Seat Alhambra 2009 Owner's Manual

Manufacturer: SEAT, Model Year: 2009, Model line: Alhambra, Model: Seat Alhambra 2009Pages: 285, PDF Size: 7.62 MB

Page 241 of 285

If and when239

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

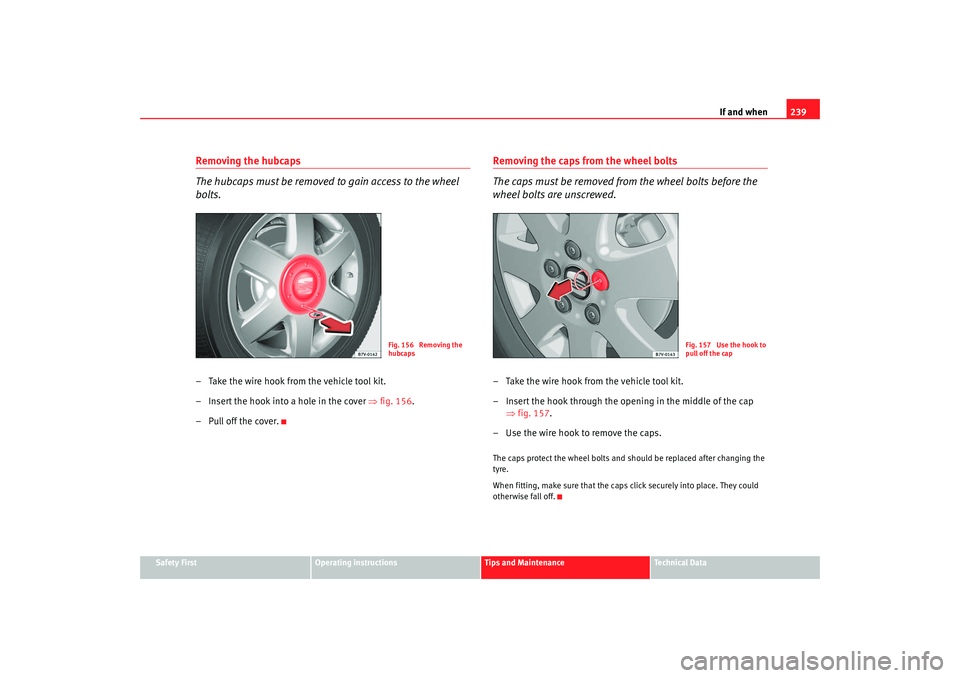

Removing the hubcaps

The hubcaps must be removed to gain access to the wheel

bolts.– Take the wire hook from the vehicle tool kit.

– Insert the hook into a hole in the cover ⇒fig. 156.

– Pull off the cover.

Removing the caps from the wheel bolts

The caps must be removed from the wheel bolts before the

wheel bolts are unscrewed.– Take the wire hook from the vehicle tool kit.

– Insert the hook through the opening in the middle of the cap ⇒fig. 157 .

– Use the wire hook to remove the caps.The caps protect the wheel bolts and should be replaced after changing the

tyre.

When fitting, make sure that the caps click securely into place. They could

otherwise fall off.

