warning RENAULT TWINGO RS 2009 2.G Panelwork Owner's Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 209

Page 84 of 209

41C-9

SIDE LOWER STRUCTURE

Sill panel closure panel: General description

41C

If there are other issues regarding access to mating fa-

ces, the various options are described in the basic ins-

tructions for structural bodywork repair (see MR 400). WARNING

If the mating faces of the parts to be welded are not

accessible, make EGW plug welds to replace the

original resistance welds (see MR 400).

Page 85 of 209

41C-10

SIDE LOWER STRUCTURE

Sill panel closure panel: Description

41C

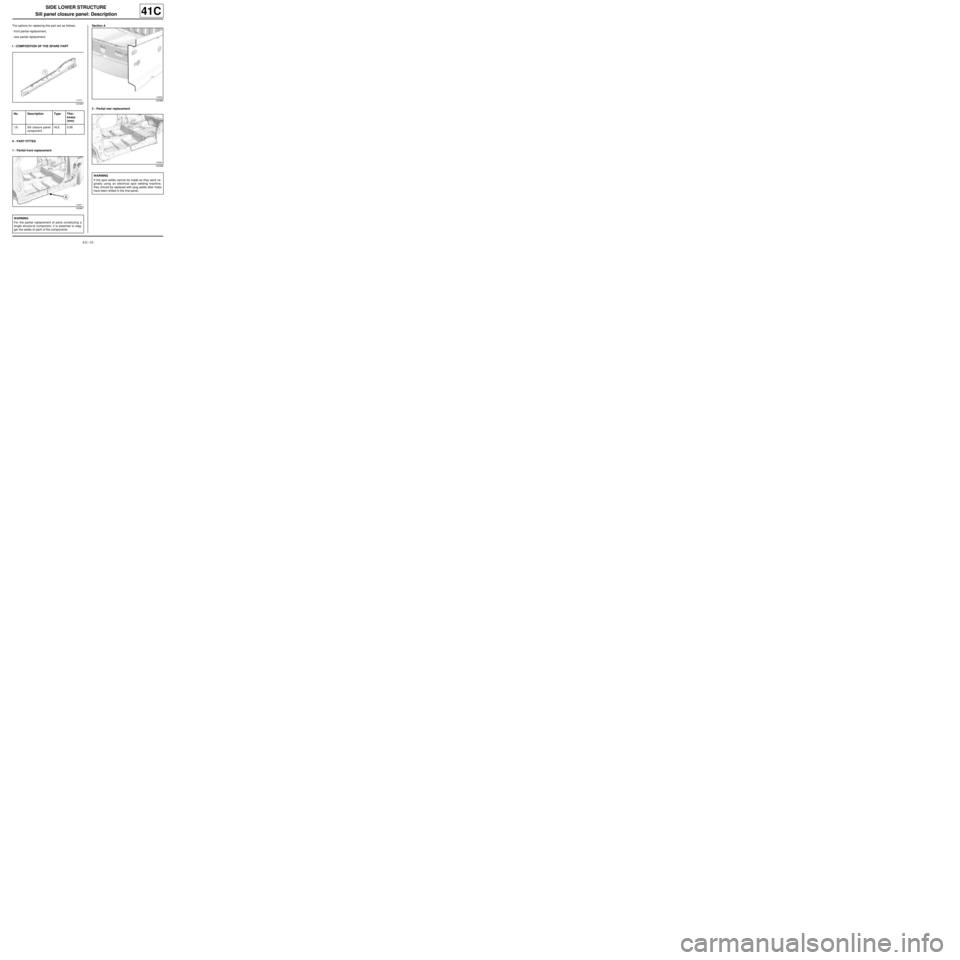

The options for replacing this part are as follows:

-front partial replacement,

-rear partial replacement.

I - COMPOSITION OF THE SPARE PART

II - PART FITTED

1 - Partial front replacementSection A

2 - Partial rear replacement

121057

No. Description Type Thic-

kness

(mm)

(1) Sill closure panel

componentHLE 0.95

120967

WARNING

For the partial replacement of parts constituting a

single structural component, it is essential to stag-

ger the welds of each of the components.

120965

120966

WARNING

If the spot welds cannot be made as they were ori-

ginally using an electrical spot welding machine,

they should be replaced with plug welds after holes

have been drilled in the first panel.

