Fuel supply RENAULT TWINGO RS 2009 2.G Engine And Peripherals Repair Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 652

Page 408 of 652

13B-47

DIESEL INJECTION

Injector rail: Removal - Refitting

K9K

13B

aRemove the blanking plugs.

aFit the injector rail.

aFit the injector rail nuts without tightening them.

III - FINAL OPERATION.

a

aRemove the blanking plugs from the high pressure

pump and the injection rail and discard them.

aFit the high pressure pipe between the high pressure

pump and the injection rail.

aTighten the high pressure pipe unions between the

pump and the rail until contact is made.

aRemove the blanking plugs on the injection rail and

the diesel fuel injectors then discard them.

aFit the new high-pressure pipes between the rail and

the injectors.

aTighten until contact the unions of the high pressure

pipes between the rail and injector.aFit and lock the new clips between the high pressure

pipes on the rail and injectors.

aTighten to torque:

-the injector rail nuts (28 Nm),

-the unions for the high pressure pipes between

the rail and the yellow-coloured injector (24

Nm) using the tool (Mot. 1746),

-the unions for the high pressure pipes between

the rail and the silver-coloured injector (28 Nm)

using the tool (Mot. 1746),

-the unions for the high pressure pipes between

the pump and the yellow-coloured rail (24 Nm)

using the tool (Mot. 1746),

-the unions for the high pressure pipes between

the pump and the silver-coloured rail (28 Nm)

using the tool (Mot. 1746),

aConnect to the high pressure pump:

-the fuel return pipe to the fuel filter,

-the fuel supply pipe.

aRefit the neck on the injection rail.

aRemove the protection fitted on the inlet opening of

the oil level dipstick on the cylinder block.

aRefit:

-the dipstick guide,

-the oil level dipstick nut,

-the oil level dipstick.

aConnect the injector rail pressure sensor connector.

aPosition the wiring harness in its channel.

aFasten the electrical wiring to the channel.

aConnect:

-the diesel temperature sensor,

-the fuel flow actuator,

-the injector connectors,

-the heater plug connectors.

aPrime the fuel circuit using a manual priming pump

until the disconnected pipes are filled with fuel.

aCheck that there are no fuel leaks.

aConnect the battery (see Battery: Removal - Refit-

ting) (80A, Battery).

aCheck the high pressure circuit (see 13B, Diesel in-

jection, High pressure pipe: Check, page 13B-34)

.

aRefit the engine cover.

20960

WARNING

Before fitting a new high-pressure pipe, lightly

lubricate the nut threads with the oil from the

applicator provided in the new parts kit.

Be careful not to allow oil into the high-pressure

pipe.

Do not lubricate high-pressure pipes supplied

without an applicator, as these high-pressure

pipes are self-lubricating.

Page 417 of 652

13C-2

PREHEATING

Heater plugs: Removal - Refitting

K9K

13C

REMOVAL

I - REMOVAL PREPARATION OPERATION

aRemove the front engine cover.

aUnclip the fuel supply pipes (1) from the right-hand

suspended engine mounting.

aMove the fuel supply pipes away from the right-hand

suspended engine mounting.II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the heater plug connectors (2) .

aClean the edges of the heater plugs using a com-

pressed air nozzle to avoid any impurities getting

into the cylinders. Equipment required

compressed air nozzle

hinged wrench for heater plug

Tightening torquesm

heater plugs15 Nm

120045

127895

IMPORTANT

Wear goggles with side protectors for this opera-

tion.

Page 418 of 652

13C-3

PREHEATING

Heater plugs: Removal - Refitting

K9K

13C

a

aLoosen the heater plugs (3) using a 10 mm long ra-

dio socket connected to a universal joint or a hinged

wrench for heater plug.

aUse a hose to unscrew the heater plugscompletely.

aRemove the heater plugs.

aBlock the plug wells on the cylinder head using clean

cloths throughout the removal operation.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRemove the protection on the openings of the plug

well(s) on the cylinder head.

aBolt without tightening the heater plugs using the

hose.

aTorque tighten the heater plugs (15 Nm).

aConnect the heater plug connectors.

II - FINAL OPERATION.

aFit the fuel pipes on the right-hand suspended en-

gine mounting.aClip the fuel supply pipes onto the right-hand sus-

pended engine mounting.

aRefit the engine cover.

