wheel bolts Seat Alhambra 2015 Owner's Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2015, Model line: Alhambra, Model: Seat Alhambra 2015Pages: 305, PDF Size: 5.46 MB

Page 235 of 305

Wheels and tyres

time to time according to the system

››› Fig. 174 . The useful life of all the tyres will

then be about the s

ame time.

SEAT recommends you take the vehicle to a

specialised workshop to have the tyres

changed.

Tyres that are over 6 years old

Tyres are subject to an ageing process as a

result of physical and chemical processes.

This may affect their performance. Tyres

which are stored for long periods of time

without being used, harden and become

more fragile than tyres which are in constant

use.

SEAT recommends that tyres over six years

old are replaced with new tyres. This also ap-

plies to tyres which appear to be in perfect

condition on the outside and which have a

tread depth within the values stipulated by

the Law ››› .

The date of manufacture, part of the tyre

identification number (TIN), indicates the age

of the tyre ››› page 238 .

St orin

g tyres

Mark tyres when you remove them to indicate

the direction of rotation (left, right, forwards,

backwards). This ensures you will be able to

mount them correctly when you replace

them. When removed, the wheels and/or

tyres should be stored in a cool, dry and pref- erably dark location. Do

not place tyres

mount

ed on the wheel in a vertical position.

Protect tyres not mounted on wheels from

dirt by storing them in suitable bags and

standing them on the ground on their tread. WARNING

Aggressive fluids or substances could result

in visible or invisible damage with the conse-

quent risks.

● Always ensure that tyres do not come into

contact with chemical products, oil, grease,

fuel, brake fluid or other aggressive substan-

ces. WARNING

Old tyres, even if they have never been used,

may lose air or burst unexpectedly while driv-

ing, resulting in serious accident or damage.

● If tyres are over six years old, they should

only be used in an emergency and with ex-

treme caution. For the sake of the environment

Old tyres must be disposed of by qualified

personnel according to the laws in the coun-

try concerned. Wheel rims

The design of wheel bolts is matched to the

rims. If different rims are fitted, the correct

wheel bolts with the right length and correct-

ly shaped bolt heads must be used. This en-

sures that wheels are fitted securely and that

the brake system functions correctly

››› page 246.

F or t

echnical reasons, it is not generally pos-

sible to use the wheels from other vehicles.

In some cases, this may also be true for the

same model of wheel.

The tyres and rims approved by SEAT are spe-

cially matched to the characteristics of the

vehicle and are critical to good road holding

and safe handling.

Note for Italy: A SEAT Service Centre should

be c on

sulted whether different sized wheels

or tyres to those originally fitted by SEAT may

be fitted, as well as the combinations al-

lowed between the front axle (axle 1) and

back axle (axle 2).

Wheel bolts

Wheel bolts must be tightened to the correct

torque ›››

page 246

.

Beadlock wheel rims

Beadlock wheel rims have various compo-

nents. These are joined together by special

bolts using a special procedure. This ensures »

233

Technical specifications

Advice

Operation

Safety

Page 236 of 305

Advice

good performance, a better seal, improved

safety and wheel run out. Therefore, worn

rims should always be replaced and must on-

ly be repaired in a specialised workshop.

SEAT recommends visiting a technical service

››› .

Wheel rims with bolted trims

Wheel rims may be fitted with interchangea-

ble trim parts which are attached to the rim

using self-locking bolts. Worn trims should

only be replaced at a specialised workshop.

SEAT recommends visiting a technical service

››› .

WARNING

The use of worn or damaged wheel rims could

make driving more dangerous and result in

serious accidents and damage.

● Only wheel rims which have been approved

for use with your vehicle should be used.

● Inspect wheel rims regularly for damage

and replace as required. WARNING

If the bolted joints of wheel rims with bolted

ring trims are not correctly tightened or loos-

ened, this could result in serious accident.

● Never loosen the bolted joints of wheel

rims with bolted ring trims.

● Any work relating to wheel rims with bolted

rims should be carried out at specialised workshop. SEAT recommends taking your car

in for technical service.

Replacement of wheel rims and new

tyres

New tyres

● When tyres are new, drive with extreme

caution for the first 500 km, as all tyres need

to be run-in . Tyres which have not been run-

in do not

have such good grip ››› or brak-

ing capacity ››› .

● All four wheels must be fitted with radial

tyres of the same type, size (rolling circumfer-

ence) and the same tread pattern.

● The tread depth of new tyres may vary, ac-

cording to the type and make of tyre and the

tread pattern.

Replacing tyres

● Where possible, always replace both

wheels on an axle (both wheels on the front

axle or both wheels on the rear axle) ››› .

● Old tyres should only be replaced by SEAT

approved tyres for the vehicle in question,

and in accordance with the maximum permit-

ted size, diameter, load and speed capacity.

● If replacing tyres, make sure the new ones

have an emergency ride system (Conti-

Seal/Run flat). Otherwise, we recommend

carrying a tyre mobility system. ●

Never use tyres which are larger than SEAT

approved tyres. If the tyres are too big, they

may knock or rub against the chassis or other

components, resulting in damage. WARNING

New tyres do not give maximum grip and will

not have reached their maximum braking ca-

pacity to start with, and therefore need run-

ning in.

