lock RENAULT TWINGO RS 2009 2.G Chasiss Service Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 281

Page 223 of 281

37A-44

MECHANICAL COMPONENT CONTROLS

Brake pedal switch: Removal - Refitting

37A

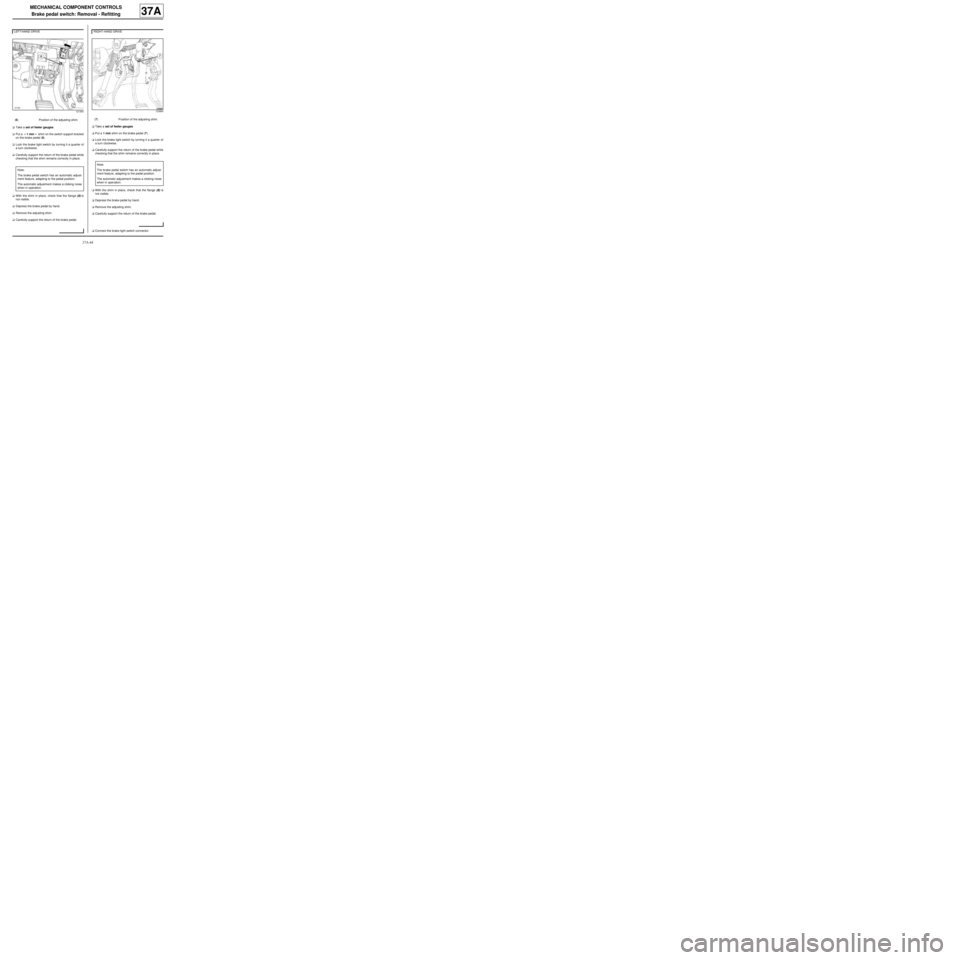

aTake a set of feeler gauges

aPut a « 1 mm » shim on the switch support bracket

on the brake pedal (6) .

aLock the brake light switch by turning it a quarter of

a turn clockwise.

aCarefully support the return of the brake pedal while

checking that the shim remains correctly in place.

aWith the shim in place, check that the flange (8) is

not visible.

aDepress the brake pedal by hand.

aRemove the adjusting shim.

aCarefully support the return of the brake pedal.aTake a set of feeler gauges

aPut a 1 mm shim on the brake pedal (7) .

aLock the brake light switch by turning it a quarter of

a turn clockwise.

aCarefully support the return of the brake pedal while

checking that the shim remains correctly in place.

aWith the shim in place, check that the flange (8) is

not visible.

aDepress the brake pedal by hand.

aRemove the adjusting shim.

aCarefully support the return of the brake pedal.

aConnect the brake light switch connector. LEFT-HAND DRIVE

121350

(6) Position of the adjusting shim.

Note:

The brake pedal switch has an automatic adjust-

ment feature, adapting to the pedal position.