Fig. 156 Removing the

hubcaps

Fig. 157 Use the hook to

pull off the cap

alhambra_aleman.book Seite 239 Montag, 23. M‰ rz 2009 1:12 13

Page 242 of 285

If and when

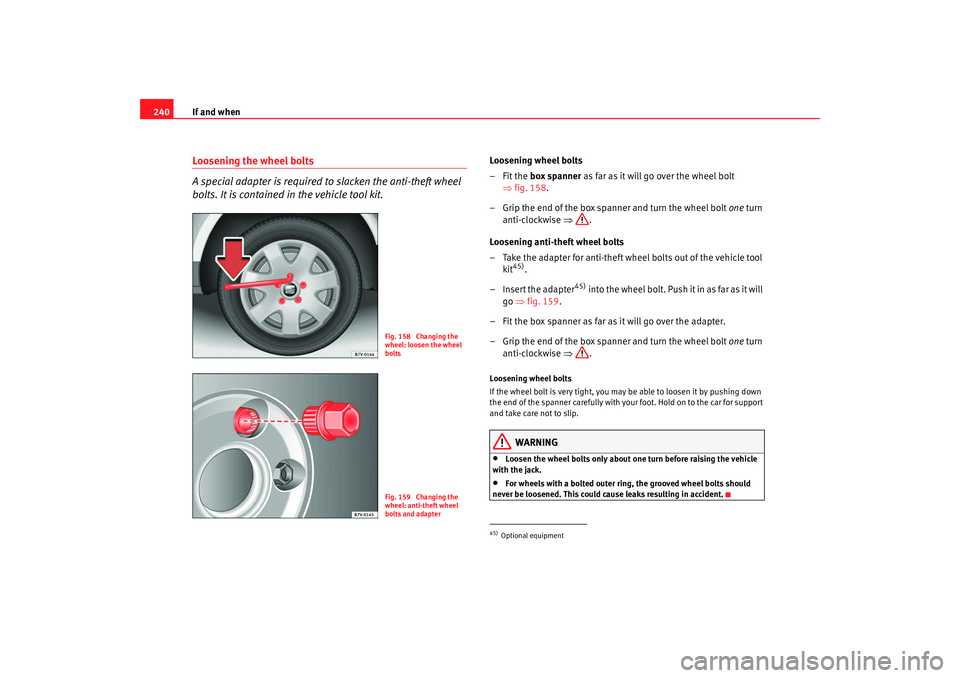

240Loosening the wheel bolts

A special adapter is required to slacken the anti-theft wheel

bolts. It is contained in the vehicle tool kit.

Loosening wheel bolts

–Fit the box spanner as far as it will go over the wheel bolt

⇒ fig. 158.

– Grip the end of the box spanner and turn the wheel bolt one turn

anti-clockwise ⇒.

Loosening anti-theft wheel bolts

– Take the adapter for anti-theft wheel bolts out of the vehicle tool kit

45)

.

– Insert the adapter

45)

into the wheel bolt. Push it in as far as it will

go ⇒fig. 159 .

– Fit the box spanner as far as it will go over the adapter.

– Grip the end of the box spanner and turn the wheel bolt one turn

anti-clockwise ⇒.

Loosening wheel bolts

If the wheel bolt is very tight, you may be able to loosen it by pushing down

the end of the spanner carefully with your foot. Hold on to the car for support

and take care not to slip.

WARNING

•

Loosen the wheel bolts only about one turn before raising the vehicle

with the jack.

•

For wheels with a bolted outer ring, the grooved wheel bolts should

never be loosened. This could cause leaks resulting in accident.