● To prevent accidents and major damage,

extreme caution should be taken for the first

600 km. WARNING

There should be adequate space between the

tyres and the vehicle in accordance with the

vehicle design. If this is not the case, the

tyres may rub against parts of the running

gear, chassis or brake lines, leading to faults

in the brake system or to tread detachment,

and the risk of burst tyres.

● The true tyre dimension should not be

greater than the dimensions of tyres manu-

factured and approved by SEAT and should

not rub against parts of the vehicle. Note

● Although tyres may be shown as being the

same size, the true dimensions of different

types of tyre may vary with respect to the

nominal size, or tread patterns may be differ-

ent. 234

Page 244 of 305

Advice

Snow chains When using snow chains, applicable local

legislation and maximum permitted speed

limits must be observed.

In winter weather, snow chains not only help

to improve grip but also improve the braking

capacity.

Snow chains must only be mounted

on the

front wheels , even on all-wheel drive vehi-

cles, and only with the tyre and rim combina-

tions listed below:Tyre sizeWheel rim

205/60 R166 1/2 J x 16 ET 33 SEAT recommends you ask a technical serv-

ice for further information on wheel, tyre and

chain sizes.

Wherever possible use fine-link chains meas-

uring less than 15 mm (37/64 inch) includ-

ing the lock.

Remove wheel hub covers and trim rings be-

fore fitting snow chains

››› . The wheel bolts

should be covered with caps for safety rea-

sons. These are available from technical serv-

ices. WARNING

The use of unsuitable or incorrectly fitted

chains could lead to serious accidents and

damage.

● Always the appropriate snow chains.

● Observe the fitting instructions provided by

the snow chain manufacturer.

● Never exceed the maximum permitted

speeds when driving with snow chains. CAUTION

● Remove the snow chains to drive on roads

without snow. Otherwise they will impair

handling, damage the tyres and wear out very

quickly.

● Wheel rims may be damaged or scratched if

the chains come into direct contact with

them. SEAT recommends the use of covered

snow chains. Note

Snow chains are available in different sizes

according to the vehicle type. Emergencies

In case of emergency First aid kit, warning triangle,

reflective vests and fire

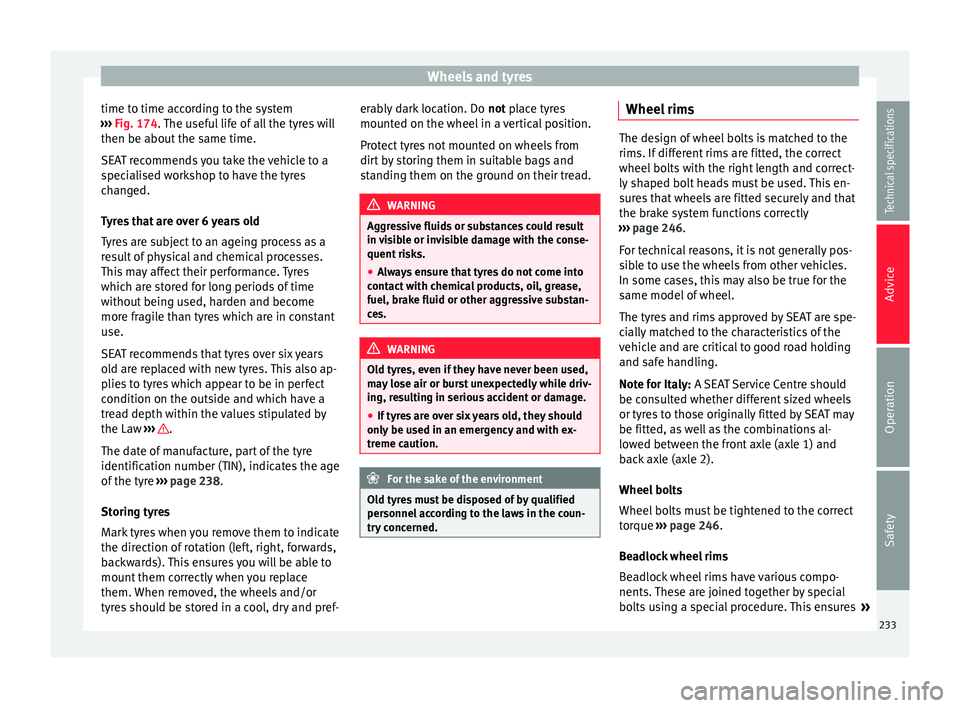

extinguishers* Fig. 178

On the rear lid: Warning triangle

bracket Reflective vests

Some vehicles will have a driver door com-

partment to store a reflective vest

››› page 38 .

W arnin

g triangle

With the boot hatch open, rotate the lock 90°

››› Fig. 178. Lower the bracket and remove

the warnin

g triangle.

