SATURN VUE 2010 Owners Manual

Manufacturer: SATURN, Model Year: 2010, Model line: VUE, Model: SATURN VUE 2010Pages: 398, PDF Size: 4.02 MB

Page 291 of 398

Vehicle Care 10-25

Notice:

.Using the wrong fluid can

badly damage brake

hydraulic system parts.

For example, just a few

drops of mineral-based oil,

such as engine oil, in the

brake hydraulic system can

damage brake hydraulic

system parts so badly that

they will have to be replaced.

Do not let someone put in

the wrong kind of fluid.

.If brake fluid is spilled on

the vehicle's painted

surfaces, the paint finish can

be damaged. Be careful not

to spill brake fluid on the

vehicle. If you do, wash it off

immediately.

Battery

Refer to the replacement number

shown on the original battery label

when a new battery is needed.

See Engine Compartment Overview

on page 10‑6for battery location.

{DANGER

Battery posts, terminals, and

related accessories contain lead

and lead compounds, chemicals

known to the State of California to

cause cancer and reproductive

harm. Wash hands after handling.

Vehicle Storage

{WARNING

Batteries have acid that can burn

you and gas that can explode.

You can be badly hurt if you are

not careful. See Jump Starting

on

page 10‑74

for tips on working

around a battery without

getting hurt.

Infrequent Usage: Remove the

black, negative (−) cable from the

battery to keep the battery from

running down.

Extended Storage: Remove the

black, negative (−) cable from the

battery or use a battery trickle

charger.

ProCarManuals.com

Page 292 of 398

10-26 Vehicle Care

All-Wheel Drive

It is recommended that the all-wheel

drive lubricants be checked and

filled by the dealer/retailer.

Transfer Case

When to Check and Change

Lubricant

Refer to the Maintenance Schedule

to determine how often to check the

lubricant and when to change it.

SeeScheduled Maintenance

on

page 11‑2. How to Check LubricantA. Fill Plug

B. Drain Plug

To get an accurate reading, the

vehicle should be on a level

surface.

If the level is below the bottom of

the filler plug hole, located on the

transfer case, you'll need to add

some lubricant. Add enough

lubricant to raise the level to the

bottom of the filler plug hole. A fluid loss could indicate a

problem; check and have it

repaired, if needed.

What to Use

Refer to the Maintenance Schedule

to determine what kind of lubricant

to use. See

Recommended Fluids

and Lubricants on page 11‑7.

Carrier Assembly-Differential

(Rear Drive Module)

When to Check and Change

Lubricant

Refer to the Maintenance Schedule

to determine how often to check the

lubricant and when to change it.

See Scheduled Maintenance

on

page 11‑2.

ProCarManuals.com

Page 293 of 398

Vehicle Care 10-27

How to Check Lubricant

AWD Differential Case

A. Fill Plug

B. Drain Plug

To get an accurate reading, the

vehicle should be on a level

surface.

If the level is below the bottom of

the filler plug hole, you'll need to

add some lubricant. Add enough

lubricant to raise the level to the

bottom of the filler plug hole. A fluid loss could indicate a

problem; check and have it

repaired, if needed.

What to Use

Refer to the Maintenance Schedule

to determine what kind of lubricant

to use. See

Recommended Fluids

and Lubricants on page 11‑7.

Starter Switch Check

{WARNING

When you are doing this

inspection, the vehicle could

move suddenly. If the vehicle

moves, you or others could be

injured.

1. Before starting this check, be sure there is enough room

around the vehicle. 2. Firmly apply both the parking

brake and the regular brake.

See Parking Brake

on

page 9‑39.

Do not use the accelerator

pedal, and be ready to turn off

the engine immediately if it

starts.

3. Try to start the engine in each gear. The vehicle should start

only in P (Park) or N (Neutral).

If the vehicle starts in any other

position, contact your dealer/

retailer for service.

ProCarManuals.com

Page 294 of 398

10-28 Vehicle Care

Automatic Transmission

Shift Lock Control

System Check

{WARNING

When you are doing this

inspection, the vehicle could

move suddenly. If the vehicle

moves, you or others could be

injured.

