light RENAULT TWINGO RS 2009 2.G Chasiss Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 281

Page 20 of 281

30A-16

GENERAL INFORMATION

Rigid brake pipe: Repair

30A

a

aShape the pipe using a bender, curve after curve,

while respecting the original shape of the pipe.

128814

WARNING

To avoid weakening the pipe, either bend once or

bend progressively by increasing the bend (that

is, by continually decreasing the curve radius).

Do not install a rigid pipe on a vehicle that may

have been bended and then unbended alterna-

tively to reach the correct curve radius.

Note:

During the bending operation, the required angle

should be passed slightly in order to compensate

for material elasticity.

Page 22 of 281

30A-18

GENERAL INFORMATION

Brake fluid: Specifications

30A

BRAKE FLUID REPLACEMENT INTERVAL

Our braking technology, and in particular the disc

brakes (hollow pistons which conduct little heat, have a

low volume of fluid in the cylinder, sliding callipers

avoiding the need for a fluid reserve in the least cooled

area of the wheel), has allowed us to prevent the risk of

« vapour lock » as far as possible, even with heavy

braking (mountainous area). However, current brake

fluids are subject to minor deterioration during the first

months of use due to slight humidity intake. This is why

it is recommended that you change the brake fluid: see

maintenance booklet for the vehicle.

1 - Topping up the level

Wear of the brake pads will result in a gradual drop in

the fluid level in the reservoir.

Do not top up the fluid, as the level will rise again when

the pads are next changed. The brake fluid level must

not fall below the minimum mark.

2 - Approved brake fluid

Mixing two incompatible brake fluids in the brake circuit

may lead to:

-serious risk of leakage due mainly to deterioration of

the cups,

-deterioration in the operation of the ESP system.

To prevent such risks, it is essential to use only brake

fluids that comply with the RENAULT standard (see

Vehicle: Parts and consumables for the repair) .

Page 53 of 281

31A-10

FRONT AXLE COMPONENTS

Front brake calliper: Removal - Refitting

EQ UIPMENT LEVEL SPORT

31A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove the front wheel (see 35A, Wheels and ty-

res, Wheel: Removal - Refitting, page 35A-1) .