Page 88 of 209

41C-13

SIDE LOWER STRUCTURE

Sill panel reinforcement: Description

41C

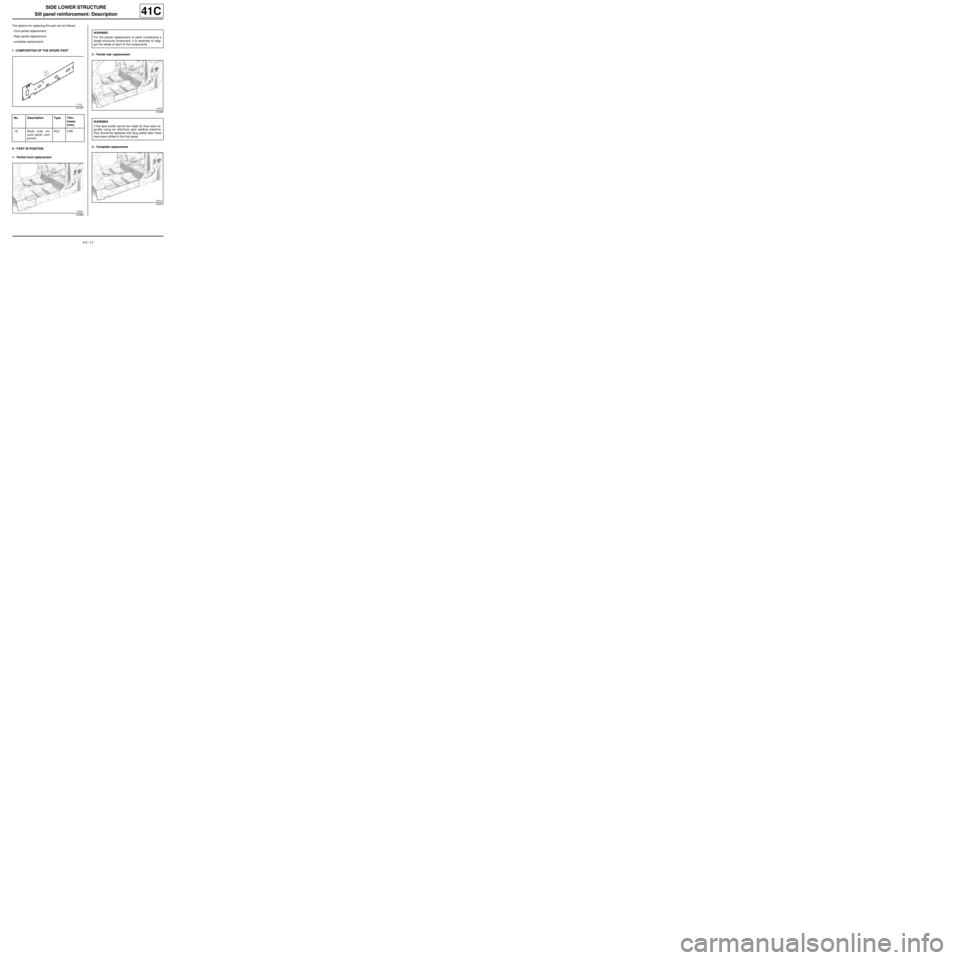

The options for replacing this part are as follows:

-front partial replacement,

-Rear partial replacement

-complete replacement.

I - COMPOSITION OF THE SPARE PART

II - PART IN POSITION

1 - Partial front replacement2 - Partial rear replacement

3 - Complete replacement

121051

No. Description Type Thic-

kness

(mm)

(1) Body side clo-

sure panel com-

ponentHLE 0.85

120969

WARNING

For the partial replacement of parts constituting a

single structural component, it is essential to stag-

ger the welds of each of the components.

120968

WARNING

If the spot welds cannot be made as they were ori-

ginally using an electrical spot welding machine,

they should be replaced with plug welds after holes

have been drilled in the first panel.