1. Before starting this check, be sure there is enough room

around the vehicle. It should be

parked on a level surface. 2. Firmly apply the parking brake.

See Parking Brake

on

page 9‑39.

Be ready to apply the regular

brake immediately if the vehicle

begins to move.

3. With the engine off, turn the ignition to ON/RUN, but do not

start the engine. Without

applying the regular brake, try to

move the shift lever out of

P (Park) with normal effort. If the

shift lever moves out of P (Park),

contact your dealer/retailer for

service.

Ignition Transmission

Lock Check

While parked, and with the parking

brake set, try to turn the ignition to

LOCK/OFF in each shift lever

position.

.For automatic transmission

vehicles, the ignition should turn

to LOCK/OFF only when the

shift lever is in P (Park). The

ignition key should come out

only in LOCK/OFF.

.For manual transmission

vehicles, the ignition key should

come out only in LOCK/OFF.

Contact your dealer/retailer if

service is required.

ProCarManuals.com

Page 295 of 398

Vehicle Care 10-29

Park Brake and P (Park)

Mechanism Check

{WARNING

When you are doing this check,

the vehicle could begin to move.

You or others could be injured

and property could be damaged.

Make sure there is room in front

of the vehicle in case it begins to

roll. Be ready to apply the regular

brake at once should the vehicle

begin to move.Park on a fairly steep hill, with the

vehicle facing downhill. Keeping

your foot on the regular brake, set

the parking brake.

.To check the parking brake's

holding ability: With the engine

running and the transmission in

N (Neutral), slowly remove foot

pressure from the regular brake

pedal. Do this until the vehicle is

held by the parking brake only.

.To check the P (Park)

mechanism's holding ability:

With the engine running, shift to

P (Park). Then release the

parking brake followed by the

regular brake.

Contact your dealer/retailer if

service is required.

Wiper Blade Replacement

Windshield wiper blades should be

inspected for wear and cracking.

See Scheduled Maintenance

on

page 11‑2for more information.

Replacement blades come in

different types and are removed in

different ways. For proper type

and length, see Maintenance

Replacement Parts on page 11‑9.

To replace the windshield wiper

blade:

1. Lift the wiper arm away from the windshield.

ProCarManuals.com

Page 296 of 398

10-30 Vehicle Care

2. Push the release lever (B) todisengage the hook and push

the wiper arm (A) out of the

blade (C).

3. Push the new wiper blade securely on the wiper arm until

you hear the release lever click

into place.

4. Return the wiper arm and blade assembly to the rest position on

the windshield. To replace the rear wiper blade:

1. Lift the rear wiper arm (A) from

the window.

2. Turn the bottom edge of the blade assembly (B) slightly away

from the underside of the

wiper arm.

3. Apply downward pressure to the blade assembly and remove

from the wiper arm.

4. Install the new wiper blade.

5. Return the wiper arm and blade assembly to the rest position on

the window.

Headlamp Aiming

The headlamp aiming system has

been preset at the factory.

If the vehicle is damaged in an

accident, the aim of the headlamps

may be affected and adjustment

may be necessary.

It is recommended that a dealer/

retailer adjust the headlamps.

To re-aim the headlamps yourself,

use the following procedure.

The vehicle should be properly

prepared as follows:

.The vehicle should be placed so

the headlamps are 7.6 m (25 ft)

from a light colored wall.

.The vehicle must have all

four tires on a level surface

which is level all the way to

the wall.

ProCarManuals.com

Page 297 of 398

Vehicle Care 10-31

.The vehicle should be placed so

it is perpendicular to the wall or

other flat surface.

.The vehicle should not have any

snow, ice, or mud on it.

.The vehicle should be fully

assembled and all other work

stopped while headlamp aiming

is being performed.

.The vehicle should be normally

loaded with a full tank of fuel and

one person or 75 kg (160 lbs)

sitting on the driver's seat.

.Tires should be properly inflated.

