RENAULT TWINGO RS 2009 2.G Transmission Owners Manual

Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 135

Page 91 of 135

21B-31

SEQUENTIAL GEARBOX

Gear selection sensor: Removal - Refitting

D4F, and JH1

21B

REMOVAL

I - REMOVAL PREPARATION OPERATION

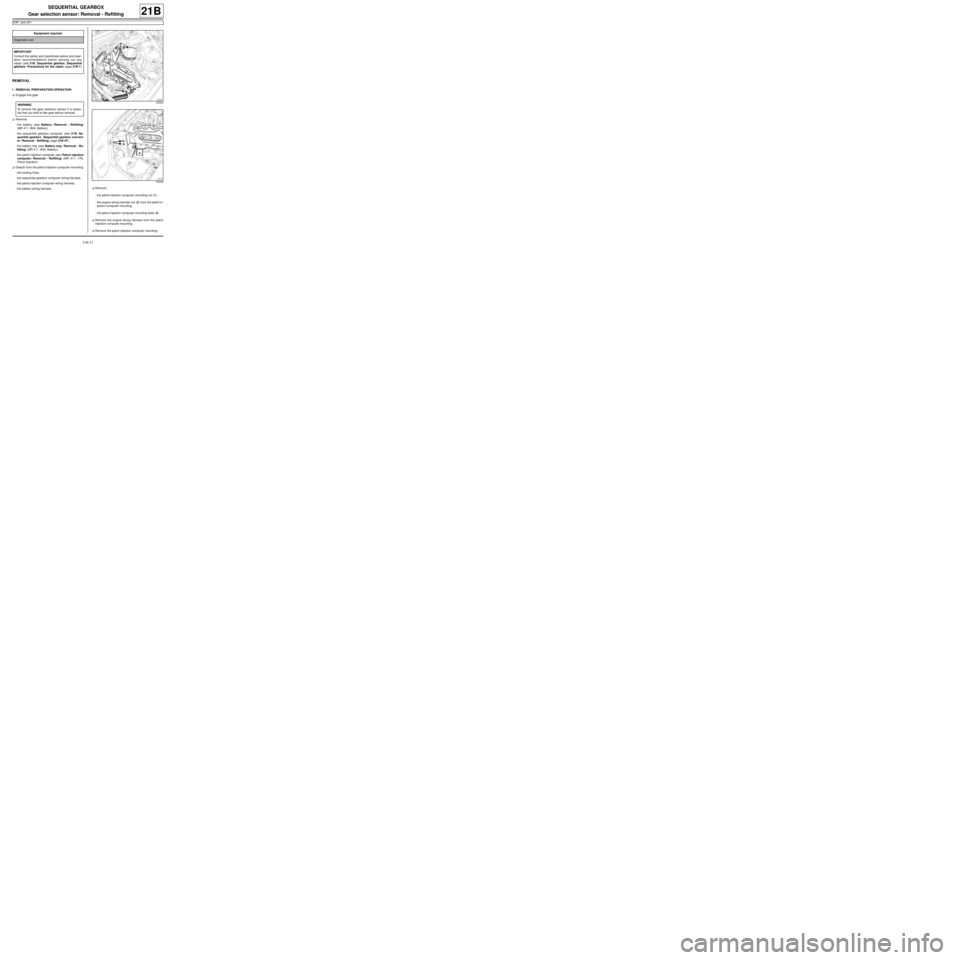

aEngage first gear

aRemove:

-the battery (see Battery: Removal - Refitting)

(MR 411, 80A, Battery),

-the sequential gearbox computer (see 21B, Se-

quential gearbox, Sequential gearbox convert-

er: Removal - Refitting, page 21B-47) ,

-the battery tray (see Battery tray: Removal - Re-

fitting) (MR 411, 80A, Battery),

-the petrol injection computer (see Petrol injection

computer: Removal - Refitting) (MR 411, 17B,

Petrol injection).