242

Page 247 of 305

Emergencies

Note

After use, return the jack to its initial position

using the handle in order to securely store it

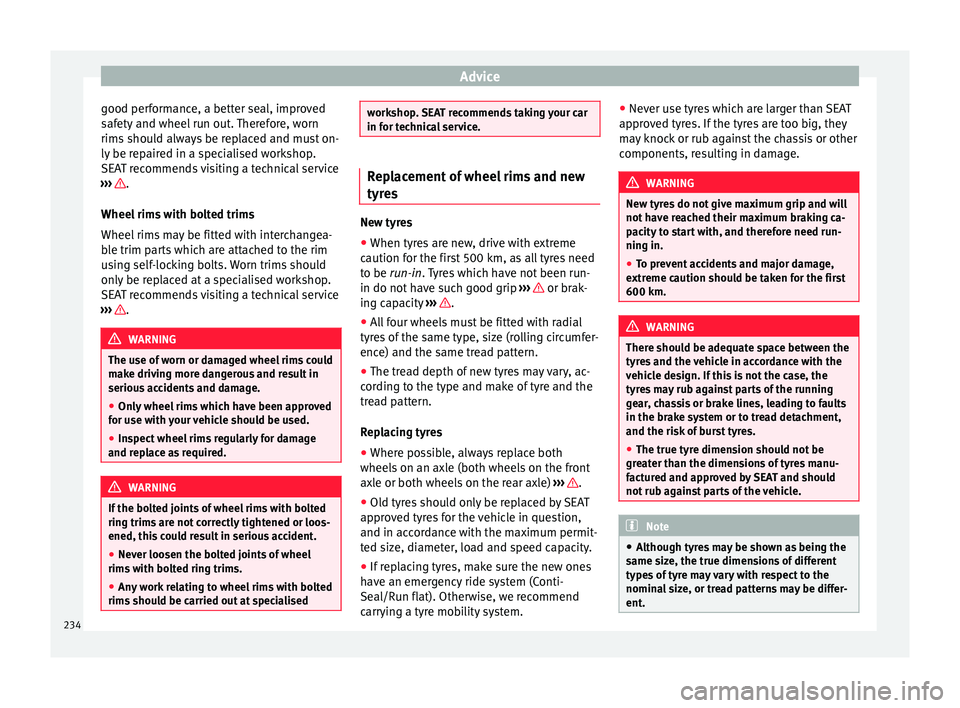

in the vehicle. Components

Fig. 181

Components of the vehicle tool kit The vehicle tool kit depends on the vehicle

equipment. The following is a description for

a vehicle with all options.

The individual elements of the vehicle tool

kit

›

›› Fig. 181

Ad apter for anti-theft bolt. SEAT recom-

mend you carry the wheel bolt adapter in

the vehicle tool kit at all times. The code

number

of the anti-theft wheel bolt is

stamped on the front of the adapter. In

case it is lost, another adapter can be or-

1 dered using this number. Note the anti-

theft bolt code for the wheels and keep it

in a place other than the vehicle.

Towline anchorage, removable.

Wheel spanner.

Jack crank handle. The crank handle

needs to be folded away before returning

it to the tool kit.

Jack. Before storing the jack in the tool

kit, fold its hook.

Screwdriver with hexagon socket in the

handle for screwing and unscrewing the

wheel bolts. The screwdriver bit is inter-

changeable. The screwdriver may be

found underneath the wheel spanner.

Wire hook for pulling off the wheel cover,

integral hubcaps and the wheel bolt

caps.

Note

The jack does not generally require any main-

tenance. If required, it should be greased us-

ing universal type grease. 2

3

4

5

6

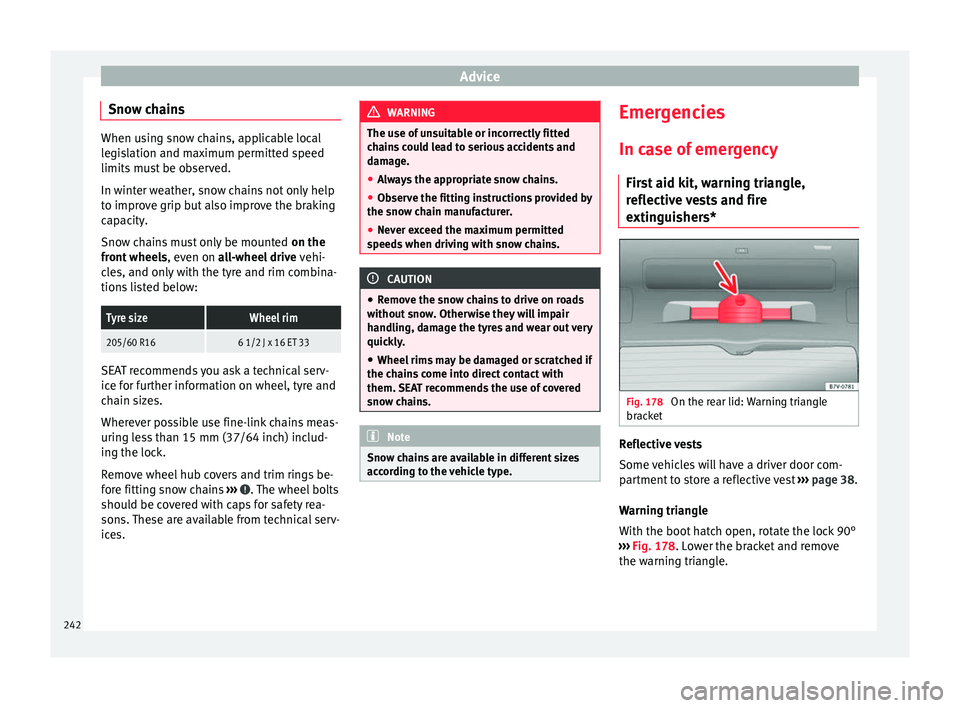

7 Folding wheel chocks*

Fig. 182

To unfold the foldable wedges. The folding chocks are in the tool kit

››› Fig. 181 .