Headlamp aiming is done with the

vehicle's low-beam headlamps.

The high-beam headlamps will be

correctly aimed if the low-beam

headlamps are aimed properly. To adjust the vertical aim, do the

following:

1. Open the hood. See

Hood

on

page 10‑5for more information.

2. Locate the aim dot on the lens of the low‐beam headlamp.

3. Measure the distance from the ground to the aim dot on the

low‐beam headlamp. Record the

distance.

4. At the wall measure from the

ground upward (A) to the

recorded distance from

Step 3 and mark it.

5. Draw or tape a horizontal line (B) on the wall the width of the

vehicle at the height of the mark

in Step 4.

ProCarManuals.com

Page 298 of 398

10-32 Vehicle Care

Notice:Do not cover a headlamp

to improve beam cut-off when

aiming. Covering a headlamp may

cause excessive heat build-up

which may cause damage to the

headlamp.

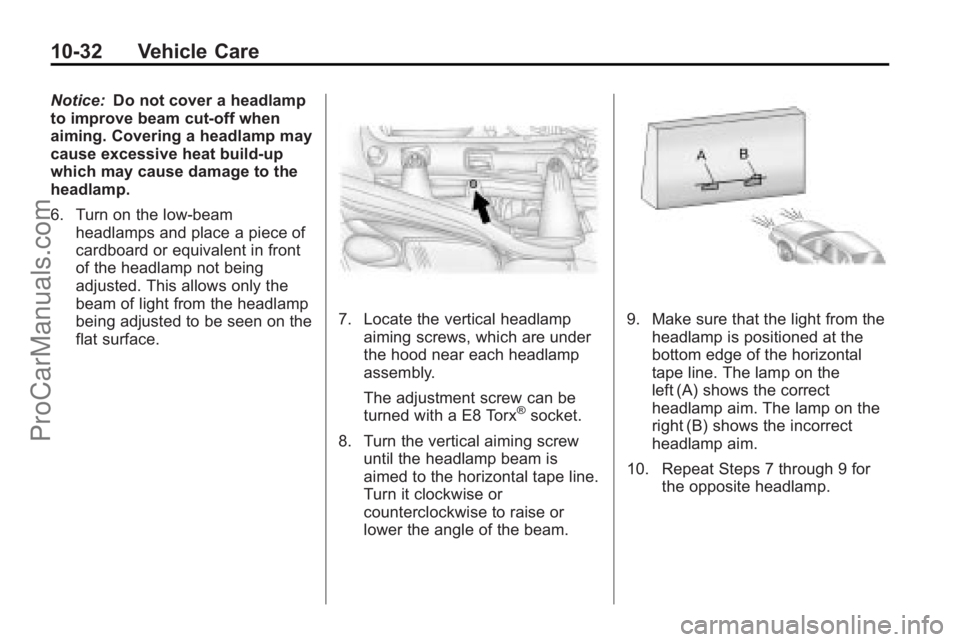

6. Turn on the low-beam

headlamps and place a piece of

cardboard or equivalent in front

of the headlamp not being

adjusted. This allows only the

beam of light from the headlamp

being adjusted to be seen on the

flat surface.

7. Locate the vertical headlampaiming screws, which are under

the hood near each headlamp

assembly.

The adjustment screw can be

turned with a E8 Torx

®socket.

8. Turn the vertical aiming screw until the headlamp beam is

aimed to the horizontal tape line.

Turn it clockwise or

counterclockwise to raise or

lower the angle of the beam.

9. Make sure that the light from theheadlamp is positioned at the

bottom edge of the horizontal

tape line. The lamp on the

left (A) shows the correct

headlamp aim. The lamp on the

right (B) shows the incorrect

headlamp aim.

10. Repeat Steps 7 through 9 for the opposite headlamp.

ProCarManuals.com

Page 299 of 398

Vehicle Care 10-33

Bulb Replacement

For the proper type of replacement

bulbs, seeReplacement Bulbson

page 10‑36.