The automatic adjustment makes a clicking noise

when in operation.

RIGHT-HAND DRIVE

123860

(7) Position of the adjusting shim.

Note:

The br ake pedal switch has an automatic adjust-

ment feature, adapting to the pedal position.

The automatic adjustment makes a clicking noise

when in oper ation.

Page 231 of 281

37A-52

MECHANICAL COMPONENT CONTROLS

Clutch pedal switch: Removal - Refitting

CRUISE CONTROL, and 5-SPEED MANUAL GEARBOX

37A

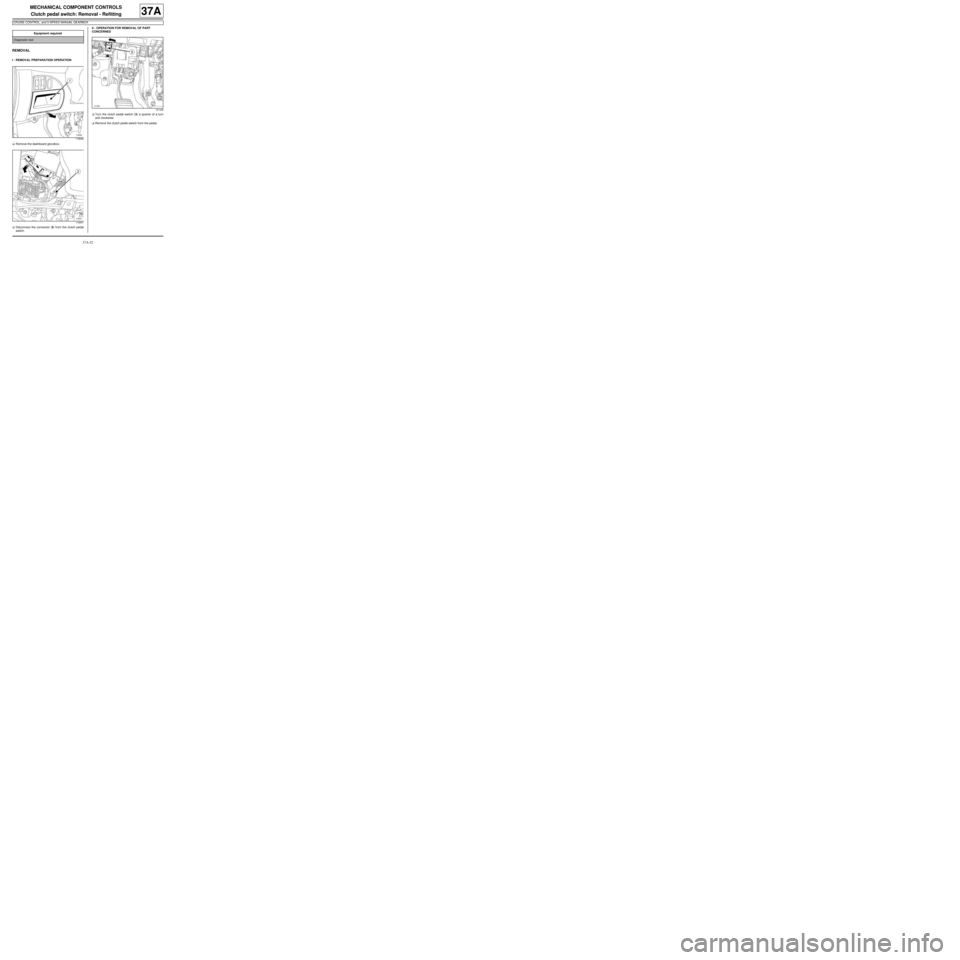

REMOVAL

I - REMOVAL PREPARATION OPERATION

aRemove the dashboard glovebox.