As semb

le the folding chocks

● Lift the base plate ››› Fig. 182 1 .

● Insert the two “tabs” of the mounting plate

into the long openings on the base plate 2 .

Correct use

The folding chocks may be used to block the

wheel diagonally opposite to the wheel being

changed.

The chocks should be placed directly in front

and behind the wheel and only be used on

firm ground. »

245

Technical specifications

Advice

Operation

Safety

Page 248 of 305

Advice

WARNING

If the folding chocks are assembled or used

incorrectly, an accident may occur and seri-

ous injury caused.

● Never use damaged chocks.

● Never use chocks to immobilize the vehicle

on a slope. Changing a wheel*

Introduction The tyres mounted on the vehicle are anti-

puncture. The wheels should only be

changed when switching from summer to

winter tyres or vice-versa. See

›››

page 237

The vehicle only comes with the necessary

tools for changing wheels if factory supplied

with winter tyres. If this is not the case, you

need to go to a specialised workshop to get

the wheels changed.

You should only change the wheels yourself if

the vehicle is parked in a safe place, you are

familiar with the procedure and safety stand-

ards and you have all the necessary tools!

Otherwise, you should seek professional as-

sistance. WARNING

Changing a wheel can be dangerous, espe-

cially on the hard shoulder. Please observe

the following rules to minimise the risk of in-

jury:

● Stop the vehicle safely as soon as possible.

Park at a safe distance from surrounding traf-

fic to change a wheel.

● When changing a wheel, keep all passen-

gers, and particularly children, a safe dis-

tance away from the work area.

● Turn on the hazard warning lights to warn

other road users.

● Ensure the ground on which you park is flat

and solid. If necessary, support the jack on a

wide solid base.

● If you are changing a wheel yourself, you

should be familiar with the required proce-

dure. Otherwise, you should seek professio-

nal assistance.

● Only use suitable tools that are not dam-

aged when changing a wheel.

● Always stop the engine, turn on the elec-

tronic parking brake and place the gear selec-

tor lever in position P, for an automatic gear-

box, or engage a gear for a manual gearbox to

reduce the risk of the vehicle moving acciden-

tally.

● Have the tightening torque of the wheel

bolts checked as soon as possible with a reli-

able torque wrench. WARNING

If the wheel trims are not appropriate or not

fitted correctly, they could cause major acci-

dents or damage.

● Incorrectly mounted wheel trims may come

off while driving and endanger other road

users.

● Damaged trims must never be mounted on

the wheels.

● Always ensure that the brake ventilation

and cooling is not cut off or blocked. This is

also valid if hubcaps are fitted later. If there

is not enough air, you may require signifi-

cantly longer braking distances. CAUTION

Remove and remount wheel trims taking care

to avoid damage to the vehicle. 246

Page 249 of 305

Emergencies

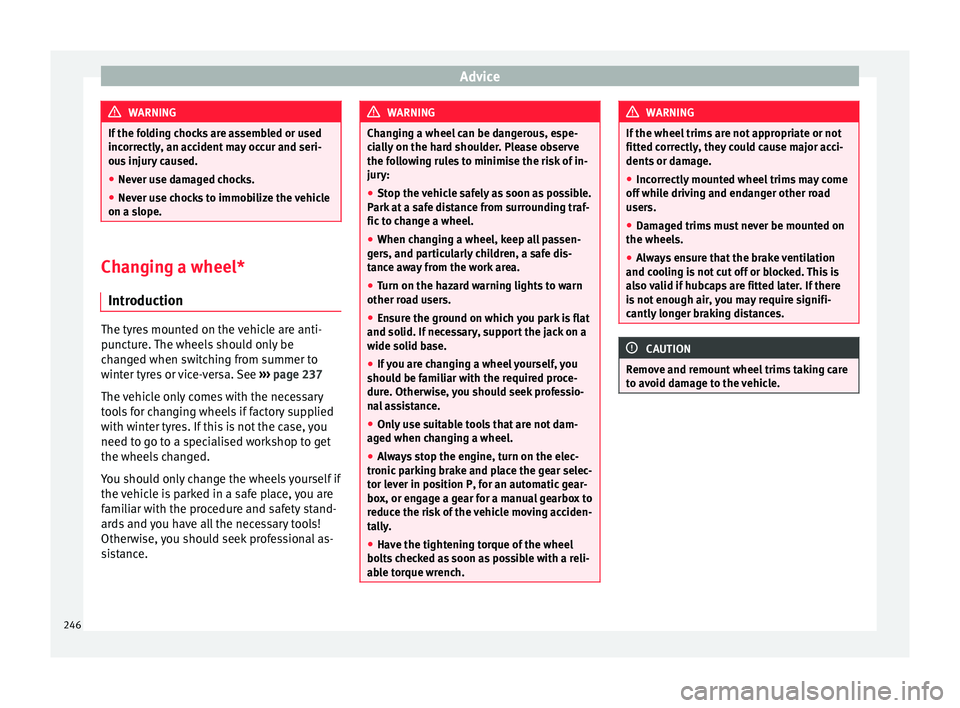

Full hubcaps* Fig. 183

Removing the full hubcap Removing the full hubcap

● Take the wheel brace and the wire hook

from the vehicle tool kit ››› page 244.