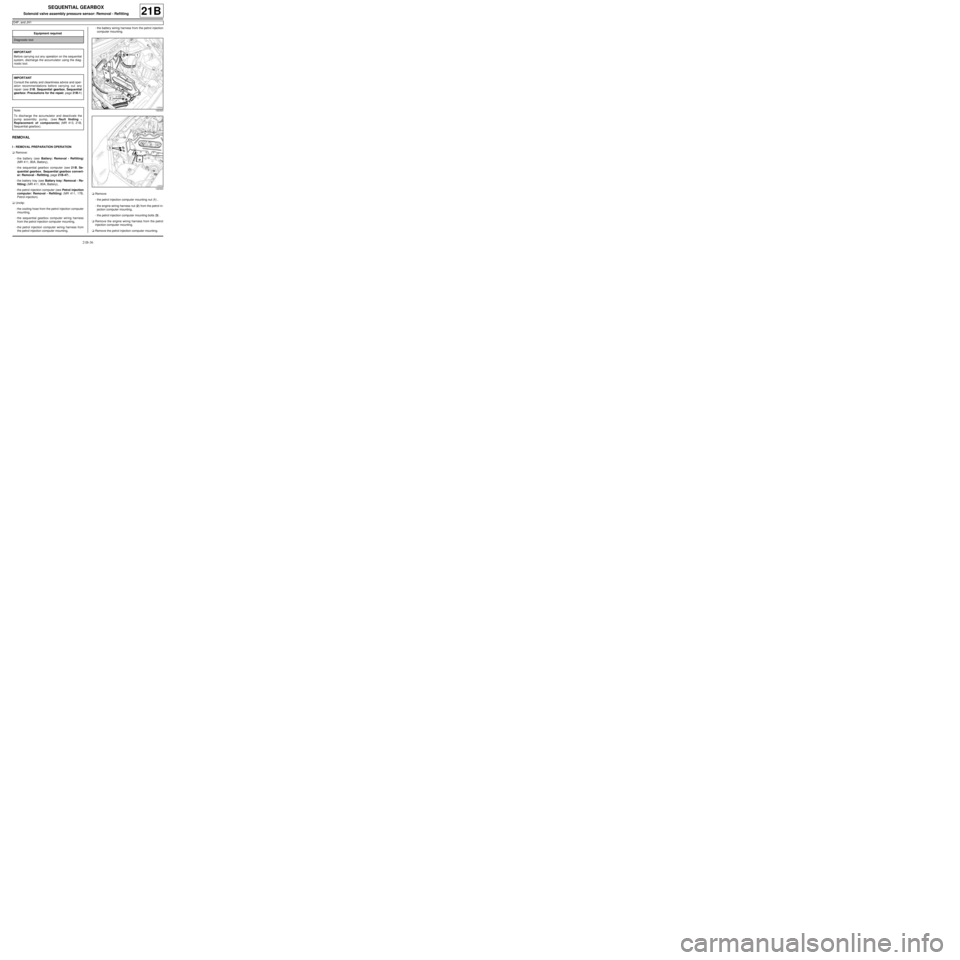

aDetach from the petrol injection computer mounting:

-the cooling hose,

-the sequential gearbox computer wiring harness,

-the petrol injection computer wiring harness,

-the battery wiring harness.aRemove:

-the petrol injection computer mounting nut (1) ,

-the engine wiring harness nut (2) from the petrol in-

jection computer mounting,

-the petrol injection computer mounting bolts (3) .

aRemove the engine wiring harness from the petrol

injection computer mounting.

aRemove the petrol injection computer mounting. Equipment required

Diagnostic tool

IMPORTANT

Consult the safety and cleanliness advice and oper-

ation recommendations before carrying out any

repair (see 21B, Sequential gearbox, Sequential

gearbox: Precautions for the repair, page 21B-1)

.

WARNING

To remove the gear selection sensor it is essen-

tial that you shift to first gear before removal.

