engine RENAULT TWINGO RS 2009 2.G Engine And Peripherals Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 652

Page 607 of 652

19B-25

EXHAUST

Expansion chamber: Removal - Refitting

K4M

19B

REMOVING THE EXHAUST PIPE FRONT

EXPANSION CHAMBER

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the engine undertray bolts,

-the engine undertray.II - OPERATION FOR REMOVAL OF PART

CONCERNED

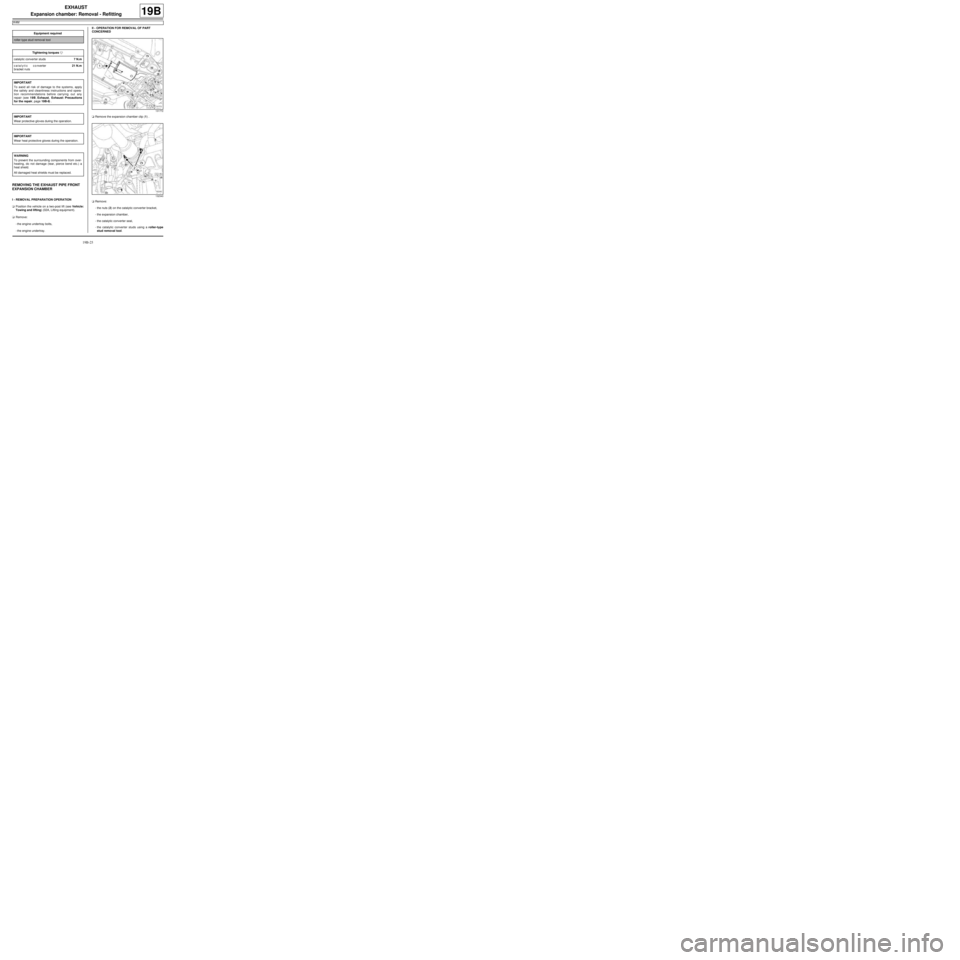

aRemove the expansion chamber clip (1) .

aRemove:

-the nuts (2) on the catalytic converter bracket,

-the expansion chamber,

-the catalytic converter seal,

-the catalytic converter studs using a roller-type

stud removal tool. Equipment required

roller-type stud removal tool

Tightening torquesm

catalytic converter studs7 N.m

catalytic converter

bracket nuts21 N.m

IMPORTANT

To avoid all risk of damage to the systems, apply

the safety and cleanliness instructions and opera-

tion recommendations before carrying out any

repair (see 19B, Exhaust, Exhaust: Precautions

for the repair, page 19B-8) .

IMPORTANT

Wear protective gloves during the operation.

IMPORTANT

Wear heat protective gloves during the operation.

WARNING

To prevent the surrounding components from over-

heating, do not damage (tear, pierce bend etc.) a

heat shield.