aFit a pedal press on the brake pedal to limit the out-

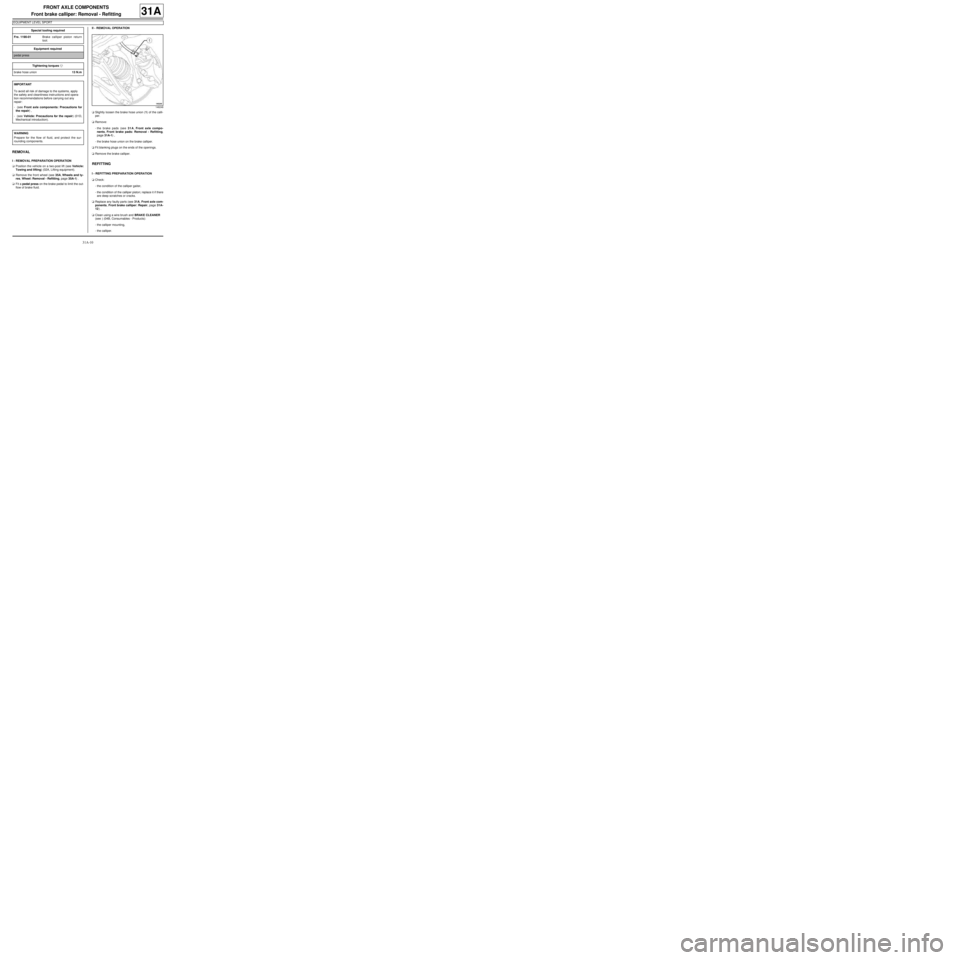

flow of brake fluid.II - REMOVAL OPERATION

aSlightly loosen the brake hose union (1) of the calli-

per.

aRemove:

-the brake pads (see 31A, Front axle compo-

nents, Front brake pads: Removal - Refitting,

page 31A-1) ,

-the brake hose union on the brake calliper.

aFit blanking plugs on the ends of the openings.

aRemove the brake calliper.

REFITTING

I - REFITTING PREPARATION OPERATION

aCheck:

-the condition of the calliper gaiter,

-the condition of the calliper piston; replace it if there

are deep scratches or cracks.

aReplace any faulty parts (see 31A, Front axle com-

ponents, Front brake calliper: Repair, page 31A-

12) .

aClean using a wire brush and BRAKE CLEANER

(see ) (04B, Consumables - Products):

-the calliper mounting,

-the calliper. Special tooling required

Fre. 1190-01Brake calliper piston return

tool.

Equipment required

pedal press

Tightening torquesm

brake hose union13 N.m

IMPORTANT

To avoid all risk of damage to the systems, apply

the safety and cleanliness instructions and opera-

tion recommendations before carrying out any

repair:

- (see Front axle components: Precautions for

the repair) ,

- (see Vehicle: Precautions for the repair) (01D,

Mechanical introduction).

WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

146248

Page 113 of 281

33A-15

REAR AXLE COMPONENTS

Rear brake lining: Removal - Refitting

33A

aRemove the leading shoe:

-the spring (10) ,

-the adjustment lever (11) .

REFITTING

I - REFITTING PREPARATIONS OPERATION

aRemove any dust from the drums and the flanges

using the cleaning station.

aLightly grease the support linkage thread.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the leading shoe:

-the adjustment lever,

-the spring.

aConnect the parking brake cable to the parking

brake lever.

aRefit:

-the trailing shoe.

86559

117348

Note:

The brake mechanism components are different

on the left and r ight-hand sides, so it is important

not to confuse them.

Note:

On the left-hand brake: the bolt thread has a

right-hand thread.

On the right-hand brake: the bolt has a left-hand

thread.