122323

122322

Page 92 of 135

21B-32

SEQUENTIAL GEARBOX

Gear selection sensor: Removal - Refitting

D4F, and JH1

21B

II - OPERATION FOR REMOVAL OF PART

CONCERNED

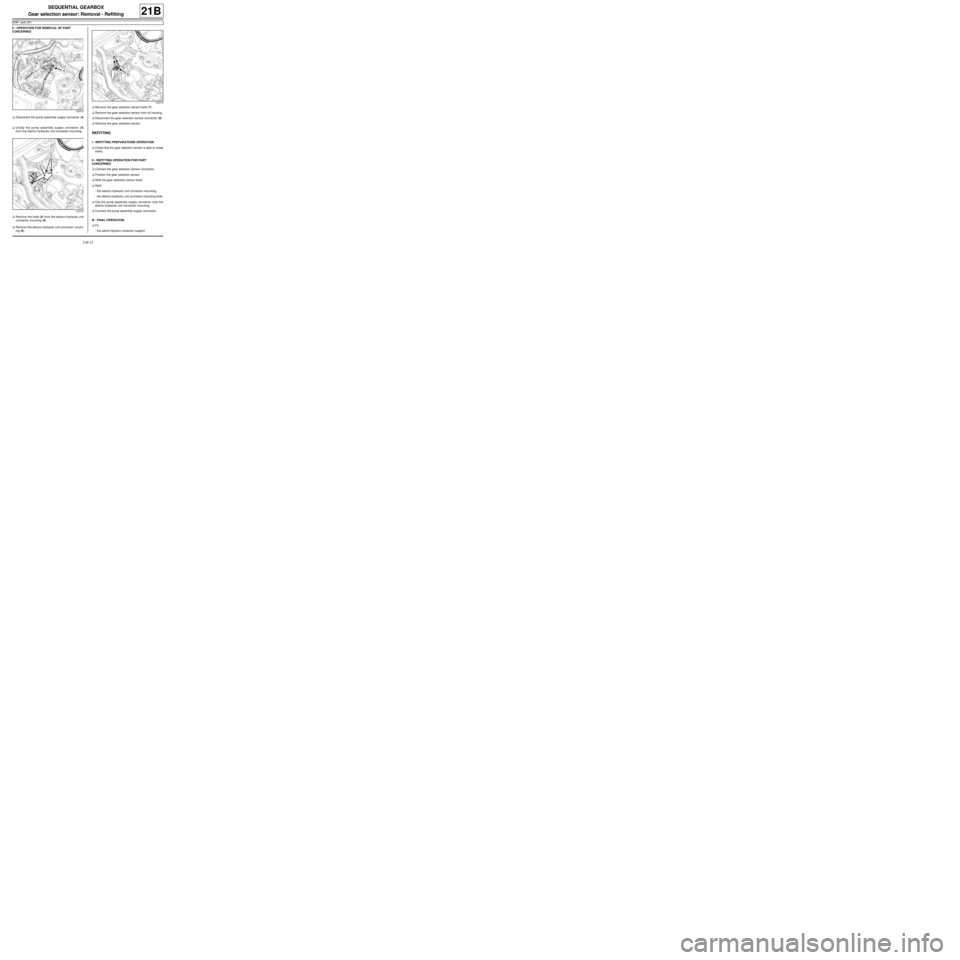

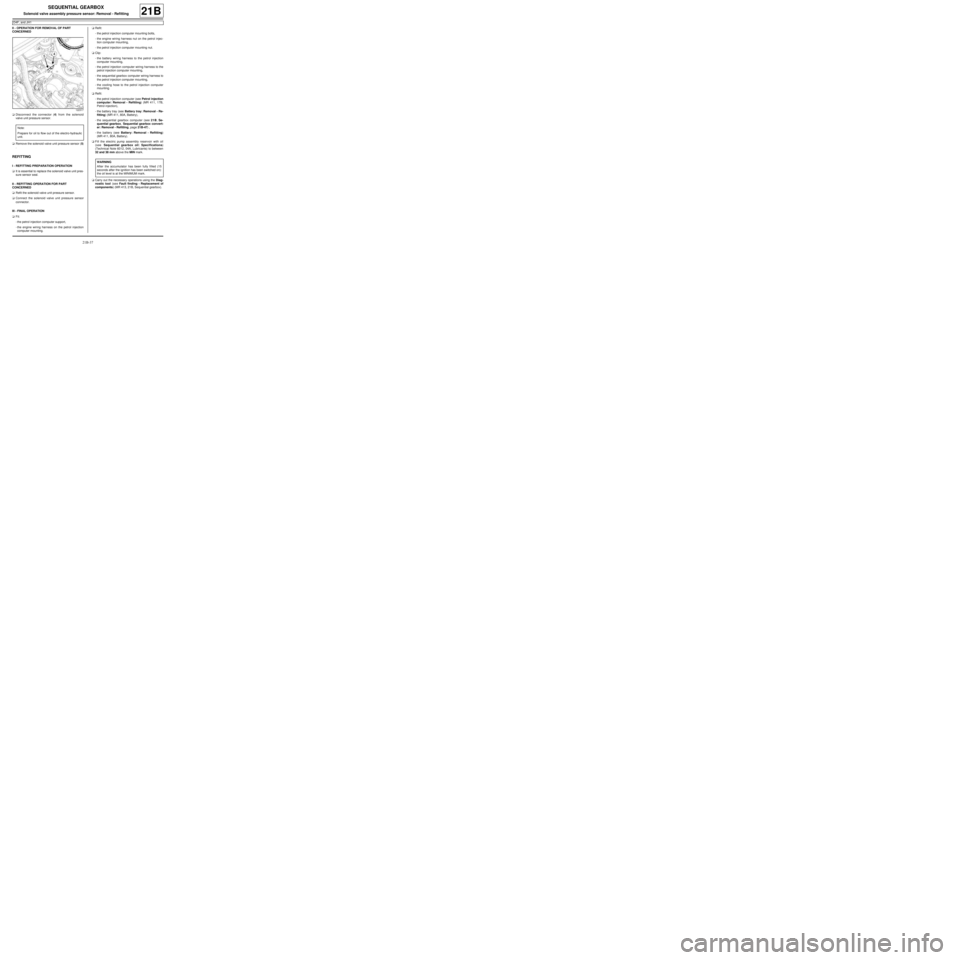

aDisconnect the pump assembly supply connector (4)

.

aUnclip the pump assembly supply connector (4)

from the electro-hydraulic unit connector mounting.

aRemove the bolts (5) from the electro-hydraulic unit

connector mounting (6) .

aRemove the electro-hydraulic unit connector mount-

ing (6) .aRemove the gear selection sensor bolts (7) .

aRemove the gear selection sensor from its housing.

aDisconnect the gear selection sensor connector (8) .

aRemove the gear selection sensor.

REFITTING

I - REFITTING PREPARATIONS OPERATION

aCheck that the gear selection sensor is able to rotate

freely.

II - REFITTING OPERATION FOR PART

CONCERNED

aConnect the gear selection sensor connector.

aPosition the gear selection sensor.

aRefit the gear selection sensor bolts.

aRefit:

-the electro-hydraulic unit connector mounting,

-the electro-hydraulic unit connector mounting bolts.

aClip the pump assembly supply connector onto the

electro-hydraulic unit connector mounting.

