engine RENAULT TWINGO RS 2009 2.G Engine And Peripherals Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 652

Page 152 of 652

11A-35

TOP AND FRONT OF ENGINE

Timing belt: Removal - Refitting

D4F

11A

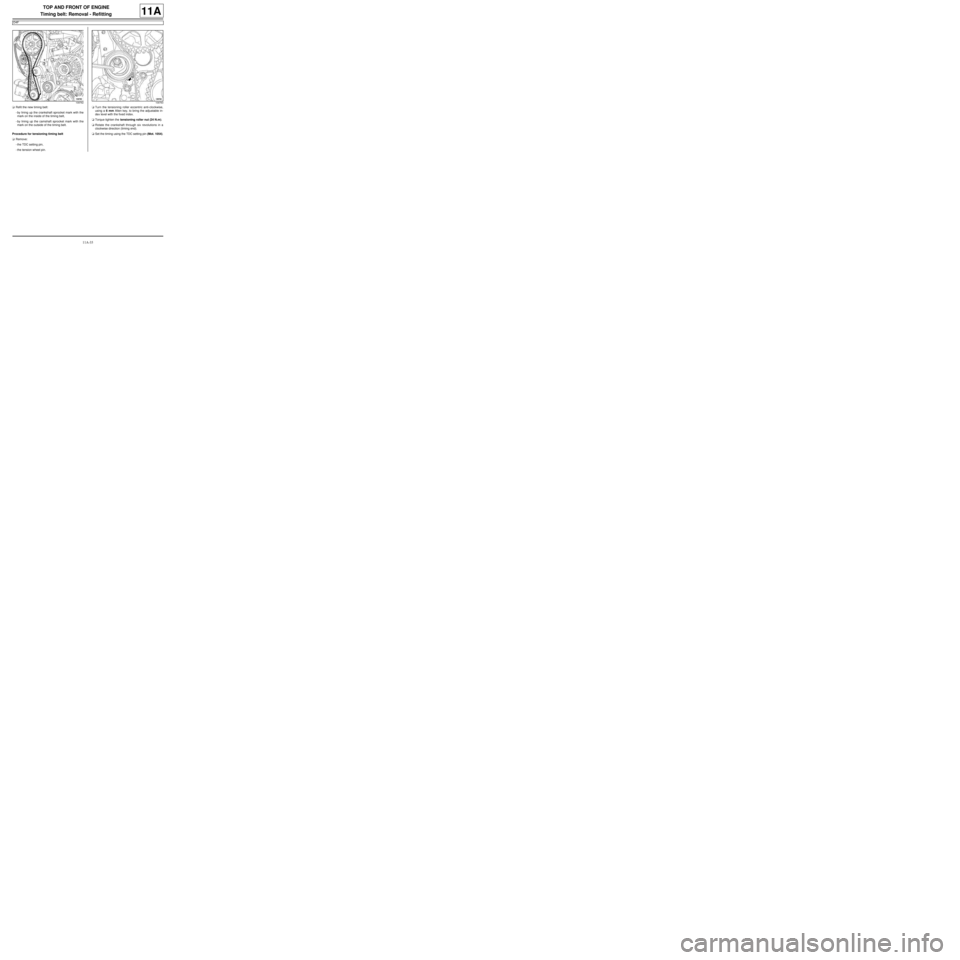

aRefit the new timing belt:

-by lining up the crankshaft sprocket mark with the

mark on the inside of the timing belt,

-by lining up the camshaft sprocket mark with the

mark on the outside of the timing belt.

Procedure for tensioning timing belt

aRemove:

-the TDC setting pin,

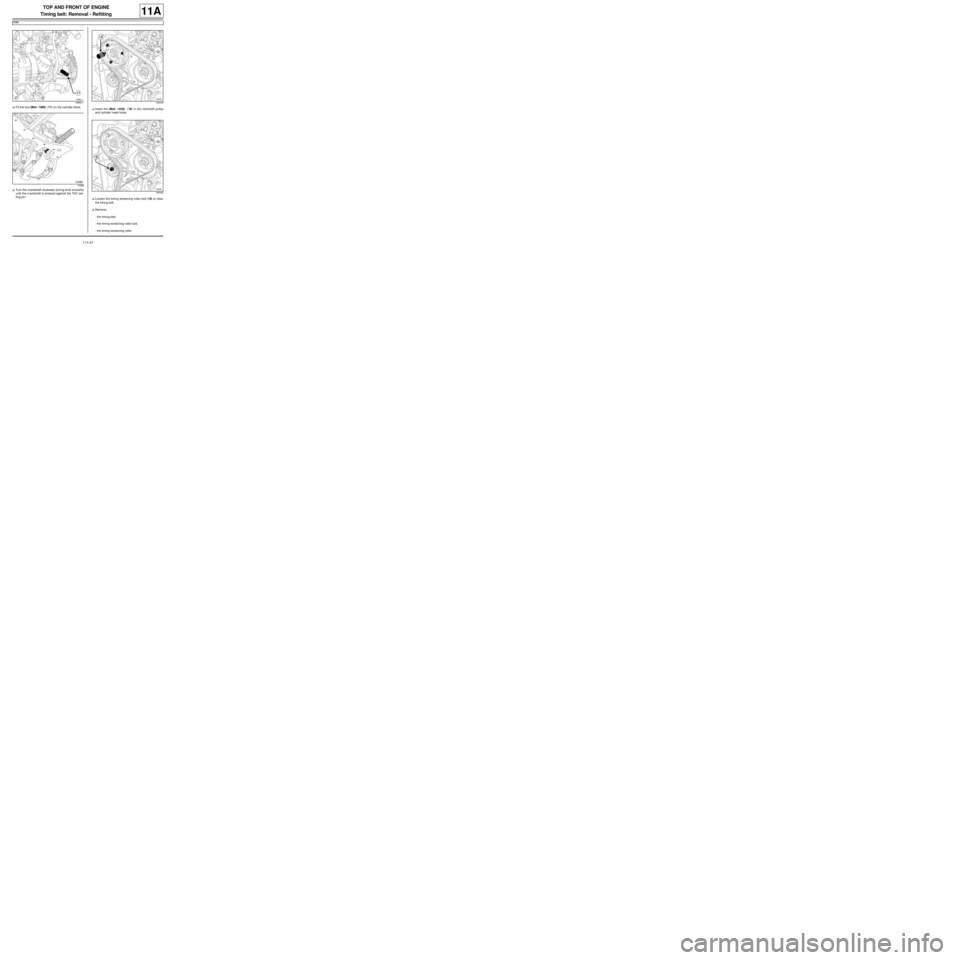

-the tension wheel pin.aTurn the tensioning roller eccentric anti-clockwise,

using a 6 mm Allen key, to bring the adjustable in-

dex level with the fixed index.

aTorque tighten the tensioning roller nut (24 N.m).

aRotate the crankshaft through six revolutions in a

clockwise direction (timing end).

aSet the timing using the TDC setting pin (Mot. 1054).