All damaged heat shields must be replaced.

131772

132340

Page 608 of 652

19B-26

EXHAUST

Expansion chamber: Removal - Refitting

K4M

19B

REMOVING THE EXHAUST PIPE REAR

EXPANSION CHAMBER

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

II - OPERATION FOR REMOVAL OF PART

CONCERNED

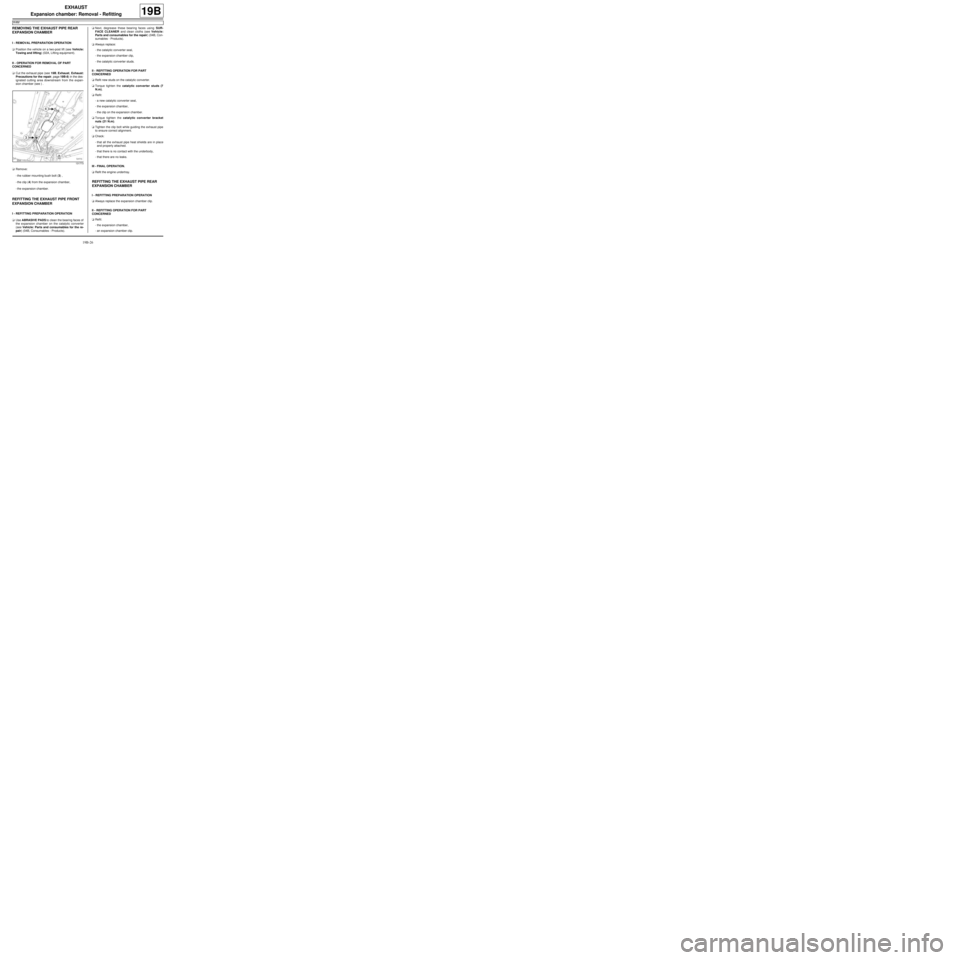

aCut the exhaust pipe (see 19B, Exhaust, Exhaust:

Precautions for the repair, page 19B-8) in the des-

ignated cutting area downstream from the expan-

sion chamber (see ) .

aRemove:

-the rubber mounting bush bolt (3) ,

-the clip (4) from the expansion chamber,

-the expansion chamber.

REFITTING THE EXHAUST PIPE FRONT

EXPANSION CHAMBER

I - REFITTING PREPARATION OPERATION

aUse ABRASIVE PADS to clean the bearing faces of

the expansion chamber on the catalytic converter

(see Vehicle: Parts and consumables for the re-

pair) (04B, Consumables - Products).aNext, degrease these bearing faces using SUR-

FACE CLEANER and clean cloths (see Vehicle:

Parts and consumables for the repair) (04B, Con-

sumables - Products).

aAlways replace:

-the catalytic converter seal,

-the expansion chamber clip,

-the catalytic converter studs.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit new studs on the catalytic converter.

aTorque tighten the catalytic converter studs (7

N.m).

aRefit:

-a new catalytic converter seal,

-the expansion chamber,

-the clip on the expansion chamber.

aTorque tighten the catalytic converter bracket

nuts (21 N.m).

aTighten the clip bolt while guiding the exhaust pipe

to ensure correct alignment.

aCheck:

-that all the exhaust pipe heat shields are in place

and properly attached.