Fig. 158 Changing the

wheel: loosen the wheel

boltsFig. 159 Changing the

wheel: anti-theft wheel

bolts and adapter

45)Optional equipment

alhambra_aleman.book Seite 240 Montag, 23. M‰ rz 2009 1:12 13

Page 243 of 285

If and when241

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

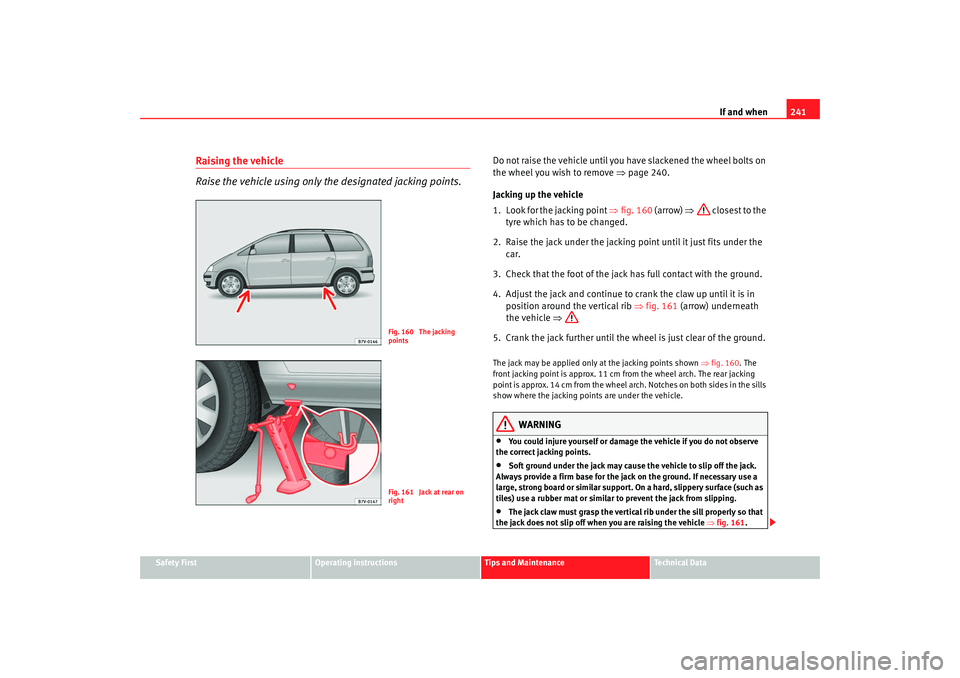

Raising the vehicle

Raise the vehicle using only the designated jacking points.

Do not raise the vehicle until you have slackened the wheel bolts on

the wheel you wish to remove ⇒page 240.

Jacking up the vehicle

1. Look for the jacking point ⇒fig. 160 (arrow) ⇒ closest to the

tyre which has to be changed.

2. Raise the jack under the jacking point until it just fits under the car.

3. Check that the foot of the jack has full contact with the ground.

4. Adjust the jack and continue to crank the claw up until it is in position around the vertical rib ⇒fig. 161 (arrow) underneath

the vehicle ⇒

5. Crank the jack further until the wheel is just clear of the ground.The jack may be applied only at the jacking points shown ⇒fig. 160 . The

front jacking point is approx. 11 cm from the wheel arch. The rear jacking

point is approx. 14 cm from the wheel arch. Notches on both sides in the sills

show where the jacking points are under the vehicle.

WARNING

•

You could injure yourself or damage the vehicle if you do not observe

the correct jacking points.

•

Soft ground under the jack may cause the vehicle to slip off the jack.

Always provide a firm base for the jack on the ground. If necessary use a

large, strong board or similar support. On a hard, slippery surface (such as

tiles) use a rubber mat or similar to prevent the jack from slipping.

•

The jack claw must grasp the vertical rib under the sill properly so that

the jack does not slip off when you are raising the vehicle ⇒ fig. 161.