127905

Note:

If the heater plugs jam, use the heater plug

removal tool (see ) (Technical Note 5197A, 06A,

Tools).

Page 449 of 652

16A-10

STARTING - CHARGING

Starter: Removal - Refitting

D4F or D7F

16A

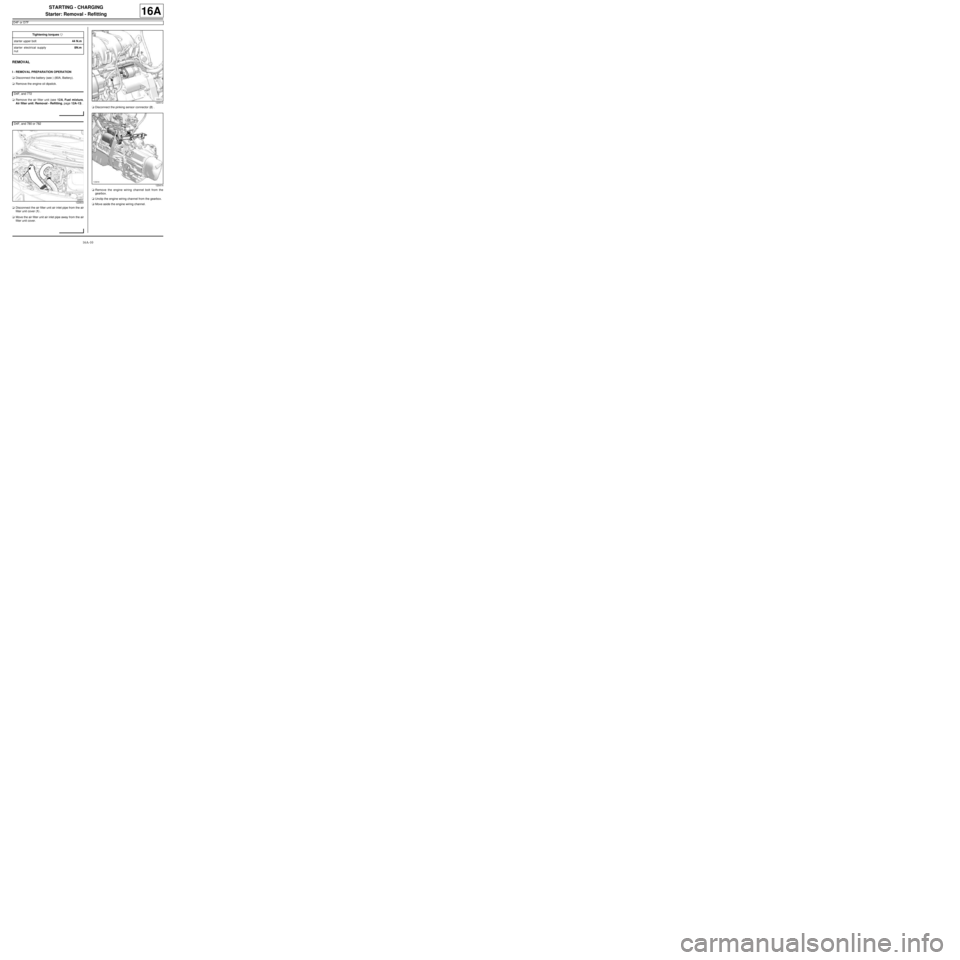

REMOVAL

I - REMOVAL PREPARATION OPERATION

aDisconnect the battery (see ) (80A, Battery).

aRemove the engine oil dipstick.

aRemove the air filter unit (see 12A, Fuel mixture,

Air filter unit: Removal - Refitting, page 12A-13) .

aDisconnect the air filter unit air inlet pipe from the air

filter unit cover (1) .

aMove the air filter unit air inlet pipe away from the air

filter unit cover.aDisconnect the pinking sensor connector (2) .

aRemove the engine wiring channel bolt from the

gearbox.

aUnclip the engine wiring channel from the gearbox.

aMove aside the engine wiring channel. Tightening torquesm

starter upper bolt44 N.m

starter electrical supply

nut8N.m

D4F, and 772

D4F, and 780 or 782

122833

120512

120414

Page 455 of 652

16A-16

STARTING - CHARGING

Starter: Removal - Refitting

K4M

16A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aRemove the air filter unit (see 12A, Fuel mixture,

Air filter unit: Removal - Refitting, page 12A-13) .

