lock RENAULT TWINGO RS 2009 2.G Chasiss User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 281

Page 58 of 281

31A-15

FRONT AXLE COMPONENTS

Front brake calliper mounting: Removal - Refitting

EQ UIPMENT LEVEL EA0 or EQUIPMENT LEVEL EA1 or EQUIPMENT LEVEL EA3 or EQUIPMENT LEVEL EA5

or EQUIPMENT LEVEL EAG or EQUIPMENT LEVEL EZ2 or EQUIPMENT LEVEL EZ4

31A

II - REMOVAL OPERATION

aRemove:

-the brake calliper mounting bolts (3) ,

-the brake calliper mounting.

REFITTING

I - REFITTING PREPARATION OPERATION

aAlways replace the guide pin upper bolt.

aUsing the cleaning station, clean:

-the brake calliper mounting,

-the brake calliper.

aCoat the brake calliper mounting bolts with HIGH

STRENGTH THREAD LOCK (see Vehicle: Parts

and consumables for the repair) (04B, Consum-

ables - Products) before refitting them.

II - REFITTING OPERATION

aRefit:

-the brake calliper mounting,

-the brake calliper mounting bolts.

aTorque tighten the brake calliper mounting bolts

(100 N.m).

III - FINAL OPERATION

aFit the front brake calliper.aRefit the upper bolt on the guide pin while holding

the nut.

aTorque tighten the guide pin upper bolt (29 N.m)

while holding the nut.

aRefit:

-the front brake pads (see 31A, Front axle compo-

nents, Front brake pads: Removal - Refitting,

page 31A-1) ,

-the front wheel (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) .

119219

Page 66 of 281

31A-23

FRONT AXLE COMPONENTS

Front driveshaft hub carrier: Removal - Refitting

31A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aRemove:

-the front wheel on the side in question (see 35A,

Wheels and tyres, Wheel: Removal - Refitting,

page 35A-1) ,

-the front brake pads of the side in question (see

31A, Front axle components, Front brake pads:

Removal - Refitting, page 31A-1) ,

aRemove:

-the front brake calliper mounting (see 31A, Front

axle components, Front brake calliper mount-

ing: Removal - Refitting, page 31A-14) ,

-the front brake disc (see 31A, Front axle compo-

nents, Front brake disc: Removal - Refitting,

page 31A-19) ,

-the front wheel speed sensor on the hub carrier

(see 38C, Anti-lock braking system, Front wheel

speed sensor: Removal - Refitting, page 38C-

15) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aPosition the (Rou. 604-01).

aRemove the hub nut (1) .

aRemove:

-the nut (2) from the track rod end,

-the bolt (3) from the lower ball joint. Special tooling required

Rou. 604-01Hub locking tool.

Tav. 476Ball joint extractor.

Tav. 1420-01Screw jack for tools Tav.

1420, Tav.1050-04 , Tar.

1454, Tar. 1850.

Tightening torquesm

shock absorber lower

bolts105 Nm

front driveshaft lower

arm ball joint bolt105 Nm

ABS wiring bracket bolt8 Nm

track rod end nut37 N.m

hub nut280 Nm

guide pin upper bolt29 Nm

119543

119222

Page 123 of 281

33A-25

REAR AXLE COMPONENTS

Shock absorber: Removal - Refitting

33A

aUsing a block, bring the component jack into con-

tact under the rear axle, near the shock absorber.

aRemove the lower shock absorber bolt (3) .

aRemove the component jack.

aRemove:

-the shock absorber upper nut while holding the

shock absorber rod end,

-the shock absorber.

REFITTING

I - REFITTING PREPARATIONS OPERATION

aThe upper lock nut on the shock absorber must al-

ways be replaced.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the shock absorber,

-the new upper nut on the shock absorber.

aRaise the vehicle.

aRefit the shock absorber lower bolt with the compo-

nent jack in contact with a block under the rear axle

near the shock absorber.

aTorque tighten:

-the shock absorber lower bolt (105 Nm) with the

component jack in position,-the shock absorber upper nut (21 Nm) while

holding the shock absorber rod end, with the

wheels on the ground.

III - FINAL OPERATION.

aRefit the luggage compartment internal trim.