● Hook the wire through one of the grooves

on the hubcap.

● Insert the wheel brace onto the wire hook

››› Fig. 183 and pull the hub cap in the direc-

tion sho wn b

y the arrow.

Fitting hubcaps

Before mounting the full trim, the anti-theft

wheel lock must be threaded into position

››› Fig. 186 2 or

3 . Otherwise it will not be

possible to mount the full hubcap.

Press the trim against the wheel so that the

space for the valve fits over the tyre valve

››› Fig. 186 1 . Make sure that the hubcap is

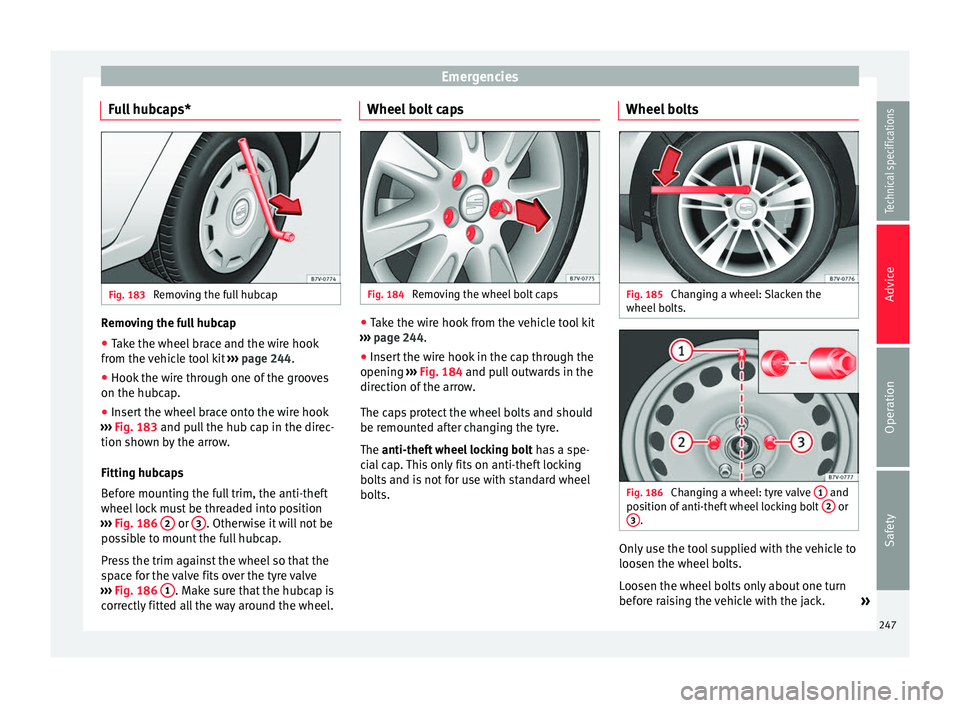

correctly fitted all the way around the wheel. Wheel bolt caps

Fig. 184

Removing the wheel bolt caps ●

Take the wire hook from the vehicle tool kit

››› page 244 .

● Inser

t the wire hook in the cap through the

opening ››› Fig. 184 and pull outwards in the

direction of

the arrow.

The caps protect the wheel bolts and should

be remounted after changing the tyre.

