Light Seat Alhambra 2012 Owner's Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2012, Model line: Alhambra, Model: Seat Alhambra 2012Pages: 388, PDF Size: 6.72 MB

Page 338 of 388

336If and when

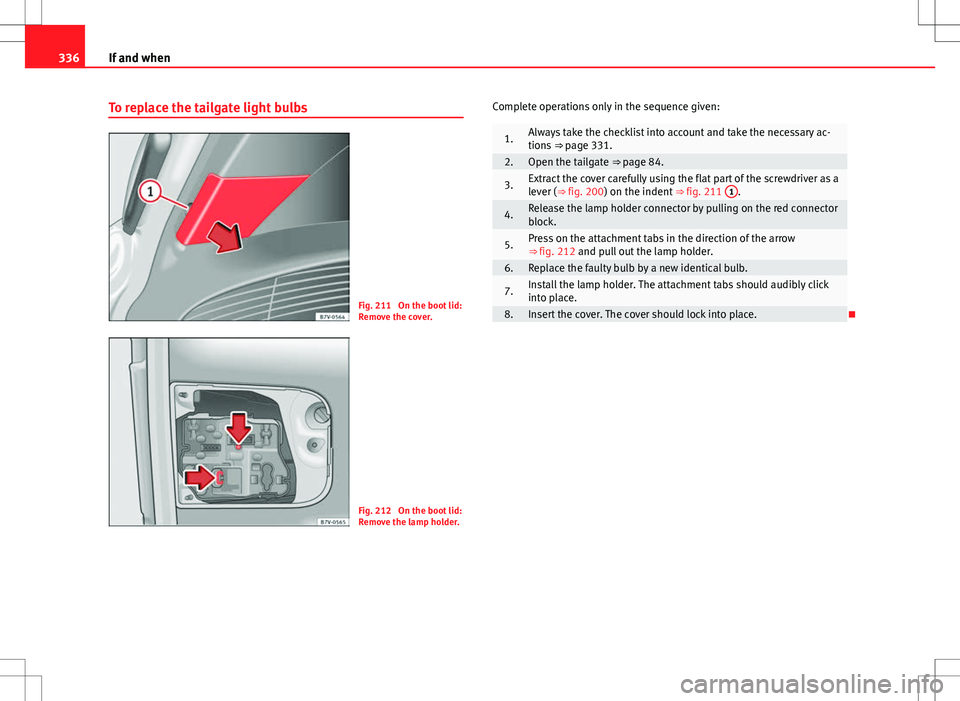

To replace the tailgate light bulbs

Fig. 211 On the boot lid:

Remove the cover.

Fig. 212 On the boot lid:

Remove the lamp holder. Complete operations only in the sequence given:

1.Always take the checklist into account and take the necessary ac-

tions

⇒ page 331.

2.Open the tailgate ⇒ page 84.

3.Extract the cover carefully using the flat part of the screwdriver as a

lever (⇒ fig. 200) on the indent ⇒ fig. 211 1.

4.Release the lamp holder connector by pulling on the red connector

block.

5.Press on the attachment tabs in the direction of the arrow

⇒ fig. 212 and pull out the lamp holder.

6.Replace the faulty bulb by a new identical bulb.

7.Install the lamp holder. The attachment tabs should audibly click

into place.

8.Insert the cover. The cover should lock into place.

