check engine RENAULT TWINGO RS 2009 2.G Engine And Peripherals Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 652

Page 3 of 652

TWINGO - Chapitre 1

Contents

Pages

TWINGO - Chapitre 1ContentsPages

10AENGINE AND CYLINDER BLOCK

ASSEMBLY

Crankshaft seal on timing

end: Removal - Refitting 10A-1

Crankshaft seal, gearbox

end: Removal - Refitting 10A-3

Lower cover: Removal -

Refitting 10A-6

Engine oil: Draining -

Refilling 10A-22

Oil filter: Removal - Refitting 10A-29

Oil-coolant heat exchanger:

Removal - Refitting 10A-33

Conrod bearing shell:

Removal - Refitting 10A-37

Oil pressure sensor:

Removal - Refitting 10A-45

Oil pump: Removal -

Refitting 10A-50

Oil pressure: Check 10A-59

Multifunction suppor t:

Removal - Refitting 10A-63

Engine - gearbox assembly:

Removal - Refitting 10A-74

Valves: Adjustment 10A-105

Flywheel: Removal - Refitting 10A-10711A TOP AND FRONT OF ENGINE

Pressure at end of

compression: Check 11A-1

Accessories belt: Removal -

Refitting 11A-3

Crankshaft accessories

pulley: Removal - Refitting 11A-20

Timing belt: Removal -

Refitting 11A-27

Rocker cover: Removal -

Refitting 11A-66

Camshaft: Removal -

Refitting 11A-82

Cylinder head: Removal -

Refitting 11A-114

Camshaft dephaser :

Removal - Refitting 11A-135

Camshaft seal, timing end:

Removal - Refitting 11A-138

Oil decanter: Removal -

Refitting 11A-147

12A FUEL MIXTURE

Air inlet: Description 12A-1

Air filter: Removal - Refitting 12A-6

Air filter unit: Removal -

Refitting 12A-13

Page 5 of 652

Contents

13C PREHEATING

Pre-postheating unit:

Removal - Refitting 13C-1

Heater plugs: Removal -

Refitting 13C-2

14A ANTIPOLLUTION

Oil vapour rebreathing

circuit: Descriptions 14A-1

Fuel vapour recirculation

circuit: Operating diagram 14A-2

Fuel vapour recirculation

circuit: Check 14A-3

Fuel vapour absorber:

Removal - Refitting 14A-4

Fuel vapour absorber: Check 14A-7

Fuel vapour absorber bleed

solenoid valve: Removal -

Refitting 14A-8

Exhaust gas recirculation

solenoid valve: Removal -

Refitting 14A-10

Exhaust gas cooler: Removal

- Refitting 14A-11

Exhaust gas recirculation

assembly: Removal -

Refitting 14A-15

Exhaust gas recirculation

rigid pipe: Removal -

Refitting 14A-19

16A STARTING - CHARGING

Alternator: Removal -

Refitting 16A-1

Star ter: Removal - Refitting 16A-10

Alternator pulley: Removal -

Refitting 16A-1717A IGNITION

Coils: Removal - Refitting 17A-1

Plugs: Removal - Refitting 17A-12

17B PETROL INJECTION

Petrol injection: List and

location of components 17B-1

Oxygen sensors: Removal -

Refitting 17B-13

Petrol injection computer:

Removal - Refitting 17B-20

Pinking sensor: Removal -

Refitting 17B-23

Crankshaft position sensor:

Removal - Refitting 17B-25

Injector rail - Injectors:

Removal - Refitting 17B-27

19A COOLING

Engine cooling system:

Specifications 19A-1

Engine cooling system:

Check 19A-2

Engine cooling circuit: List

and location of components 19A-4

Engine cooling system:

Operating diagram 19A-5

Cooling system: Draining -

Refilling 19A-9

Cooling radiator: Removal -

Refitting 19A-12

Coolant pump: Removal -

Refitting 19A-24

Thermostat: Removal -

Refitting 19A-34

Water chamber: Removal -

Refitting 19A-40

Page 28 of 652

10A-22

ENGINE AND CYLINDER BLOCK ASSEMBLY

Engine oil: Draining - Refilling

D4F or D7F

10A

PARTS AND CONSUMABLES FOR THE

REPAIR WORK

aParts always to be replaced :

-copper seal.aConsumable (see Vehicle: Parts and consuma-

bles for the repair) (04B, Consumables - Products).

