pipes have a rigid section and a flexible section.

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift ( (see Vehicle:

Towing and lifting) ).

aFit the pedal press tool to the brake pedal to limit

the escape of brake fluid.II - OPERATION FOR REMOVAL OF PART

CONCERNED

1 - Rear left-hand rigid brake pipe

aUnscrew:

-the rigid brake pipe union at the brake hose (1) .

-the rigid brake pipe union on the rear brake cylinder

(2) .

aUnclip the rear axle rigid brake pipe (3) .

aRemove the rigid brake pipe. Equipment required

pedal press

Tightening torquesm

rigid brake pipe unions

on the rear brake cylin-

ders15 Nm

rigid brake pipe unions

on the rear brake hoses17 Nm

WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

119339

119337

Page 122 of 281

33A-24

REAR AXLE COMPONENTS

Shock absorber: Removal - Refitting

33A

If a shock absorber is replaced, the shock absorber on

the opposite side must also be replaced.

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).aRemove the luggage compartment internal trim (1) .

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aUndo the upper shock absorber nut (2) when the

wheels are on the ground.

aRaise the vehicle. Equipment required

component jack

Tightening torquesm

shock absorber lower

bolt105 Nm

shock absorber upper

nut21 Nm

WARNING

To prevent any damage, do not use the rear axle as

support for the lifting system.

WARNING

To prevent any suspension asymmetry, replace

both of the shock absorbers on the same axle.

WARNING

To avoid damaging the rear axle components

(elastic joints, brake hoses etc.) do not remove

both shock absorbers at the same time. Proceed

one side at a time.

119428

119434

Page 124 of 281

33A-26

REAR AXLE COMPONENTS

Shock absorber: Removal - Refitting

G44

33A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aRemove the luggage compartment interior trim (see

Rear loading trim: Removal - Refitting) (MR 412,

71A, Body internal trim).II - OPERATION FOR REMOVAL OF PART

CONCERNED

aUndo the upper shock absorber nut (1) when the

wheels are on the ground.

aRaise the vehicle. Equipment required

component jack

Tightening torquesm

lower shock absorber

bolt105 Nm

shock absorber upper

nut21 Nm

WARNING

To prevent any damage, do not use the rear axle as

support for the lifting system.

WARNING

To prevent any suspension asymmetry, replace

both of the shock absorbers on the same axle.

WARNING

To avoid damaging the rear axle components

(elastic joints, brake hoses etc.) do not remove

both shock absorbers at the same time. Proceed

one side at a time.

119434

Page 126 of 281

33A-28

REAR AXLE COMPONENTS

Rear suspension spring: Removal - Refitting

33A

REMOVAL

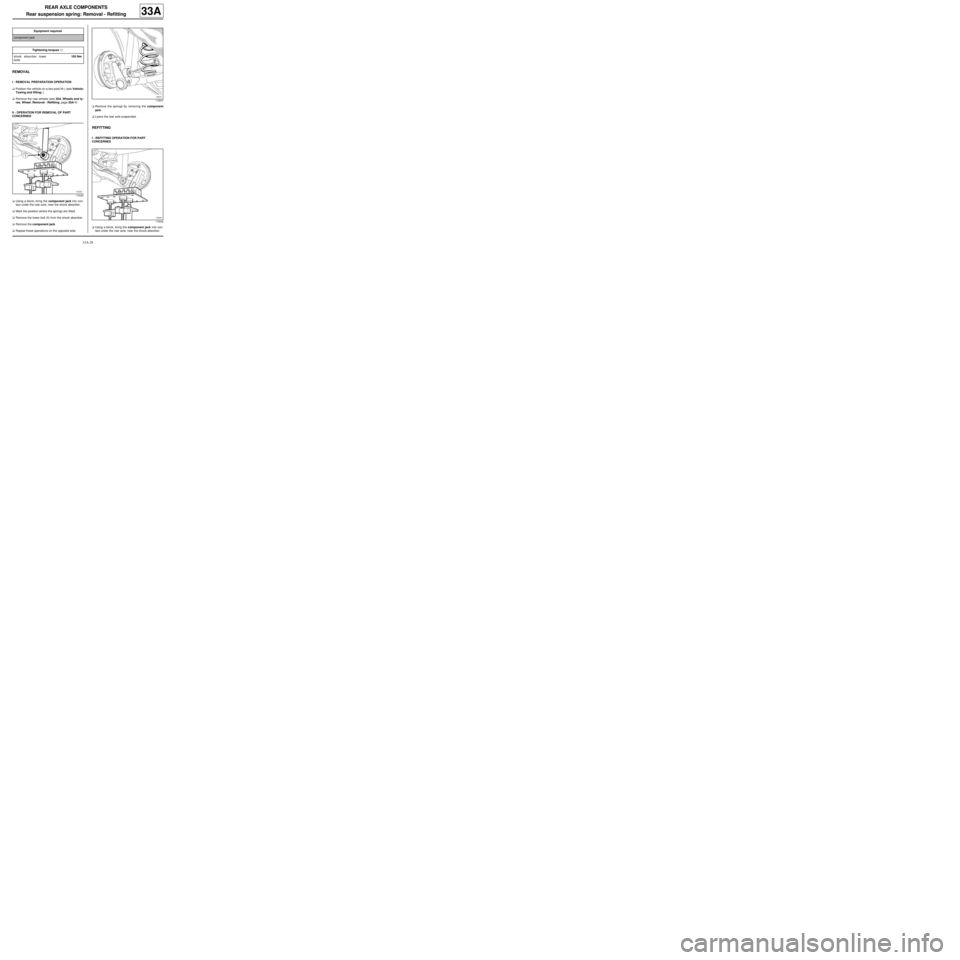

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift ( (see Vehicle:

Towing and lifting) ).

aRemove the rear wheels (see 35A, Wheels and ty-

res, Wheel: Removal - Refitting, page 35A-1) .