aConnect the pump assembly supply connector.

III - FINAL OPERATION.

aFit:

-the petrol injection computer support,

122313

122316

122318

Page 93 of 135

21B-33

SEQUENTIAL GEARBOX

Gear selection sensor: Removal - Refitting

D4F, and JH1

21B

-the engine wiring harness on the petrol injection

computer mounting.

aRefit:

-the petrol injection computer mounting bolts,

-the engine wiring harness nut on the petrol injec-

tion computer mounting,

-the petrol injection computer mounting nut.

aClip onto the petrol injection computer mounting:

-the battery wiring harness,

-the petrol injection computer wiring harness,

-the sequential gearbox computer wiring harness,

-the cooling hose.

aRefit:

-the petrol injection computer (see Petrol injection

computer: Removal - Refitting) (MR 411, 17B,

Petrol injection),

-the battery tray (see Battery tray: Removal - Re-

fitting) (MR 411, 80A, Battery),

-the sequential gearbox computer (see 21B, Se-

quential gearbox, Sequential gearbox convert-

er: Removal - Refitting, page 21B-47) ,

-the battery (see Battery: Removal - Refitting)

(MR 411, 80A, Battery),

aCarry out the necessary operations using the Diag-

nostic tool (see Fault finding - Replacement of

components) (MR 413, 21B, Sequential gearbox).

