wheel SAAB 9-5 2001 Workshop Manual

[x] Cancel search | Manufacturer: SAAB, Model Year: 2001, Model line: 9-5, Model: SAAB 9-5 2001Pages: 272, PDF Size: 14.83 MB

Page 226 of 272

226 Car care and technical informationChanging a wheel

WARNING

The car jack is designed solely for use

in changing a wheel or fitting snow

chains. It must not be used to support

the car during repair work or servicing.

Never crawl under a car that is

supported only by a jack.

Special care must be taken if the car is

on a slope – use wheel chocks!

Position chocks, one ahead and one

behind, the wheel that is diagonally

opposite to the one to be changed.

Switch on the hazard warning lights if

the car is on a road.

Apply the parking brake and leave the

car in gear (1st or reverse). Automatic

transmission: move selector to the

P position.

Ensure that everybody is out of the car

before jacking it up.

Never start the engine while the car is

jacked up.

The jack must stand on a firm, level

surface.

Stow the jack in the place provided for

it under the panel in the floor of the lug-

gage compartment. Secure it properly

to avert injury to passengers in the

event of an accident.

Do not use the jack for any purpose

other than for jacking up the car.

ProCarManuals.com

Page 227 of 272

227 Car care and technical information

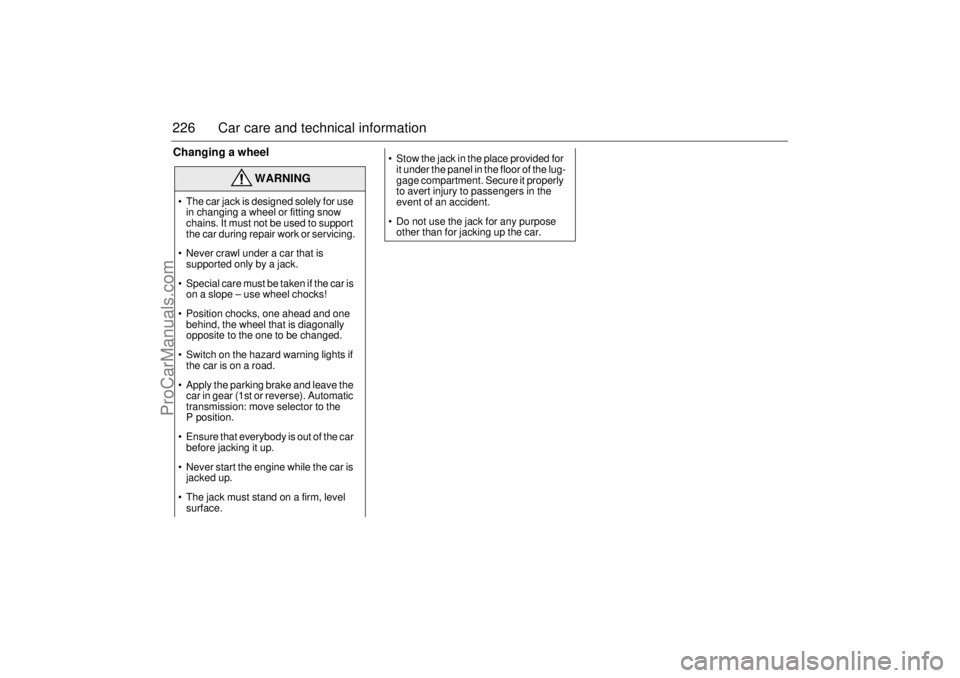

To jack up the car, apply the jack to one of

the special jacking points under the sills.Pos i ti o n for j ack

IB536

IB1553

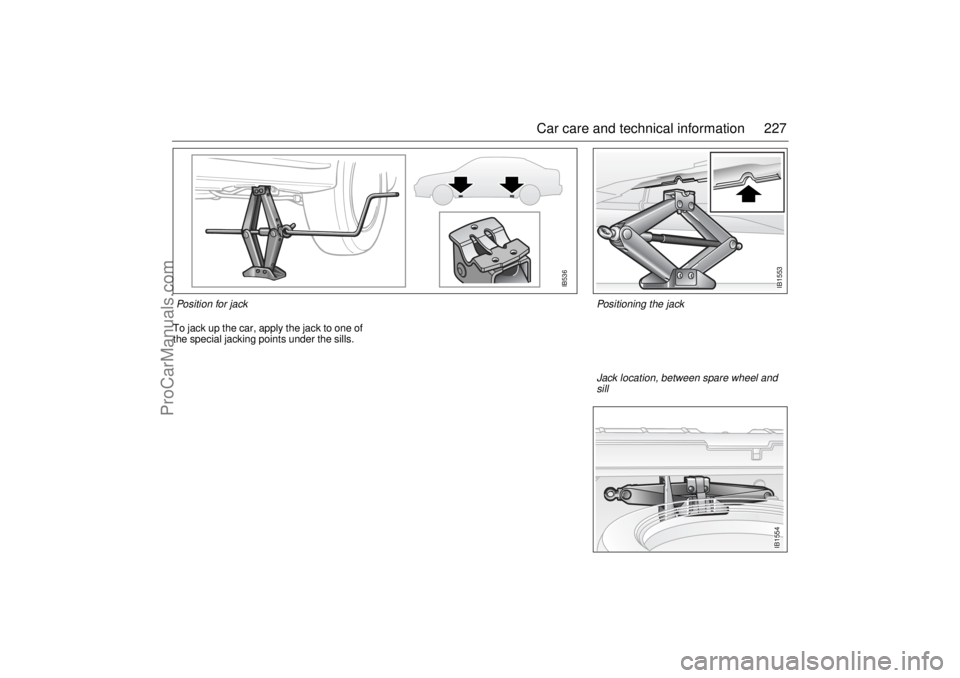

Positioning the jack

IB1554

Jack location, between spare wheel and

sill

ProCarManuals.com

Page 228 of 272

228 Car care and technical informationIf a floor jack is used, it can be applied to the

standard jacking points used by the dealer.

A floor jack can lift both front wheels or both

rear wheels off the ground simultaneously.

A jack stand must then be applied under-

neath the front of the engine subframe (at

the fixing point for the towrope-attachment

eye) or to the rear towrope-attachment eye

(or under the trailer hitch, if fitted).

1 Put the car in 1st gear (automatic trans-

mission: move selector to the P position)

and apply the parking brake.2 Wind the jack up to a suitable height

before placing it under the recess in the

sill.

Make sure that the jack fully engages

the recess in the sill and that the base of

the jack is steady and flat on the ground.