-Engine oil (see Engine oil: Specifications) (Tech-

nical Note 6013A, 04A, Lubricants).

I - OIL SERVICE

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment). Special tooling required

Mot. 10188 mm square engine drain

plug spanner.

Equipment required

oil change wrench

oil recovery tray

torque wrench

oil change end piece with an 8 mm square drive

Tightening torquesm

drain plug20 N.m

EngineAverage oil capacity

(adjusting using dipstick) (l)

Oil change with-

out filter

replacementOil change with

filter replace-

ment

D7F

3.8 4

D4F

WARNING

Always check the oil level using the dipstick.

Do not exceed the maximum level on the dipstick

(could destroy the engine).

Correct the engine oil level if necessary before

deliver ing the vehicle to the customer.

Note:

When topping up the engine oil, always leave at

least 10 minutes before checking the level with a

dipstick.

Page 30 of 652

10A-24

ENGINE AND CYLINDER BLOCK ASSEMBLY

Engine oil: Draining - Refilling

D4F or D7F

10A

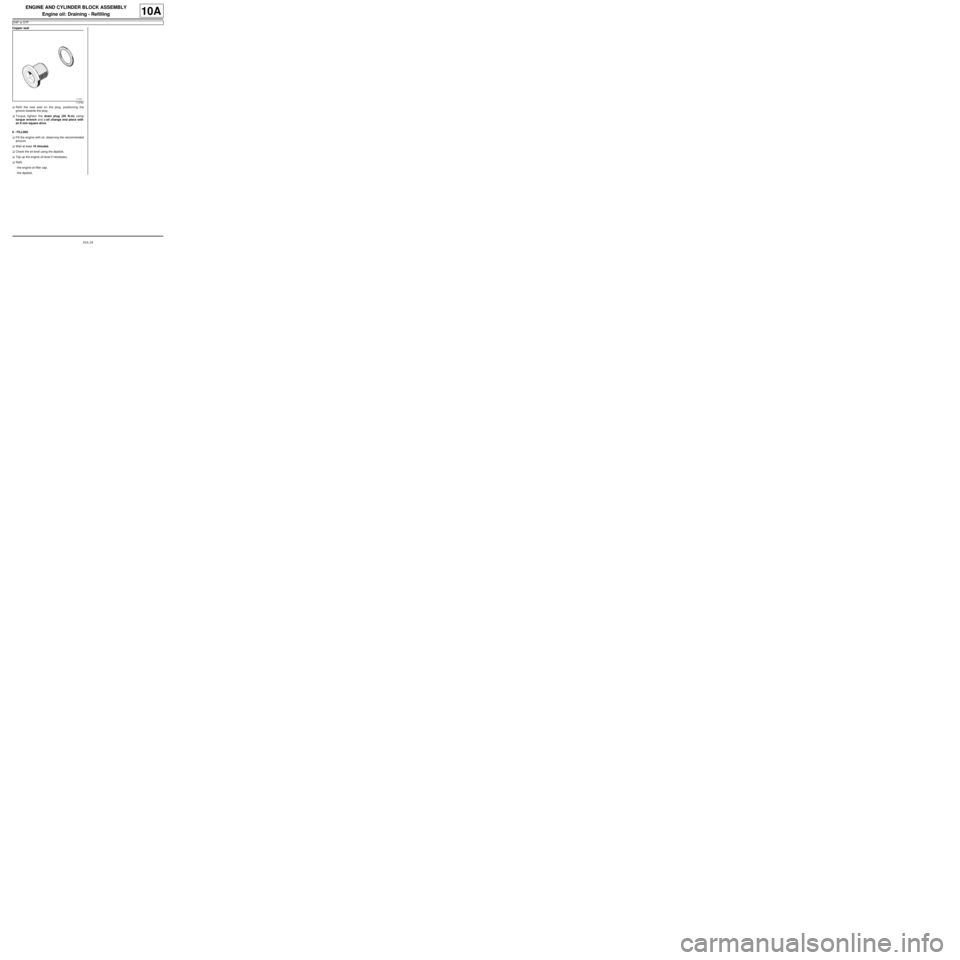

Copper seal

aRefit the new seal on the plug, positioning the

groove towards the plug.

aTorque tighten the drain plug (20 N.m) using

torque wrench and a oil change end piece with

an 8 mm square drive.