Page 94 of 135

21B-34

SEQUENTIAL GEARBOX

Clutch position sensor: Removal - Refitting

D4F, and JH1

21B

REMOVAL

I - REMOVAL PREPARATION OPERATION

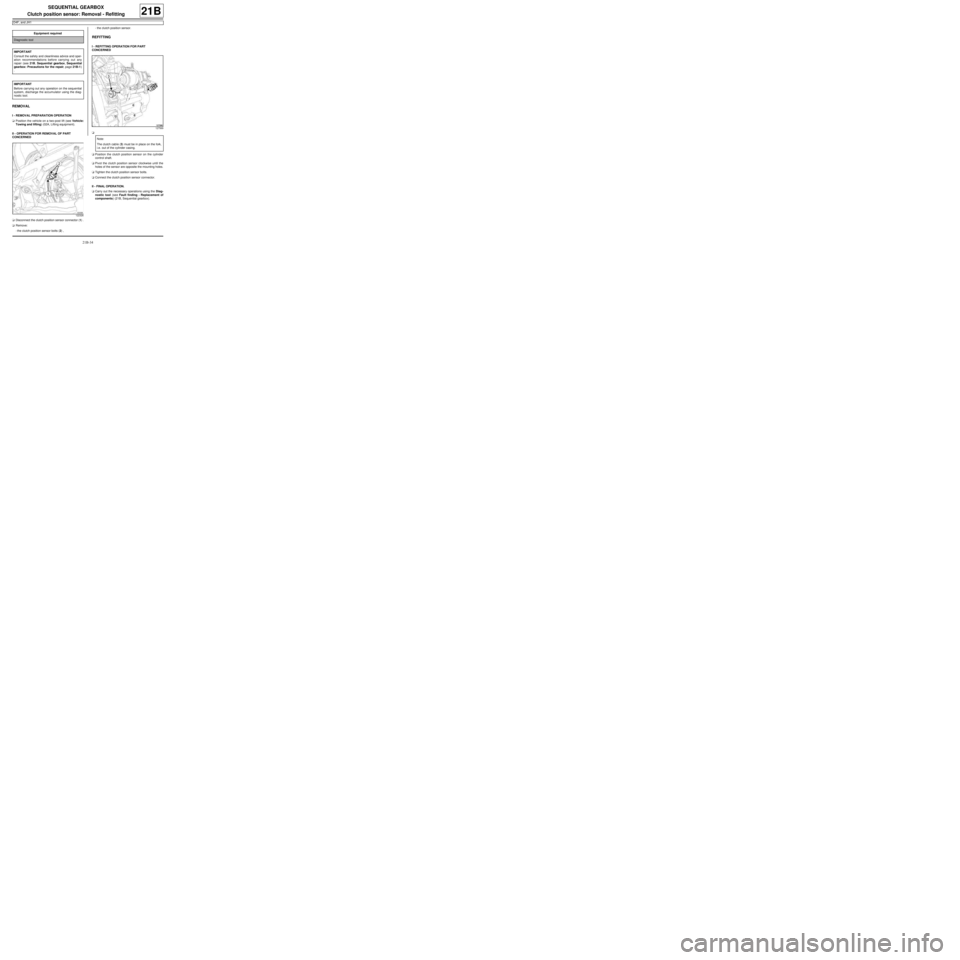

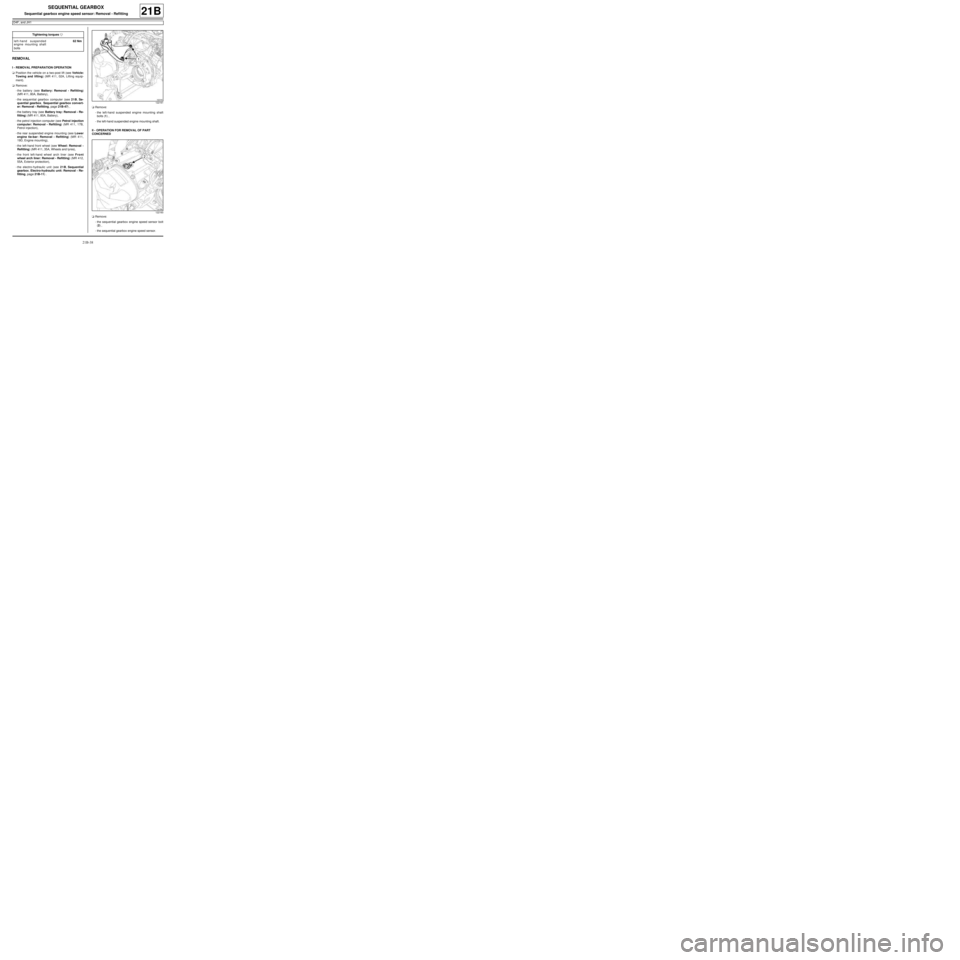

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the clutch position sensor connector (1) .

aRemove:

-the clutch position sensor bolts (2) ,-the clutch position sensor.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

a

aPosition the clutch position sensor on the cylinder

control shaft.

aPivot the clutch position sensor clockwise until the

holes of the sensor are opposite the mounting holes.

aTighten the clutch position sensor bolts.

aConnect the clutch position sensor connector.

II - FINAL OPERATION.

aCarry out the necessary operations using the Diag-

nostic tool (see Fault finding - Replacement of

components) (21B, Sequential gearbox). Equipment required

Diagnostic tool

IMPORTANT

Consult the safety and cleanliness advice and oper-

ation recommendations before carrying out any

repair (see 21B, Sequential gearbox, Sequential

gearbox: Precautions for the repair, page 21B-1)

.

IMPORTANT

Before carrying out any operation on the sequential

system, discharge the accumulator using the diag-

nostic tool.

122326

127569

Note:

The clutch cab le (3) must be in place on the fork,

i.e. out of the cylinder casing.

Page 95 of 135

21B-35

SEQUENTIAL GEARBOX

Clutch position sensor: Removal - Refitting