-that there is no contact with the underbody,

-that there are no leaks.

III - FINAL OPERATION.

aRefit the engine undertray.

REFITTING THE EXHAUST PIPE REAR

EXPANSION CHAMBER

I - REFITTING PREPARATION OPERATION

aAlways replace the expansion chamber clip.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the expansion chamber,

-an expansion chamber clip.

131773

Page 611 of 652

19B-29

EXHAUST

Intermediate pipe: Removal - Refitting

K9K

19B

REFITTING THE INTERMEDIATE PIPE

REFITTING OPERATION FOR PART CONCERNED

aRefit:

-the rubber mounting bush of the intermediate pipe,

-the rubber mounting bush bolt on the intermediate

pipe.

aFit the intermediate pipe.

aAttach the intermediate pipe to the vehicle using the

intermediate pipe rubber mounting bush bolt.

aFit a new After-Sales sleeve and follow the instruc-

tions (see 19B, Exhaust, Exhaust: Precautions

for the repair, page 19B-8) .

aRefit a new clip between the front section of the in-

termediate pipe and the intermediate pipe.

aCheck the following and deal with if necessary:

-that there is no contact with the underbody,

-the presence and correct positioning of all the ex-

haust pipe heat shields.

aStart the engine.

aCheck that there are no leaks and deal with them if

necessary.Note:

If replacing the rubber mounting bush, spray the

inside of the rubber mounting bush with BRAKE

CLEANER ( (see Vehicle: Parts and consum-

ables for the repair) ) in the form of an aerosol

spray to facilitate fitting.

Page 615 of 652

19C-1

TANK

Fuel tank: Draining

K9K

19C

I - DRAINING PREPARATION OPERATION

aDisconnect the battery (see ) (MR 441, 80A, Bat-

tery).

aRemove the front engine cover.aDisconnect the engine fuel supply quick-release

union (1) from the fuel filter outlet.

II - DRAINING THE FUEL TANK

aConnect a pneumatic transfer pump for fuels to

the fuel filter outlet.

aDrain the fuel tank.

III - FINAL OPERATION.

aDisconnect the pneumatic transfer pump for fuels

from the fuel filter.

aConnect the engine fuel filter outlet engine supply

quick-release union to the fuel filter.

aRefit the engine cover.

aConnect the battery (see ) (MR 441, 80A, Battery). Equipment required

pneumatic transfer pump for fuels

IMPORTANT

During this oper ation, be sure to:

-refrain from smoking or bringing red hot objects

close to the working area,

-be careful of fuel splashes when disconnecting the

union.

IMPORTANT

Wear goggles with side protectors for this opera-

tion.

IMPORTANT

Wear latex gloves during the operation.

WARNING

To prevent impurities from entering the circuit, plugs

must be fitted to the openings of all the fuel circuit

components exposed to the open air.

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to run.

121441

Page 616 of 652

19C-2

TANK

Fuel tank: Draining

D4F or D7F or K4M

19C

I - DRAINING PREPARATION OPERATION

aDisconnect the battery (see ) (80A, Battery).

aRemove the engine oil filler neck.aDisconnect the fuel supply union (1) from the injector

rail.

aFit a T (Mot. 1311-08) union. Special tooling required

Mot. 1311-08Union for taking fuel pres-

sure measurements .

Equipment required

pneumatic transfer pump for fuels

IMPORTANT

During this oper ation, be sure to:

-refrain from smoking or bringing red hot objects

close to the working area,

-be careful of fuel splashes when disconnecting the

union.

IMPORTANT

Wear goggles with side protectors for this opera-

tion.

IMPORTANT

Wear leaktight gloves (Nitrile type) for this opera-

tion.

WARNING

To prevent impurities from entering the circuit, place

protective plugs on all fuel circuit components

exposed to the open air.

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to run.