120970

Page 90 of 209

41C-15

SIDE LOWER STRUCTURE

Sill panel stiffener: Description

41C

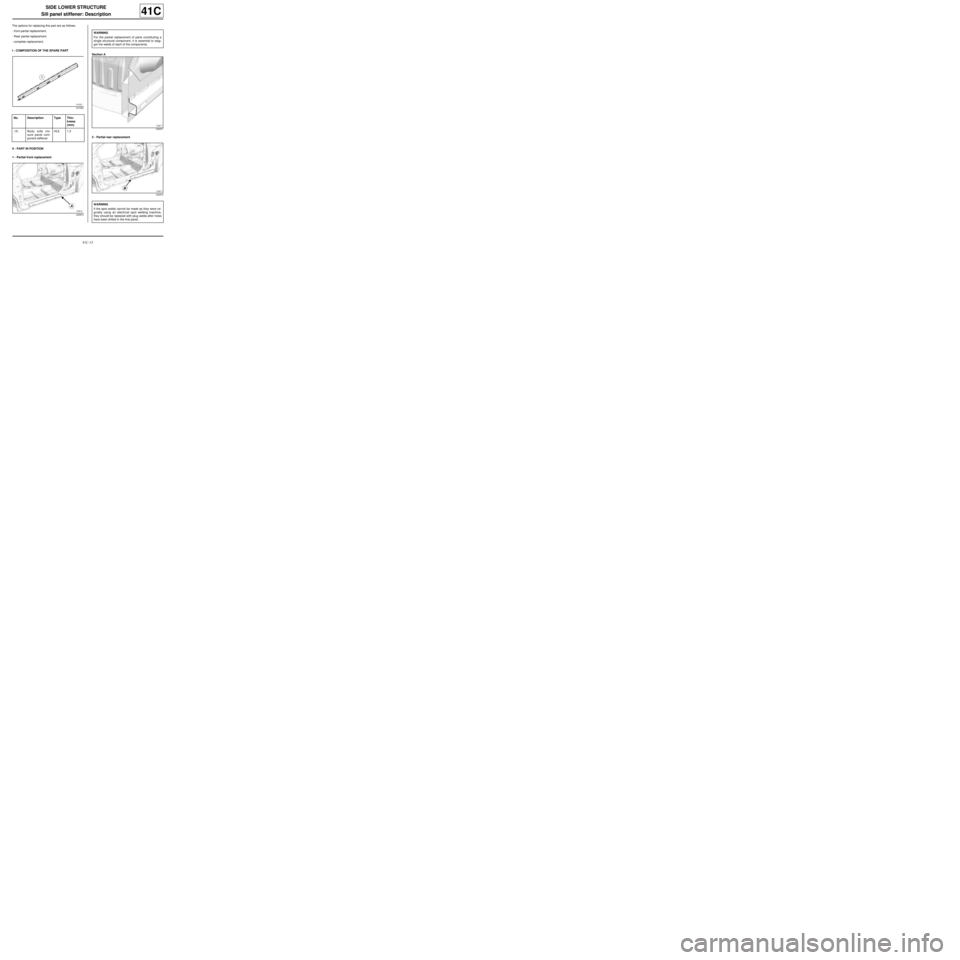

The options for replacing this part are as follows:

-front partial replacement,

-Rear partial replacement

-complete replacement.

I - COMPOSITION OF THE SPARE PART

II - PART IN POSITION

1 - Partial front replacementSection A

2 - Partial rear replacement

121052

No. Description Type Thic-

kness

(mm)

(1) Body side clo-

sure panel com-

ponent stiffenerHLE 1.2

120974

WARNING

For the partial replacement of parts constituting a

single structural component, it is essential to stag-

ger the welds of each of the components.

120971

120973

WARNING

If the spot welds cannot be made as they were ori-

ginally using an electrical spot welding machine,

they should be replaced with plug welds after holes

have been drilled in the first panel.

Page 93 of 209

41D-2

REAR LOWER STRUCTURE

Rear floor: Description

41D

II - PART FITTED

1 - Partial rear replacement

2 - Complete replacement No. Description Type Thic-

kness

(mm)

(1) Cross member HLE 1.5

(2) Reservoir front

centre mountingHLE 1.17

(3) Rear seat run-

ners front stiffe-

nerMild

steel1.2

(4) Rear floor Mild

steel0.65

(5) Rear tow eye

mountingMild

steel1.8

(6) Emergency spare

wheel bridge

mounting piece

unitMild

steel1.17

(7) Emergency spare

wheel arch rear

stiffenerHLE 1.5

(8) Left-hand rear

seat stiffener

mountingHLE 1.7

(9) Rear seat rear

centre stiffener

mountingHLE 1.7

(10) Right-hand rear

seat rear stiffe-

ner mountingHLE 1.7

120988

120987

WARNING

If the spot welds cannot be made as they originally

were with an electrical spot welding machine, they

should be replaced with securing beads.