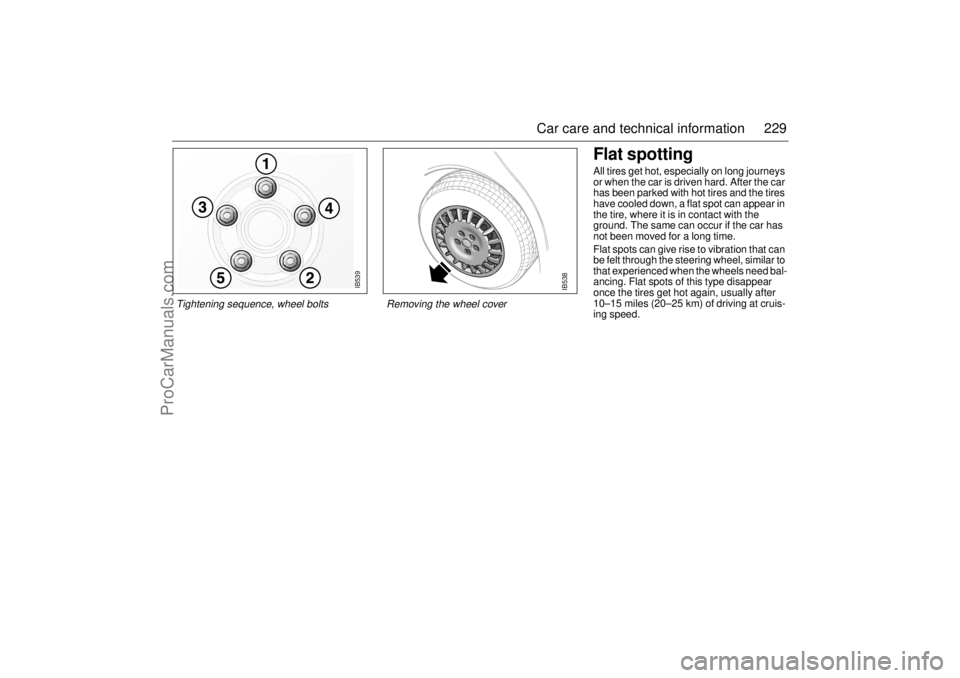

3 Remove the wheel cover (where appli-

cable).

Loosen the wheel bolts by half a turn.

4 Wind the jack to raise the wheel clear of

the ground. Remove the wheel bolts and

lift off the wheel.

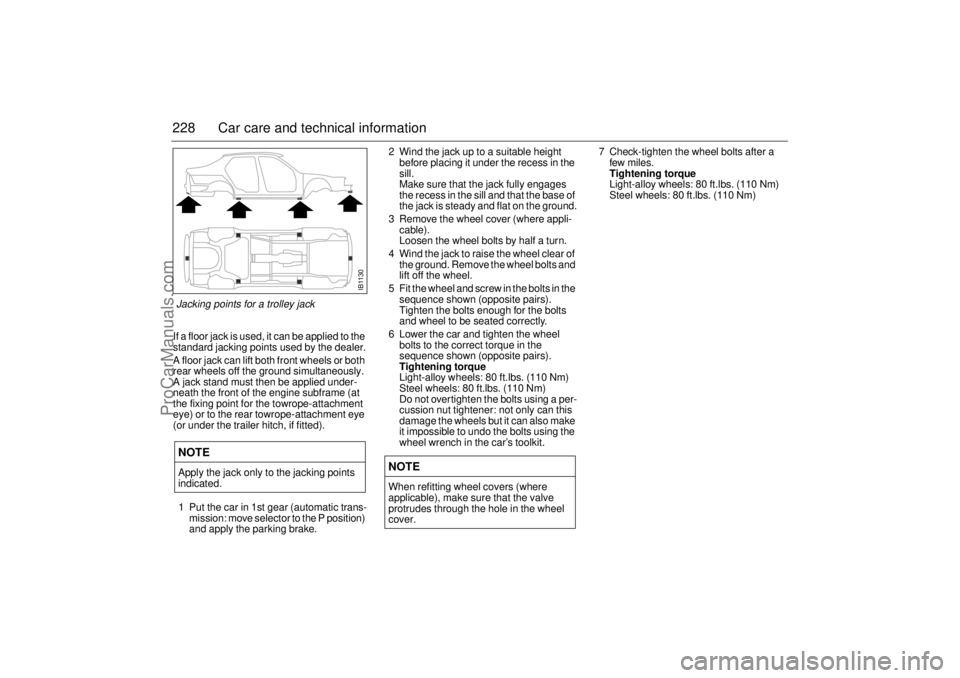

5 Fit the wheel and screw in the bolts in the

sequence shown (opposite pairs).

Tighten the bolts enough for the bolts

and wheel to be seated correctly.

6 Lower the car and tighten the wheel

bolts to the correct torque in the

sequence shown (opposite pairs).

Tightening torque

Light-alloy wheels: 80 ft.lbs. (110 Nm)

Steel wheels: 80 ft.lbs. (110 Nm)

Do not overtighten the bolts using a per-

cussion nut tightener: not only can this

damage the wheels but it can also make

it impossible to undo the bolts using the

wheel wrench in the car’s toolkit. 7 Check-tighten the wheel bolts after a

few miles.