For any bulb changing procedure

not listed in this section, contact

your dealer/retailer.

Halogen Bulbs

{WARNING

Halogen bulbs have pressurized

gas inside and can burst if you

drop or scratch the bulb. You or

others could be injured. Be sure

to read and follow the instructions

on the bulb package.

Headlamps

To replace one of the headlamp

bulbs, use the following procedure.

To replace the parking/turn signal

lamp bulb, see Front Turn Signal

and Parking Lamps on page 10‑34.

1. Open the hood. See Hood

on

page 10‑5for more information.

2. Remove the two screws from the top of the front fascia and grille.

They are inboard of the

headlamp assembly.

3. Remove the three screws retaining the headlamp

assembly. 4. Insert a flat blade tool through

the opening in the top. Make

sure the tool fits through the

opening in the headlamp bracket

lower arm.

5. Push the locking tab toward the rear of the vehicle with the tool

to lift the headlamp bracket

lower arm.

6. Pull back on the front fascia and then pull the headlamp assembly

out from the vehicle. Another

person might be needed to

assist with this step.

ProCarManuals.com

Page 300 of 398

10-34 Vehicle Care

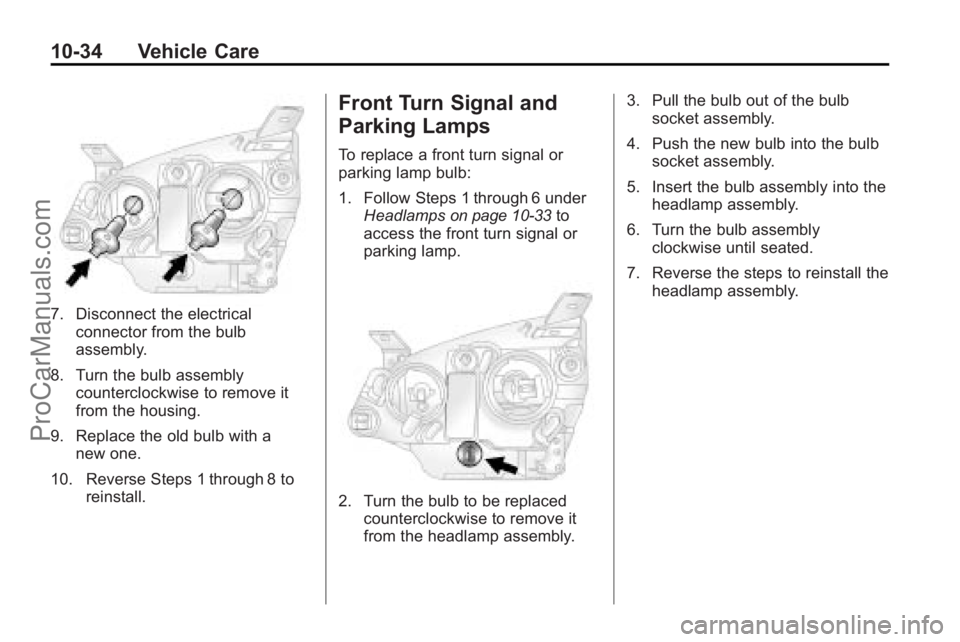

7. Disconnect the electricalconnector from the bulb

assembly.

8. Turn the bulb assembly counterclockwise to remove it

from the housing.

9. Replace the old bulb with a new one.

10. Reverse Steps 1 through 8 to reinstall.

Front Turn Signal and

Parking Lamps

To replace a front turn signal or

parking lamp bulb:

1. Follow Steps 1 through 6 under

Headlamps

on page 10‑33to

access the front turn signal or

parking lamp.

2. Turn the bulb to be replaced counterclockwise to remove it

from the headlamp assembly. 3. Pull the bulb out of the bulb

socket assembly.

4. Push the new bulb into the bulb socket assembly.

5. Insert the bulb assembly into the headlamp assembly.

6. Turn the bulb assembly clockwise until seated.

7. Reverse the steps to reinstall the headlamp assembly.

ProCarManuals.com