Page 339 of 388

337

If and when

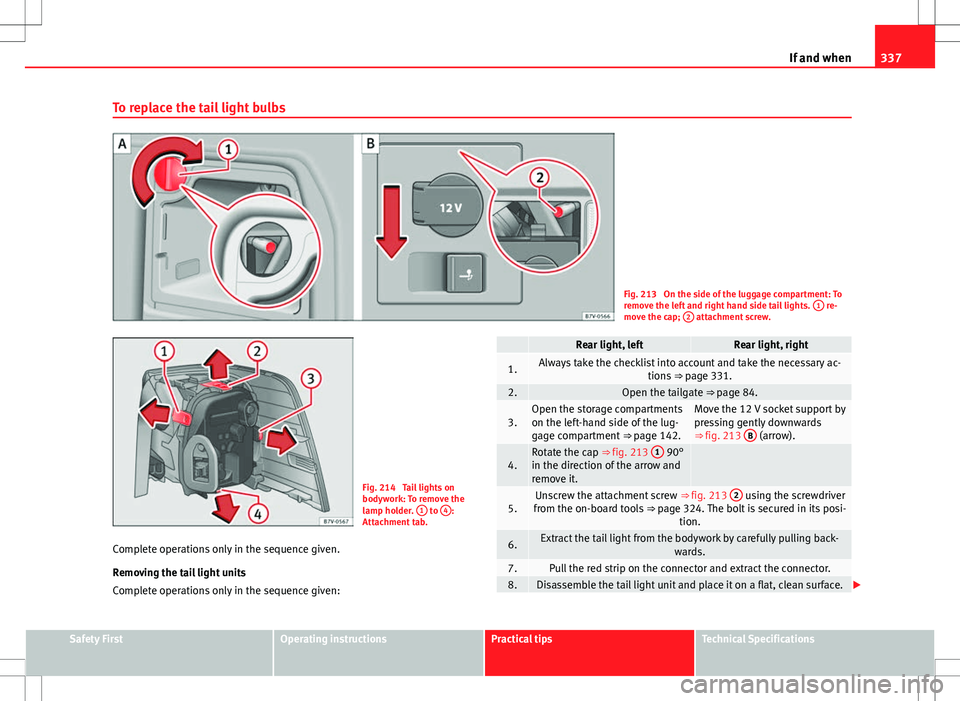

To replace the tail light bulbs

Fig. 213 On the side of the luggage compartment: To

remove the left and right hand side tail lights. 1 re-

move the cap; 2 attachment screw.

Fig. 214 Tail lights on

bodywork: To remove the

lamp holder. 1

to 4:

Attachment tab.

Complete operations only in the sequence given.

Removing the tail light units

Complete operations only in the sequence given:

Rear light, leftRear light, right

1.Always take the checklist into account and take the necessary ac- tions ⇒ page 331.

2.Open the tailgate ⇒ page 84.

3.Open the storage compartments

on the left-hand side of the lug-

gage compartment ⇒ page 142.Move the 12 V socket support by

pressing gently downwards

⇒ fig. 213 B

(arrow).

4.Rotate the cap ⇒ fig. 213 1 90°

in the direction of the arrow and

remove it.

5.Unscrew the attachment screw ⇒ fig. 213 2 using the screwdriver

from the on-board tools ⇒ page 324. The bolt is secured in its posi-

tion.

6.Extract the tail light from the bodywork by carefully pulling back- wards.

7.Pull the red strip on the connector and extract the connector.8.Disassemble the tail light unit and place it on a flat, clean surface.

Safety FirstOperating instructionsPractical tipsTechnical Specifications

Page 340 of 388

338If and when

To change the bulb

9.To release the lamp holder, press on the attachment tabs

⇒ fig. 214 1 to 4 in the direction of the arrow.10.Remove the lamp holder from the tail light unit.11.Replace the faulty bulb by a new identical bulb.

12.Place the lamp holder in the tail light unit. The attachment tabs

should audibly click into place.

13.Insert the connector and press the red attachment strip in so that

the connector is locked into place.