D4F, and JH1

21B

Page 96 of 135

21B-36

SEQUENTIAL GEARBOX

Solenoid valve assembly pressure sensor: Removal - Refitting

D4F, and JH1

21B

REMOVAL

I - REMOVAL PREPARATION OPERATION

aRemove:

-the battery (see Battery: Removal - Refitting)

(MR 411, 80A, Battery),

-the sequential gearbox computer (see 21B, Se-

quential gearbox, Sequential gearbox convert-

er: Removal - Refitting, page 21B-47) ,

-the battery tray (see Battery tray: Removal - Re-

fitting) (MR 411, 80A, Battery),

-the petrol injection computer (see Petrol injection

computer: Removal - Refitting) (MR 411, 17B,

Petrol injection).

aUnclip:

-the cooling hose from the petrol injection computer

mounting,

-the sequential gearbox computer wiring harness

from the petrol injection computer mounting,

-the petrol injection computer wiring harness from

the petrol injection computer mounting,-the battery wiring harness from the petrol injection

computer mounting.

aRemove:

-the petrol injection computer mounting nut (1) ,

-the engine wiring harness nut (2) from the petrol in-

jection computer mounting,

-the petrol injection computer mounting bolts (3) .

aRemove the engine wiring harness from the petrol

injection computer mounting.

aRemove the petrol injection computer mounting. Equipment required

Diagnostic tool

IMPORTANT

Before carrying out any operation on the sequential

system, discharge the accumulator using the diag-

nostic tool.