Fig. 160 The jacking

pointsFig. 161 Jack at rear on

right

alhambra_aleman.book Seite 241 Montag, 23. M‰ rz 2009 1:12 13

Page 244 of 285

If and when

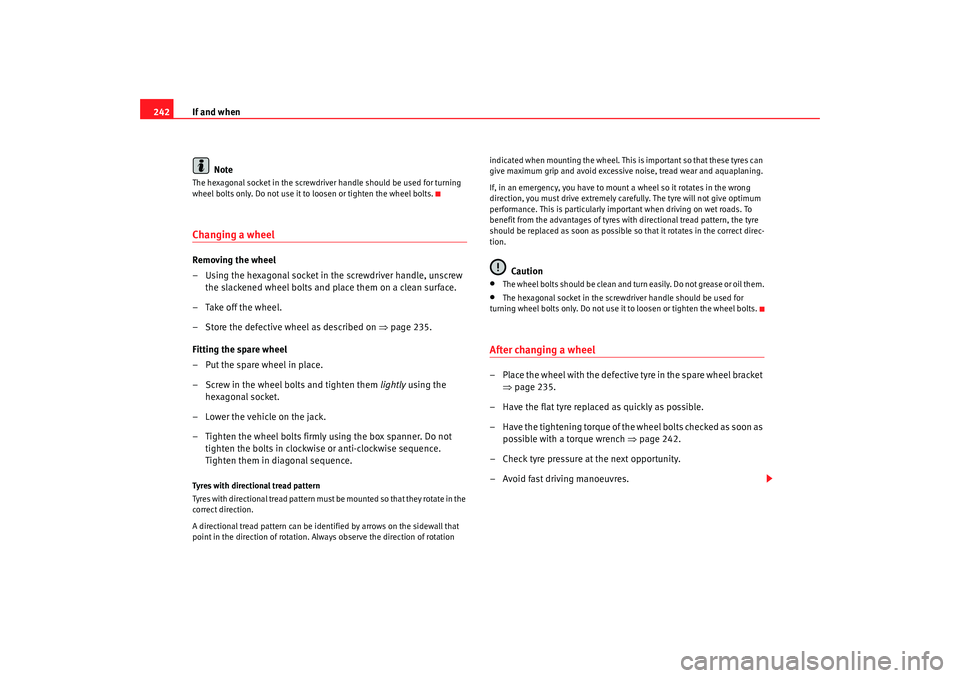

242

NoteThe hexagonal socket in the screwdriver handle should be used for turning

wheel bolts only. Do not use it to loosen or tighten the wheel bolts.Changing a wheel Removing the wheel

– Using the hexagonal socket in the screwdriver handle, unscrew

the slackened wheel bolts and place them on a clean surface.

– Take off the wheel.

– Store the defective wheel as described on ⇒page 235.

Fitting the spare wheel

– Put the spare wheel in place.

– Screw in the wheel bolts and tighten them lightly using the

hexagonal socket.

– Lower the vehicle on the jack.

– Tighten the wheel bolts firmly using the box spanner. Do not tighten the bolts in clockwise or anti-clockwise sequence.

Tighten them in diagonal sequence.Tyres with directional tread pattern

Tyres with directional tread pattern must be mounted so that they rotate in the

correct direction.

A directional tread pattern can be identified by arrows on the sidewall that

point in the direction of rotation. Always observe the direction of rotation indicated when mounting the wheel. This is important so that these tyres can

give maximum grip and avoid excessive noise, tread wear and aquaplaning.

If, in an emergency, you have to mount a wheel so it rotates in the wrong

direction, you must drive extremely carefully. The tyre will not give optimum

performance. This is particularly important when driving on wet roads. To

benefit from the advantages of tyres with directional tread pattern, the tyre

should be replaced as soon as possible so that it rotates in the correct direc-

tion.

Caution

•

The wheel bolts should be clean and turn easily. Do not grease or oil them.

•

The hexagonal socket in the screwdriver handle should be used for

turning wheel bolts only. Do not use it to loosen or tighten the wheel bolts.

After changing a wheel– Place the wheel with the defective tyre in the spare wheel bracket ⇒page 235.

– Have the flat tyre replaced as quickly as possible.

– Have the tightening torque of the wheel bolts checked as soon as possible with a torque wrench ⇒page 242.

– Check tyre pressure at the next opportunity.

– Avoid fast driving manoeuvres.

alhambra_aleman.book Seite 242 Montag, 23. M‰ rz 2009 1:12 13

Page 245 of 285

If and when243

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

WARNING

•

If the prescribed torque of the wheel bolts is too low, they could loosen

whilst the vehicle is in motion. Risk of accident! If the tightening torque is

too high, the wheel bolts and threads could be damaged.Caution

The stipulated torque for the wheel bolts on steel wheels and alloy wheels is

170 Nm with a tolerance of ±10 Nm. You should visit a specialised workshop

as soon as possible to check the torque with a torque wrench.

Note

•

The wheel bolts should be clean and turn easily. Do not grease or oil them.

•

The hexagonal socket in the screwdriver handle should be used only for

turning wheel bolts which have been slackened off. Do not use it to loosen or

tighten the wheel bolts.

•

If you notice that the wheel bolts are corroded and difficult to turn when

changing a wheel, they must be replaced before you have the tightening

torque checked.

•

If the spare tyre is not the same as the tyres that are mounted on the car -

for example with winter tyres - you should only use the spare tyre for a short

period of time and drive with extra care. Refit the normal road wheel as soon

as possible.

•

Have the flat tyre replaced as quickly as possible.