Page 97 of 209

41D-6

REAR LOWER STRUCTURE

Rear side member assembly: Description

C44

41D

II - PART FITTEDIII - POSITIONING OF LOCAL ELECTRICAL

EARTHS No. Description Type Thic-

kness

(mm)

(1) Rear side mem-

ber reinforcementHLE1.5

(2) Connection com-

ponent reinforce-

mentHLE1.5

(3) Rear spring cup

reinforcementHLE1.5

(4) Side cross mem-

ber reinforcementMild

steel0.95

(5) Lower section of

rear side cross

memberHLE0.95

(6) Upper section of

rear side cross

memberHLE0.95

(7) Rear axle bea-

ring spacerHLE2.5

(8) Rear spring cup HLE1.5

(9) Rear side mem-

berHLE1.5

(10) Exhaust moun-

ting stiffenerMild

steel2

120977

IMPORTANT

If the mating faces of the parts to be welded are not

accessible, make EGW plug welds to replace the

original resistance welds (see MR 400).

121249

WARNING

To avoid damaging the vehicles electric and electro-

nic components, the earths of any wiring harness

near the weld area must be disconnected.

Position the earth of the welding machine as closely

as possible to the weld area (see MR 400).

Page 98 of 209

41D-7

REAR LOWER STRUCTURE

Rear side member: General description

41D

I - DESIGN OF THE STRUCTURAL COMPONENT

This is a basic part; it simply fulfils the function of a rear

side member.II - AREA TO BE CUT FOR PARTIAL

REPLACEMENT

Cut 1:

This line marks the area in which it is possible to make

a partial replacement.

This marking shows the area in which it is possible to

make a partial replacement.

III - ASSEMBLY INSTRUCTIONS FOR A PARTIAL

REPLACEMENT

Only the connections which are specific to the partial

replacement by cutting are indicated.

If there are other issues regarding access to mating fa-

ces, the various replacement options are described in

the basic instructions for structural bodywork repair

(see MR 400). IMPORTANT

Use a repair bench to ensure the positioning of the

points and the geometr y of the axle assemblies.

Note:

The information contained in the following descri-

bes the general repair procedure for all vehicles

having the same design for this part.

Before reading this general information, check that

there are no special notes associated with this vehi-

cle. These special notes will be specified if applica-

ble in other parts of this subsection dealing with the

par t.

Note:

For a detailed description of a particular connec-

tion, see MR 400.

121042

120979

WARNING

If the mating faces of the parts to be welded are not

accessible, make EGW plug welds to replace the

original resistance welds (see MR 400).