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aUsing a block, bring the component jack into con-

tact under the rear axle, near the shock absorber.

aMark the position where the springs are fitted.

aRemove the lower bolt (1) from the shock absorber.

aRemove the component jack.

aRepeat these operations on the opposite side.aRemove the springs by removing the component

jack.

aLeave the rear axle suspended.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aUsing a block, bring the component jack into con-

tact under the rear axle, near the shock absorber. Equipment required

component jack

Tightening torquesm

shock absorber lower

bolts105 Nm

119340

119547

119546

Page 128 of 281

33A-30

REAR AXLE COMPONENTS

Rear drum bearing: Removal - Refitting

33A

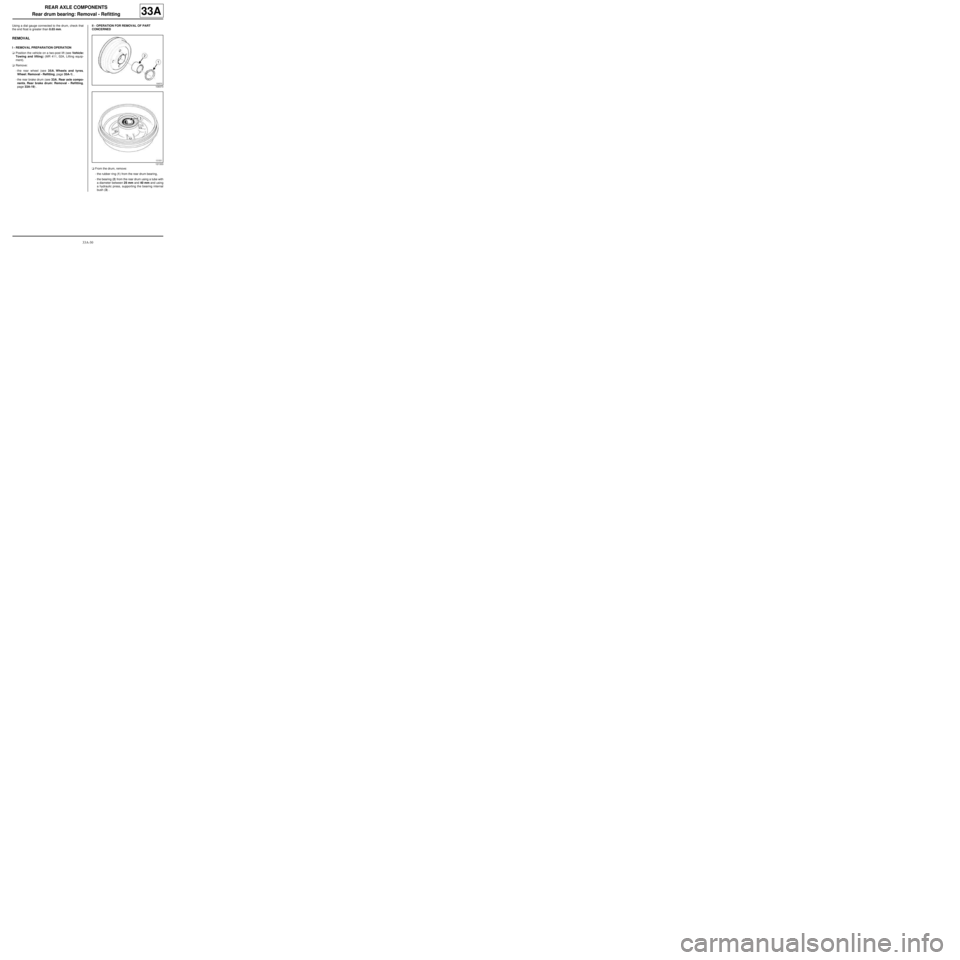

Using a dial gauge connected to the drum, check that

the end float is greater than 0.03 mm.

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aRemove:

-the rear wheel (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) ,

-the rear brake drum (see 33A, Rear axle compo-

nents, Rear brake drum: Removal - Refitting,

page 33A-19) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aFrom the drum, remove:

-the rubber ring (1) from the rear drum bearing,

-the bearing (2) from the rear drum using a tube with

a diameter between 25 mm and 40 mm and using

a hydraulic press, supporting the bearing internal

bush (3) .

109373

121333

Page 130 of 281

33A-32

REAR AXLE COMPONENTS

Rear stub axle carrier: Removal - Refitting

33A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift ( (see Vehicle:

Towing and lifting) ).

aRelease the parking brake.

aRemove:

-the rear wheel on the side concerned (see 35A,

Wheels and tyres, Wheel: Removal - Refitting,

page 35A-1) ,

-the brake drum (see 33A, Rear axle components,

Rear brake drum: Removal - Refitting, page

33A-19) .

aFit the component jack to undo the shock absorber

mountings.

aRemove the shock absorber lower bolt.II - OPERATION FOR REMOVAL OF PART

CONCERNED

aAdjust the component jack.

aRemove:

-the stub axle carrier bolts (1) ,

-the stub axle carrier. Equipment required

component jack

Tightening torquesm

stub axle carrier bolts53 Nm

119648

Note:

Mar k the position of the stub axle carrier writing.