ignition RENAULT TWINGO RS 2009 2.G Heating And Air Conditioning - Climate Control Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 99

Page 2 of 99

62B-2

MR-413-X44-62B000$046_eng.mif

V1

62B

CLIMATE CONTROL

Fault finding - Introduction

1. SCOPE OF THIS DOCUMENT

This document presents the fault finding procedure applicable to all computers with the following specifications:

2. PREREQUISITES FOR FAULT FINDING

Documentation type

Fault finding procedures (this document and the Technical Notes concerning the injection system fitted to

the vehicle, and the UCH):

–Assisted fault finding (integrated into the diagnostic tool), Dialogys.

Wiring Diagrams:

–Visu-Schéma (CD-ROM), paper.

Type of diagnostic tools

–CLIP + multiplex line sensor

Special tooling required

3. REMINDERS

Procedure

To run fault finding on the vehicle computers, proceed as follows:

–turn the ignition key to APC,

–connect the diagnostic tool and perform the required operations.

To cut off the + after ignition feed, proceed as follows:

–disconnect the diagnostic tool,

–turn the ignition key to OFF,

–switch off the ignition. Vehicle(s): New Twingo

Function concerned: Climate controlComputer name: CAREG

Vdiag No.: 44

Special tooling required

Multimeter

Elé. 1681 Universal bornier

CLIM_V44_PRELI

Vdiag No.: 44

MR-413-X44-62B000$046_eng.mif

Page 3 of 99

62B-3

MR-413-X44-62B000$046_eng.mif

V1

CLIMATE CONTROL

Fault finding - Introduction

Vdiag No.: 44

62B

Faults

Faults are declared as either present or stored (depending on whether they appeared in a certain context and have

disappeared since, or whether they remain present but have not been diagnosed within the current context).

The present or stored status of faults should be taken into consideration when the diagnostic tool is switched on

after the + after ignition feed (without any system components being active).

For a present fault, apply the procedure described in the Interpretation of faults section.

For a stored fault, note the faults displayed and apply the Notes section.

If the fault is confirmed when the instructions in the Notes section are applied, the fault is present. Deal with the

fault.

If the fault is not confirmed, check:

–the electrical lines which correspond to the fault,

–the connectors on these lines (corrosion, bent pins, etc.),

–the resistance of the component detected as faulty,

–the condition of the wires (melted or split insulation, wear).

Conformity check

The aim of the conformity check is to check data that does not produce a fault on the diagnostic tool because the

data is inconsistent. Therefore, this stage is used to:

–carry out fault finding on faults that do not have a fault display, and which may correspond to a customer

complaint.

–check that the system is operating correctly and that there is no risk of a fault recurring after repairs.

This section gives the fault finding procedures for statuses and parameters and the conditions for checking them.

If a status is not behaving normally or a parameter is outside the permitted tolerance values, consult the

corresponding fault finding page.

Special notes on the conformity check for the air conditioning function:

All variables (statuses and parameters) and commands required for the air conditioning function are divided into

three sub-functions:

●The COLD LOOP sub-function groups together all the information required for producing cold air.

●The HEATING sub-function groups together all the information required for producing warm air.

●The PASSENGER COMPARTMENT VENTILATION sub-function groups together all the information relating to

ventilation and the mixing and distribution of air within the passenger compartment.

Page 21 of 99

62B-21

MR-413-X44-62B000$276_eng.mif

V1

62B

CLIMATE CONTROL

Fault finding - Replacement of components

REPLACING THE CLIMATE CONTROL COMPUTER

–Note the computer configuration according to the optional equipment fitted on the vehicle (see climate control

computer configuration) or using the Shared World Information (ICM).

–Ensure that the ignition is switched off.

–After approval from the Techline, replace the computer.

–Switch on the ignition and carry out a check using the diagnostic tool.

–Configure the computer according to the vehicle specifications.

–Switch off the ignition and then back on for the configurations to register.

–Check in the Read configuration menu that the configurations have been recognised correctly.

–Check for faults and apply the corresponding fault finding procedure for any faults shown on the diagnostic tool.

–Clear any stored faults.

–Run command VP001 Enter VIN.

–Start the engine, switch on the air conditioning and ensure that it is operating correctly. WARNING

Before replacing the climate control computer, check that it is faulty (read faults, conformity of variables,

read customer complaints). Replacement of the computer must be authorised by the Techline after a fault

finding log has been completed and submitted.