Page 99 of 209

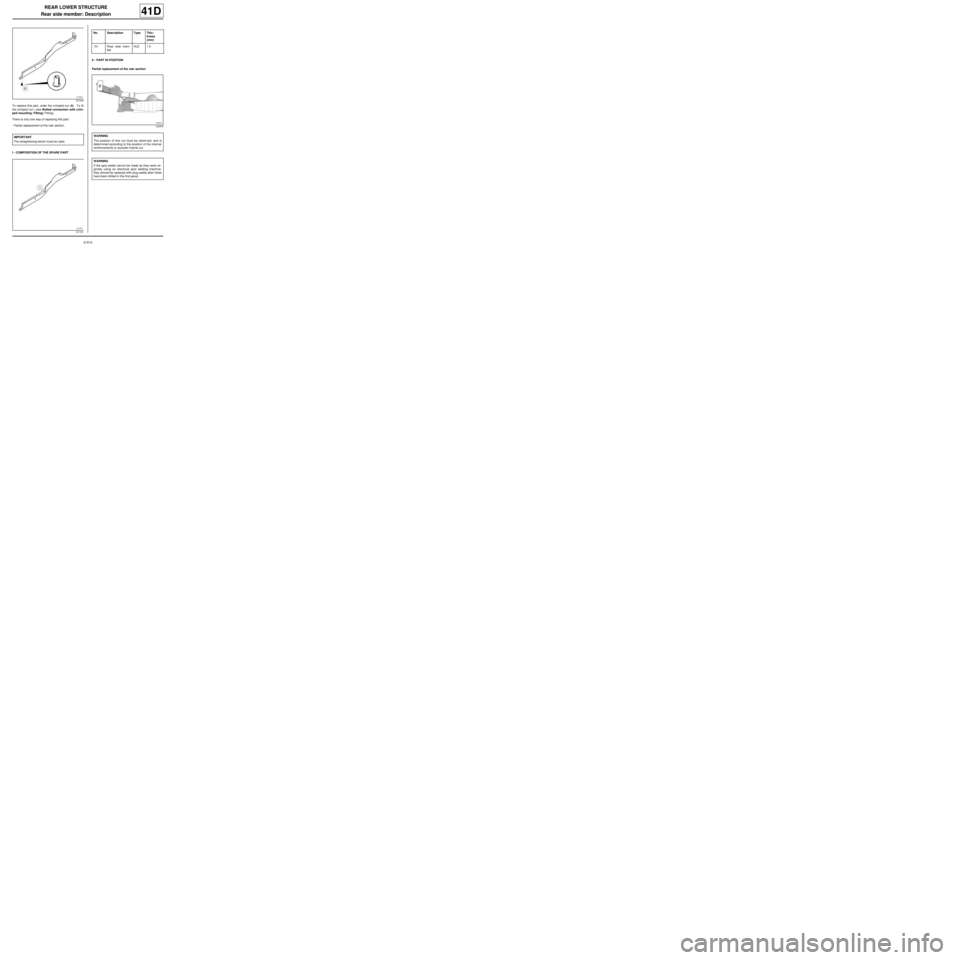

41D-8

REAR LOWER STRUCTURE

Rear side member: Description

41D

To replace this part, order the crimped nut (A) . To fit

the crimped nut ( (see Bolted connection with crim-

ped mounting: Fitting) Fitting).

There is only one way of replacing this part:

-Partial replacement of the rear section.

I - COMPOSITION OF THE SPARE PARTII - PART IN POSITION

Partial replacement of the rear section

121043

IMPORTANT

The straightening bench must be used.

121181

No. Description Type Thic-

kness

(mm)

(1) Rear side mem-

berHLE 1.5

120979

WARNING

The position of this cut must be obser ved, and is

determined according to the position of the internal

reinforcements or acoustic inserts cut.

WARNING

If the spot welds cannot be made as they were ori-

ginally using an electrical spot welding machine,

they should be replaced with plug welds after holes

have been drilled in the first panel.

Page 101 of 209

41D-10

REAR LOWER STRUCTURE

Rear floor front cross member: General description

41D

I - DESIGN OF THE STRUCTURAL COMPONENT

This part is commonly called « cross member » .

The rear seat anchoring reinforcements are connected

to the rear floor front cross member.

II - AREA TO BE CUT FOR PARTIAL

REPLACEMENT

Cut 1:

This line marks the place in which it is possible to makea partial replacement. WARNING

The information contained in the following descri-

bes the general repair procedure for all vehicles

having the same design for this part.

Before reading this general information, check that

there are no special notes associated with this vehi-

cle. These special notes will be specified if applica-

ble in other parts of this subsection dealing with the

par t.

Note:

For a detailed description of a particular connec-

tion, see MR 400, 40A, General Information.

109662

110644

Page 102 of 209

41D-11

REAR LOWER STRUCTURE

Rear floor front cross member: General description

41D

This operation allows you to access the inside of the

hollow section of the structural element to straighten it.

III - ASSEMBLY INSTRUCTIONS FOR A PARTIAL

REPLACEMENT

Only the connections which are specific to the partial

replacement by cutting are indicated.

If there are other issues regarding access to mating fa-

ces, the various replacement options are described in

the basic instructions for structural bodywork repair

(see MR 400, 40A, General Information).

Line (2) on the diagram shows a joint made by joggling

connected with plug welds at regular intervals.WARNING

If the spot welds cannot be made as they were ori-

ginally using an electrical spot welding machine,

they should be replaced with plug welds after holes

have been drilled in the first panel.

110644