IMPORTANT

Consult the safety and cleanliness advice and oper-

ation recommendations before carrying out any

repair (see 21B, Sequential gearbox, Sequential

gearbox: Precautions for the repair, page 21B-1)

.

Note:

To discharge the accumulator and deactivate the

pump assembly pump, (see Fault finding -

Replacement of components) (MR 413, 21B,

Sequential gearbox).

122323

122322

Page 97 of 135

21B-37

SEQUENTIAL GEARBOX

Solenoid valve assembly pressure sensor: Removal - Refitting

D4F, and JH1

21B

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the connector (4) from the solenoid

valve unit pressure sensor.

aRemove the solenoid valve unit pressure sensor (5)

.

REFITTING

I - REFITTING PREPARATION OPERATION

aIt is essential to replace the solenoid valve unit pres-

sure sensor seal.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the solenoid valve unit pressure sensor.

aConnect the solenoid valve unit pressure sensor

connector.

III - FINAL OPERATION

aFit:

-the petrol injection computer support,

-the engine wiring harness on the petrol injection

computer mounting.aRefit:

-the petrol injection computer mounting bolts,

-the engine wiring harness nut on the petrol injec-

tion computer mounting,

-the petrol injection computer mounting nut.

aClip:

-the battery wiring harness to the petrol injection

computer mounting,

-the petrol injection computer wiring harness to the

petrol injection computer mounting,

-the sequential gearbox computer wiring harness to

the petrol injection computer mounting,

-the cooling hose to the petrol injection computer

mounting.

aRefit:

-the petrol injection computer (see Petrol injection

computer: Removal - Refitting) (MR 411, 17B,

Petrol injection),

-the battery tray (see Battery tray: Removal - Re-

fitting) (MR 411, 80A, Battery),

-the sequential gearbox computer (see 21B, Se-

quential gearbox, Sequential gearbox convert-

er: Removal - Refitting, page 21B-47) ,

-the battery (see Battery: Removal - Refitting)

(MR 411, 80A, Battery).

aFill the electric pump assembly reservoir with oil

(see Sequential gearbox oil: Specifications)

(Technical Note 6012, 04A, Lubricants) to between

32 and 38 mm above the MIN mark.

aCarry out the necessary operations using the Diag-

nostic tool (see Fault finding - Replacement of

components) (MR 413, 21B, Sequential gearbox).

122317

Note:

Prepare for oil to flow out of the electro-hydraulic

unit.

WARNING

After the accumulator has been fully filled (15

seconds after the ignition has been switched on):

the oil level is at the MINIMUM mark.

Page 98 of 135

21B-38

SEQUENTIAL GEARBOX

Sequential gearbox engine speed sensor: Removal - Refitting

D4F, and JH1

21B

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aRemove:

-the battery (see Battery: Removal - Refitting)

(MR 411, 80A, Battery),

-the sequential gearbox computer (see 21B, Se-

quential gearbox, Sequential gearbox convert-

er: Removal - Refitting, page 21B-47) ,

-the battery tray (see Battery tray: Removal - Re-

fitting) (MR 411, 80A, Battery),

-the petrol injection computer (see Petrol injection

computer: Removal - Refitting) (MR 411, 17B,

Petrol injection),

-the rear suspended engine mounting (see Lower

engine tie-bar: Removal - Refitting) (MR 411,

19D, Engine mounting),

-the left-hand front wheel (see Wheel: Removal -

Refitting) (MR 411, 35A, Wheels and tyres),

-the front left-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (MR 412,

55A, Exterior protection),

-the electro-hydraulic unit (see 21B, Sequential

gearbox, Electro-hydraulic unit: Removal - Re-

fitting, page 21B-11) .aRemove:

-the left-hand suspended engine mounting shaft

bolts (1) ,

-the left-hand suspended engine mounting shaft.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the sequential gearbox engine speed sensor bolt

(2) ,

-the sequential gearbox engine speed sensor. Tightening torquesm

left-hand suspended

engine mounting shaft

bolts62 Nm

122161

122160

Page 99 of 135

21B-39

SEQUENTIAL GEARBOX

Sequential gearbox engine speed sensor: Removal - Refitting

D4F, and JH1

21B

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the sequential gearbox engine speed sensor,

-the sequential gearbox engine speed sensor bolt.