Vdiag No.: 44

MR-413-X44-62B000$276_eng.mif

Page 23 of 99

62B-23

MR-413-X44-62B000$322_eng.mif

V1

CLIMATE CONTROL

Fault finding - Configuration and programming

Vdiag No.: 44

62B

MIXING AND DISTRIBUTION MOTOR PROGRAMMING PROCEDURE:

There is no specific programming operation for the air mixing motor or the distribution motor.

However, the minimum and maximum limits of these motors have to be programmed. This operation is automatic

and is performed in the following cases:

–after communication using the diagnostic tool, the next time ignition is switched on,

–if a fault, declared as present when the ignition was switched off, disappears the next time the ignition is switched

on.

WARNING

It is imperative that communication is established with the diagnostic tool (to initiate programming the

next time the ignition is switched on) after any operation on the distribution and mixing motors or on the

control panel.

Page 25 of 99

62B-25

MR-413-X44-62B000$414_eng.mif

V1

62B

CLIMATE CONTROL

Fault finding - Interpretation of faults

DF001

PRESENT

OR

STOREDCOMPUTER

1. DEF: Internal electronic fault

NOTESConditions for running fault finding on a present or stored fault:

Apply this fault finding procedure if the fault reappears as present or stored after the

ignition is switched of f and on again.

Switch off the ignition and wait for the immobiliser warning light (Power-latch) to come one,

–Switch on the ignition again.

–Start the engine and switch on the air conditioning.

If the fault recurs, contact the Techline.

If the fault does not reappear: leave the climate control switched on and select various ventilation and air

distribution settings to check that the system is operating correctly.

–Check that no fault is displayed.

If the fault is still present, contact the Techline.

AFTER REPAIRFollow the instructions to confirm repair.

If the computer was replaced (at the request of the Techline), reconfigure the

computer (see Configurations and programming).

Deal with any other faults.

CLIM_V44_DF001

Vdiag No.: 44

MR-413-X44-62B000$414_eng.mif

Page 26 of 99

62B-26

MR-413-X44-62B000$414_eng.mif

V1

CLIMATE CONTROL

Fault finding - Interpretation of faults

Vdiag No.: 44

62B

DF007

PRESENT

OR

STOREDINTERIOR TEMPERATURE SENSOR CIRCUIT

CC.0 : Short circuit to earth

CO.1 : Short circuit or open circuit to + 12 V

NOTESConditions for running fault finding on a present or stored fault:

Apply this fault finding procedure if the fault reappears as present or stored after the

ignition is switched on and air conditioning activation is requested with the engine

running.

Special notes:

The interior temperature sensor is located at the top of the roof in the unit under the

rear view mirror.

Use the Wiring Diagram Technical Note for the New Twingo.

Check the connection and condition (possible wiring damage) of the connector of component 1872.

If the connector is faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for the

repair), repair the connector, otherwise replace the wiring.

With connector A of component 419 and connector of union R301 disconnected, check the insulation and

continuity of the following connections between components R301 (dashboard/interior lights intermediate union)

and 419.

●connection 38JN

●connection 38GZ

If the connection or connections are faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring:

Precautions for repair), repair the wiring, otherwise replace it.

With the connector of component 1872 disconnected, check the insulation and continuity of the following

connections between components R301 (dashboard/interior lights intermediate union) and 1872.

●connection 38JN

●connection 38GZ

If the connection or connections are faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring:

Precautions for repair), repair the wiring, otherwise replace it.

Check the insulation of connections 38JN and 38GZ of component 1872.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Check the resistance of component 1872 between connections 38JN and 38GZ.

Replace the sensor if the resistance is not 10 kΩΩ Ω Ω

± 500 ΩΩ Ω Ω

at 25 ˚C. For more details, consult the electrical

specifications of the sensor according to the temperature (see Help).

If the fault is still present, contact the Techline.

AFTER REPAIRClear the stored faults.

Follow the instructions to confirm repair.

Deal with any other faults.

CLIM_V44_DF007

Page 27 of 99

62B-27

MR-413-X44-62B000$414_eng.mif

V1

CLIMATE CONTROL

Fault finding - Interpretation of faults

Vdiag No.: 44

62B

DF010

PRESENT

OR

STOREDMIXING MOTOR CIRCUIT

CO.0 : Open circuit or short circuit to earth

CC.1 : Short circuit to + 12 V

NOTESConditions for running fault finding on a present or stored fault:

The fault is declared present when the temperature control is activated (minimum or

maximum temperature request and air conditioning control panel on).

Special notes:

Wait 1 minute after repairing the fault so that the climate control computer can control

the mixer motor. To avoid having to wait for 1 minute, switch the ignition off and then

back on again.

There is no specific programming operation for the mixing motor, however, after it has

been replaced, the motor needs to program its limits (minimum and maximum).

