Fuel supply RENAULT TWINGO RS 2009 2.G Engine And Peripherals User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 652

Page 183 of 652

11A-66

TOP AND FRONT OF ENGINE

Rocker cover: Removal - Refitting

D7F

11A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aDisconnect the battery ( (see Battery: Removal -

Refitting) ).

aRemove:

-the intake distributor (see 12A, Fuel mixture, Inlet

distributor: Removal - Refitting, page 12A-29) ,

-the air filter box (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) .

aUnclip:

-The harness from the heat shield,

-the brake servo pipe from the heat shield.

aDisconnect the ignition coil supply.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the rocker cover bolts,

-the rocker cover.ON THE WORKBENCH

aRemove:

-the ignition coil,

-the heat shield.

REFITTING

I - REFITTING PREPARATIONS OPERATION

ON THE WORKBENCH

aRefit:

-the heat shield,

-the ignition coil.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the rocker cover,

-the rocker cover bolts.

aTorque tighten the rocker cover bolts (10 Nm).

III - FINAL OPERATION.

aConnect the ignition coil supply.

aClip:

-the brake servo pipe onto the heat shield,

-the harness onto the heat shield.

aRefit:

-the air filter box (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the intake distributor (see 12A, Fuel mixture, Inlet

distributor: Removal - Refitting, page 12A-29) .

aConnect the battery ( (see Battery: Removal - Re-

fitting) ). Tightening torquesm

rocker cover bolts10 Nm

110422

Page 186 of 652

11A-69

TOP AND FRONT OF ENGINE

Rocker cover: Removal - Refitting

D4F, and 772

11A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aRemove:

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the inlet distributor (see 12A, Fuel mixture, Inlet

distributor: Removal - Refitting, page 12A-29) ,

-the ignition coil (see 17A, Ignition, Coils: Remov-

al - Refitting, page 17A-1) .

aUnclip the rocker cover electric wiring harnesses.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the rocker cover bolts,

-the rocker cover,

-the rocker cover gasket.

REFITTING

I - REFITTING PREPARATION OPERATION

aClean the joint faces with SUPER CLEANER FOR

JOINT FACES (see Vehicle: Parts and consum-

ables for the repair) (04B, Consumables - Prod-

ucts) to dissolve any part of the seal still adhering.

aparts always to be replaced: rocker cover seal.

110422

WARNING

Do not allow this product to dr ip onto the paint-

work.

Clean the cylinder head carefully to prevent for-

eign bodies from entering the oil supply and

return galleries.

Failure to follow this advice could lead to the

blocking of the various oil inlet galleries, which

would quickly result in engine damage.

Page 190 of 652

11A-73

TOP AND FRONT OF ENGINE

Rocker cover: Removal - Refitting

D4F, and 780 or 782 or 784

11A

aDisconnect the oil vapour rebreathing circuit unions

(9) .

-on the inlet distributor,

-on the air filter box outlet air pipe,

-on the rocker cover.

aRemove the oil vapour rebreathing circuit.

aDisconnect the fuel vapour rebreathing circuit

unions (10) .

-on the air filter box outlet air pipe,

-to the inlet distributor.

aMove the fuel vapour rebreathing pipes to one side.

aDisconnect the vacuum pipe from the brake servo

(11) .

aMove the brake servo vacuum pipe to one side.II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the rocker cover bolts,

-the rocker cover,

-the rocker cover gasket.

REFITTING

I - REFITTING PREPARATION OPERATION

aClean the joint faces with SUPER CLEANER FOR

JOINT FACES (see Vehicle: Parts and consum-

ables for the repair) (04B, Consumables - Prod-

ucts) to dissolve any part of the seal still adhering.

aparts always to be replaced: rocker cover seal.

122828

121026

WARNING

Do not allow this product to dr ip onto the paint-

work.

Clean the cylinder head carefully to prevent for-

eign bodies from entering the oil supply and

return galleries.

Failure to follow this advice could lead to the

blocking of the various oil inlet galleries, which

would quickly result in engine damage.