aDisconnect the connector (2) from the clutch pedal

switch.II - OPERATION FOR REMOVAL OF PART

CONCERNED

aTurn the clutch pedal switch (3) a quarter of a turn

anti-clockwise

aRemove the clutch pedal switch from the pedal. Equipment required

Diagnostic tool

119506

119507

121349

Page 232 of 281

37A-53

MECHANICAL COMPONENT CONTROLS

Clutch pedal switch: Removal - Refitting

CRUISE CONTROL, and 5-SPEED MANUAL GEARBOX

37A

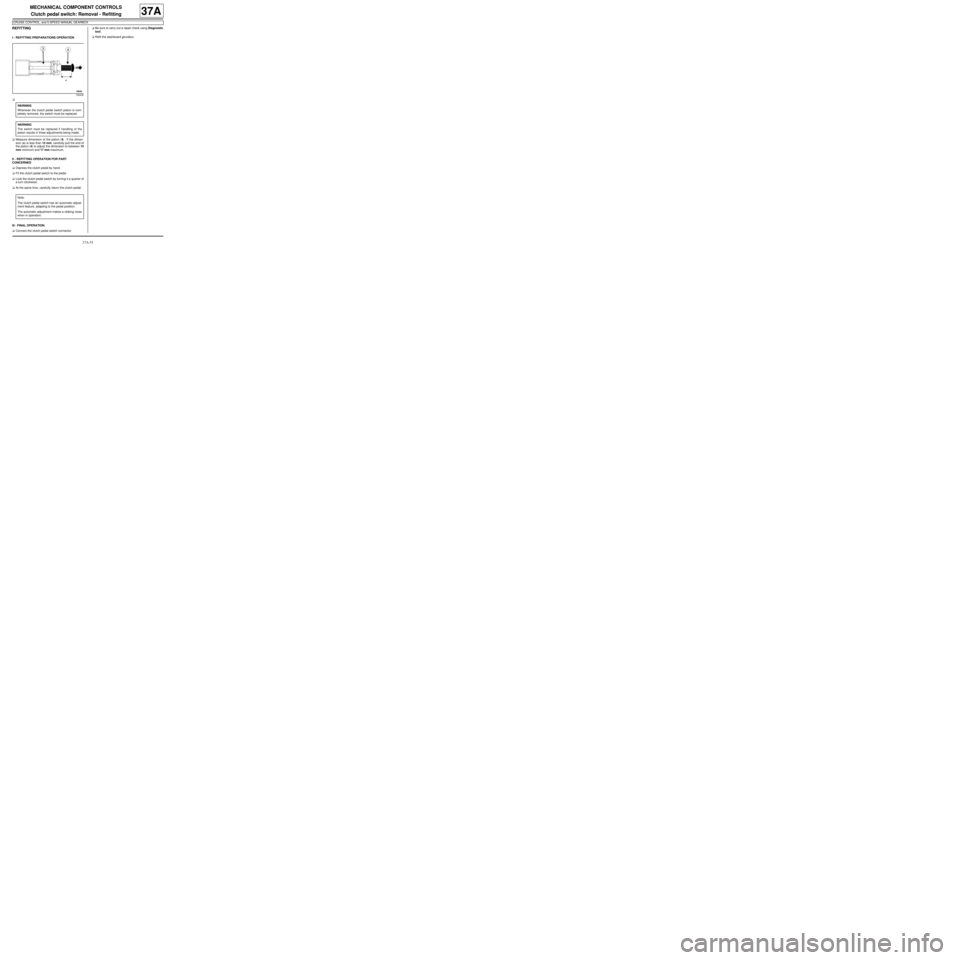

REFITTING

I - REFITTING PREPARATIONS OPERATION

a

aMeasure dimension of the piston (4) . If the dimen-

sion (x) is less than 15 mm, carefully pull the end of

the piston (4) to adjust the dimension to between 15

mm minimum and 17 mm maximum.

II - REFITTING OPERATION FOR PART

CONCERNED

aDepress the clutch pedal by hand.

aFit the clutch pedal switch to the pedal.

aLock the clutch pedal switch by turning it a quarter of

a turn clockwise.

aAt the same time, carefully return the clutch pedal.

III - FINAL OPERATION.

aConnect the clutch pedal switch connector.aBe sure to carry out a repair check using Diagnostic

tool.

aRefit the dashboard glovebox.

108436

WARNING

Whenever the clutch pedal switch piston is com-

pletely removed, the switch must be replaced.

WARNING

The switch must be replaced if handling of the

piston results in three adjustments being made.

Note:

The clutch pedal switch has an automatic adjust-

ment feature, adapting to the pedal position.

The automatic adjustment makes a clicking noise

when in operation.