Page 158 of 281

36A-7

STEERING ASSEMBLY

Steering column: Removal - Refitting

LEFT-HAND DRIVE

36A

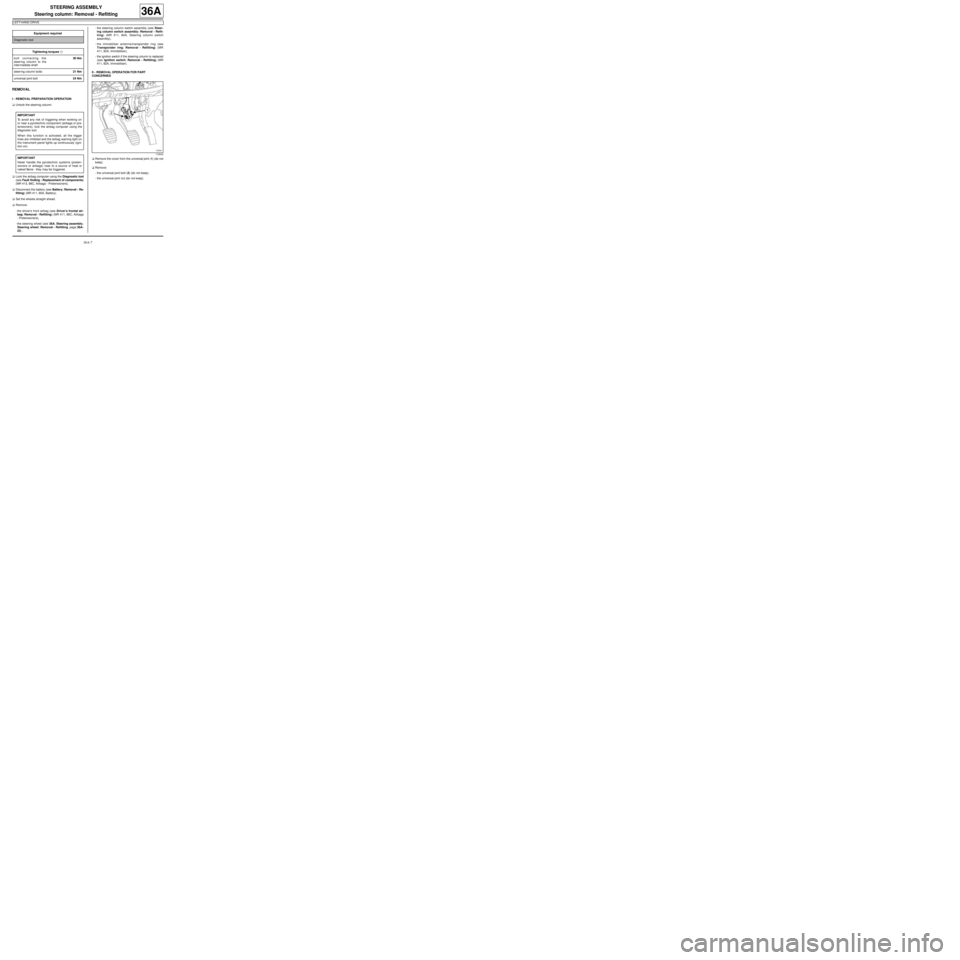

REMOVAL

I - REMOVAL PREPARATION OPERATION

aUnlock the steering column.

aLock the airbag computer using the Diagnostic tool

(see Fault finding - Replacement of components)

(MR 413, 88C, Airbags - Pretensioners).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (MR 411, 80A, Battery).

aSet the wheels straight ahead.

aRemove:

-the driver's front airbag (see Driver's frontal air-

bag: Removal - Refitting) (MR 411, 88C, Airbags

- Pretensioners),

-the steering wheel (see 36A, Steering assembly,

Steering wheel: Removal - Refitting, page 36A-

23) ,-the steering column switch assembly (see Steer-

ing column switch assembly: Removal - Refit-

ting) (MR 411, 84A, Steering column switch

assembly),

-the immobiliser antenna/transponder ring (see

Transponder ring: Removal - Refitting) (MR

411, 82A, Immobiliser),

-the ignition switch if the steering column is replaced

(see Ignition switch: Removal - Refitting) (MR

411, 82A, Immobiliser).