Tightening torque

Light-alloy wheels: 80 ft.lbs. (110 Nm)

Steel wheels: 80 ft.lbs. (110 Nm)NOTEApply the jack only to the jacking points

indicated.

NOTEWhen refitting wheel covers (where

applicable), make sure that the valve

protrudes through the hole in the wheel

cover.

IB1130

Jacking points for a trolley jack

ProCarManuals.com

Page 229 of 272

229 Car care and technical information

Flat spottingAll tires get hot, especially on long journeys

or when the car is driven hard. After the car

has been parked with hot tires and the tires

have cooled down, a flat spot can appear in

the tire, where it is in contact with the

ground. The same can occur if the car has

not been moved for a long time.

Flat spots can give rise to vibration that can

be felt through the steering wheel, similar to

that experienced when the wheels need bal-

ancing. Flat spots of this type disappear

once the tires get hot again, usually after

10–15 miles (20–25 km) of driving at cruis-

ing speed.

IB539

Tightening sequence, wheel bolts

IB538

Removing the wheel cover

ProCarManuals.com

Page 234 of 272

234 Car care and technical information

Two-coat enamel As the name implies, two-coat enamel is

applied in two operations. The first coat, the

base color, contains the pigment, metal

flakes and binder. The second coat consists

of a clear enamel, which provides the final

gloss for the paintwork and protects the

base from moisture and environmental con-

taminants.

Touch-up stone-chip damage as follows:

1 Thoroughly clean the damaged area.

2 Apply the primer, base color and finally,

the enamel. To achieve the best finish,

apply two or three coats of primer.

Anticorrosion treatmentThe entire car is corrosion-protected at the

factory in different stages by an electrolytic

immersion coating and a polyester-based

protective coating to protect against corro-

sion caused by stones flung up by the

wheels. A thin penetrating anti-rust oil is

also applied in cavities and body members.

In addition to conventional anti-corrosion

treatment like painting, underbody treat-

ment and cavity treatment, most of the body

panel surfaces are galvanized. These

include the hood, the doors and the under-

body.

The anti-corrosion treatment on the under-

side of the car and inside the wheel arches

is particularly exposed to constant wear and

possible damage, the degree of which will

obviously depend on driving conditions.