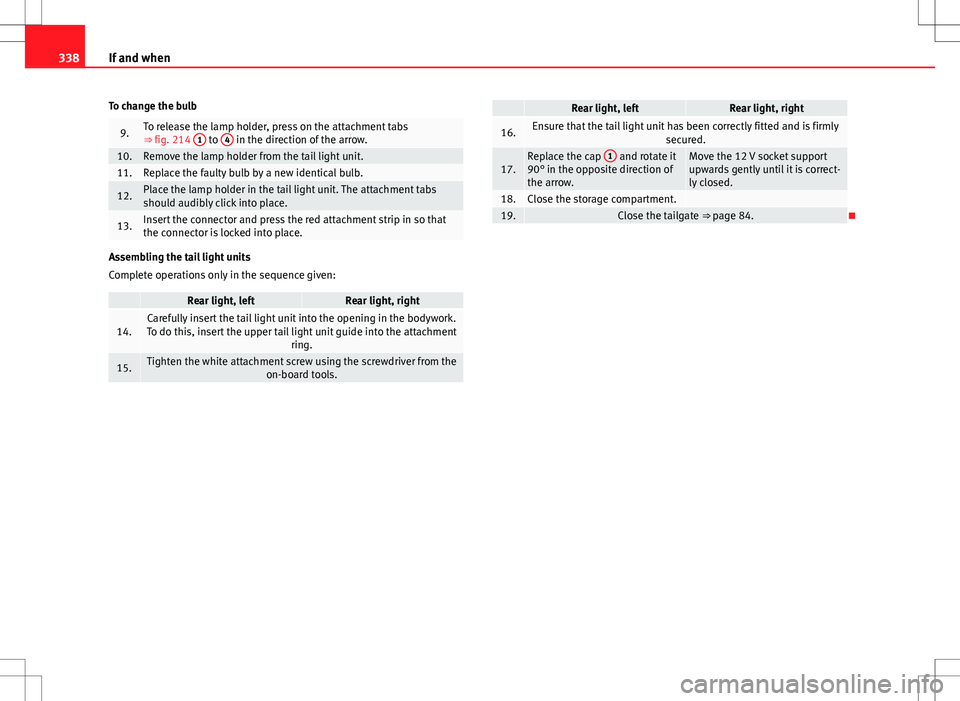

Assembling the tail light units

Complete operations only in the sequence given:

Rear light, leftRear light, right

14.Carefully insert the tail light unit into the opening in the bodywork.

To do this, insert the upper tail light unit guide into the attachment ring.

15.Tighten the white attachment screw using the screwdriver from theon-board tools.

Rear light, leftRear light, right

16.Ensure that the tail light unit has been correctly fitted and is firmly secured.

17.Replace the cap 1 and rotate it

90° in the opposite direction of

the arrow.Move the 12 V socket support

upwards gently until it is correct-

ly closed.

18.Close the storage compartment. 19.Close the tailgate ⇒ page 84.

Page 341 of 388

339

If and when

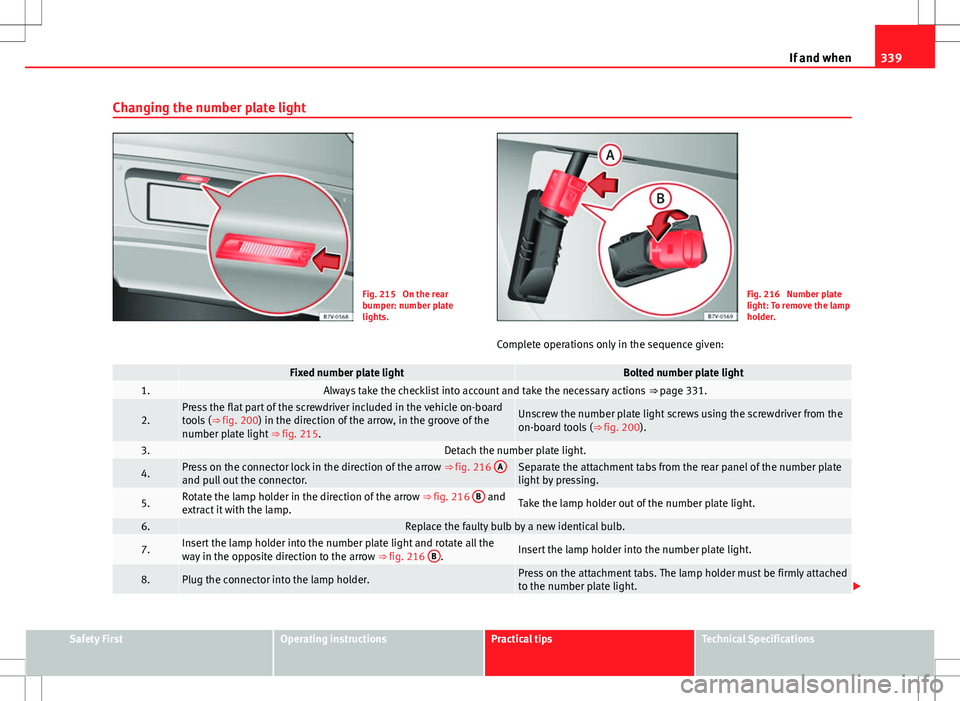

Changing the number plate light

Fig. 215 On the rear

bumper: number plate

lights.Fig. 216 Number plate

light: To remove the lamp

holder.