119340

Page 125 of 281

33A-27

REAR AXLE COMPONENTS

Shock absorber: Removal - Refitting

G44

33A

aFit a component jack until contact is made with a

shim, under the rear axle near the shock absorber.

aRemove the lower shock absorber bolt (2) .

aRemove the component jack.

aRemove:

-the shock absorber upper nut while holding the

shock absorber rod end,

-the shock absorber.

REFITTING

I - REFITTING PREPARATIONS OPERATION

aThe upper lock nut on the shock absorber must al-

ways be replaced.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the shock absorber,

-the new upper nut on the shock absorber.

aRaise the vehicle.

aRefit the shock absorber lower bolt using a compo-

nent jack in contact with a shim, under the rear axle

near the shock absorber.

aTorque tighten:

-the lower shock absorber bolt (105 Nm) with a

component jack,-the shock absorber upper nut (21 Nm) while

holding the shock absorber rod end, with the

wheels on the ground.

III - FINAL OPERATION.

aRefit the luggage compartment interior trim (see

Rear loading trim: Removal - Refitting) (MR 412,

71A, Body internal trim).

119340

Page 126 of 281

33A-28

REAR AXLE COMPONENTS

Rear suspension spring: Removal - Refitting

33A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift ( (see Vehicle:

Towing and lifting) ).

aRemove the rear wheels (see 35A, Wheels and ty-

res, Wheel: Removal - Refitting, page 35A-1) .

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aUsing a block, bring the component jack into con-

tact under the rear axle, near the shock absorber.

aMark the position where the springs are fitted.

aRemove the lower bolt (1) from the shock absorber.

aRemove the component jack.

aRepeat these operations on the opposite side.aRemove the springs by removing the component

jack.

aLeave the rear axle suspended.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aUsing a block, bring the component jack into con-

tact under the rear axle, near the shock absorber. Equipment required

component jack

Tightening torquesm

shock absorber lower

bolts105 Nm

119340

119547

119546

Page 139 of 281

33A-41

REAR AXLE COMPONENTS

Complete rear axle system: Removal - Refitting

33A

aUnclip the end of the parking brake cables at (10) .

aUnclip the cable sleeve stops at (11) and extract the

parking brake cables from the rear drum flanges.

aRemove:

-the rear brake pads (see 33A, Rear axle compo-

nents, Rear brake lining: Removal - Refitting,

page 33A-14) ,

-the rear brake cylinders (see 33A, Rear axle com-

ponents, Rear brake cylinder: Removal - Refit-

ting, page 33A-17) ,

-the rear wheel speed sensors (see 38C, Anti-lock

braking system, Rear wheel speed sensor: Re-

moval - Refitting, page 38C-17) ,

-the rear rigid brake pipes from the rear axle,

-the rear rigid brake pipe clips from the rear axle,

-the rear stub axle carriers (see 33A, Rear axle

components, Rear stub axle carrier: Removal -

Refitting, page 33A-32) ,

-the rear brake drum flanges,

REFITTING

I - REFITTING PREPARATIONS OPERATION

aStrap the rear axle onto the (Mot. 1390).

aPosition the rear axle under the vehicle.II - REFITTING OPERATION FOR PART

CONCERNED

1 - Replacement

aRefit:

-the rear brake drum flanges,

-the rear stub axle carriers (see 33A, Rear axle

components, Rear stub axle carrier: Removal -

Refitting, page 33A-32) ,

-the rigid brake pipe clips on the rear axle,

-the rear rigid brake pipes from the rear axle,

-the rear wheel speed sensors (see 38C, Anti-lock

braking system, Rear wheel speed sensor: Re-

moval - Refitting, page 38C-17) ,

-the rear brake cylinders (see 33A, Rear axle com-

ponents, Rear brake cylinder: Removal - Refit-

ting, page 33A-17) ,

-the rear brake pads (see 33A, Rear axle compo-

nents, Rear brake lining: Removal - Refitting,

page 33A-14) .

-the parking brake cables (see 37A, Mechanical

component controls, Parking brake cables: Re-

moval - Refitting, page 37A-74) ,

-the rear brake drums (see 33A, Rear axle compo-

nents, Rear brake drum: Removal - Refitting,

page 33A-19) .

121331

Page 142 of 281

35A-2

WHEELS AND TYRES

Wheel: Removal - Refitting

35A

If this procedure does not work:

aStrike the inner surface of the wheel (2) using a mal-

let and a wooden block to detach it.

aRemove:

-the wheel bolts,

-the wheel.