II - REMOVAL OPERATION FOR PART

CONCERNED

aRemove the cover from the universal joint (1) (do not

keep).

aRemove:

-the universal joint bolt (2) (do not keep),

-the universal joint nut (do not keep). Equipment required

Diagnostic tool

Tightening torquesm

bolt connecting the

steering column to the

inter mediate shaft30 Nm

steer ing column bolts21 Nm

universal joint bolt24 Nm

IMPORTANT

To avoid any risk of triggering when working on

or near a pyrotechnic component (airbags or pre-

tensioners), lock the airbag computer using the

diagnostic tool.

When this function is activated, all the trigger

lines are inhibited and the airbag warning light on

the instrument panel lights up continuously (igni-

tion on).

IMPORTANT

Never handle the pyrotechnic systems (preten-

sioners or airbags) near to a source of heat or

naked flame - they may be triggered.

119544

Page 162 of 281

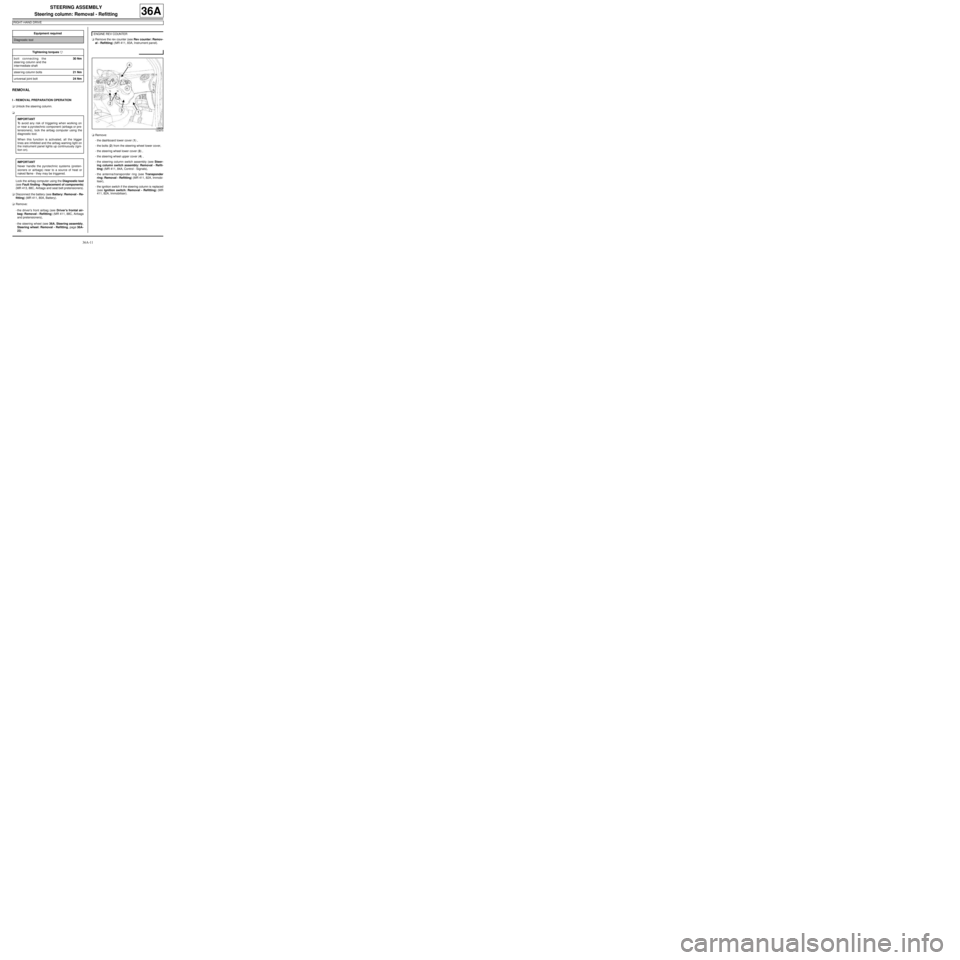

36A-11

STEERING ASSEMBLY

Steering column: Removal - Refitting

RIGHT-HAND DRIVE

36A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aUnlock the steering column.

a

Lock the airbag computer using the Diagnostic tool

(see Fault finding - Replacement of components)