IB1334

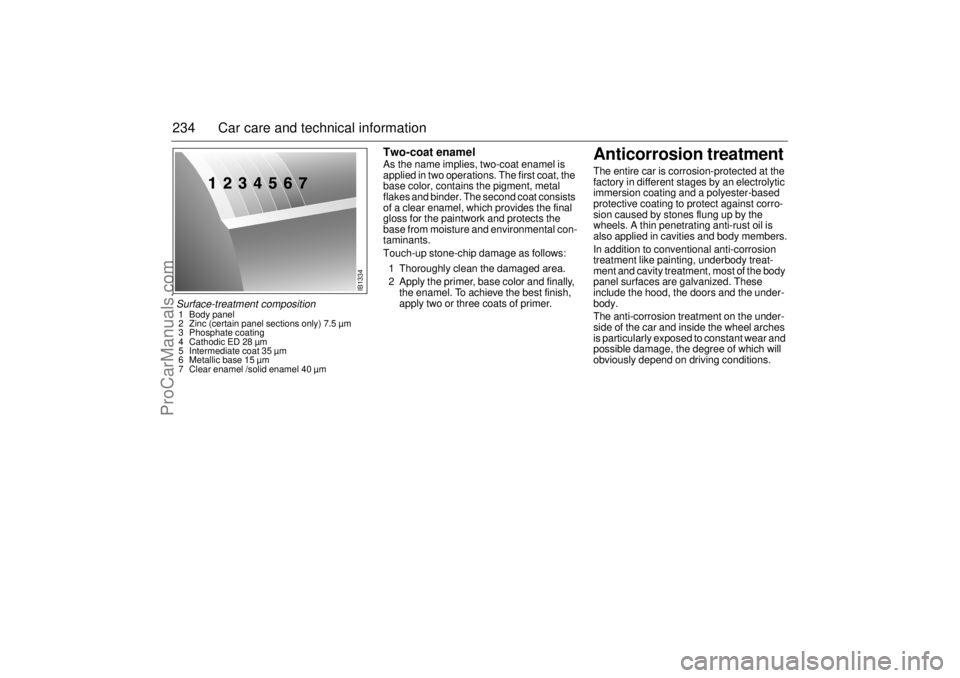

Surface-treatment composition 1 Body panel

2 Zinc (certain panel sections only) 7.5 µm

3 Phosphate coating

4 Cathodic ED 28 µm

5 Intermediate coat 35 µm

6 Metallic base 15 µm

7 Clear enamel /solid enamel 40 µm

ProCarManuals.com

Page 235 of 272

235 Car care and technical information

What causes rust?Steel body panels of automobiles are sub-

ject to rusting whenever air and moisture

manage to penetrate the protective finish,

and body panels may rust through if the pro-

cess is unchecked. Rusting can occur wher-

ever water is trapped or where the car’s

panels are continuously damp. Damage to

paint and undercoating by stones, gravel

and minor accidents immediately exposes

metal to air and moisture. Road salts used

for de-icing will collect on the bottom of the

car and promote rusting. Areas of the coun-

try with high humidity have great potential

for rust problems, especially where salt is

used on roads or there is moist sea air.

Industrial pollution (fallout) may also

damage paint and promote rusting.

Preventive maintenanceThe following procedures are necessary to

help protect against rusting. Refer also to

the terms and conditions of the Sheet Metal

Coverage described in the warranty book-

let.

1Wash the car frequently, and wax at

least twice a year. Under adverse con-

ditions, where there is a rapid buildup of

dirt, sand or road salt, wash your car at

least once a week. After extreme expo-

sure to salted snow or slush, evidenced

by a white film on the car, wash the car

immediately. Frequent washing will pre-

vent paint damage from acid rain and

other airborne contaminants such as

tree sap and bird droppings. If any of

these contaminants are noticed on the

car the finish should be washed immedi-

ately.

Begin washing by rinsing the entire car

with water to loosen and flush off heavy

concentrations of dirt (include the

underbody).

Sponge the car with a solution of either

a good quality car soap or mild general

purpose (dish washing) detergent and

water.

Rinse car thoroughly with clean water.

After washing, check and clear all

drains in doors and body panels.

Wipe the car dry, preferably using a

chamois.2Clean the underside of the car during

the winter. Use high pressure water to

clean the car’s underside (floor panels,

wheel wells) at least at mid- winter and

in the spring.

3Inspect the car frequently for leaks or

damage, and arrange for needed

repairs promptly. After washing or after

heavy rain, check for leaks. When wash-

ing the car inspect body surfaces for

paint damage. While checking for leaks,

lift the floor mats and check beneath

them. Water can collect in these areas

and remain for prolonged periods. Dry

any wet areas including the floor mats.

Have leaks repaired as soon as possi-

ble.

Use touch-up paint to repair small

scratches or minor finish damage. Areas

where metal is exposed will rust quickly

and MUST be repaired immediately by

touch-up or professional repainting.

Rust must be removed, the bare metal

primed and painted. Major body

damage should be repaired immediately

and new panels or exposed areas

should be undercoated with anti- corro-

sion material.

Repairs of this type are the owner’s

responsibility and are not covered under

warranty.

ProCarManuals.com

Page 236 of 272

236 Car care and technical information4Inspect the undercoating and touch

up if necessary. Pay particular atten-

tion to the fenders and wheel housings,

which are exposed to abrasion by flying

gravel, etc. If the composition has worn

or flaked off, the steel must be thor-

oughly cleaned and dried before a fresh

coat is applied. The cleaning is best

done with a scraper and a steel wire

brush, followed by washing with solvent.