II - FINAL OPERATION

aFit the left-hand suspended engine mounting shaft

onto the sequential gearbox.

aFit the left-hand suspended engine mounting shaft

bolts without tightening them.

aTorque tighten the left-hand suspended engine

mounting shaft bolts (62 Nm).

aRefit:

-the electro-hydraulic unit (see 21B, Sequential

gearbox, Electro-hydraulic unit: Removal - Re-

fitting, page 21B-11) ,

-the front left-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (MR 412,

55A, Exterior protection),

-the left-hand front wheel (see Wheel: Removal -

Refitting) (MR 411, 35A, Wheels and tyres),

-the rear suspended engine mounting (see Lower

engine tie-bar: Removal - Refitting) (MR 411,

19D, Engine mounting),

-the petrol injection computer (see Petrol injection

computer: Removal - Refitting) (MR 411, 17B,

Petrol injection),

-the battery tray (see Battery tray: Removal - Re-

fitting) (MR 411, 80A, Battery),

-the sequential gearbox computer (see 21B, Se-

quential gearbox, Sequential gearbox convert-

er: Removal - Refitting, page 21B-47) ,

-the battery (see Battery: Removal - Refitting)

(MR 411, 80A, Battery).

Page 100 of 135

21B-40

SEQUENTIAL GEARBOX

Sequential gearbox: Removal - Refitting

D4F, and JH1

21B

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aRemove:

-the battery (see Battery: Removal - Refitting)

(MR 411, 80A, Battery),

-the sequential gearbox computer (see 21B, Se-

quential gearbox, Sequential gearbox convert-

er: Removal - Refitting, page 21B-47) ,

-the battery tray (see Battery tray: Removal - Re-

fitting) (MR 411, 80A, Battery),

-the petrol injection computer (see Petrol injection

computer: Removal - Refitting) (MR 411, 17B,

Petrol injection),-the air filter unit (see Air filter unit: Removal - Re-

fitting) (MR 411, 12A, Fuel mixture),

-the front wheels (see Wheel: Removal - Refitting)

(MR 411, 35A, Wheels and tyres),

-the catalytic converter (see Catalytic converter:

Removal - Refitting) ,

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (MR 412, 55A, Exterior

protection),

-the front bumper (see Front bumper: Removal -

Refitting) (MR 412, 55A, Exterior protection).

aDrain:

-the cooling system (see Cooling system: Drain-

ing - Refilling) (MR 411, 19A, Cooling),

-the sequential gearbox (see 21A, Manual gear-

box, Manual gearbox oils: Draining - Filling,

page 21A-2) .

aDrain the refrigerant circuit (see Refrigerant circuit:

Draining - Filling) (MR 411, 62A, Air conditioning).

aRemove:

-the engine - gearbox assembly (see Engine -

gearbox assembly: Removal - Refitting) (MR

411, 10A, Engine and peripherals),

-the hub-carrier - driveshaft assembly (see ) (MR

411, 31A, Front axle components),

-the starter (see Starter: Removal - Refitting) (MR

411, 16A, Starting - Charging),

-the crankshaft position sensor (see Crankshaft

position sensor: Removal - Refitting) (MR 411,

17B, Petrol injection). Special tooling required

Mot. 1448Remote operation pliers for

hose clips .

Equipment required

workshop hoist

load balancer

roller-type stud removal tool

Tightening torquesm

sequential gearbox

studs7 Nm

sequential gearbox bolts44 Nm

sequential gearbox nuts44 Nm

flywheel protection plate

bolts (18)44 Nm

IMPORTANT

Consult the safety and cleanliness advice and oper-

ation recommendations before carrying out any

repair (see 21B, Sequential gearbox, Sequential

gearbox: Precautions for the repair, page 21B-1)

.

AIR CONDITIONING or CLIMATE CONTROL