Complete operations only in the sequence given:

Fixed number plate lightBolted number plate light1.Always take the checklist into account and take the necessary actions ⇒ page 331.

2.Press the flat part of the screwdriver included in the vehicle on-board

tools (⇒ fig. 200) in the direction of the arrow, in the groove of the

number plate light ⇒ fig. 215.Unscrew the number plate light screws using the screwdriver from the

on-board tools (⇒ fig. 200).

3.Detach the number plate light.

4.Press on the connector lock in the direction of the arrow ⇒ fig. 216 Aand pull out the connector.Separate the attachment tabs from the rear panel of the number plate

light by pressing.

5.Rotate the lamp holder in the direction of the arrow

⇒ fig. 216 B and

extract it with the lamp.Take the lamp holder out of the number plate light.

6.Replace the faulty bulb by a new identical bulb.

7.Insert the lamp holder into the number plate light and rotate all the

way in the opposite direction to the arrow ⇒ fig. 216 B.Insert the lamp holder into the number plate light.

8.Plug the connector into the lamp holder.Press on the attachment tabs. The lamp holder must be firmly attached

to the number plate light.

Safety FirstOperating instructionsPractical tipsTechnical Specifications

Page 342 of 388

340If and when

Fixed number plate lightBolted number plate light9.Insert the number plate light carefully into the opening on the bumper. Ensure that the number plate light is in the correct position.

10.Insert the number plate light into the bumper until it audibly clicks into

place.Tighten the attachment screws for the number plate light using the

screwdriver.

Page 345 of 388

343

If and when

The vehicles should not touch. Otherwise, current may be allowed to flow

when the positive poles are connected.

Connect the clamps so they have good metal-to-metal contact with the ter-

minals.

If the engine fails to start straight-away, switch off the starter after about 10

seconds and try again after about a minute.

Complete operations only in the sequence given.

Jump lead terminal connections

● Switch off the ignition of both vehicles ⇒ page 172.

● Likewise, open the battery cover in the engine compartment

⇒ page 292, or remove the positive pole cap from one side 1)

, in the direc-

tion of the arrow ⇒ fig. 217.

● Connect one end of the red jump lead to the positive terminal

⇒ fig. 218 +

or ⇒

fig. 217 + of the vehicle with the flat battery A ⇒ .

● Connect the other end of the red jump lead to the positive terminal + in

the vehicle providing assistance B.

● For vehicles without Start-Stop system: Connect one end of the black

jump lead to the negative terminal -

in the vehicle providing assistance

B ⇒ fig. 218.

● For vehicles with Start-Stop system: Connect one end of the black X

jump lead to a suitable ground connection, a solid piece of metal in the en-

gine block, or to the engine block

⇒ fig. 219.

● Connect the other end of the black jump lead X

to a solid metal compo-

nent connected to the engine block, or onto the engine block itself of the

vehicle with the flat battery however, connect it as far away as possible from

the battery A

⇒ .

● Place the leads so that they cannot be caught by any moving parts in the

engine compartment. Switching on

●

Start the engine of the vehicle supplying current and let it run at idling

speed.

● Start the engine of the car with the flat battery and wait two or three mi-

nutes until the engine is “running smoothly”.

Removing the jump leads

● Before you remove the jump leads, switch off the headlights (if they are

switched on).

● Turn on the heating and rear window heater in the vehicle with the flat

battery. This helps minimise voltage peaks which are generated when the

leads are disconnected.

● With the engines running, disconnect the leads in reverse order to con-

nection.

● Close the battery cover, or replace the positive pole cap 1)

.

WARNING

Incorrectly jump starting could cause the battery to explode resulting in

serious injury. Please observe the following rules to minimise the risk of

a battery explosion:

● All work involving the vehicle battery and electrical system can cause

corrosion, fire and serious electric shocks. Always read and take into ac-

count the safety warnings and standards before beginning work on the

battery ⇒ page 292, Vehicle battery.

● Always protect your eyes with suitable working goggles and never

lean over the vehicle battery.

● The jump leads must be connected in the correct order: first the posi-

tive cable, then the negative cable.

1)

Vehicles whose battery is not located in the engine compartment ⇒ page 342.