D4F

D4F

121778

Page 617 of 652

19C-3

TANK

Fuel tank: Draining

D4F or D7F or K4M

19C

aDisconnect the fuel supply union (2) from the injector

rail.

aFit a T (Mot. 1311-08) union.aDisconnect the fuel supply union (3) from the injector

rail.

aFit a T (Mot. 1311-08) union.

II - TANK DRAINING PROCEDURE

aConnect a pneumatic transfer pump for fuels on

the outlet of the "T" union.

aDrain the fuel tank.

III - FINAL OPERATION.

aDisconnect the pneumatic transfer pump for fu-

els. .

aRemove the “T” union (Mot. 1311-08).

aConnect the fuel supply union.

aRefit the engine oil filler neck.

aConnect the battery (see ) (80A, Battery). D7F

121779

K4M

132334

D4F

Page 631 of 652

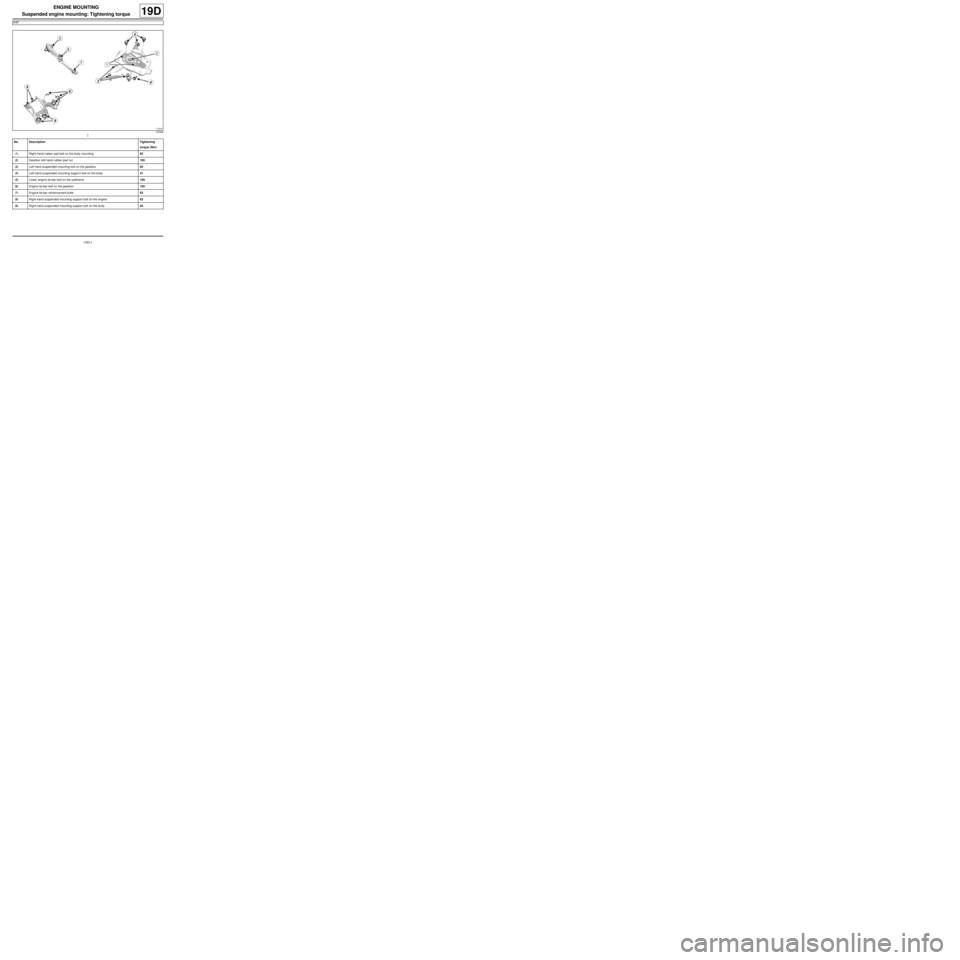

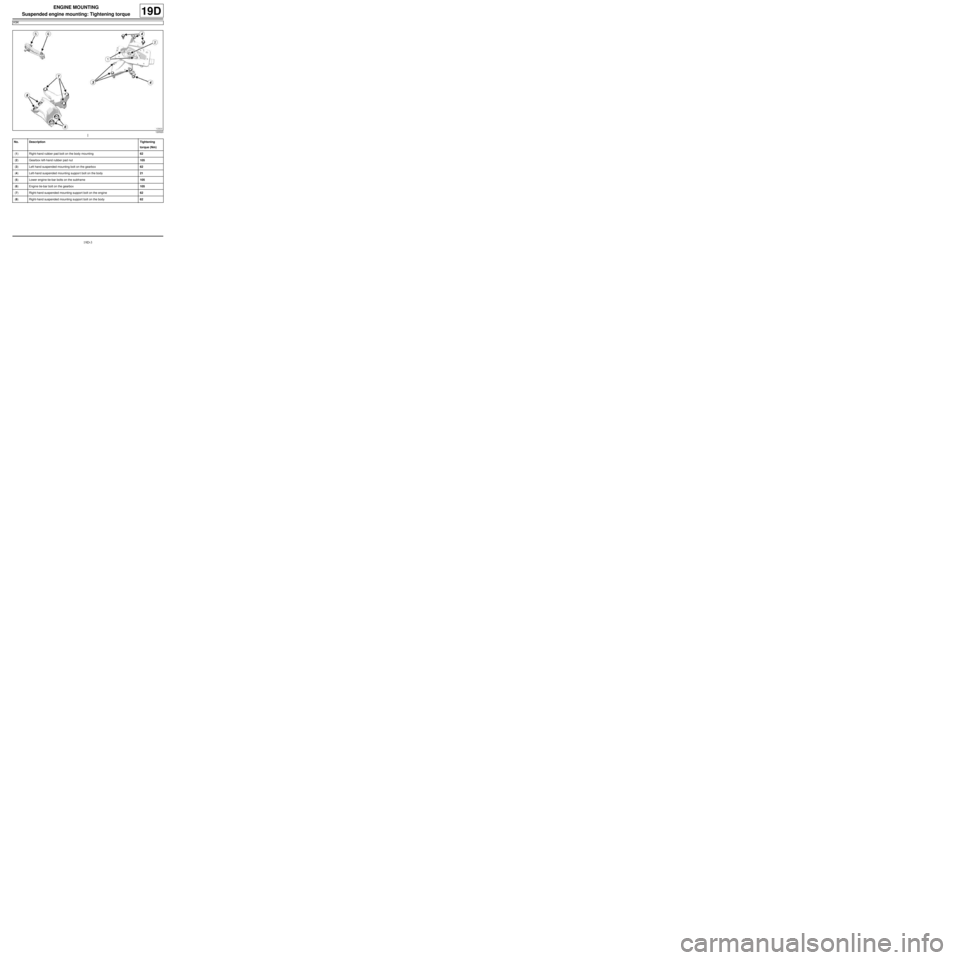

19D-1

ENGINE MOUNTING

Suspended engine mounting: Tightening torque

D4F

19D

120308

No. Description Tightening

torque (Nm)