II - REMOVAL OPERATION

aRemove:

-the starter supply cable nut (1) ,

-the starter excitation cable nut (2) .

aMove the starter wiring aside.aRemove:

-the starter bolts (3) ,

-the starter.

REFITTING

I - REFITTING PREPARATION OPERATION

aCheck that the centring dowel is in place.

II - REFITTING OPERATION

aRefit the starter.

aFit the starter wiring.

aTorque tighten:

-the starter supply cable nut (8 N.m),

-the starter excitation cable nut (5 N.m).

III - FINAL OPERATION

aRefit the air filter unit (see 12A, Fuel mixture, Air fil-

ter unit: Removal - Refitting, page 12A-13) .

aConnect the battery (see Battery: Removal - Refit-

ting) (80A, Battery). Tightening torquesm

starter supply cable nut8 N.m

starter excitation cable

nut5 N.m

132366

132367

Page 506 of 652

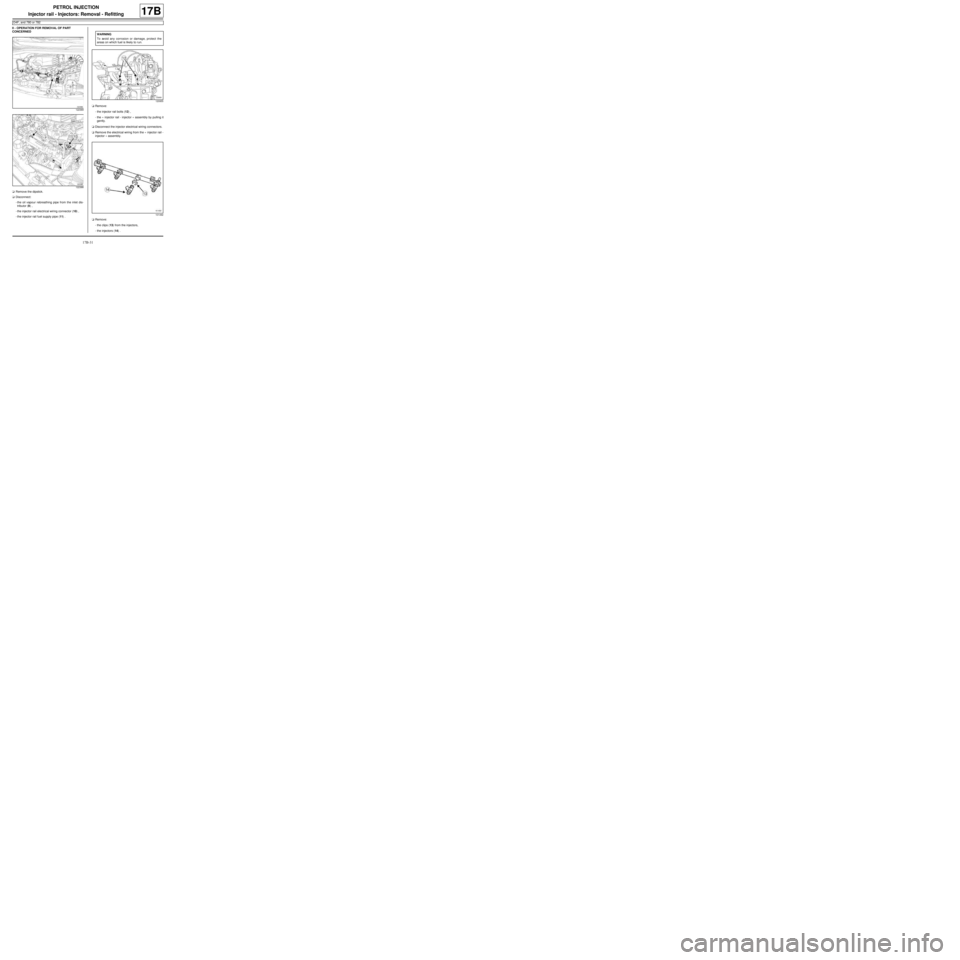

17B-31

PETROL INJECTION

Injector rail - Injectors: Removal - Refitting

D4F, and 780 or 782

17B

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the dipstick.

aDisconnect:

-the oil vapour rebreathing pipe from the inlet dis-

tributor (9) ,

-the injector rail electrical wiring connector (10) ,

-the injector rail fuel supply pipe (11) .aRemove:

-the injector rail bolts (12) ,

-the « injector rail - injector » assembly by pulling it

gently.

aDisconnect the injector electrical wiring connectors.

aRemove the electrical wiring from the « injector rail -

injector » assembly.

aRemove:

-the clips (13) from the injectors,

-the injectors (14) .