The

anti-theft wheel locking bolt has a spe-

cial cap. This only fits on anti-theft locking

bolts and is not for use with standard wheel

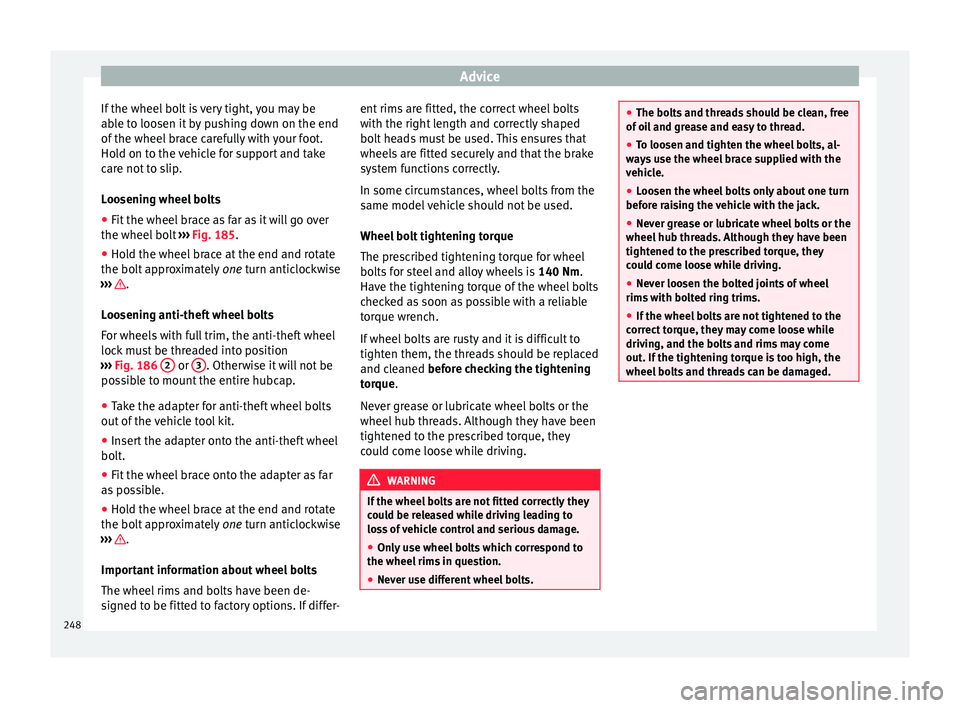

bolts. Wheel bolts

Fig. 185

Changing a wheel: Slacken the

wheel bolts. Fig. 186

Changing a wheel: tyre valve 1 and

position of anti-theft wheel locking bolt 2 or

3 .

Only use the tool supplied with the vehicle to

loosen the wheel bolts.

Loosen the wheel bolts only about one turn

before raising the vehicle with the jack.

»

247

Technical specifications

Advice

Operation

Safety

Page 250 of 305

Advice

If the wheel bolt is very tight, you may be

able to loosen it by pushing down on the end

of the wheel brace carefully with your foot.

Hold on to the vehicle for support and take

care not to slip.

Loosening wheel bolts

● Fit the wheel brace as far as it will go over

the wheel bolt ››› Fig. 185 .

● Ho l

d the wheel brace at the end and rotate

the bolt approximately one turn anticlockwise

››

› .

Loosening anti-theft wheel bolts

For wheels with full trim, the anti-theft wheel

lock must be threaded into position

››› Fig. 186 2 or

3 . Otherwise it will not be

possible to mount the entire hubcap.

● Take the adapter for anti-theft wheel bolts

out of the vehicle tool kit.

● Insert the adapter onto the anti-theft wheel

bolt.

● Fit the wheel brace onto the adapter as far

as possible.

● Hold the wheel brace at the end and rotate

the bolt approximately one turn anticlockwise

› ›

› .

Important information about wheel bolts

The wheel rims and bolts have been de-

signed to be fitted to factory options. If differ- ent rims are fitted, the correct wheel bolts

with the right length and correctly shaped

bolt heads must be used. This ensures that

wheels are fitted securely and that the brake

system functions correctly.

In some circumstances, wheel bolts from the

same model vehicle should not be used.

Wheel bolt tightening torque

The prescribed tightening torque for wheel

bolts for steel and alloy wheels is

140 Nm.

Hav e the tight

ening torque of the wheel bolts

checked as soon as possible with a reliable

torque wrench.

If wheel bolts are rusty and it is difficult to

tighten them, the threads should be replaced

and cleaned before checking the tightening

tor

que.

Never grease or lubricate wheel bolts or the

wheel hub threads. Although they have been

tightened to the prescribed torque, they

could come loose while driving. WARNING

If the wheel bolts are not fitted correctly they

could be released while driving leading to

loss of vehicle control and serious damage.

● Only use wheel bolts which correspond to

the wheel rims in question.

● Never use different wheel bolts. ●

The bolts and threads should be clean, free

of oil and grease and easy to thread.

● To loosen and tighten the wheel bolts, al-

ways use the wheel brace supplied with the

vehicle.

● Loosen the wheel bolts only about one turn

before raising the vehicle with the jack.

● Never grease or lubricate wheel bolts or the

wheel hub threads. Although they have been

tightened to the prescribed torque, they

could come loose while driving.

● Never loosen the bolted joints of wheel

rims with bolted ring trims.