Page 250 of 281

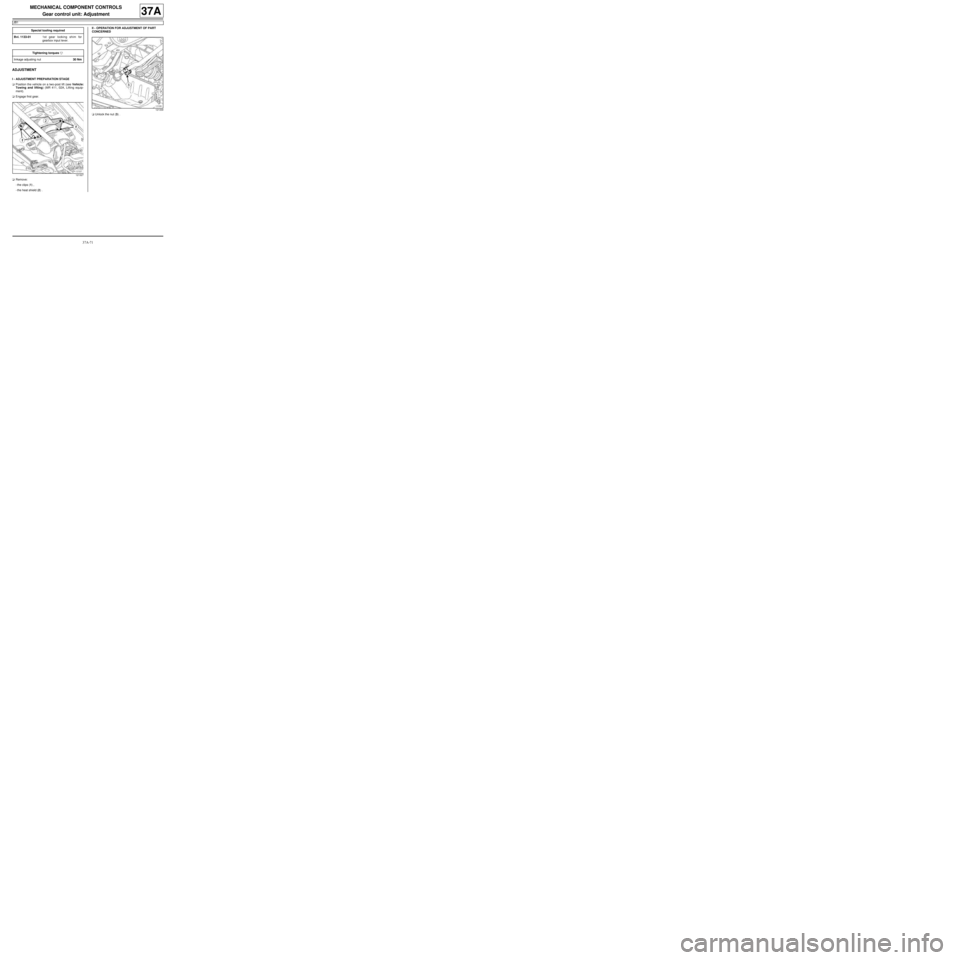

37A-71

MECHANICAL COMPONENT CONTROLS

Gear control unit: Adjustment

JB1

37A

ADJUSTMENT

I - ADJUSTMENT PREPARATION STAGE

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aEngage first gear.

aRemove:

-the clips (1) ,

-the heat shield (2) .II - OPERATION FOR ADJUSTMENT OF PART

CONCERNED

aUnlock the nut (3) . Special tooling required

Bvi. 1133-011st gear locking shim for

gearbox input lever.

Tightening torquesm

linkage adjusting nut30 Nm

121327

121339

Page 260 of 281

38C-1

ANTI-LOCK BRAKING SYSTEM

Hydraulic brake unit: List and location of components38C

The anti-lock braking system pump assembly is

equipped with a 26-track computer.

102311

(1) Master cylinder pr imar y circuit

(2) Circuit for front left-hand wheel

(3) Circuit for front right-hand wheel

(4) Master cylinder secondary cir-

cuit

(5) Circuit for rear right-hand wheel

(6) Circuit for rear left-hand wheel

19113

(7) Braking computer

(8) Hydraulic assembly

Page 261 of 281

38C-2

ANTI-LOCK BRAKING SYSTEM

Hydraulic brake unit: Removal - Refitting

K9K, and LEFT-HAND DRIVE

38C

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (MR 411, 80A, Battery).

aPosition the pedal press on the brake pedal to limit

the outflow of brake fluid.

aRemove:

-the front wheel on the passenger side (see 35A,

Wheels and tyres, Wheel: Removal - Refitting,

page 35A-1) ,

-the front wheel arch liner, on the passenger side

(see Front wheel arch liner: Removal - Refitting)

(MR 412, 55A, Exterior protection),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (MR 412, 56A, Exterior

equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (MR 412, 56A, Exterior equipment),

-the air filter box (see Air filter unit: Removal - Re-

fitting) (MR 411, 12A, Fuel mixture).aRemove:

-the bolts (1) from the lifting eye on the right-hand

side,

-the lifting eye on the right-hand side (2) ,

-the rigid pipe (3) from the EGR circuit.

aRemove the clip (4) from the soundproofing.

aMove the soundproofing aside (5) to access the hy-

draulic unit. Equipment required

pedal press

Tightening torquesm

hydraulic unit bolts on

its inter mediate bracket8 Nm

hydraulic unit inter medi-

ate bracket bolts on the

main hydraulic unit

mounting6.5 Nm

hydraulic unit main

mounting bolts on the

body8 Nm

rigid brake pipe unions

on the hydraulic unit13 Nm

112329

121358

Page 262 of 281

38C-3

ANTI-LOCK BRAKING SYSTEM

Hydraulic brake unit: Removal - Refitting

K9K, and LEFT-HAND DRIVE

38C

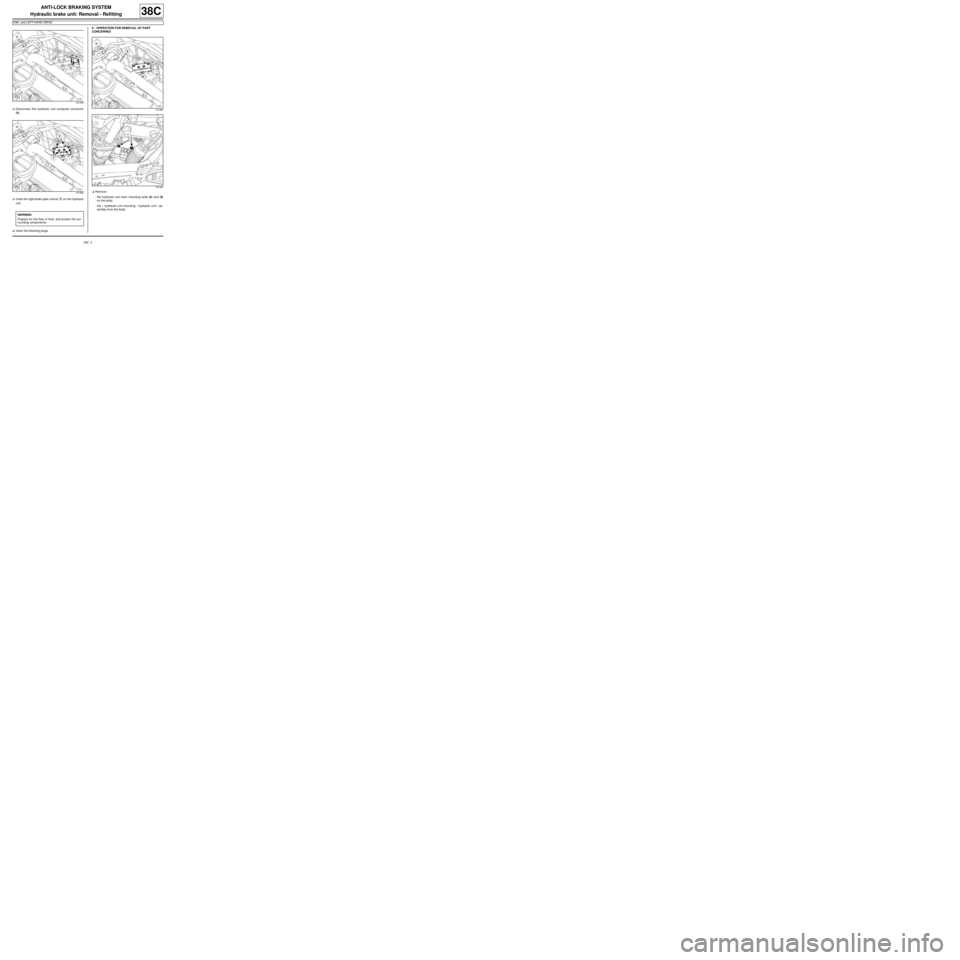

aDisconnect the hydraulic unit computer connector

(6) .

aUndo the rigid brake pipe unions (7) on the hydraulic

unit.

aInsert the blanking plugs.II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the hydraulic unit main mounting bolts (8) and (9)

on the body,

-the « hydraulic unit mounting - hydraulic unit » as-

sembly from the body.