(1) Right-hand rubber pad bolt on the body mounting62

(2) Gearbox left-hand rubber pad nut105

(3) Left hand suspended mounting bolt on the gearbox62

(4) Left-hand suspended mounting suppor t bolt on the body21

(5) Lower engine tie-bar bolt on the subframe105

(6) Engine tie-bar bolt on the gearbox105

(7) Engine tie-bar reinforcement bolts62

(8) Right-hand suspended mounting support bolt on the engine62

(9) Right-hand suspended mounting support bolt on the body62

Page 632 of 652

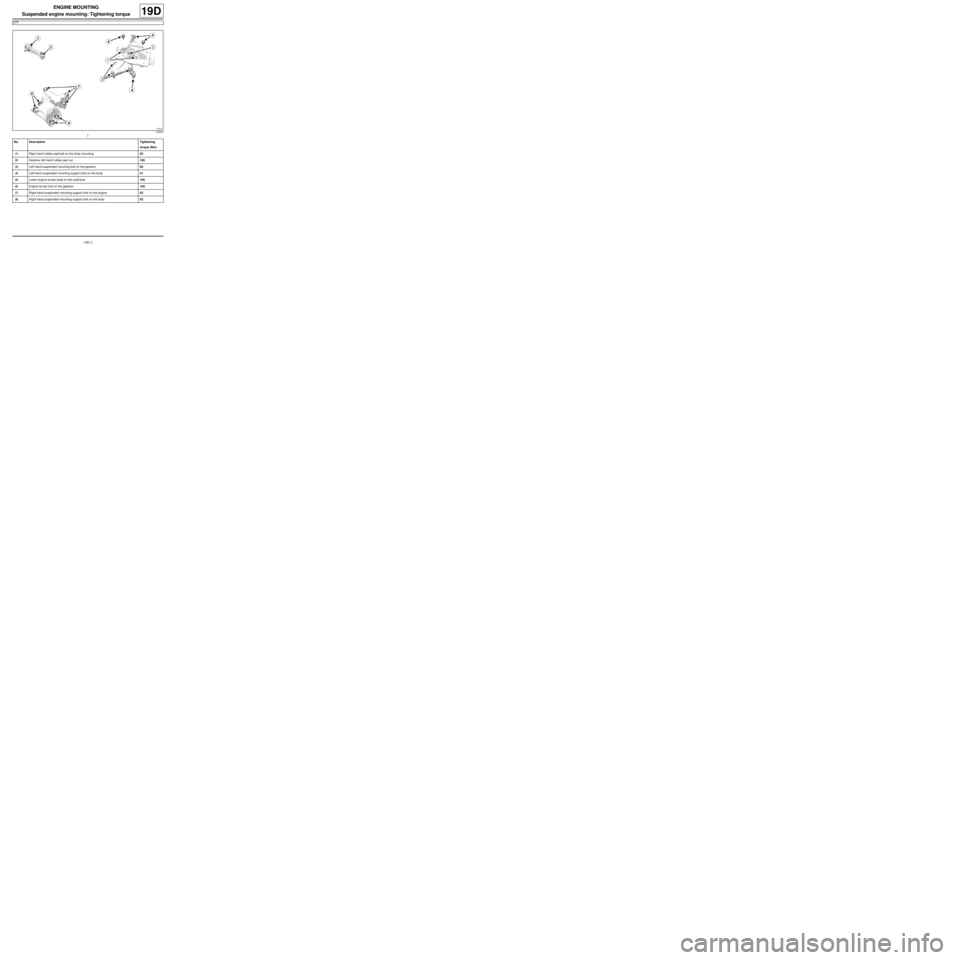

19D-2

ENGINE MOUNTING

Suspended engine mounting: Tightening torque

D7F

19D

120520

No. Description Tightening

torque (Nm)

(1) Right-hand rubber pad bolt on the body mounting62

(2) Gearbox left-hand rubber pad nut105

(3) Left hand suspended mounting bolt on the gearbox62

(4) Left-hand suspended mounting suppor t bolt on the body21

(5) Lower engine tie-bar bolts on the subframe105

(6) Engine tie-bar bolt on the gearbox105

(7) Right-hand suspended mounting support bolt on the engine62

(8) Right-hand suspended mounting support bolt on the body62

Page 633 of 652

19D-3

ENGINE MOUNTING

Suspended engine mounting: Tightening torque

K9K

19D

120520

No. Description Tightening

torque (Nm)

(1) Right-hand rubber pad bolt on the body mounting62

(2) Gearbox left-hand rubber pad nut105

(3) Left hand suspended mounting bolt on the gearbox62

(4) Left-hand suspended mounting suppor t bolt on the body21

(5) Lower engine tie-bar bolts on the subframe105

(6) Engine tie-bar bolt on the gearbox105

(7) Right-hand suspended mounting support bolt on the engine62

(8) Right-hand suspended mounting support bolt on the body62

Page 634 of 652

19D-4

ENGINE MOUNTING

Left-hand suspended engine mounting: Removal - Refitting

D4F or D7F

19D

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the battery (see ) (80A, Battery),

-the battery tray (see Battery tray: Removal - Re-

fitting) (80A, Battery),

-the front left-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the petrol injection computer (see 17B, Petrol in-

jection, Petrol injection computer: Removal -

Refitting, page 17B-20) ,

-the petrol injection computer mounting bolts,

-the petrol injection computer mounting nuts.

aRemove:

-the engine wiring nut,

-the petrol injection computer mounting.

aMark the position of the left-hand suspended engine

mounting using an indelible pencil.aPut a 20 mm shim between the gearbox and the

front axle subframe. Equipment required

indelible pencil

Tightening torquesm

bolts of the left-hand

suspended engine

mounting cover62 N.m

left-hand suspended

engine mounting shaft105 N.m

bolts of the left-hand

suspended engine

mounting rubber pad

support21 N.m

bolts of the left-hand

suspended engine

mounting r ubber pad62 N.m

central nut of the left-

hand suspended engine

mounting shaft62 N.m

120778