(MR 413, 88C, Airbags and seat belt pretensioners).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (MR 411, 80A, Battery).

aRemove:

-the driver's front airbag (see Driver's frontal air-

bag: Removal - Refitting) (MR 411, 88C, Airbags

and pretensioners),

-the steering wheel (see 36A, Steering assembly,

Steering wheel: Removal - Refitting, page 36A-

23) .aRemove the rev counter (see Rev counter: Remov-

al - Refitting) (MR 411, 83A, Instrument panel).

aRemove:

-the dashboard lower cover (1) ,

-the bolts (2) from the steering wheel lower cover,

-the steering wheel lower cover (3) ,

-the steering wheel upper cover (4) ,

-the steering column switch assembly (see Steer-

ing column switch assembly: Removal - Refit-

ting) (MR 411, 84A, Control - Signals),

-the antenna/transponder ring (see Transponder

ring: Removal - Refitting) (MR 411, 82A, Immobi-

liser),

-the ignition switch if the steering column is replaced

(see Ignition switch: Removal - Refitting) (MR

411, 82A, Immobiliser). Equipment required

Diagnostic tool

Tightening torquesm

bolt connecting the

steer ing column and the

inter mediate shaft30 Nm

steer ing column bolts21 Nm

universal joint bolt24 Nm

IMPORTANT

To avoid any risk of triggering when working on

or near a pyrotechnic component (airbags or pre-

tensioners), lock the airbag computer using the

diagnostic tool.

When this function is activated, all the trigger

lines are inhibited and the airbag warning light on

the instrument panel lights up continuously (igni-

tion on).

IMPORTANT

Never handle the pyrotechnic systems (preten-

sioners or airbags) near to a source of heat or

naked flame - they may be triggered.