● If the wheel bolts are not tightened to the

correct torque, they may come loose while

driving, and the bolts and rims may come

out. If the tightening torque is too high, the

wheel bolts and threads can be damaged. 248

Page 251 of 305

Emergencies

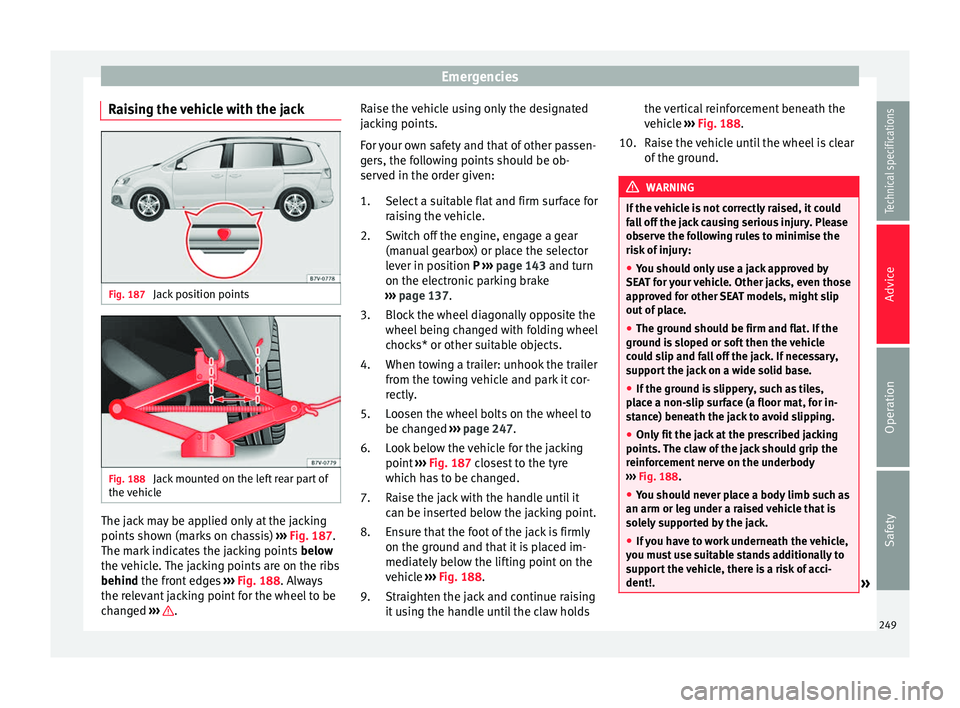

Raising the vehicle with the jack Fig. 187

Jack position points Fig. 188

Jack mounted on the left rear part of

the vehicle The jack may be applied only at the jacking

points shown (marks on chassis)

››› Fig. 187 .

The m ark

indicates the jacking points below

the vehicle. The jacking points are on the ribs

behind

the front edges ››› Fig. 188. Always

the rel

evant jacking point for the wheel to be

changed ››› . Raise the vehicle using only the designated

jacking points.

For your own safety and that of other passen-

gers, the following points should be ob-

served in the order given:

Select a suitable flat and firm surface for

raising the vehicle.

Switch off the engine, engage a gear

(manual gearbox) or place the selector

lever in position P

›

›› p

age 143 and turn

on the electronic parking brake

››› page 137.

Block

the wheel diagonally opposite the

wheel being changed with folding wheel

chocks* or other suitable objects.

When towing a trailer: unhook the trailer

from the towing vehicle and park it cor-

rectly.

Loosen the wheel bolts on the wheel to

be changed ››› page 247.

Look below the vehicle for the jacking

point ››› Fig. 187 closest to the tyre

which h

as to be changed.

Raise the jack with the handle until it

can be inserted below the jacking point.

Ensure that the foot of the jack is firmly

on the ground and that it is placed im-

mediately below the lifting point on the

vehicle ››› Fig. 188

.

Straighten the jack and continue raising

it using the handle until the claw holds

1.

2.

3.

4.

5.

6.

7.

8.

9. the vertical reinforcement beneath the

vehicle

››› Fig. 188

.

Raise the vehicle until the wheel is clear

of the ground. WARNING

If the vehicle is not correctly raised, it could

fall off the jack causing serious injury. Please

observe the following rules to minimise the

risk of injury:

● You should only use a jack approved by

SEAT for your vehicle. Other jacks, even those

approved for other SEAT models, might slip

out of place.

● The ground should be firm and flat. If the

ground is sloped or soft then the vehicle

could slip and fall off the jack. If necessary,

support the jack on a wide solid base.

● If the ground is slippery, such as tiles,

place a non-slip surface (a floor mat, for in-

stance) beneath the jack to avoid slipping.

● Only fit the jack at the prescribed jacking

points. The claw of the jack should grip the

reinforcement nerve on the underbody

››› Fig. 188.

● You shou

ld never place a body limb such as

an arm or leg under a raised vehicle that is

solely supported by the jack.

● If you have to work underneath the vehicle,

you must use suitable stands additionally to

support the vehicle, there is a risk of acci-

dent!. » 10.

249

Technical specifications

Advice

Operation

Safety

Page 252 of 305

Advice

●

Never raise the vehicle if it is tilting to one

side or the engine is running.