Apply the new coating thinly, as other-

wise it may run off or fall off when dry.

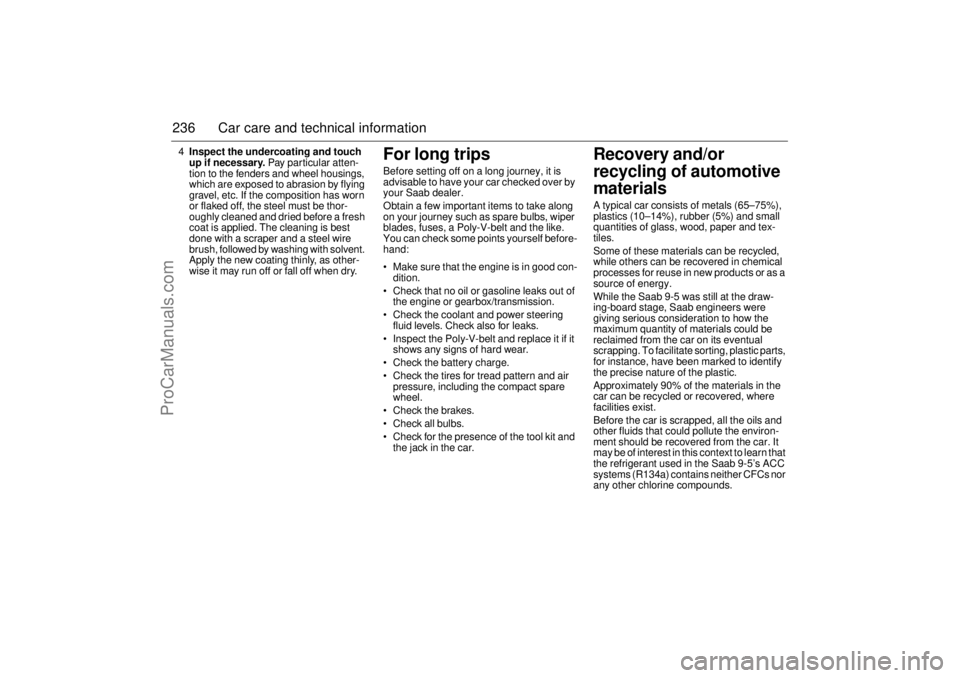

For long tripsBefore setting off on a long journey, it is

advisable to have your car checked over by

your Saab dealer.

Obtain a few important items to take along

on your journey such as spare bulbs, wiper

blades, fuses, a Poly-V-belt and the like.

You can check some points yourself before-

hand:

Make sure that the engine is in good con-

dition.

Check that no oil or gasoline leaks out of

the engine or gearbox/transmission.

Check the coolant and power steering

fluid levels. Check also for leaks.

Inspect the Poly-V-belt and replace it if it

shows any signs of hard wear.

Check the battery charge.

Check the tires for tread pattern and air

pressure, including the compact spare

wheel.

Check the brakes.

Check all bulbs.

Check for the presence of the tool kit and

the jack in the car.

Recovery and/or

recycling of automotive

materialsA typical car consists of metals (65–75%),

plastics (10–14%), rubber (5%) and small

quantities of glass, wood, paper and tex-

tiles.

Some of these materials can be recycled,

while others can be recovered in chemical

processes for reuse in new products or as a

source of energy.

While the Saab 9-5 was still at the draw-

ing-board stage, Saab engineers were

giving serious consideration to how the

maximum quantity of materials could be

reclaimed from the car on its eventual

scrapping. To facilitate sorting, plastic parts,

for instance, have been marked to identify

the precise nature of the plastic.

Approximately 90% of the materials in the

car can be recycled or recovered, where

facilities exist.