109762109763

Page 153 of 652

11A-36

TOP AND FRONT OF ENGINE

Timing belt: Removal - Refitting

D4F

11A

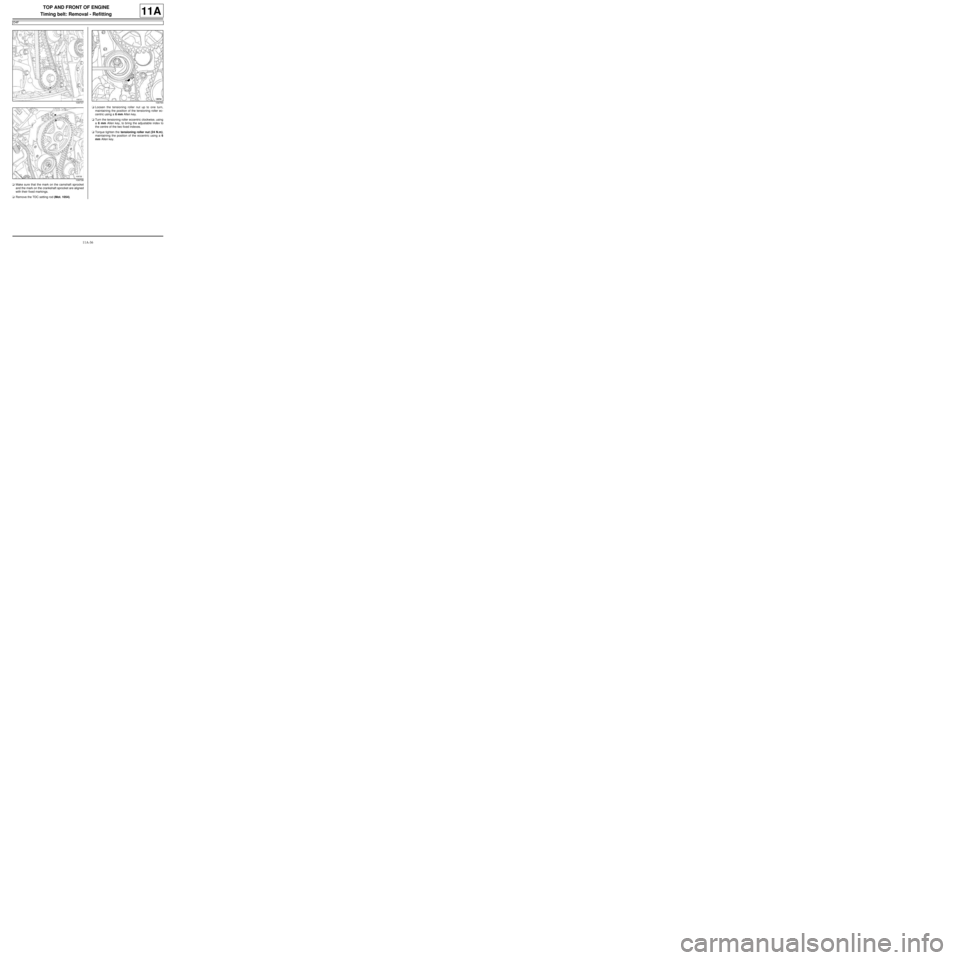

aMake sure that the mark on the camshaft sprocket

and the mark on the crankshaft sprocket are aligned

with their fixed markings.

aRemove the TDC setting rod (Mot. 1054).aLoosen the tensioning roller nut up to one turn,

maintaining the position of the tensioning roller ec-

centric using a 6 mm Allen key.

aTurn the tensioning roller eccentric clockwise, using

a 6 mm Allen key, to bring the adjustable index to

the centre of the two fixed indexes.

aTorque tighten the tensioning roller nut (24 N.m),

maintaining the position of the eccentric using a 6

mm Allen key.