Use the Wiring Diagram Technical Note for the New Twingo.

Check the connection and condition of the connector of component 420.

If the connector is faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for the

repair), repair the connector, otherwise replace the wiring.

With connector B of component 419 disconnected, check the insulation and continuity of the following

connections between components 419 and 420:

●connection 38LC

●connection 38LD

●connection 38LG

●connection 38LH

If the connection or connections are faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring:

Precautions for repair), repair the wiring, otherwise replace it.

Connector of component 1115 disconnected,

Check the insulation and continuity of connection S between components 419 and 420.

If the connection or connections are faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring:

Precautions for repair), repair the wiring, otherwise replace it.

Connector of component 419 connected and ignition on,

●Check for 12 V supply on connection S of component 420 in relation to earth NAM.

If the connection is faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for the

repair), repair the wiring, otherwise replace the wiring.

If the supply is not present and if no faulty connections are detected during the continuity checks, contact your

Techline.

AFTER REPAIRClear the stored faults.

Follow the instructions to confirm repair.

If the motor has been replaced (see Configuration and programming).

Deal with any other faults.

CLIM_V44_DF010

Page 29 of 99

62B-29

MR-413-X44-62B000$414_eng.mif

V1

CLIMATE CONTROL

Fault finding - Interpretation of faults

Vdiag No.: 44

62B

DF012

PRESENT

OR

STOREDDISTRIBUTION MOTOR CIRCUIT

CO.0 : Open circuit or short circuit to earth

CC.1 : Short circuit to + 12 V

NOTESConditions for running fault finding on a present or stored fault:

The fault is declared present with the air conditioning control panel on and the

distribution control activated (de-icing, ventilation, footwells, etc.).

Special notes:

Wait 1 minute after repairing the fault so that the climate control computer can control

the distribution motor. To avoid having to wait for 1 minute, switch the ignition off and

then back on again.

There is no specific programming operation for the distribution motor, however, after it

has been replaced, the motor needs to program its limits (minimum and maximum).

Use the Wiring Diagram Technical Note for the New Twingo.

Check the connection and condition of the connector of component 1115.

If the connector is faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for the

repair), repair the connector, otherwise replace the wiring.

With connector of component 419 disconnected, check the insulation and continuity of the following

connections between components 419 and 1115:

●connection 38KY

●connection 38KZ

●connection 38LA

●connection 38LB

If the connection or connections are faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring:

Precautions for repair), repair the wiring, otherwise replace it.

With the connector of component 420 disconnected, check the insulation and continuity of connection S

between components 419 and 1115.

If the connection or connections are faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring:

Precautions for repair), repair the wiring, otherwise replace it.

Connector of component 419 connected and ignition on (air conditioning control panel on).

Check for 12 V supply on connection S of component 1115 in relation to earth NAM.

If the connection is faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for the

repair), repair the wiring, otherwise replace the wiring.

If the supply is not present and if no faulty connections are detected during the continuity checks, contact your

Techline.

AFTER REPAIRClear the stored faults.

Follow the instructions to confirm repair.

If the motor has been replaced (see Configuration and programming).

Deal with any other faults.