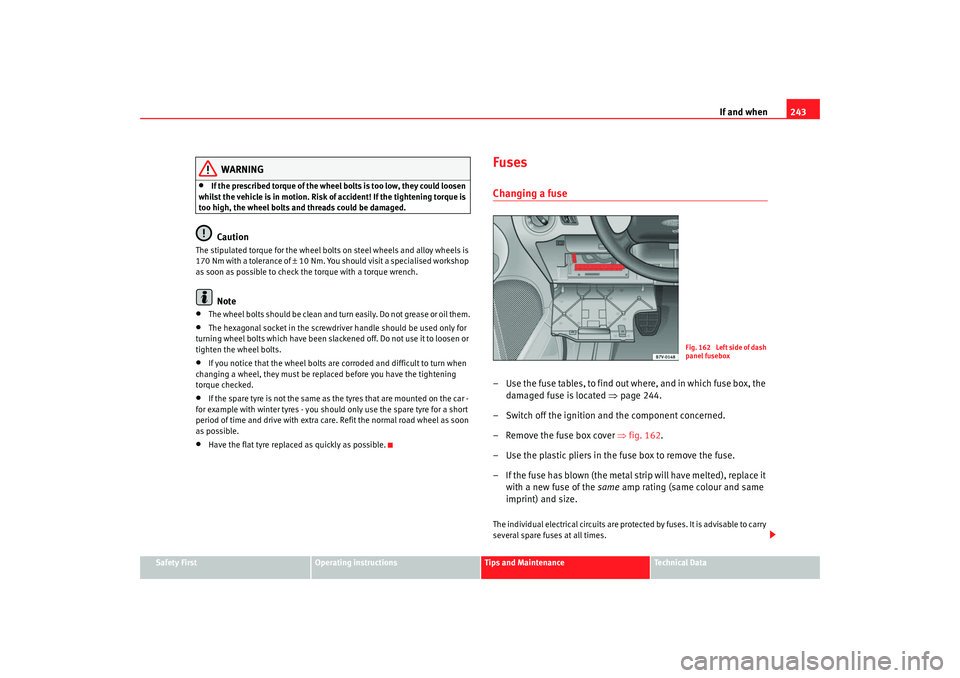

FusesChanging a fuse– Use the fuse tables, to find out where, and in which fuse box, the damaged fuse is located ⇒ page 244.

– Switch off the ignition and the component concerned.

– Remove the fuse box cover ⇒fig. 162 .

– Use the plastic pliers in the fuse box to remove the fuse.

– If the fuse has blown (the metal strip will have melted), replace it with a new fuse of the same amp rating (same colour and same

imprint) and size.The individual electrical circuits are protected by fuses. It is advisable to carry

several spare fuses at all times.

F ig . 1 6 2 Le f t si d e o f d as h

panel fusebox

alhambra_aleman.book Seite 243 Montag, 23. M‰ rz 2009 1:12 13

Page 246 of 285

If and when

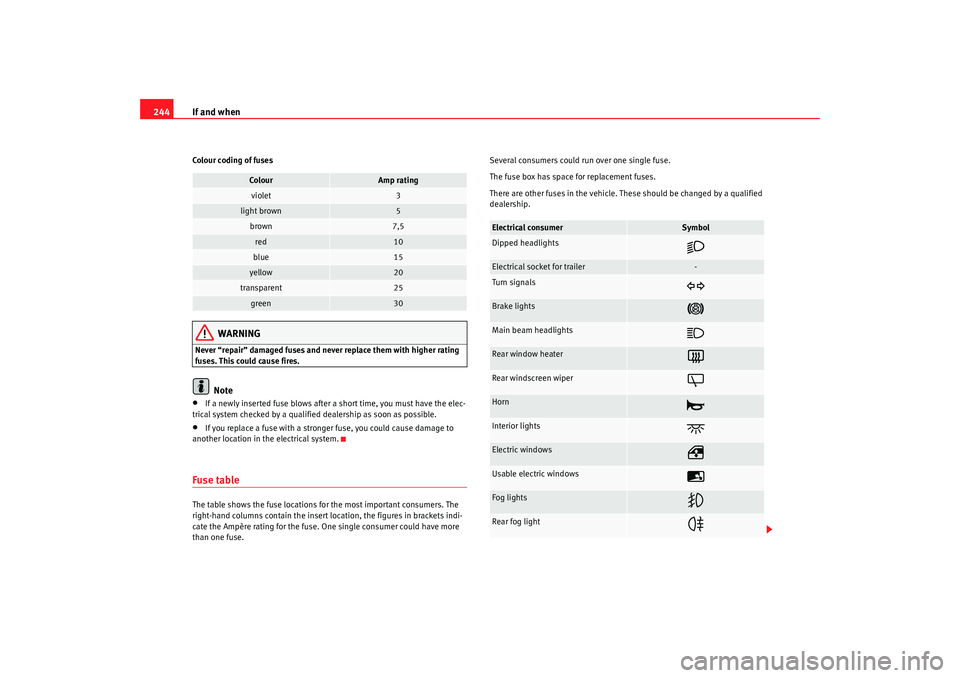

244Colour coding of fuses

WARNING

Never “repair” damaged fuses and never replace them with higher rating

fuses. This could cause fires.