II - FILLING

aFill the engine with oil, observing the recommended

amount.

aWait at least 10 minutes.

aCheck the oil level using the dipstick.

aTop up the engine oil level if necessary.

aRefit:

-the engine oil filler cap,

-the dipstick.

113764

Page 31 of 652

10A-25

ENGINE AND CYLINDER BLOCK ASSEMBLY

Engine oil: Draining - Refilling

K4M

10A

I - RECOMMENDATIONS FOR REPAIR

aDirection of fitting for a drain plug seal.For a sheet metal engine oil sump

aThere is no direction of fitting for a seal fitted with a

rubber lip.

II - PARTS AND CONSUMABLES FOR THE REPAIR

aparts always to be replaced: Drain plug seal on

engine oil sump.

aconsumable:

-engine oil (see Engine oil: Specifications) (Tech-

nical Note 6013A, 04A, Lubricants). Equipment required

oil recovery tray

oil change wrench

torque wrench

oil change end piece with an 8 mm square drive

Tightening torquesm

engine oil sump drain

plug20 N.m

EngineAverage oil capacity (adjust with

dipstick) (l)

DrainingOil change

plus oil filter

replacement

K4M4.9 5

113765

IMPORTANT

Wear leaktight gloves (Nitrile type) for this opera-

tion.

WARNING

Always check the oil level using the dipstick.

Do not exceed the maximum level on the dipstick

(could destroy the engine).

Correct the engine oil level if necessary before

delivering the vehicle to the customer.

Note:

When topping up the engine oil, always leave at

least 10 minutes before checking the level with a

dipstic k.

Page 32 of 652

10A-26

ENGINE AND CYLINDER BLOCK ASSEMBLY

Engine oil: Draining - Refilling

K4M

10A

III - DRAINING

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the engine oil filler cap (1) ,

-the dipstick (2) ,

-the engine undertray bolts,

-the engine undertray.

aPlace the oil recovery tray under the engine.aRemove the drain plug (3) from the engine oil sump

using the oil change wrench.

aLet the engine oil run into the oil recovery tray.

aRemove the drain plug seal.

aFit a new seal onto the engine oil drain plug.

aTorque tighten the engine oil sump drain plug (20

N.m) using a torque wrench and a oil change end

piece with an 8 mm square drive.

aWipe the oil drips on the sump using a cloth.

aRemove the oil recovery tray.

aRefit the engine undertray.

IV - FILLING

aPosition the vehicle back on the ground.

aFill the engine with oil, observing the recommended

amount.

aWait at least 10 minutes.

aCheck the oil level using the dipstick.

aTop up the engine oil level if necessary.

aRefit:

-the dipstick,

-the engine oil filler cap.

132431

18749

Page 33 of 652

10A-27

ENGINE AND CYLINDER BLOCK ASSEMBLY

Engine oil: Draining - Refilling

K9K

10A

I - PRECAUTIONS FOR REPAIR

aThere is no direction of fitting for a seal fitted with a

rubber lip.

II - PARTS AND CONSUMABLES FOR THE REPAIR

WORK

aparts always to be replaced: Drain plug seal on

engine oil sump.

aConsumable:

-engine oil (see Engine oil: Specifications) (Tech-

nical Note 6013A, 04A, Lubricants). Special tooling required

Mot. 10188 mm square engine drain

plug spanner.

Equipment required

oil recovery tray

oil change wrench

oil change end piece with an 8 mm square drive

Tightening torquesm

the drain plug20 N.m

Engine SuffixAverage oil capacity

(adjusting using dipstick) (l)

Oil change

without fil-

ter replace-

mentOil change

with filter

replacement

K9K740 4.3 4.4

718 4.5 4.6

113765

IMPORTANT

Wear leaktight gloves (Nitrile type) for this opera-

tion.

WARNING

Always check the oil level using the dipstick.

Do not exceed the maximum level on the dipstick

(could destroy the engine).

Correct the engine oil level if necessary before

delivering the vehicle to the customer.

Note:

When topping up the engine oil, always leave at

least 10 minutes before checking the level with a

dipstic k.