ENGINE REV COUNTER

123870

Page 211 of 281

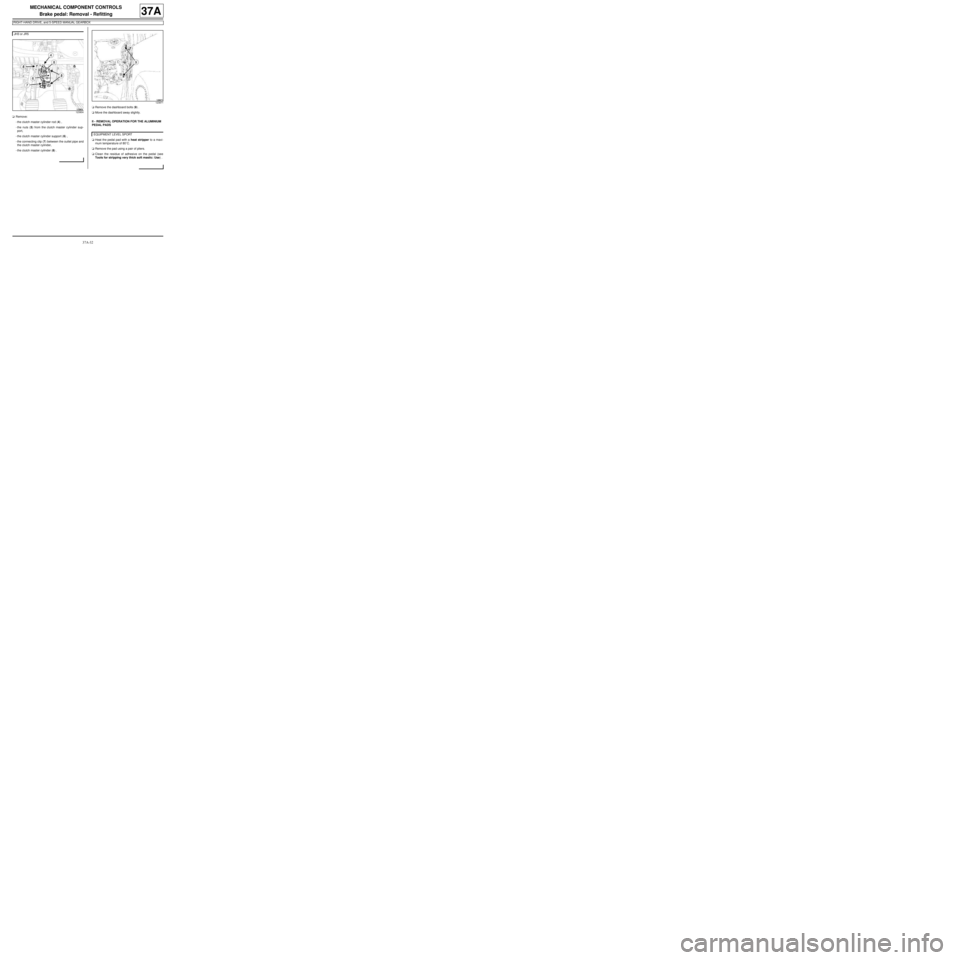

37A-32

MECHANICAL COMPONENT CONTROLS

Brake pedal: Removal - Refitting

RIGHT-HAND DRIVE, and 5-SPEED MANUAL GEARBOX

37A

aRemove:

-the clutch master cylinder rod (4) ,

-the nuts (5) from the clutch master cylinder sup-

port,

-the clutch master cylinder support (6) ,

-the connecting clip (7) between the outlet pipe and

the clutch master cylinder,

-the clutch master cylinder (8) .aRemove the dashboard bolts (9) .

aMove the dashboard away slightly.

II - REMOVAL OPERATION FOR THE ALUMINIUM

PEDAL PADS

aHeat the pedal pad with a heat stripper to a maxi-

mum temperature of 80˚C.

aRemove the pad using a pair of pliers.