Note

•

If a newly inserted fuse blows after a short time, you must have the elec-

trical system checked by a qualified dealership as soon as possible.

•

If you replace a fuse with a stronger fuse, you could cause damage to

another location in the electrical system.

Fuse tableThe table shows the fuse locations for the most important consumers. The

right-hand columns contain the insert location, the figures in brackets indi-

cate the Ampère rating for the fuse. One single consumer could have more

than one fuse. Several consumers could run over one single fuse.

The fuse box has space for replacement fuses.

There are other fuses in the vehicle. These should be changed by a qualified

dealership.

Colour

Amp rating

violet

3

light brown

5

brown

7,5

red

10

blue

15

yellow

20

transparent

25

green

30

Electrical consumer

Symbol

Dipped headlights

Electrical socket for trailer

-

Turn signals

Brake lights

Main beam headlights

Rear window heater

Rear windscreen wiper

Horn

Interior lights

Electric windows

Usable electric windows

Fog lights

Rear fog light

alhambra_aleman.book Seite 244 Montag, 23. M‰

rz 2009 1:12 13

Page 247 of 285

If and when245

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

Changing a lightBulbs, changing

Bulbs should be changed by a professional mechanic only.Technical knowledge is required to change bulbs. This is because, in certain

cases, access can be gained only by removing other vehicle components.

This applies in particular to bulbs which can be accessed only from the

engine compartment.

We recommend bulbs are changed by a qualified dealership or, if this is not

possible, by a qualified person.

However, if you wish to change the bulb, please observe the following:

Before changing a bulb, you must switch off the light (light switch in O posi-

tion), and the turn signal lever must be in the neutral position.

Always replace damaged bulbs with identical bulbs with the same designa-

tion. The type is inscribed on the bulb, either on the glass or on the base.

You should store spare light bulbs in the vehicle for safety-relevant lights.

Bulbs can be obtained from SEAT Service Centres.

WARNING

•

The high voltage element of gas discharge lamps must be handled

correctly. Failure to comply could result in fatal injuries.

•

H7* bulbs are pressurised and could explode when they are being

changed. Risk of injury.

•

In vehicles fitted with gas discharge lamps*, there is a mortal danger if

the high voltage section of the lamp is incorrectly handled.

•

When working in the engine compartment, always observe the safety

warnings ⇒page 211.

Hazard warning light switch

Instrument panel lighting

Climate control

Heating

Radio, navigation system

/

Rear light

-

Registration plate light

Windscreen washers

Windscreen washer system

Sliding sunroof

Seat heating

Mirror adjustment

Heating the exterior mirrors

Side lights

Socket (luggage compartment)

Central locking.