Safety FirstOperating instructionsPractical tipsTechnical Specifications

Page 347 of 388

345

If and when

Instructions for tow starting

In general, the vehicle should not be started by towing. Jump-starting is

much more preferable ⇒ page 341.

For technical reasons, the following vehicles can not be tow started:

● Vehicles with an automatic gearbox.

● Vehicles with an electronic parking brake, given that it is possible that

the brake will not be disengaged.

● If the vehicle battery is flat, it is possible that the engine control units do

not operate correctly.

However, if your vehicle must absolutely be tow-started (manual gearbox):

● Engage the 2nd or 3rd gear.

● Keep the clutch pressed down.

● Switch on the ignition and the hazard warning lights.

● Release the clutch when both vehicles are moving.

● As soon as the engine starts, press the clutch and move the gear lever

into neutral. This helps to prevent a collision with the towing vehicle.

CAUTION

When tow-starting, fuel could enter the catalytic converter and damage it.

Towing instructions

Tow-rope or tow-bar

When towing, the tow bar is the safest and vehicle friendly way. You should

only use a tow-rope if you do not have a tow-bar. A tow-rope should be slightly elastic to avoid damage to both vehicles. It is

advisable to use a tow-rope made of synthetic fibre or similarly elastic mate-

rial.

Only secure the tow rope or tow bar to the tow ring or specially designed

fitting.

Vehicles with a

factory fitted towing device , can only be used for towing

with a tow-bar, specially designed to fit on a tow hitch ball ⇒ page 237.

Towing vehicles with an automatic gearbox

Note the following for a towed vehicle:

● Make sure the gear selector lever is in the N position.

● Do not drive faster than 50 km/h (30 mph) when towing a vehicle.

● Do not tow further than 50 km (30 miles).

● If a breakdown truck is used, the vehicle must be towed with the front

wheels raised. Note the following instructions for towing four wheel drive

vehicles.

Instructions for towing four-wheel-drive vehicles

Four wheel drive vehicles can be towed using a toolbar or tow rope. If the

vehicle is towed with the front or rear axle raised, the engine must be turned

off to avoid transmission damage.

For vehicles with a double clutched DSG ®

(direct shift gearbox) the instruc-

tions for towing vehicles with an automatic gearbox apply ⇒ page 345.

Situations in which the vehicle should not be towed

In the following cases, the vehicle should not be towed but transported on a

trailer or special vehicle:

● If the vehicle gearbox does not contain lubricant due to a fault.

● If the vehicle battery is flat and, as a result, the electronic steering lock

and electronic parking brake cannot be disengaged if applied.

● If the vehicle to be towed has an automatic gearbox and the distance to

be covered is greater than 50 km (30 miles).

Safety FirstOperating instructionsPractical tipsTechnical Specifications

Page 349 of 388

347

If and when

Fitting the tow ring to the rear for vehicles without factory fitted tow hitch

● Take the tow ring from the on-board tools ⇒ page 324.

● Press on the upper cover and carefully remove it back. This may require

some strength. Allow the cover to hang.

● Screw in the tow ring into its position anticlockwise as far as it will go

⇒

. Use a suitable tool to firmly tighten the tow ring in its location.

● After towing, remove the tow ring by turning it clockwise and put the

cover back in place.

CAUTION

● The tow ring must always be completely and firmly tightened. Other-

wise, it could be released while towing and tow-starting.

● Vehicles with a factory fitted towing device, can only be used for towing

with a tow-bar, specially designed to fit on a tow hitch ball. Otherwise, the

tow hitch ball and the vehicle may be damaged. Otherwise, a tow rope

should be used.

Towing advice

Towing requires some experience, especially when using a tow-rope. Both

drivers should be familiar with the technique required for towing. For this

reason, inexperienced drivers should abstain.

While driving, avoid excessive traction forces and jerking. When towing on

an unpaved road, there is always a risk of overloading and damaging the

anchorage points.

If the vehicle is towed, with the hazard warning lights on and the ignition

switched on, the turn signal may be used to indicate changes of direction.

Simply operate the turn indicator lever as usual. Meanwhile, the hazard

warning lights will go off. When the turn signal lever is returned to the rest

position, the hazard warning lights will be turned on automatically. Notes for the driver of the towed vehicle

●

Leave the ignition on to avoid locking the steering wheel, to release the

electronic parking brake and to activate the turn signal indicators, the horn

as well as the window wipers and window washers.