CLIM_V44_DF012

Page 31 of 99

62B-31

MR-413-X44-62B000$414_eng.mif

V1

CLIMATE CONTROL

Fault finding - Interpretation of faults

Vdiag No.: 44

62B

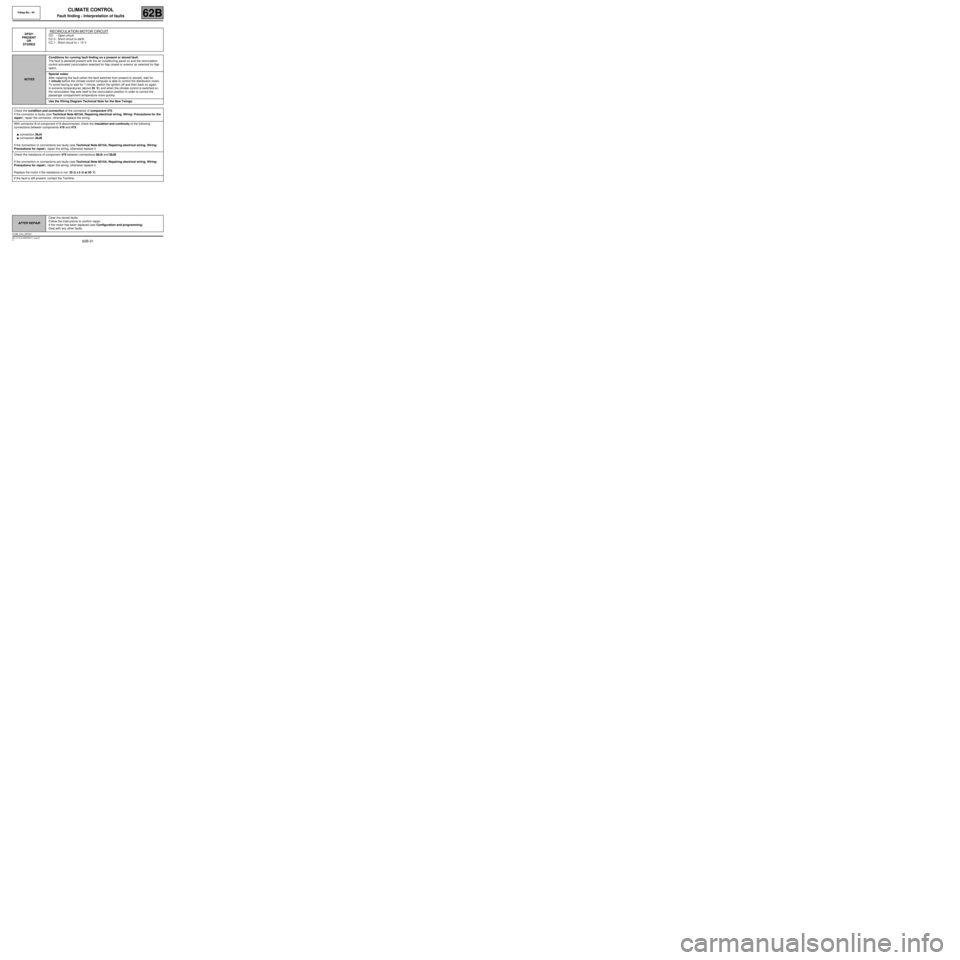

DF021

PRESENT

OR

STORED RECIRCULATION MOTOR CIRCUIT

CO : Open circuit

CC.0 : Short circuit to earth

CC.1 : Short circuit to + 12 V

NOTESConditions for running fault finding on a present or stored fault:

The fault is declared present with the air conditioning panel on and the recirculation

control activated (recirculation selected for flap closed or exterior air selected for flap

open).

Special notes:

After repairing the fault (when the fault switches from present to stored), wait for

1 minute before the climate control computer is able to control the distribution motor.

To avoid having to wait for 1 minute, switch the ignition off and then back on again.

In extreme temperatures (above 35 ˚C) and when the climate control is switched on,

the recirculation flap sets itself to the recirculation position in order to correct the

passenger compartment temperature more quickly.

Use the Wiring Diagram Technical Note for the New Twingo.

Check the condition and connection of the connector of component 475.

If the connector is faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for the

repair), repair the connector, otherwise replace the wiring.

With connector B of component 419 disconnected, check the insulation and continuity of the following

connections between components 419 and 475:

●connection 38JA

●connection 38JB

If the connection or connections are faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring:

Precautions for repair), repair the wiring, otherwise replace it.

Check the resistance of component 475 between connections 38JA and 38JB.

If the connection or connections are faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring:

Precautions for repair), repair the wiring, otherwise replace it.

Replace the motor if the resistance is not: 35 ΩΩ Ω Ω

± 5 ΩΩ Ω Ω

at 20 ˚C.

If the fault is still present, contact the Techline.

AFTER REPAIRClear the stored faults.

Follow the instructions to confirm repair.

If the motor has been replaced (see Configuration and programming).

Deal with any other faults.