-

Electrical consumer

Symbol

alhambra_aleman.book Seite 245 Montag, 23. M‰ rz 2009 1:12 13

Page 248 of 285

If and when

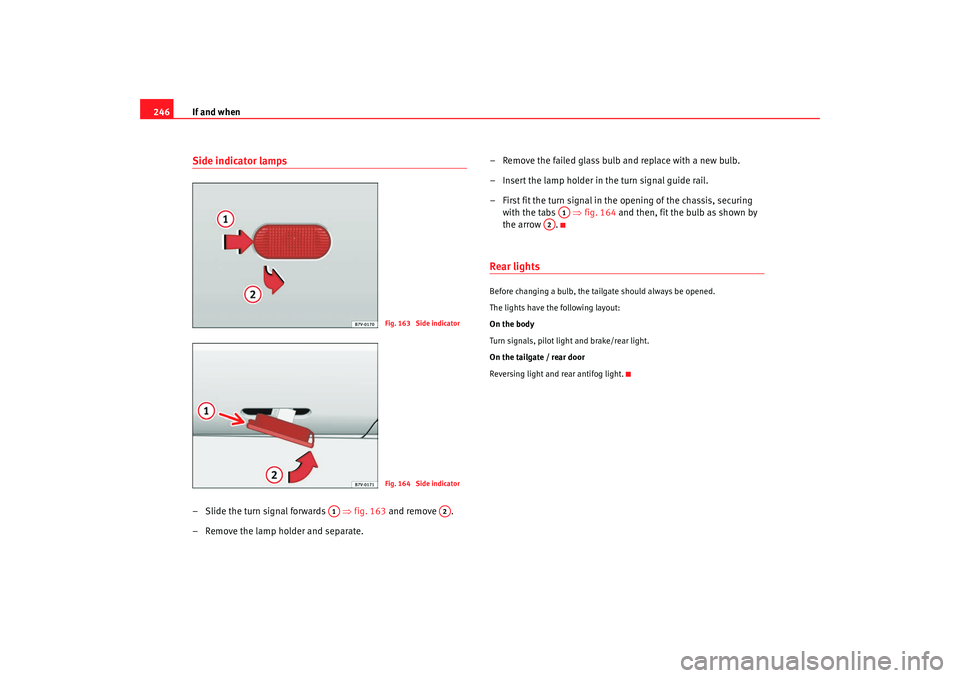

246Side indicator lamps– Slide the turn signal forwards ⇒fig. 163 and remove .

– Remove the lamp holder and separate. – Remove the failed glass bulb and replace with a new bulb.

– Insert the lamp holder in the turn signal guide rail.

– First fit the turn signal in the opening of the chassis, securing

with the tabs ⇒fig. 164 and then, fit the bulb as shown by

the arrow .

Rear lightsBefore changing a bulb, the tailgate should always be opened.

The lights have the following layout:

On the body

Turn signals, pilot light and brake/rear light.

On the tailgate / rear door

Reversing light and rear antifog light.

Fig. 163 Side indicatorFig. 164 Side indicator

A1

A2

A1

A2

alhambra_aleman.book Seite 246 Montag, 23. M‰ rz 2009 1:12 13

Page 249 of 285

If and when247

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

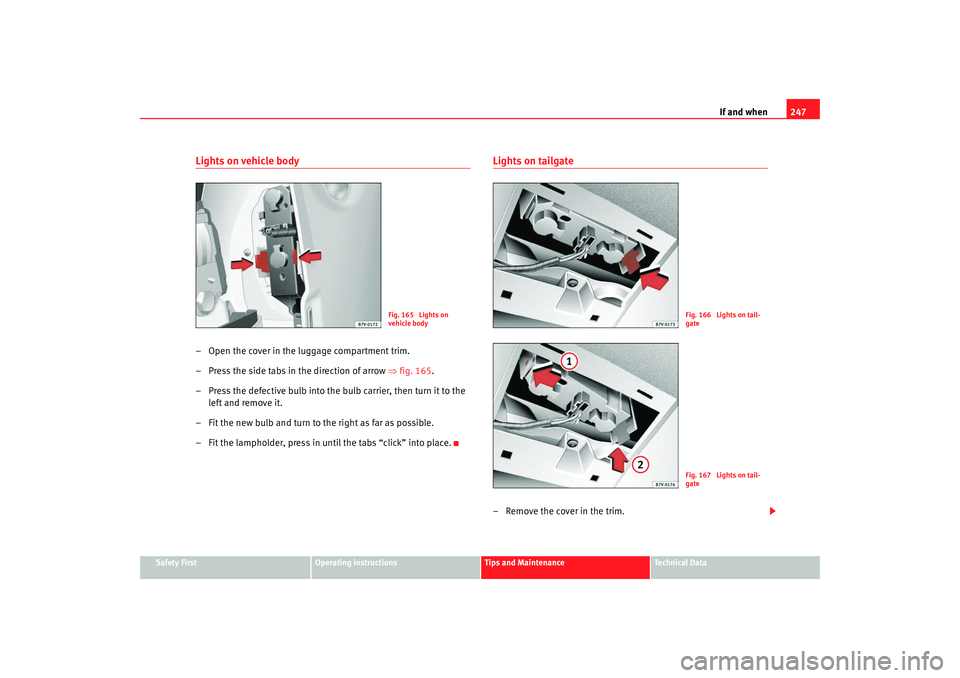

Lights on vehicle body – Open the cover in the luggage compartment trim.