Page 248 of 652

11A-131

TOP AND FRONT OF ENGINE

Cylinder head: Removal - Refitting

D4F, and 780 or 782

11A

aRemove the bolts (2) on the intercooler outlet air

pipe.

aMove the intercooler outlet air pipe away from the

throttle valve.

aUndo the compressor discharge valve air pipe clip

(3) .

aDisconnect:

-the turbocharging solenoid valve connector to the

turbocharger,

-the compressor discharge valve air pipe from the

air filter unit outlet air pipe.aUnclip the injection wiring from the inlet manifold.

aDisconnect:

-the upstream oxygen sensor connector (4) .

-the air inlet pressure connector (5) ,

-the injector rail - injector wiring connector (6) ,

-the fuel vapour rebreather solenoid valve connec-

tor,

-the throttle body connector ,

-the coolant temperature sensor connector.

aDisconnect the petrol supply union on the injector

rail - injector.

aPlug the openings.

aMove aside the engine wiring.

122390121765

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to r un.

IMPORTANT

Dur ing this operation, be sure to:

-refrain from smoking or bringing red hot objects

close to the working area,

-be careful of fuel splashes when disconnecting

the union.

Page 295 of 652

12A-30

FUEL MIXTURE

Inlet distributor: Removal - Refitting

D7F

12A

aDisconnect the spark plug high voltage wiring har-

ness (2) .

aMove aside the spark plug high voltage wiring har-

ness.

aDisconnect:

-the petrol vapour rebreather pipe from the inlet dis-

tributor (3) ,

-the non-return valve pipe on the inlet distributor (4)

,

-the air inlet pressure sensor connector (5) ,

-the air temperature sensor connector (6) ,

-the injector connector (7) ,-the fuel supply pipe intermediate union (8) ,

-the oil vapour rebreathing pipe from the inlet dis-

tributor.

aRemove the dipstick.

aRemove:

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the alternator upper bolt.

aTilt the alternator forward.

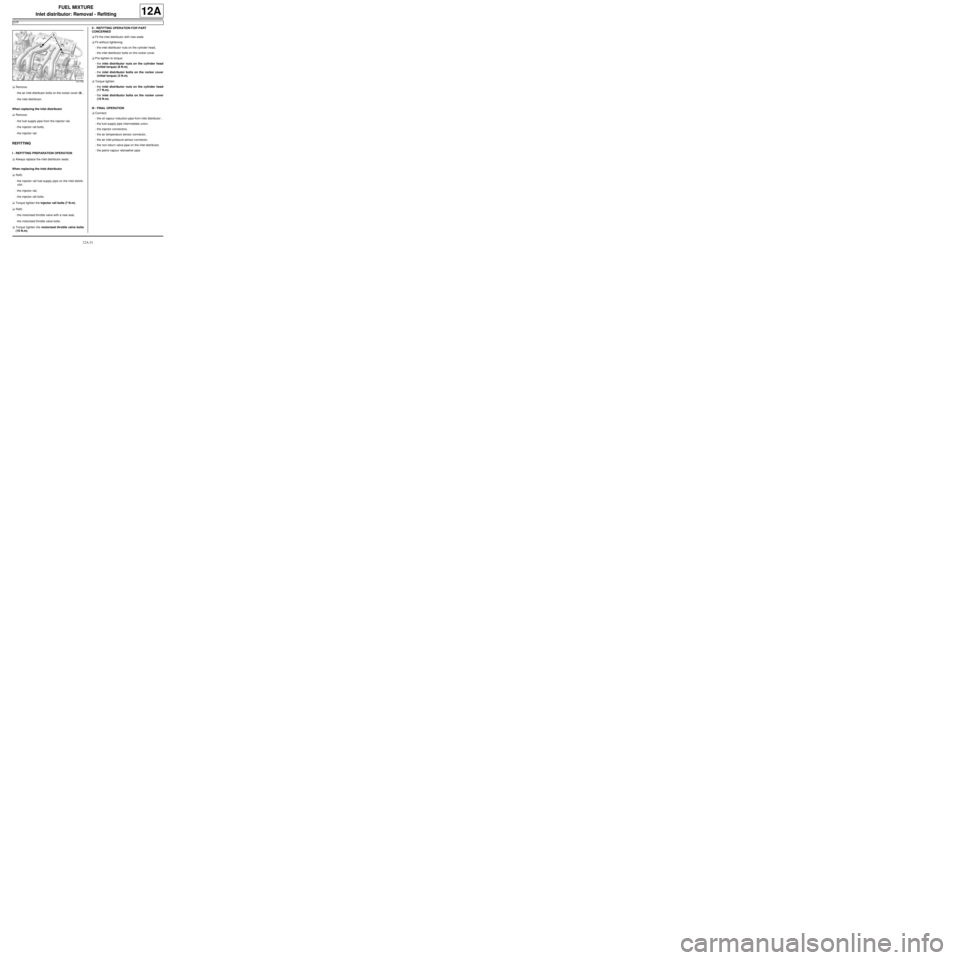

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the nuts from the air inlet distributor on the