REFITTING

I - REFITTING PREPARATION OPERATION

aClean the hub carrier using a wire brush.

aCheck the condition of the tyre.

aDo not move or remove the balance weights.

II - REFITTING OPERATION FOR PART

CONCERNED

aClean the mating surfaces between the wheel and

the hub carrier using a wire brush.aCoat the wheel-mating face (3) with COPPER ANTI-

SEIZE AGENT (see Vehicle: Parts and consum-

ables for the repair) (04B, Consumables - Prod-

ucts).

aAlign the mark on the wheel with the mark made on

the hub when it was removed.

aFit the wheel to the vehicle, positioning the valve at

the top.

aInsert the wheel bolts.

aTighten the wheel bolts to bring all the bolt heads

into contact with the wheel.

106089

Note:

Do not strike the surface of the wheel using

excessive force as this may damage it.

Note:

there are two types of wheel bolts for alloy and

steel wheel rims; do not swap them.

124750

113180

Page 145 of 281

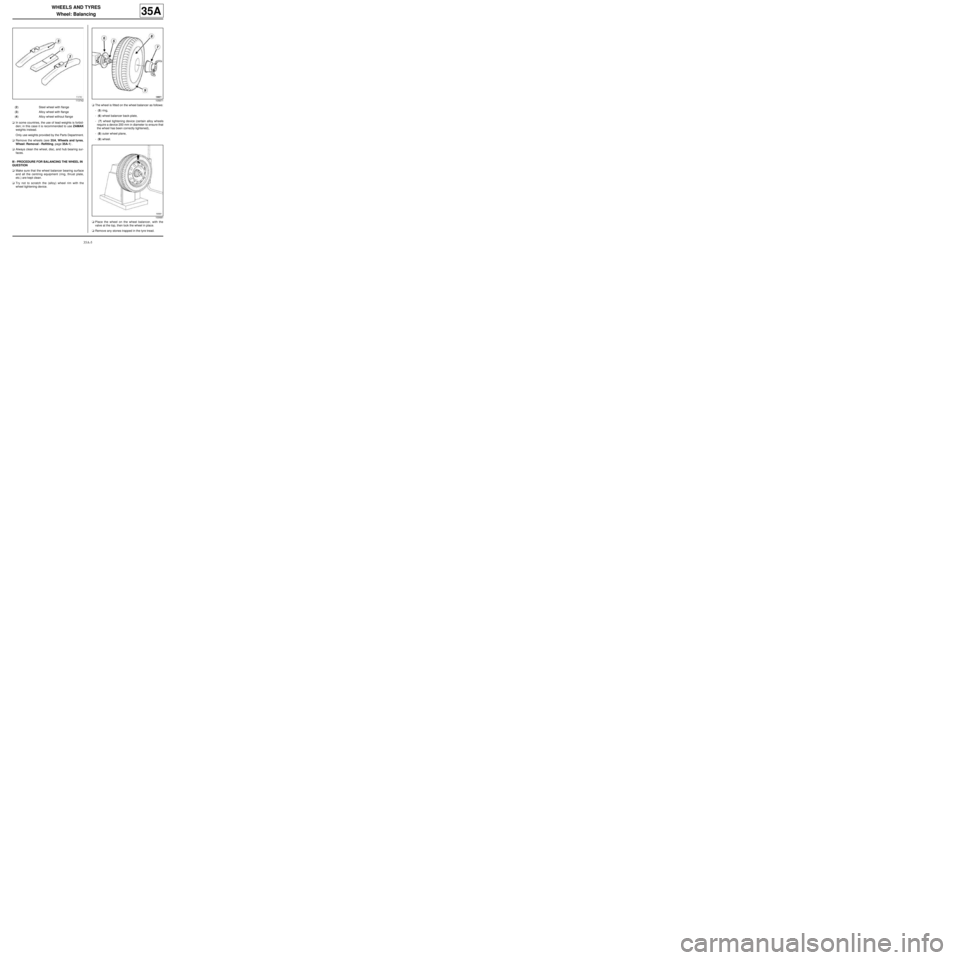

35A-5

WHEELS AND TYRES

Wheel: Balancing

35A

aIn some countries, the use of lead weights is forbid-

den; in this case it is recommended to use ZAMAK

weights instead.