109737

109738109764

Page 154 of 652

11A-37

TOP AND FRONT OF ENGINE

Timing belt: Removal - Refitting

D4F

11A

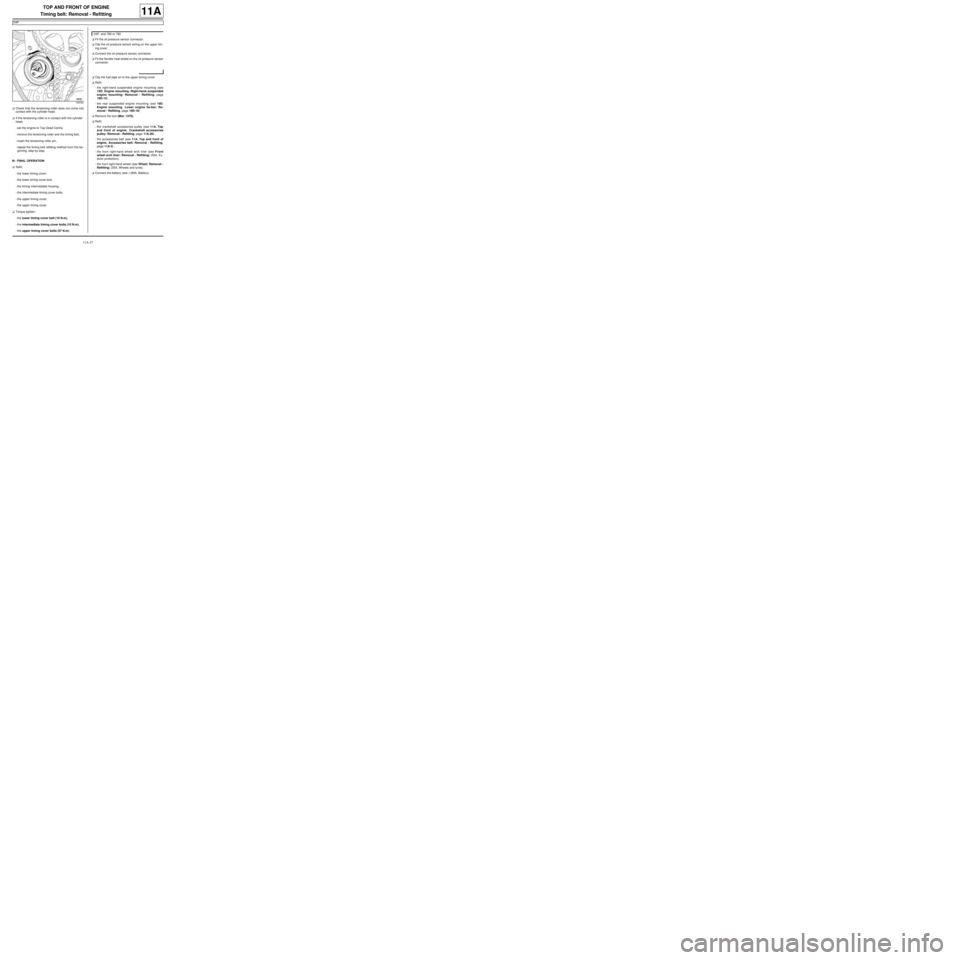

aCheck that the tensioning roller does not come into

contact with the cylinder head.

aIf the tensioning roller is in contact with the cylinder

head:

-set the engine to Top Dead Centre,

-remove the tensioning roller and the timing belt,

-insert the tensioning roller pin,

-repeat the timing belt refitting method from the be-

ginning, step by step.

III - FINAL OPERATION

aRefit:

-the lower timing cover,

-the lower timing cover bolt,

-the timing intermediate housing,

-the intermediate timing cover bolts,

-the upper timing cover,

-the upper timing cover.

aTorque tighten:

-the lower timing cover bolt (10 N.m),

-the intermediate timing cover bolts (10 N.m),

-the upper timing cover bolts (37 N.m)aFit the oil pressure sensor connector.

aClip the oil pressure sensor wiring on the upper tim-

ing cover.

aConnect the oil pressure sensor connector.

aFit the flexible heat shield on the oil pressure sensor

connector.

aClip the fuel pipe on to the upper timing cover.

aRefit:

-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) ,

-the rear suspended engine mounting (see 19D,

Engine mounting, Lower engine tie-bar: Re-

moval - Refitting, page 19D-18) .

aRemove the tool (Mot. 1379).

aRefit:

-the crankshaft accessories pulley (see 11A, Top

and front of engine, Crankshaft accessories

pulley: Removal - Refitting, page 11A-20) ,

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres).

aConnect the battery (see ) (80A, Battery).