cylinder head.

121737

IMPORTANT

During this operation, be sure to:

-refrain from smoking or bringing red hot objects

close to the working area,

-be careful of fuel splashes when disconnecting

the union.

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to run.

IMPORTANT

Wear latex gloves during the operation.

AIR CONDITIONING

121734

Page 296 of 652

12A-31

FUEL MIXTURE

Inlet distributor: Removal - Refitting

D7F

12A

aRemove:

-the air inlet distributor bolts on the rocker cover (9) ,

-the inlet distributor.

When replacing the inlet distributor

aRemove:

-the fuel supply pipe from the injector rail,

-the injector rail bolts,

-the injector rail.

REFITTING

I - REFITTING PREPARATION OPERATION

aAlways replace the inlet distributor seals.

When replacing the inlet distributor

aRefit:

-the injector rail fuel supply pipe on the inlet distrib-

utor,

-the injector rail,

-the injector rail bolts.

aTorque tighten the injector rail bolts (7 N.m).

aRefit:

-the motorised throttle valve with a new seal,

-the motorised throttle valve bolts.

aTorque tighten the motorised throttle valve bolts

(10 N.m).II - REFITTING OPERATION FOR PART

CONCERNED

aFit the inlet distributor with new seals

aFit without tightening:

-the inlet distributor nuts on the cylinder head,

-the inlet distributor bolts on the rocker cover.

aPre-tighten to torque:

-the inlet distributor nuts on the cylinder head

(initial torque) (8 N.m),

-the inlet distributor bolts on the rocker cover

(initial torque) (3 N.m).

aTorque tighten:

-the inlet distributor nuts on the cylinder head

(17 N.m),

-the inlet distributor bolts on the rocker cover

(10 N.m).

III - FINAL OPERATION

aConnect:

-the oil vapour induction pipe from inlet distributor ,

-the fuel supply pipe intermediate union,

-the injector connectors,

-the air temperature sensor connector,

-the air inlet pressure sensor connector,

-the non-return valve pipe on the inlet distributor,

-the petrol vapour rebreather pipe.