● As the power assisted steering does not work if the engine is not run-

ning, you will need more strength to steer than normally.

● The brake must be depressed must harder as the brake servo does not

operate. Avoid hitting the towing vehicle.

● Note the instructions and information contained in the instruction man-

ual for the vehicle to be towed.

Notes for the driver of the towing vehicle

● Accelerate gently and carefully. Avoid sudden manoeuvres.

● Brake well in advance than usual and brake gently.

● Note the instructions and information contained in the instruction man-

ual for the vehicle to be towed.

Safety FirstOperating instructionsPractical tipsTechnical Specifications

Page 353 of 388

351

Description of specifications

Towing a trailer Trailer weights

Trailer weight

The trailer weights and drawbar loads approved are selected in intensive tri-

als according to precisely defined criteria. The approved trailer weights are

valid for vehicles in the EU for maximum speeds of 80 km/h (in certain cir-

cumstances up to 100 km/h). The figures may be different in other coun-

tries. All data in the official vehicle documents take precedence over these

data ⇒

.

Drawbar load

The maximum permitted weight exerted by the trailer drawbar on the ball

joint of the towing bracket must not exceed 100 kg.

In the interest of road safety, we recommend that you always tow approach-

ing the maximum drawbar load. The response of the trailer on the road will

be poor if the drawbar load is too small.

If the maximum permissible drawbar load cannot be met (e.g. with small,

empty and light-weight single axle trailers or tandem axle trailers with a

wheelbase of less than 1 metre), a minimum of 4% of the actual trailer

weight is legally required for the drawbar load.

WARNING

● For safety reasons, do not exceed the 80 km/h limit. This is also valid

in countries where higher speeds are permitted.

● Never exceed the maximum trailer weights or the drawbar load. If the

permissible axle load or the permissible total weight is exceeded, the

driving characteristics of the vehicle may change, leading to accidents,

injuries and damage to the vehicle.

Wheels

Tyre pressure, snow chains, wheel bolts

Tyre pressures

The sticker with the tyre pressure values can be found on the inside of the

tank flap. The tyre pressure values given there are for cold tyres. The slightly

raised pressures of warm tyres must not be reduced. ⇒

Snow chains

Snow chains may be fitted only to the front wheels.

Consult the chapter “wheels” of this manual.

Wheel bolts

After the wheels have been changed, the tightening torque of the wheel

bolts should be checked as soon as possible with a torque wrench ⇒

.

The tightening torque for steel and alloy wheels is 140 Nm.

WARNING

● Check the tyre pressure at least once per month. Checking the tyre

pressure is very important. If the tyre pressure is too high or too low,

there is an increased danger of accidents, particularly at high speeds.

● If the torque of the wheel bolts is too low, they could loosen while the

vehicle is in motion. Risk of accident! If the tightening torque is too high,

the wheel bolts and threads can be damaged.

Note

We recommend that you ask your Technical Service for information about

appropriate wheel, tyre and snow chain size.

Safety FirstOperating instructionsPractical tipsTechnical Specifications

Page 369 of 388

367

Technical specifications

Dimensions and capacities

DimensionsLength, width 4854 mm1904 mmHeight at kerb weight 1720 mmFront and rear projection Wheelbase 2919 mmTurning circle

Track width a)FrontRear1557 – 1569 mm1605 – 1617 mmCapacitiesFuel tank 70 litres. Reserve 8 litres.Windscreen washer fluid container with headlight washer 3.5 l/ 6 lTyre pressureSummer-grade tyres:The correct tyre pressure can be seen on the sticker on the inside of the tank flap.Winter tyres:The pressure of these tyres is the same as the summer tyre pressure plus 0.2 bar.a)

This data will change depending on the type of wheel rim.

CAUTION

● Special care should be taken when parking in areas with high kerbs or

fixed barriers. Objects protruding from the ground may damage the bumper

or other parts of the vehicle during manoeuvres.

● Special attention is required when driving through entrances, over

ramps, kerbs or other objects. The vehicle underbody, bumpers, mudguards

and running gear, and the engine and exhaust system could be damaged as

you drive over these objects.

Safety FirstOperating instructionsPractical tipsTechnical Specifications