Page 34 of 652

10A-28

ENGINE AND CYLINDER BLOCK ASSEMBLY

Engine oil: Draining - Refilling

K9K

10A

III - OIL SERVICE

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the engine oil filler cap (1) ,

-the dipstick (2) ,

-the engine undertray bolts,

-the engine undertray.

aPlace the oil recovery tray under the engine.aRemove the drain plug (3) from the engine oil sump

using the (Mot. 1018) or a oil change wrench.

aLet the engine oil flow out.

aRemove the drain plug seal.

aRefit the new seal to the drain plug.

aTorque tighten the drain plug (20 N.m) using a oil

change wrench and a oil change end piece with

an 8 mm square drive.

aWipe the oil drips around the drain plug using a

cloth.

aRemove the oil recovery tray.

aRefit the engine undertray.

IV - FILLING

aPosition the vehicle back on the ground.

aFill the engine with oil, observing the correct quantity

of oil as recommended by the manufacturer.

aWait at least 10 minutes.

aCheck the oil level using the dipstick.

aTop up the engine oil level if necessary.

aRefit:

-the engine oil filler cap,

-the dipstick.

120041

120042

Page 35 of 652

10A-29

ENGINE AND CYLINDER BLOCK ASSEMBLY

Oil filter: Removal - Refitting

D4F or D7F

10A

PARTS AND CONSUMABLES FOR THE

REPAIR WORK

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aDrain the engine oil (see 10A, Engine and cylinder

block assembly, Engine oil: Draining - Refilling,

page 10A-22) .

II - REMOVAL OPERATION FOR PART

CONCERNED

aRemove the oil filter using tool (Mot. 1330).

REFITTING

I - REFITTING PREPARATIONS OPERATION

aparts always to be replaced: Oil filter.aCoat the new oil filter sealing ring with engine oil.

II - REFITTING OPERATION FOR PART

CONCERNED

aTighten the oil filter until it makes contact.

aTighten the oil filter by 3/4 of a turn with the (Mot.

1330).

III - FINAL OPERATION

aWipe any oil run-off with a cloth.

aTop up the engine oil (see 10A, Engine and cylin-

der block assembly, Engine oil: Draining - Refill-

ing, page 10A-22) .

aStart the engine and leave it running for approxi-

mately 30 seconds.

aCheck that there are no leaks around the oil filter.

aWait at least 10 minutes. Special tooling required

Mot. 1330Oil filter removing tool (66

mm diameter).

120304

WARNING

The joint faces must be clean, dr y and free from

grease (avoid finger marks).

WARNING

Always check the oil level using the dipstick.

Do not exceed the maximum level on the dipstick

(could destroy the engine).

Correct the engine oil level if necessary before

delivering the vehicle to the customer.

Page 36 of 652

10A-30

ENGINE AND CYLINDER BLOCK ASSEMBLY

Oil filter: Removal - Refitting

C44, and K9K

10A

PARTS AND CONSUMABLES FOR THE

REPAIR WORK

aParts always to be replaced with new ones

-the oil filter

aConsumable:

-engine oil (see Technical Note 6013, Engine oils,

04A, Lubricants, Engine oil: Specifications).

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift ( (see Vehicle:

Towing and lifting) ).

aRemove the front engine cover.

aSet up the (Mot. 1329) (1) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the oil filter using the ratchet fitted with a

long extension and a universal joint.

aCheck that the oil filter seal is not in contact with the

oil filter holder.

aWipe off oil runs with a clean cloth.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aLubricate the oil filter seal with new engine oil.

aTighten the oil filter until the seal makes contact with

the oil filter holder.

aTighten the oil filter three-quarters of a turn by hand.

aStart the engine.

aAllow the engine to run.

II - FINAL OPERATION.

aCheck that there are no oil leaks.

aSwitch off the engine.

aTop up the engine oil.

aRefit the engine cover. Special tooling required

Mot. 1329Oil filter removing tool (76

mm diameter)

WARNING

Always check the oil level using the dipstick.

Do not exceed the maximum level on the dipstick

(could destroy the engine).

Correct the engine oil level if necessary before

delivering the vehicle to the customer.

120046

Note:

Always wait at least 10 min for the oil to drain

down bef ore checking the level with the dipstick.