109765

D4F, and 780 or 782

Page 155 of 652

11A-38

TOP AND FRONT OF ENGINE

Timing belt: Removal - Refitting

K9K

11A

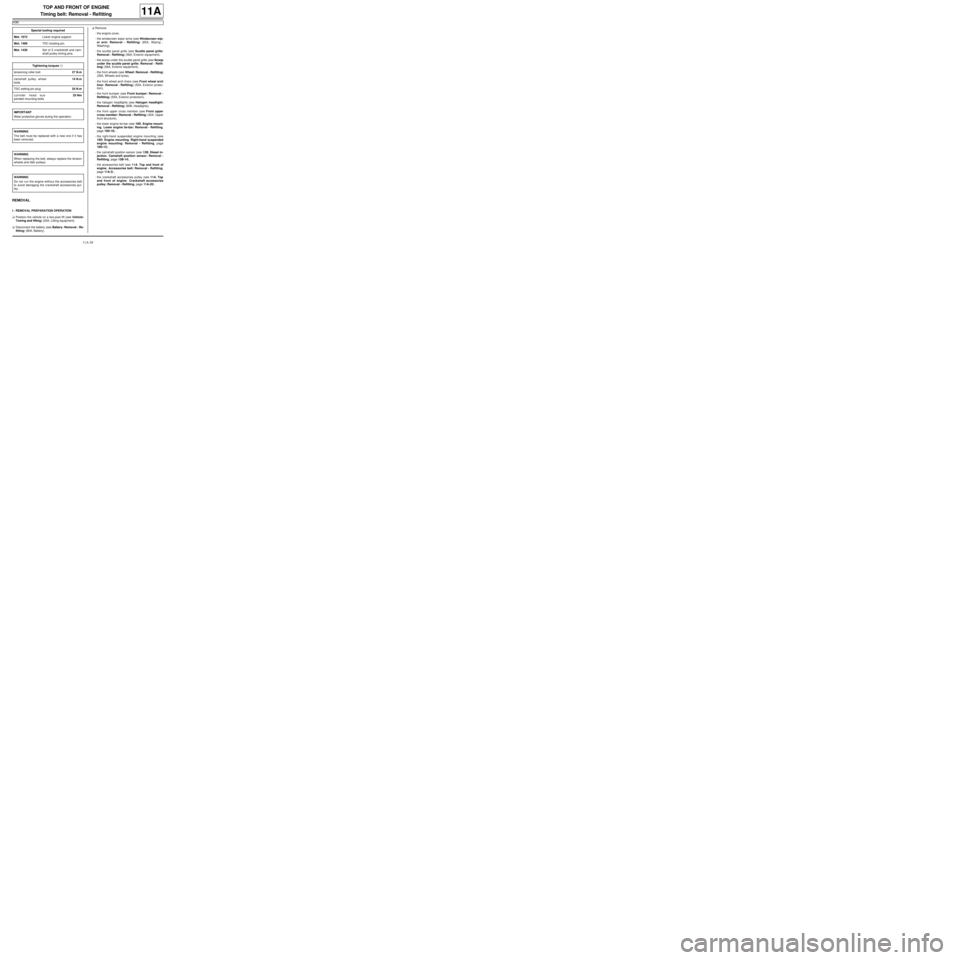

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).aRemove:

-the engine cover,

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the halogen headlights (see Halogen headlight:

Removal - Refitting) (80B, Headlights),

-the front upper cross member (see Front upper

cross member: Removal - Refitting) (42A, Upper

front structure),

-the lower engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) ,

-the camshaft position sensor (see 13B, Diesel in-

jection, Camshaft position sensor: Removal -

Refitting, page 13B-14) ,

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the crankshaft accessories pulley (see 11A, Top

and front of engine, Crankshaft accessories

pulley: Removal - Refitting, page 11A-20) . Special tooling required

Mot. 1672Low er engine support.

Mot. 1489TDC locating pin.

Mot. 1430Set of 5 crankshaft and cam-

shaft pulley timing pins.

Tightening torquesm

tensioning roller bolt27 N.m

camshaft pulley wheel

bolts14 N.m

TDC setting pin plug25 N.m

cylinder head sus-

pended mounting bolts25 Nm

IMPORTANT

Wear protective gloves during the operation.

WARNING

The belt must be replaced with a new one if it has

been removed.

WARNING

When replacing the belt, always replace the tension

wheels and idler pulleys.

WARNING

Do not r un the engine without the accessories belt

to avoid damaging the crankshaft accessories pul-

ley.