– Press the side tabs in the direction of arrow ⇒fig. 165.

– Press the defective bulb into the bulb carrier, then turn it to the left and remove it.

– Fit the new bulb and turn to the right as far as possible.

– Fit the lampholder, press in until the tabs “click” into place.

Lights on tailgate– Remove the cover in the trim.

Fig. 165 Lights on

vehicle body

Fig. 166 Lights on tail-

gateFig. 167 Lights on tail-

gate

alhambra_aleman.book Seite 247 Montag, 23. M‰ rz 2009 1:12 13

Page 250 of 285

If and when

248

– Press the elastic tab in the direction of the arrow ⇒page 247,

fig. 166 and remove the lampholder downwards.

– Press the defective bulb into the bulb carrier, then turn it to the left and remove it.

– Fit the new bulb and turn to the right as far as possible.

– Fit the lampholder in the corresponding opening at the front tab and press the lampholder upwards at the back , until the

elastic tab engages ⇒page 247, fig. 167 .

– Replace the cover. To do so, insert the the two tabs of the exterior part of the cover behind the tailgate trim and push the cover

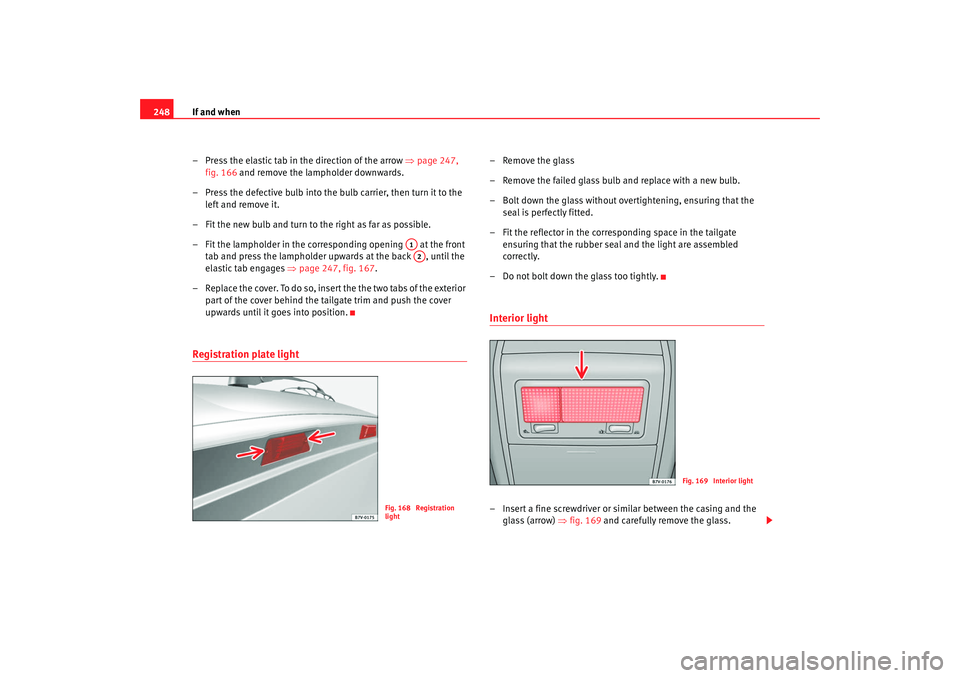

upwards until it goes into position.Registration plate light

– Remove the glass

– Remove the failed glass bulb and replace with a new bulb.

– Bolt down the glass without overtightening, ensuring that the

seal is perfectly fitted.

– Fit the reflector in the corresponding space in the tailgate ensuring that the rubber seal and the light are assembled

correctly.

– Do not bolt down the glass too tightly.Interior light– Insert a fine screwdriver or similar between the casing and the glass (arrow) ⇒fig. 169 and carefully remove the glass.

A1A2

Fig. 168 Registration

light

Fig. 169 Interior light

alhambra_aleman.book Seite 248 Montag, 23. M‰ rz 2009 1:12 13