121359

121360

WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

121360

121361

Page 263 of 281

38C-4

ANTI-LOCK BRAKING SYSTEM

Hydraulic brake unit: Removal - Refitting

K9K, and LEFT-HAND DRIVE

38C

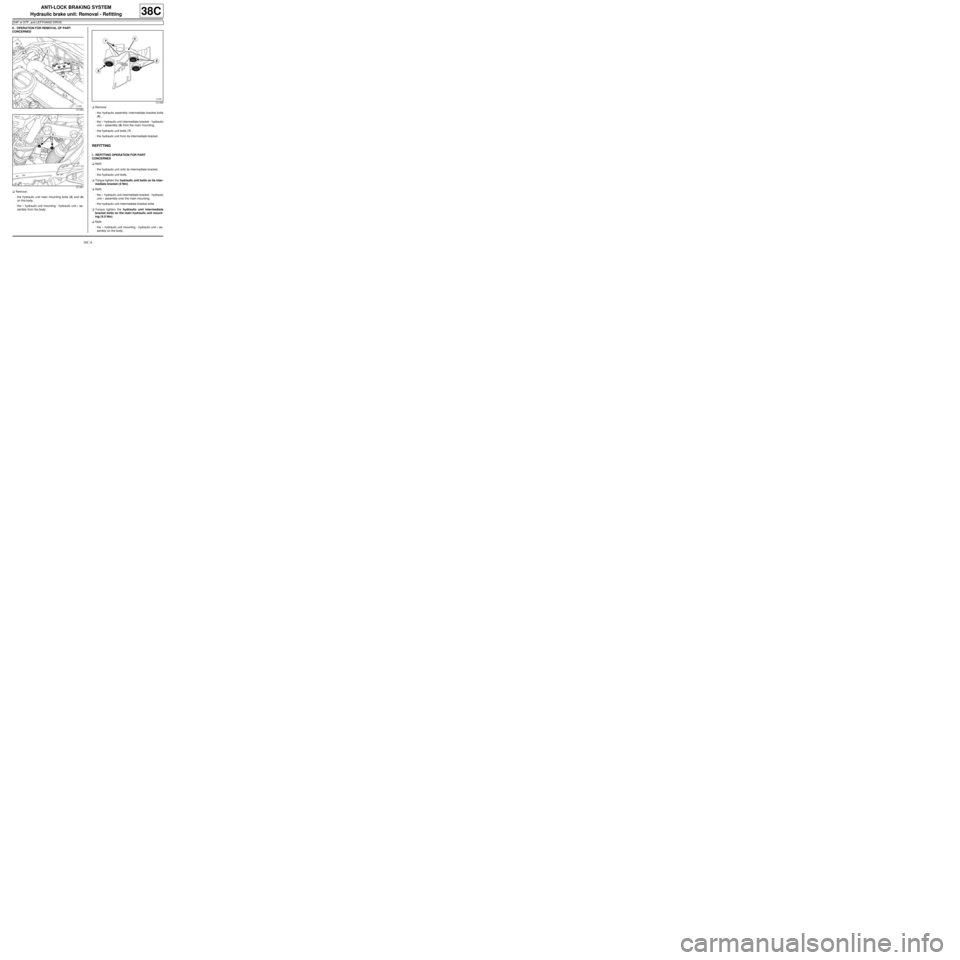

aRemove:

-the hydraulic assembly intermediate bracket bolts

(10) ,

-the « hydraulic unit intermediate bracket - hydraulic

unit » assembly (11) from the main mounting,

-the hydraulic unit bolts (12) from its intermediate

bracket,

-the hydraulic unit from its intermediate bracket.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the hydraulic unit onto its intermediate bracket,

-the hydraulic unit bolts onto its intermediate brack-

et.

aTorque tighten the hydraulic unit bolts on its inter-

mediate bracket (8 Nm).

aRefit:

-the « hydraulic unit intermediate bracket - hydraulic

unit » assembly onto the main mounting,

-the hydraulic unit intermediate bracket bolts onto

the main hydraulic unit mounting.

aTorque tighten the hydraulic unit intermediate

bracket bolts on the main hydraulic unit mount-

ing (6.5 Nm).aRefit:

-the « hydraulic unit mounting - hydraulic unit » as-

sembly on the body,

-the hydraulic unit main mounting bolts on the body.

aTorque tighten the hydraulic unit main mounting

bolts on the body (8 Nm).