Page 156 of 652

11A-39

TOP AND FRONT OF ENGINE

Timing belt: Removal - Refitting

K9K

11A

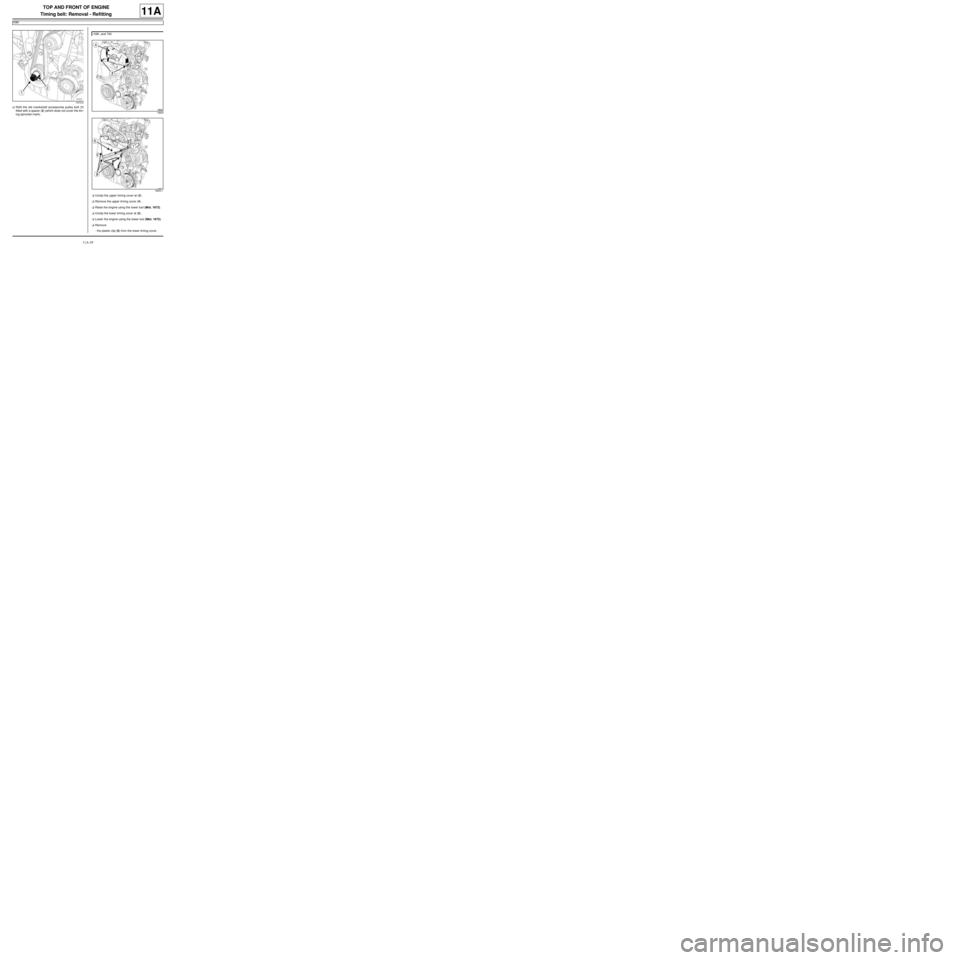

aRefit the old crankshaft accessories pulley bolt (1)

fitted with a spacer (2) (which does not cover the tim-

ing sprocket mark).

aUnclip the upper timing cover at (3) .

aRemove the upper timing cover (4) .

aRaise the engine using the lower tool (Mot. 1672).

aUnclip the lower timing cover at (5) .

aLower the engine using the lower tool (Mot. 1672).

aRemove:

-the plastic clip (6) from the lower timing cover,

107272

K9K, and 740

19654

19654-1

Page 157 of 652

11A-40

TOP AND FRONT OF ENGINE

Timing belt: Removal - Refitting

K9K

11A

-the lower timing cover (7) .

Page 158 of 652

11A-41

TOP AND FRONT OF ENGINE

Timing belt: Removal - Refitting

K9K

11A

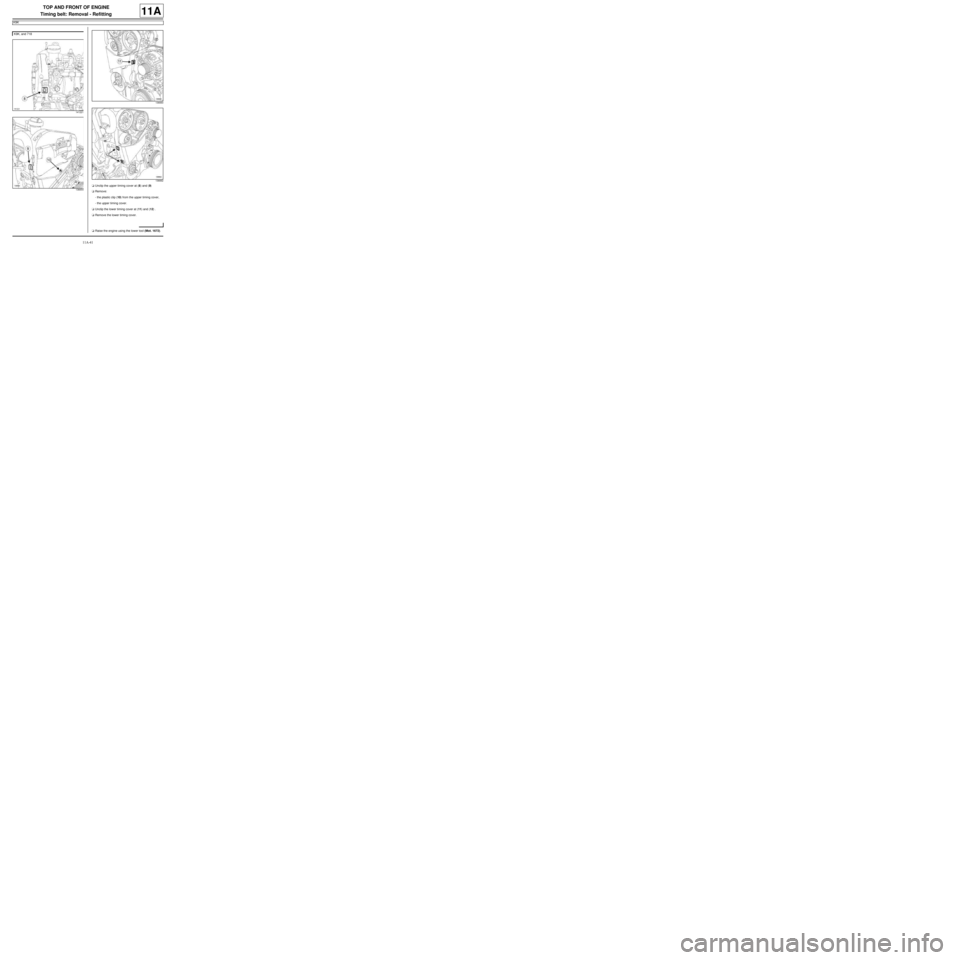

aUnclip the upper timing cover at (8) and (9)

aRemove:

-the plastic clip (10) from the upper timing cover,

-the upper timing cover.

aUnclip the lower timing cover at (11) and (12) .

aRemove the lower timing cover.

aRaise the engine using the lower tool (Mot. 1672). K9K, and 718

141221

136654

136660

136662

Page 159 of 652

11A-42

TOP AND FRONT OF ENGINE

Timing belt: Removal - Refitting

K9K

11A

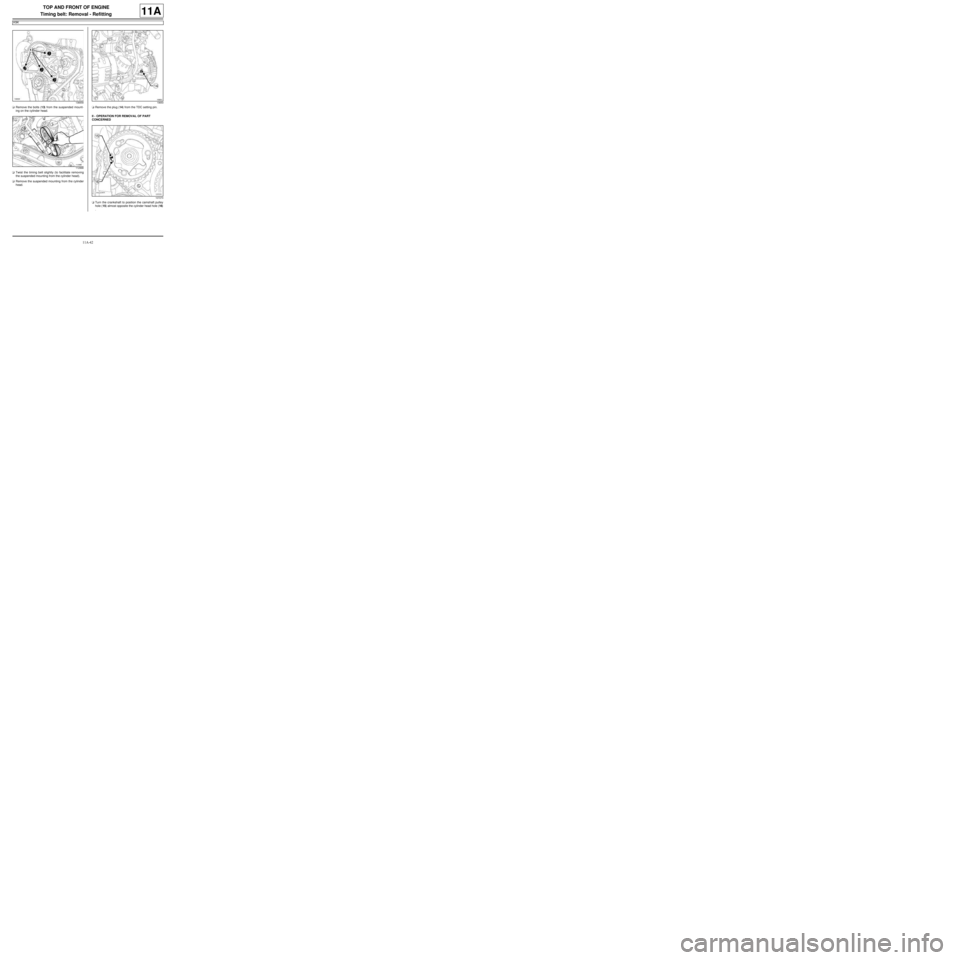

aRemove the bolts (13) from the suspended mount-

ing on the cylinder head.

aTwist the timing belt slightly (to facilitate removing

the suspended mounting from the cylinder head).

aRemove the suspended mounting from the cylinder

head.aRemove the plug (14) from the TDC setting pin.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aTurn the crankshaft to position the camshaft pulley

hole (15) almost opposite the cylinder head hole (16)

.