121735

Page 298 of 652

12A-33

FUEL MIXTURE

Inlet distributor: Removal - Refitting

D4F, and 772

12A

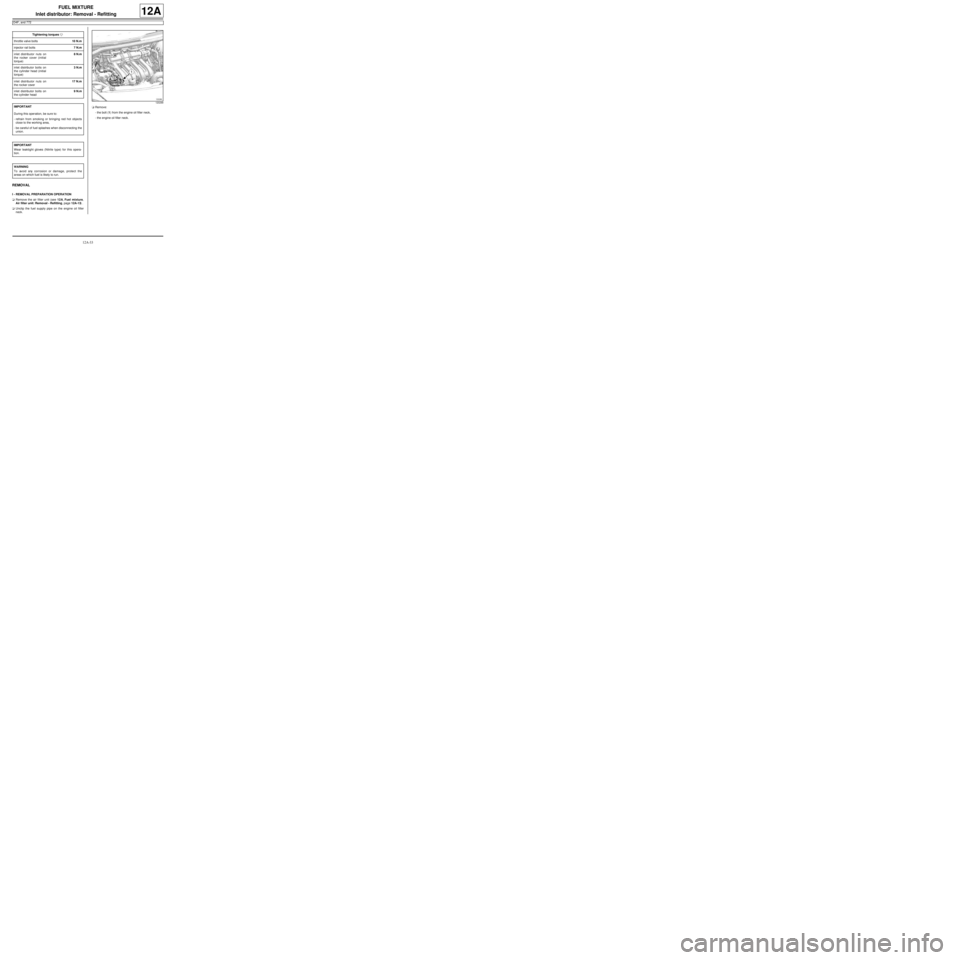

REMOVAL

I - REMOVAL PREPARATION OPERATION

aRemove the air filter unit (see 12A, Fuel mixture,

Air filter unit: Removal - Refitting, page 12A-13) .

aUnclip the fuel supply pipe on the engine oil filler

neck.aRemove:

-the bolt (1) from the engine oil filler neck,

-the engine oil filler neck. Tightening torquesm

throttle valve bolts10 N.m

injector rail bolts7 N.m

inlet distributor nuts on

the rocker cover (initial

torque)8 N.m

inlet distributor bolts on

the cylinder head (initial

torque)3 N.m

inlet distributor nuts on

the rocker cover17 N.m

inlet distributor bolts on

the cylinder head9 N.m

IMPORTANT

During this oper ation, be sure to:

-refrain from smoking or bringing red hot objects

close to the working area,

-be careful of fuel splashes when disconnecting the

union.

IMPORTANT

Wear leaktight gloves (Nitrile type) for this opera-

tion.

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to run.