122389

122388

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to r un.

120955

101492

Page 507 of 652

17B-32

PETROL INJECTION

Injector rail - Injectors: Removal - Refitting

D4F, and 780 or 782

17B

REFITTING

I - REFITTING PREPARATION OPERATION

aparts always to be replaced: injector clip on in-

jector rail.

aparts always to be replaced: injector seal.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the injectors with new seals,

-new clips on the injectors,

-the injector rail - injector electrical wiring.

aConnect the connectors of the electrical wiring to the

injectors.

aRefit:

-the « injector rail - injector » assembly,

-the « injector rail - injector » assembly bolts.

aTorque tighten the injector rail - injector bolts (4.5

N.m).

aConnect:

-the fuel supply pipe on the injector rail,

-the electrical wiring connector to the injector rail,

-the oil vapour rebreathing pipe on the inlet distribu-

tor.

aRefit the dipstick.

III - FINAL OPERATION

aFit the petrol vapour rebreathing pipe.

aClip on the petrol vapour rebreathing pipe.

aConnect the petrol vapour rebreathing pipe to:

-the air outlet pipe of the air filter unit,

-the inlet distributor.aPush the clip of the intercooler air inlet pipe in the di-

rection of the arrow (15) .

aConnect the intercooler air inlet pipe on the turbo-

charger.

aRefit the bolt of the intercooler air inlet pipe on the

throttle valve.

aFit the air filter unit air inlet pipe.

aConnect:

-the air filter unit air inlet pipe on the air filter unit

cover,

-the battery (see ) (80A, Battery).