Before the car is scrapped, all the oils and

other fluids that could pollute the environ-

ment should be recovered from the car. It

may be of interest in this context to learn that

the refrigerant used in the Saab 9-5’s ACC

systems (R134a) contains neither CFCs nor

any other chlorine compounds.

ProCarManuals.com

Page 237 of 272

237 Car care and technical information

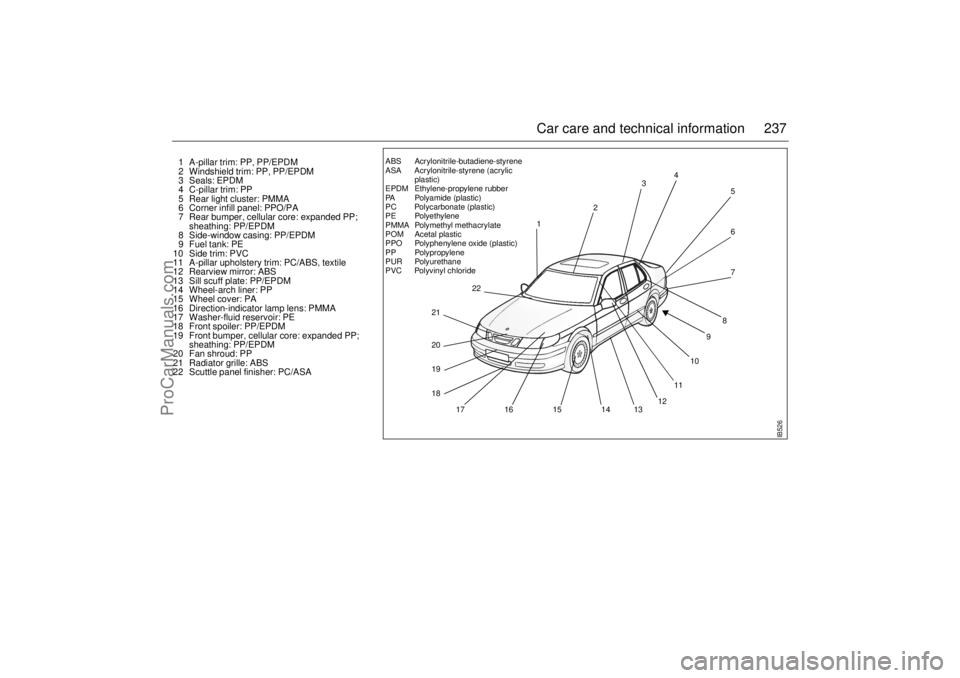

1 A-pillar trim: PP, PP/EPDM

2 Windshield trim: PP, PP/EPDM

3 Seals: EPDM

4 C-pillar trim: PP

5 Rear light cluster: PMMA

6 Corner infill panel: PPO/PA

7 Rear bumper, cellular core: expanded PP;

sheathing: PP/EPDM

8 Side-window casing: PP/EPDM

9 Fuel tank: PE

10 Side trim: PVC

11 A-pillar upholstery trim: PC/ABS, textile

12 Rearview mirror: ABS

13 Sill scuff plate: PP/EPDM

14 Wheel-arch liner: PP

15 Wheel cover: PA

16 Direction-indicator lamp lens: PMMA

17 Washer-fluid reservoir: PE

18 Front spoiler: PP/EPDM

19 Front bumper, cellular core: expanded PP;

sheathing: PP/EPDM

20 Fan shroud: PP

21 Radiator grille: ABS

22 Scuttle panel finisher: PC/ASA

IB526

ABS Acrylonitrile-butadiene-styrene

ASA Acrylonitrile-styrene (acrylic

plastic)

EPDM Ethylene-propylene rubber

PA Polyamide (plastic)

PC Polycarbonate (plastic)

PE Polyethylene

PMMA Polymethyl methacrylate

POM Acetal plastic

PPO Polyphenylene oxide (plastic)