120299

Page 299 of 652

12A-34

FUEL MIXTURE

Inlet distributor: Removal - Refitting

D4F, and 772

12A

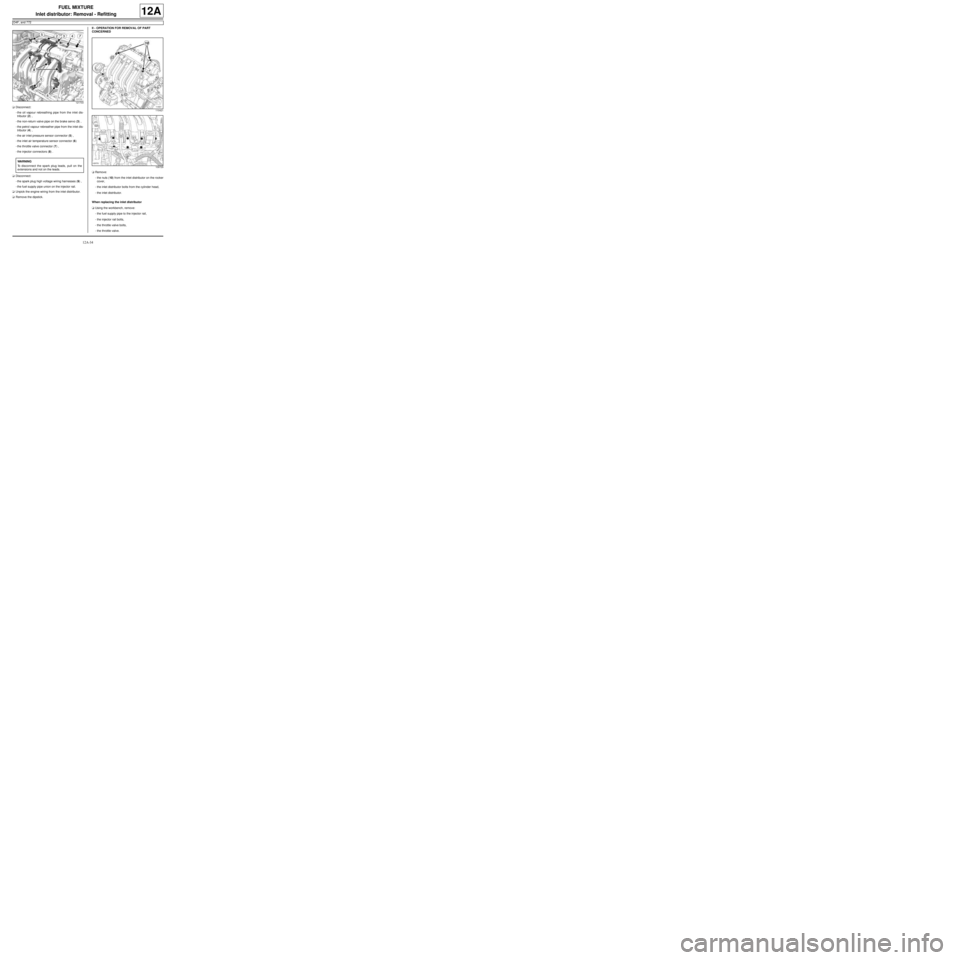

aDisconnect:

-the oil vapour rebreathing pipe from the inlet dis-

tributor (2) ,

-the non-return valve pipe on the brake servo (3) ,

-the petrol vapour rebreather pipe from the inlet dis-

tributor (4) ,

-the air inlet pressure sensor connector (5) ,

-the inlet air temperature sensor connector (6)

-the throttle valve connector (7) ,

-the injector connectors (8) .

aDisconnect:

-the spark plug high voltage wiring harnesses (9) ,

-the fuel supply pipe union on the injector rail.

aUnpick the engine wiring from the inlet distributor.

aRemove the dipstick.II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the nuts (10) from the inlet distributor on the rocker

cover,

-the inlet distributor bolts from the cylinder head,

-the inlet distributor.

When replacing the inlet distributor

aUsing the workbench, remove:

-the fuel supply pipe to the injector rail,

-the injector rail bolts,

-the throttle valve bolts,

-the throttle valve.

121733

WARNING

To disconnect the spark plug leads, pull on the

extensions and not on the leads.

110421

109729

Page 301 of 652

12A-36

FUEL MIXTURE

Inlet distributor: Removal - Refitting

D4F, and 772

12A

III - FINAL OPERATION

aIt is essential to apply a bead of FLUOSTAR 2L

grease (see Vehicle: Parts and consumables for

the repair) (04B, Consumables - Products) 2 mm in

diameter on the inner edge of the high tension caps.

aConnect:

-the high voltage wiring harnesses to the spark

plugs,

-the fuel supply pipe union on the injector rail,

-the motorised throttle valve connector,

-the injector connectors,

-the air inlet temperature sensor connector,

-the non-return valve pipe on the brake servo,

-the petrol vapour rebreather pipe.

aRefit the dipstick.

aClip the engine wiring onto the inlet distributor.

aRefit the air filter unit (see 12A, Fuel mixture, Air fil-

ter unit: Removal - Refitting, page 12A-13) .

aConnect the battery (see Battery: Removal - Refit-

ting) (80A, Battery).