136658

11299819650

107270

Page 160 of 652

11A-43

TOP AND FRONT OF ENGINE

Timing belt: Removal - Refitting

K9K

11A

aFit the tool (Mot. 1489) (17) on the cylinder block.

aTurn the crankshaft clockwise (timing end) smoothly

until the crankshaft is pressed against the TDC set-

ting pin.aInsert the (Mot. 1430) (18) in the camshaft pulley

and cylinder head holes.

aLoosen the timing tensioning roller bolt (19) to relax

the timing belt.

aRemove:

-the timing belt,

-the timing tensioning roller bolt,

-the timing tensioning roller.

19650-1

14489109049

109046

Page 161 of 652

11A-44

TOP AND FRONT OF ENGINE

Timing belt: Removal - Refitting

K9K

11A

REFITTING

I - REFITTING PREPARATION OPERATION

aparts always to be replaced: Timing belt

aparts always to be replaced: Timing belt tension-

ing rollerII - REFITTING OPERATION FOR PART

CONCERNED

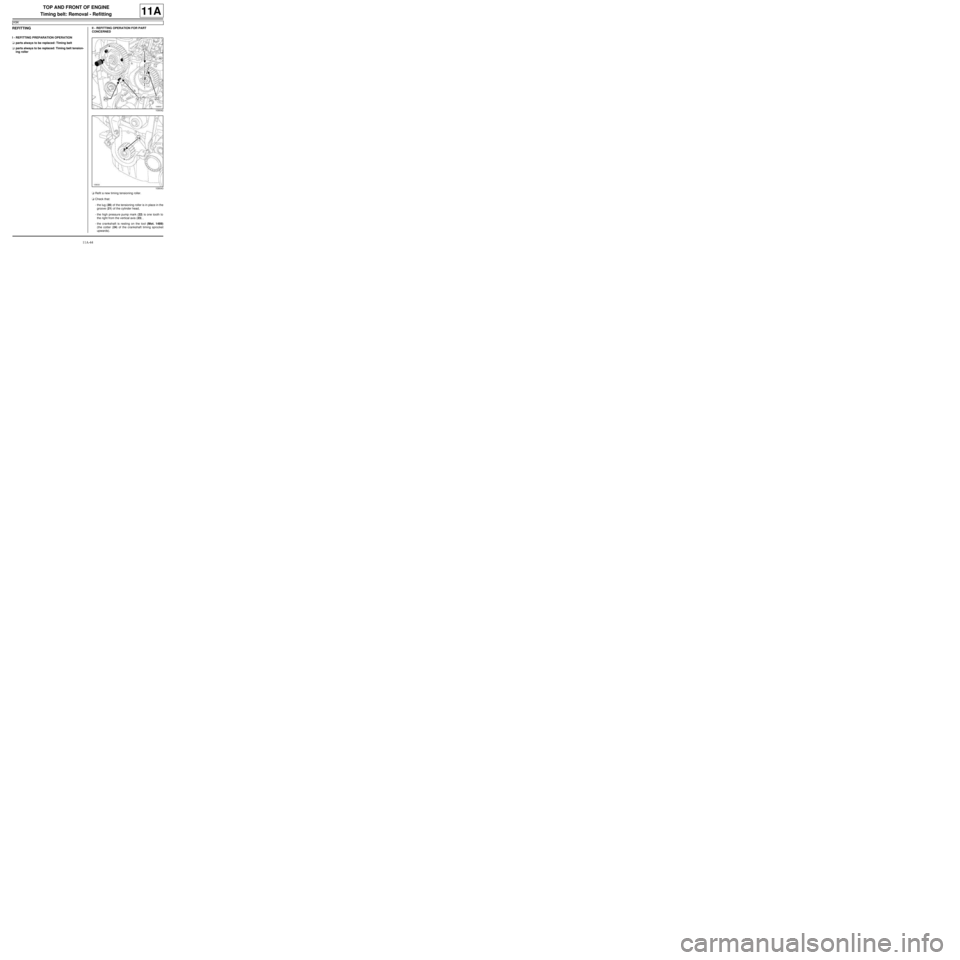

aRefit a new timing tensioning roller.

aCheck that:

-the lug (20) of the tensioning roller is in place in the

groove (21) of the cylinder head,

-the high pressure pump mark (22) is one tooth to

the right from the vertical axis (23) ,

-the crankshaft is resting on the tool (Mot. 1489)

(the cotter (24) of the crankshaft timing sprocket

upwards).

109042

109043