PP Polypropylene

PUR Polyurethane

PVC Polyvinyl chloride 1234

5

6

7

98

10

11

12

13 14 15 16 19

18 20 21

1722

ProCarManuals.com

Page 247 of 272

247 Maintenance and owner assistance

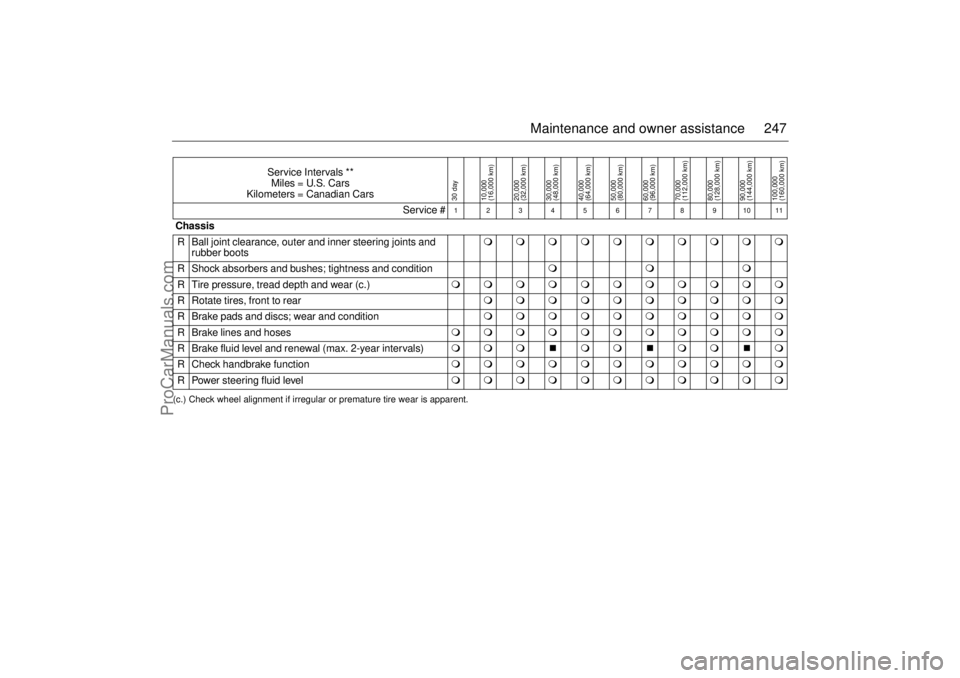

(c.) Check wheel alignment if irregular or premature tire wear is apparent.

Service Intervals **

Miles = U.S. Cars

Kilometers = Canadian Cars

30 day

10,000

(16,000 km)

20,000

(32,000 km)

30,000

(48,000 km)

40,000

(64,000 km)

50,000

(80,000 km)

60,000

(96,000 km)

70,000

(112,000 km)

80,000

(128,000 km)

90,000

(144,000 km)

100,000

(160,000 km)

Service #

1234567891011

Chassis

R Ball joint clearance, outer and inner steering joints and

rubber boots""""""""""

R Shock absorbers and bushes; tightness and condition"""

R Tire pressure, tread depth and wear (c.)"""""""""""

R Rotate tires, front to rear""""""""""

R Brake pads and discs; wear and condition""""""""""

R Brake lines and hoses"""""""""""

R Brake fluid level and renewal (max. 2-year intervals)""" ! "" ! "" ! "

R Check handbrake function"""""""""""

R Power steering fluid level"""""""""""

ProCarManuals.com

Page 249 of 272

249 Specifications

Specifications General.............................. 250

Engine ............................... 252

Fuel.................................... 252

Engine oil .......................... 253

Engine variants ................ 254

Electrical system.............. 254

Drive belts......................... 255

Manual gearbox................ 255

Automatic transmission .. 256

Suspension....................... 256

Steering............................. 256

Brake system.................... 257

Wheels and tires .............. 257

Plates and labels .............. 259

IB603

ProCarManuals.com