Only use weights provided by the Parts Department.

aRemove the wheels (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) .

aAlways clean the wheel, disc, and hub bearing sur-

faces.

III - PROCEDURE FOR BALANCING THE WHEEL IN

QUESTION

aMake sure that the wheel balancer bearing surface

and all the centring equipment (ring, thrust plate,

etc.) are kept clean.

aTry not to scratch the (alloy) wheel rim with the

wheel tightening device.aThe wheel is fitted on the wheel balancer as follows:

- (5) ring,

- (6) wheel balancer back-plate,

- (7) wheel tightening device (certain alloy wheels

require a device 200 mm in diameter to ensure that

the wheel has been correctly tightened),

- (8) outer wheel plane,

- (9) wheel.

aPlace the wheel on the wheel balancer, with the

valve at the top, then lock the wheel in place.

aRemove any stones trapped in the tyre tread.

113742

(2) Steel wheel with flange

(3) Alloy wheel with flange

(4) Alloy wheel without flange

105871

100681

Page 153 of 281

36A-2

STEERING ASSEMBLY

Track rod: Removal - Refitting

36A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove the front wheel (see 35A, Wheels and ty-

res, Wheel: Removal - Refitting, page 35A-1) .

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aLoosen the wheel alignment adjustment lock nut (1)

.

aRemove the track rod ball joint nut (2) .aExtract the ball joint using (3) (Tav. 476).

aUnscrew the track rod anti-clockwise and note the

number of turns for refitting.

aRemove the track rod.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aScrew the track rod back in place by the number of

turns noted during removal.

aFit the track rod end in the hub carrier.

aRefit the track rod ball joint nut.

aTighten to torque:

-the track rod ball joint nut (37 N.m),

-the wheel alignment adjusting lock nut (53

N.m).

II - FINAL OPERATION

aRefit the wheel (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) .

aCheck the axle geometry (see 30A, General infor-

mation, Axle assemblies: Check, page 30A-23) .

aIf necessary, adjust the geometry of the axle assem-

blies (see 30A, General information, Front axle

system: Adjustment, page 30A-36) . Special tooling required

Tav. 476Ball joint extractor.

Tightening torquesm

track rod ball joint nut37 N.m

wheel alignment adjust-

ing lock nut53 N.m

IMPORTANT

Consult the safety and cleanliness advice and oper-

ation recommendations before carrying out any

repair (see Steering: Precautions for the repair) .

122722

122713

Page 155 of 281

36A-4

STEERING ASSEMBLY

Axial ball joint linkage: Removal - Refitting

36A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift ( (see Vehicle:

Towing and lifting) ).

a

aApply the before repair procedure using the dia-

gnostic tool:

-connect the diagnostic tool,

-select the airbag computer,

-go to repair mode,

-apply the "before repair procedure".

aRemove:

-the front wheel on the side in question (see 35A,

Wheels and tyres, Wheel: Removal - Refitting,

page 35A-1) ,

-the track rod (see 36A, Steering assembly, Track

rod: Removal - Refitting, page 36A-2) ,

-the steering box gaiter (see 36A, Steering assem-

bly, Steering box gaiter: Removal - Refitting,

page 36A-16) .

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aLock the wheels to disengage the rod teeth on the

valve side.aSet up the (Dir. 1306-03) (1) on the steering rack, at

the pinion end.

aUnlock the axial ball joint using tool (Dir. 1305-01)

(2) .

aRemove the axial ball joint.

REFITTING

I - REFITTING PREPARATION OPERATION

aAlways replace the following after each removal

operation:

-the limiter (3) ,

-the steering box gaiter. Special tooling required

Dir. 1306-03Steering r ack locking tool.

Dir. 1305-01Tool for removal - refitting of

the axial ball joint (diameter

35 mm to 41 mm).

Tightening torquesm

axial ball joint50 Nm

Note:

It is necessary to lock the airbag computer in

order to unlock the steering column.

97469

116991

Note:

Before refitting the new track rods, inser t a 12 x

100 tap into the threading at the ends of the

steer ing rack in order to remove any trace of

FRENETANCHE from the original fitting and so

pre vent seizure of the threaded sections on refit-

ting.