122666

Page 508 of 652

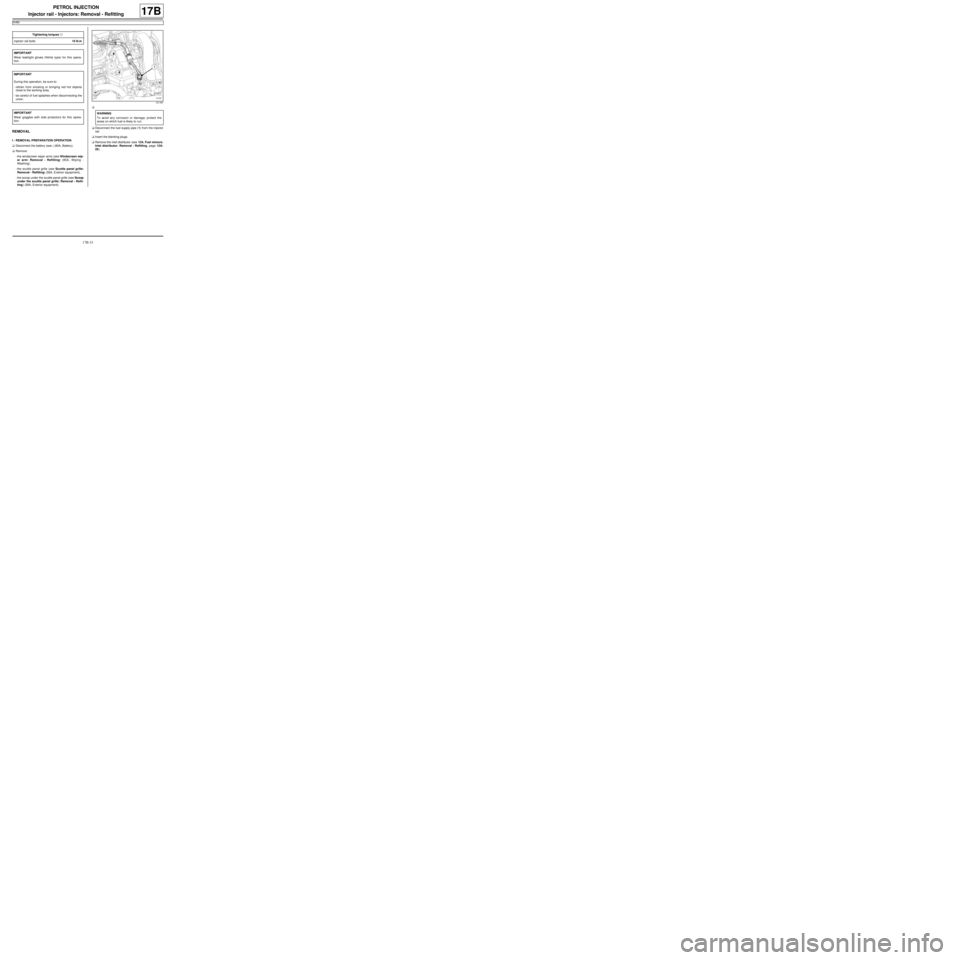

17B-33

PETROL INJECTION

Injector rail - Injectors: Removal - Refitting

K4M

17B

REMOVAL

I - REMOVAL PREPARATION OPERATION

aDisconnect the battery (see ) (80A, Battery).

aRemove:

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment).a

aDisconnect the fuel supply pipe (1) from the injector

rail.

aInsert the blanking plugs.

aRemove the inlet distributor (see 12A, Fuel mixture,

Inlet distributor: Removal - Refitting, page 12A-

29) . Tightening torquesm

injector rail bolts10 N.m

IMPORTANT

Wear leaktight gloves (Nitrile type) for this opera-

tion.

IMPORTANT

During this oper ation, be sure to:

-refrain from smoking or bringing red hot objects

close to the working area,

-be careful of fuel splashes when disconnecting the

union.

IMPORTANT

Wear goggles with side protectors for this opera-

tion.

131767

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to r un.

Page 509 of 652

17B-34

PETROL INJECTION

Injector rail - Injectors: Removal - Refitting

K4M

17B

II - REMOVAL OPERATION

aDisconnect the connector (2) from each injector.

aUnclip the wiring on the injector rail.

aRemove:

-the « injector rail - injector » assembly bolts (3) ,

-the « injector rail - injector » assembly.

aRemove:

-the clip (4) from each injector,

-the injectors (5) from the injector rail.REFITTING

I - REFITTING PREPARATION OPERATION

aparts always to be replaced: injector clip on in-

jector rail.

aAlways replace the injector seals.

aRefit:

-new seals on the injectors,

-the injectors on the injector rail,

-new clips on each injector.

II - REFITTING OPERATION

aRefit the « injector rail - injector » assembly.

aClip the wiring on the injector rail.

aConnect the connector on each injector.

aTorque tighten in order the injector rail bolts (10

N.m).

III - FINAL OPERATION

aRefit the inlet distributor (see 12A, Fuel mixture, In-

let distributor: Removal - Refitting, page 12A-29)

.

aRemove the blanking plugs.

aConnect the fuel supply pipe union on the injector

rail.

132390

128397

132390

Page 615 of 652

19C-1

TANK

Fuel tank: Draining

K9K

19C

I - DRAINING PREPARATION OPERATION

aDisconnect the battery (see ) (MR 441, 80A, Bat-

tery).

aRemove the front engine cover.aDisconnect the engine fuel supply quick-release

union (1) from the fuel filter outlet.

II - DRAINING THE FUEL TANK

aConnect a pneumatic transfer pump for fuels to

the fuel filter outlet.

aDrain the fuel tank.

III - FINAL OPERATION.

aDisconnect the pneumatic transfer pump for fuels

from the fuel filter.

aConnect the engine fuel filter outlet engine supply

quick-release union to the fuel filter.

aRefit the engine cover.

aConnect the battery (see ) (MR 441, 80A, Battery). Equipment required

pneumatic transfer pump for fuels

IMPORTANT

During this oper ation, be sure to:

-refrain from smoking or bringing red hot objects

close to the working area,

-be careful of fuel splashes when disconnecting the

union.

IMPORTANT

Wear goggles with side protectors for this opera-

tion.

IMPORTANT

Wear latex gloves during the operation.

WARNING

To prevent impurities from entering the circuit, plugs

must be fitted to the openings of all the fuel circuit

components exposed to the open air.

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to run.

121441