CLIM_V44_DF021

Page 32 of 99

62B-32

MR-413-X44-62B000$460_eng.mif

V1

62B

CLIMATE CONTROL

Fault finding - Conformity check

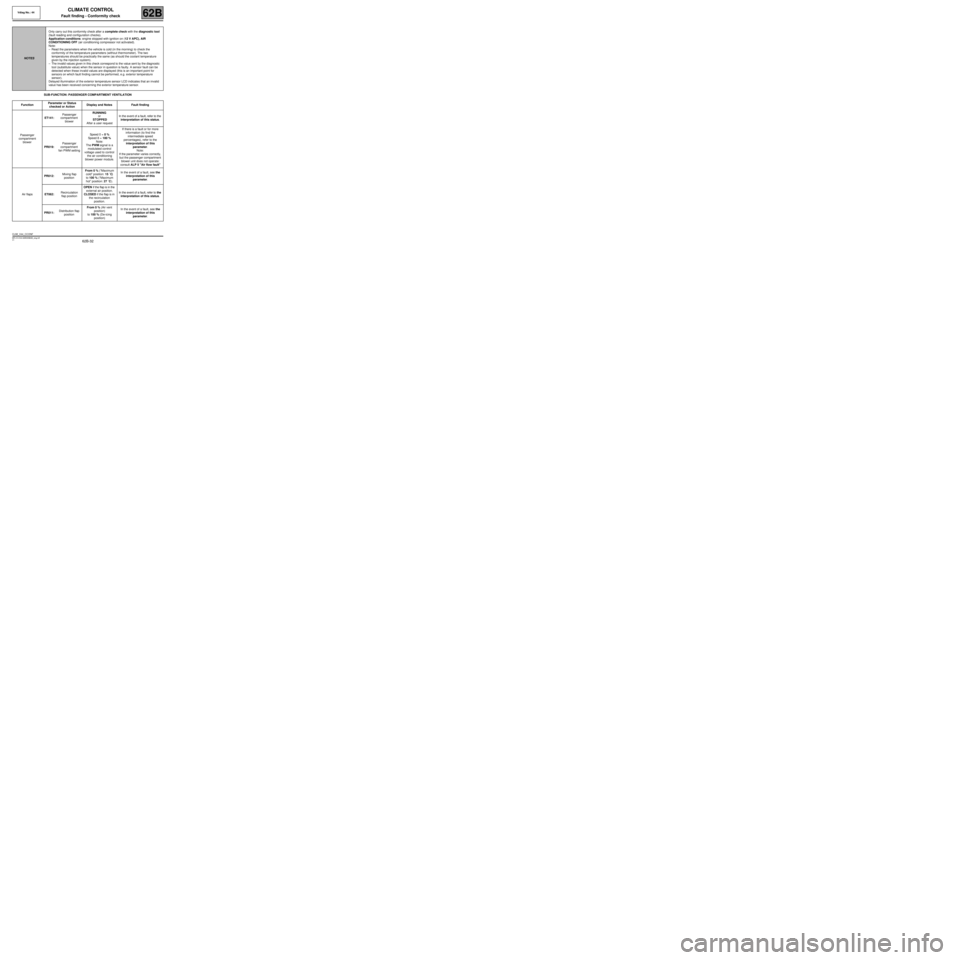

SUB-FUNCTION: PASSENGER COMPARTMENT VENTILATION

NOTESOnly carry out this conformity check after a complete check with the diagnostic tool

(fault reading and configuration checks).

Application conditions: engine stopped with ignition on (12 V APC), AIR

CONDITIONING OFF (air conditioning compressor not activated).

Note:

–Read the parameters when the vehicle is cold (in the morning) to check the

conformity of the temperature parameters (without thermometer). The two

temperatures should be practically the same (as should the coolant temperature

given by the injection system).

–The invalid values given in this check correspond to the value sent by the diagnostic

tool (substitute value) when the sensor in question is faulty. A sensor fault can be

detected when these invalid values are displayed (this is an important point for

sensors on which fault finding cannot be performed, e.g. exterior temperature

sensor).

Delayed illumination of the exterior temperature sensor LCD indicates that an invalid

value has been received concerning the exterior temperature sensor.

FunctionParameter or Status

checked or ActionDisplay and Notes Fault finding

Passenger

compartment

blowerET141:Passenger

compartment

blowerRUNNING

or

STOPPED

After a user requestIn the event of a fault, refer to the

interpretation of this status.

PR019:Passenger

compartment

fan PWM settingSpeed 0 = 0 %

Speed 8 = 100 %

Note:

The PWM signal is a

modulated control

voltage used to control

the air conditioning

blower power module.If there is a fault or for more

information (to find the

intermediate speed

percentages), refer to the

interpretation of this

parameter.

Note:

If the parameter varies correctly,

but the passenger compartment

blower unit does not operate:

consult ALP 5 "Air flow fault"

Air flapsPR012:Mixing flap

positionFrom 0 % (“Maximum

cold” position: 15 ˚C)

to 100 % (“Maximum

hot” position: 27 ˚C).In the event of a fault, see the

interpretation of this

parameter.

ET062:Recirculation

flap positionOPEN if the flap is in the

external air position.

CLOSED if the flap is in

the recirculation

position.In the event of a fault, refer to the

interpretation of this status.

PR011:Distribution flap

positionFrom 0 % (Air vent

position)

to 100 % (De-icing

position)In the event of a fault, see the

interpretation of this

parameter.

CLIM_V44_CCONF

Vdiag No.: 44

MR-413-X44-62B000$460_eng.mif