106640

Page 333 of 652

12B-8

TURBOCHARGING

Turbocharger: Removal - Refitting

D4F, and 780 or 782

12B

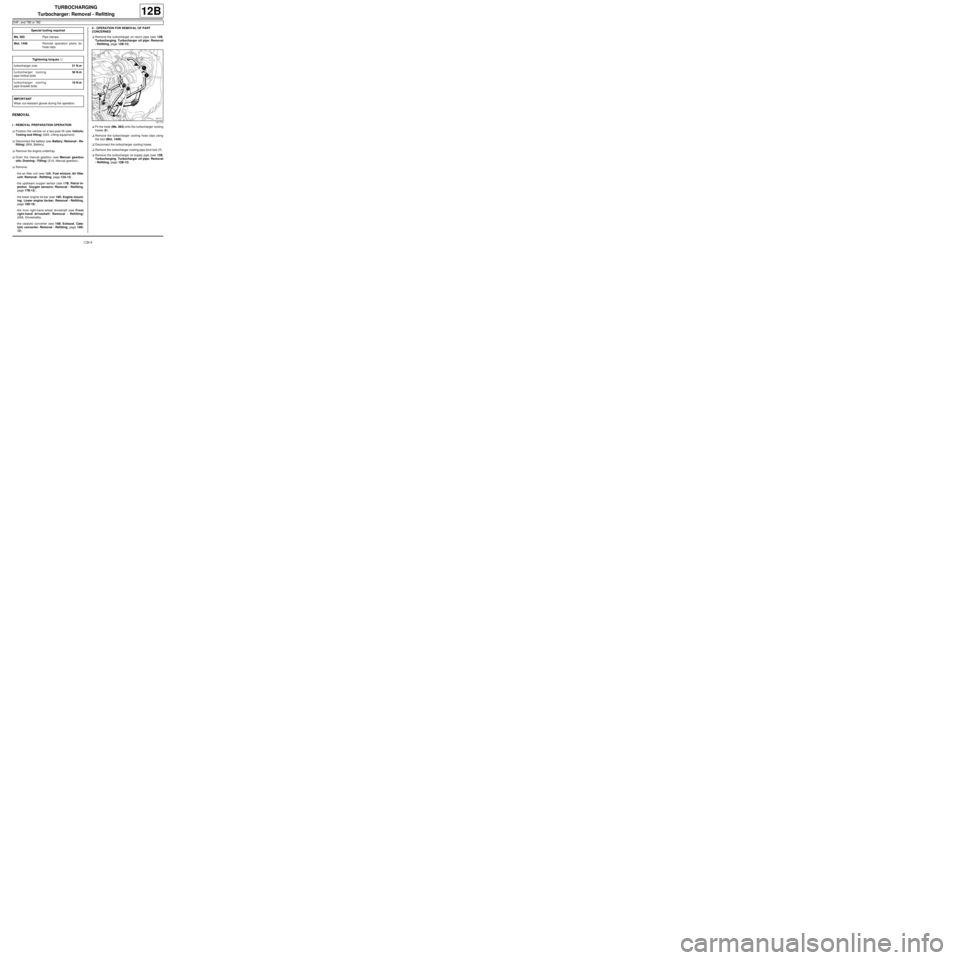

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aRemove the engine undertray.

aDrain the manual gearbox (see Manual gearbox

oils: Draining - Filling) (21A, Manual gearbox).

aRemove:

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the upstream oxygen sensor (see 17B, Petrol in-

jection, Oxygen sensors: Removal - Refitting,

page 17B-13) ,

-the lower engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the front right-hand wheel driveshaft (see Front

right-hand driveshaft: Removal - Refitting)

(29A, Driveshafts),

-the catalytic converter (see 19B, Exhaust, Cata-

lytic converter: Removal - Refitting, page 19B-

12) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the turbocharger oil return pipe (see 12B,

Turbocharging, Turbocharger oil pipe: Removal

- Refitting, page 12B-12) .

aFit the tools (Ms. 583) onto the turbocharger cooling

hoses (6) .

aRemove the turbocharger cooling hose clips using

the tool (Mot. 1448).

aDisconnect the turbocharger cooling hoses.

aRemove the turbocharger cooling pipe strut bolt (7) .

aRemove the turbocharger oil supply pipe (see 12B,

Turbocharging, Turbocharger oil pipe: Removal

- Refitting, page 12B-12) . Special tooling required

Ms. 583Pipe clamps .

Mot. 1448Remote operation pliers for

hose clips .

Tightening torquesm

turbocharger nuts21 N.m

turbocharger cooling

pipe hollow bolts30 N.m

turbocharger cooling

pipe bracket bolts10 N.m

IMPORTANT

Wear cut-resistant gloves during the operation.121773