II - FINAL OPERATION.

aRemove the blanking plugs.

aFit and tighten the rigid brake pipe unions on the hy-

draulic unit.

aTorque tighten the rigid brake pipe unions on the

hydraulic unit (13 Nm).

aConnect the computer connector on the hydraulic

unit.

aFit the bulkhead soundproofing.

aRefit:

-the soundproofing clip,

-the rigid exhaust gas recirculation circuit pipe,

-the lifting eye on the right-hand side,

-the air filter box (see Air filter unit: Removal - Re-

fitting) (MR 411, 12A, Fuel mixture),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (MR 412, 56A, Exterior equipment),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (MR 412, 56A, Exterior

equipment),

-the front wheel arch liner, on the passenger side

(see Front wheel arch liner: Removal - Refitting)

(MR 412, 55A, Exterior protection),

-the front wheel on the passenger side (see 35A,

Wheels and tyres, Wheel: Removal - Refitting,

page 35A-1) .

aRemove the pedal press from the brake pedal.

aConnect the battery (see Battery: Removal - Refit-

ting) (MR 411, 80A, Battery).

aBleed the braking circuit (see 30A, General infor-

mation, Braking circuit: Bleed, page 30A-4) .

121456

Page 264 of 281

38C-5

ANTI-LOCK BRAKING SYSTEM

Hydraulic brake unit: Removal - Refitting

D4F or D7F, and LEFT-HAND DRIVE

38C

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (MR 411, 80A, Battery).

aPosition the pedal press on the brake pedal to limit

the outflow of brake fluid.

aRemove:

-the front wheel on the passenger side (see 35A,

Wheels and tyres, Wheel: Removal - Refitting,

page 35A-1) ,

-the front wheel arch liner, on the passenger side

(see Front wheel arch liner: Removal - Refitting)

(MR 412, 55A, Exterior protection),

-the ignition coil (see Coils: Removal - Refitting)

(MR 411, 17A, Ignition),

-the fuel vapour recirculation circuit solenoid valve

(see Fuel vapour absorber: Removal - Refitting)

(MR 411, 14A, Emission control),

-the air filter box (see Air filter unit: Removal - Re-

fitting) (MR 411, 12A, Fuel mixture).aDisconnect the hydraulic unit computer connector

(1) .

aUndo the rigid brake pipe unions (2) on the hydraulic

unit.

aInsert the blanking plugs. Equipment required

pedal press

Tightening torquesm

hydraulic unit bolts on

its inter mediate bracket8 Nm

hydraulic unit inter medi-

ate bracket bolts on the

main hydraulic unit

mounting6.5 Nm

hydraulic unit main

mounting bolts on the

body8 Nm

rigid brake pipe unions

on the hydraulic unit13 Nm

121359

121360

WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

Page 265 of 281

38C-6

ANTI-LOCK BRAKING SYSTEM

Hydraulic brake unit: Removal - Refitting

D4F or D7F, and LEFT-HAND DRIVE

38C

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the hydraulic unit main mounting bolts (3) and (4)

on the body,

-the « hydraulic unit mounting - hydraulic unit » as-

sembly from the body.aRemove:

-the hydraulic assembly intermediate bracket bolts

(5) ,

-the « hydraulic unit intermediate bracket - hydraulic

unit » assembly (6) from the main mounting,

-the hydraulic unit bolts (7) ,

-the hydraulic unit from its intermediate bracket.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the hydraulic unit onto its intermediate bracket,

-the hydraulic unit bolts.

aTorque tighten the hydraulic unit bolts on its inter-

mediate bracket ( 8 Nm).

aRefit:

-the « hydraulic unit intermediate bracket - hydraulic

unit » assembly onto the main mounting,

-the hydraulic unit intermediate bracket bolts.

aTorque tighten the hydraulic unit intermediate

bracket bolts on the main hydraulic unit mount-

ing ( 6.5 Nm).

aRefit:

-the « hydraulic unit mounting - hydraulic unit » as-

sembly on the body,

121360

121361

121456