aClean the residue of adhesive on the pedal (see

Tools for stripping very thick soft mastic: Use) . JH3 or JR5

123904

123871

EQUIPMENT LEVEL SPORT

Page 216 of 281

37A-37

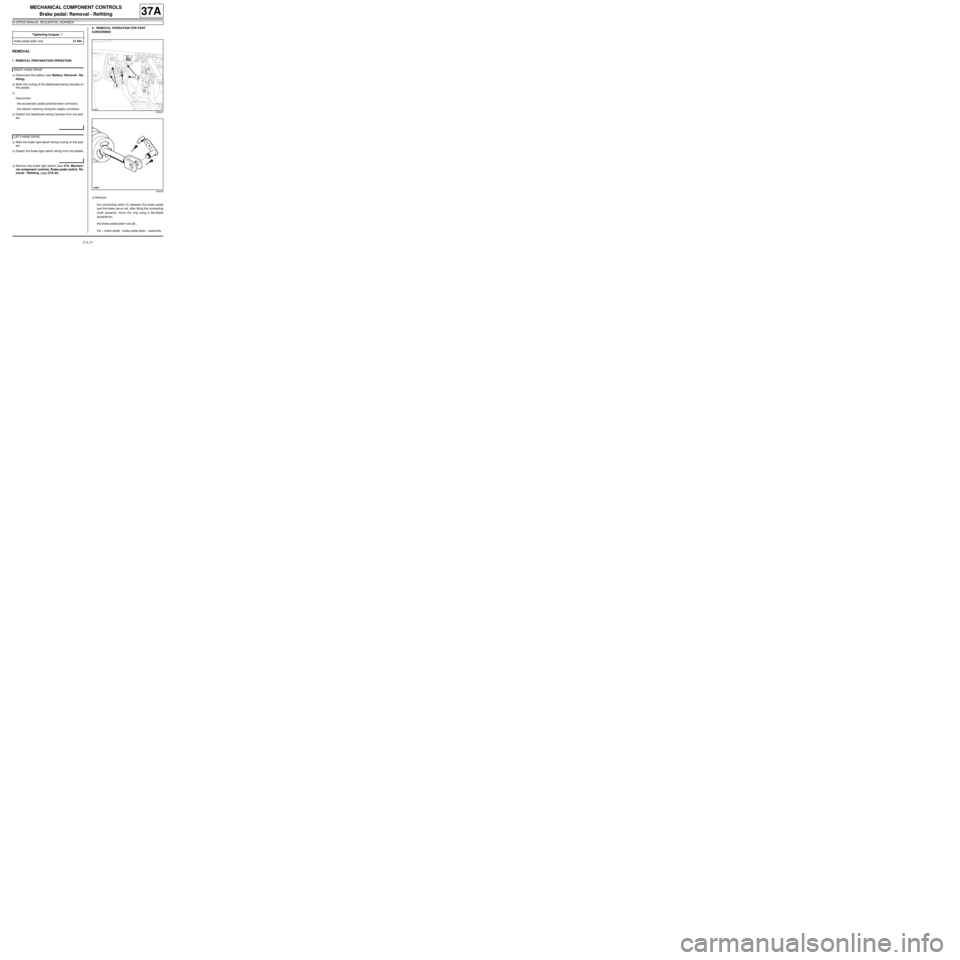

MECHANICAL COMPONENT CONTROLS

Brake pedal: Removal - Refitting

5-SPEED MANUAL SEQUENTIAL GEARBOX

37A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aDisconnect the battery (see Battery: Removal - Re-

fitting) .

aMark the routing of the dashboard wiring harness on

the pedals.

a

Disconnect:

-the accelerator pedal potentiometer connector,

-the electric steering computer supply connector.

aDetach the dashboard wiring harness from the ped-

als.

aMark the brake light switch wiring routing on the ped-

als.

aDetach the brake light switch wiring from the pedals.

aRemove the brake light switch (see 37A, Mechani-

cal component controls, Brake pedal switch: Re-

moval - Refitting, page 37A-42) .II - REMOVAL OPERATION FOR PART

CONCERNED

aRemove:

-the connecting shaft (1) between the brake pedal

and the brake servo rod, after tilting the connecting

shaft upwards, move the ring using a flat-blade

screwdriver,

-the brake pedal plate nuts (2) ,

-the « brake pedal - brake pedal plate » assembly. Tightening torquesm

brake pedal plate nuts21 Nm

RIGHT-HAND DRIVE

LEFT-HAND DRIVE

122227

109205

Page 217 of 281

37A-38

MECHANICAL COMPONENT CONTROLS

Brake pedal: Removal - Refitting

5-SPEED MANUAL SEQUENTIAL GEARBOX

37A

REFITTING

I - REFITTING PREPARATIONS OPERATION

aThe shaft connecting the brake servo pushrod and

the brake pedal must be replaced every time it is re-

moved.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the « brake pedal - brake pedal plate » assembly,

-the brake pedal plate nuts (2) .

aTorque tighten the brake pedal plate nuts (21 Nm).

aRefit the connecting shaft (1) between the brake

pedal and the brake servo rod from right to left and

from top to bottom.

III - FINAL OPERATION.

aRefit the brake light switch (see 37A, Mechanical

component controls, Brake pedal switch: Re-

moval - Refitting, page 37A-42) .

aRefit the brake light switch wiring in the position

marked during the removal operation.a

Connect:

-the accelerator pedal potentiometer connector,

-the electric steering computer supply connector.

aRefit the dashboard wiring harness in the position

marked during removal.

aConnect the battery (see Battery: Removal - Refit-

ting) .

109205

LEFT-HAND DRIVE

RIGHT-HAND DRIVE

Page 221 of 281

37A-42

MECHANICAL COMPONENT CONTROLS

Brake pedal switch: Removal - Refitting

37A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aRemove:

-the bolts (1) of the steering wheel cover,

-the steering wheel cover (2) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the brake light switch connector (3) .

aTurn the brake light switch (4) a quarter of a turn

anti-clockwise.

aRemove the switch from the pedal assembly. Equipment required

set of feeler gauges

Diagnostic tool

WARNING

The brake pedal position switch must be replaced if

the notched segment is pulled completely out of the

switch.

120279

121350