● Never start the engine when the vehicle is

raised. The vehicle may come loose from the

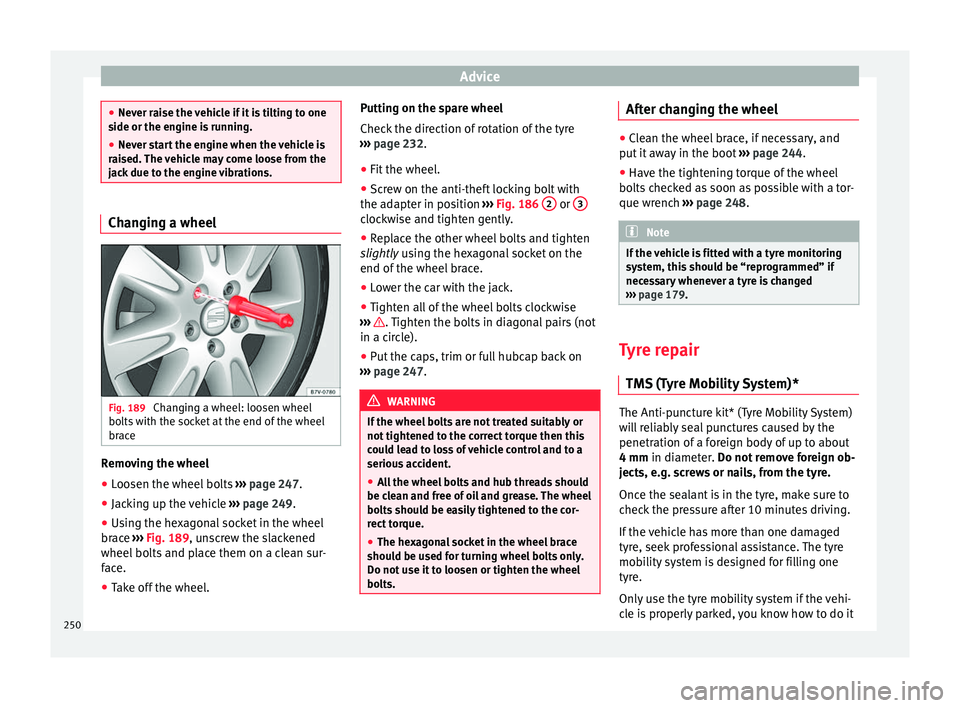

jack due to the engine vibrations. Changing a wheel

Fig. 189

Changing a wheel: loosen wheel

bolts with the socket at the end of the wheel

brace Removing the wheel

● Loosen the wheel bolts ››› page 247 .

● Jacking up the vehicle ››› page 249.

● Using the hexagonal socket in the wheel

brace ››› Fig. 189 , unscrew the slackened

wheel bo

lts and place them on a clean sur-

face.

● Take off the wheel. Putting on the spare wheel

Check the direction of rotation of the tyre

››› page 232.

● Fit the wheel

.

● Screw on the anti-theft locking bolt with

the adapter in position ››› Fig. 186 2 or

3 clockwise and tighten gently.

●

Replace the other wheel bolts and tighten

slightly using the hexagonal socket on the

end of the wheel

brace.

● Lower the car with the jack.

● Tighten all of the wheel bolts clockwise

››› . Tighten the bolts in diagonal pairs (not

in a circle).

● Put the caps, trim or full hubcap back on

››› page 247 . WARNING

If the wheel bolts are not treated suitably or

not tightened to the correct torque then this

could lead to loss of vehicle control and to a

serious accident.

● All the wheel bolts and hub threads should

be clean and free of oil and grease. The wheel

bolts should be easily tightened to the cor-

rect torque.

● The hexagonal socket in the wheel brace

should be used for turning wheel bolts only.

Do not use it to loosen or tighten the wheel

bolts. After changing the wheel

●

Clean the wheel brace, if necessary, and

put it away in the boot ››› page 244.

● Have the tightening torque of the wheel

bolts checked as soon as possible with a tor-

que wrench ››› page 248. Note

If the vehicle is fitted with a tyre monitoring

system, this should be “reprogrammed” if

necessary whenever a tyre is changed

››› page 179. Tyre repair

TMS (Tyre Mobility System)* The Anti-puncture kit* (Tyre Mobility System)

will reliably seal punctures caused by the

penetration of a foreign body of up to about

4 mm

in diameter.

Do not remove foreign ob-

j

ects, e.g. screws or nails, from the tyre.

Once the sealant is in the tyre, make sure to

check the pressure after 10 minutes driving.

If the vehicle has more than one damaged

tyre, seek professional assistance. The tyre

mobility system is designed for filling one

tyre.

Only use the tyre mobility system if the vehi-

cle is properly parked, you know how to do it

250

Page 278 of 305

Technical specifications

Towing a trailer Trailer weights Trailer weight

The trailer weights and drawbar loads ap-

proved are selected in intensive trials accord-

ing to precisely defined criteria. The ap-

proved trailer weights are valid for vehicles in

the EU

for maximum speeds of 80 km/h (50

mph) (in c ertain circumstances up to 100

km/h (62 mph)). The figures may be different

in other countries. All data in the official vehi-

cle documentation takes precedence over

these data at all times ››› .

Drawbar loads

The maximum

permitted drawbar load on the

b

all joint of the towing bracket must not ex-

ceed

100 kg.

In the interest of road safety, we recommend

that you always tow approaching the maxi-

mum drawbar load. The response of the trail-

er on the road will be poor, if the drawbar

load is too small.

If the maximum permissible drawbar load

cannot be met (e.g. with small, empty and

light-weight single axle trailers or tandem

axle trailers with a wheelbase of less than 1

metre), a minimum of 4% of the actual trailer

weight is legally required for the drawbar

load. WARNING

● For safety reasons, do not exceed the 80

km/h (50 mph) limit. This is also valid in

countries where higher speeds are permitted.

● Never exceed the maximum trailer weights

or the drawbar load. If the permissible axle

load or the permissible total weight is excee-

ded, the driving characteristics of the vehicle

may change, leading to accidents, injuries

and damage to the vehicle. Wheels

Tyre pressure, snow chains, wheel

bolts Tyre pressures

The sticker with the tyre pressure values can

be found on the inside of the fuel tank flap.

The tyre pressure values given there are for

cold

tyres. The slightly raised pressures of

w arm ty

res must not be reduced. ››› Snow chains

Snow chains may be fitted only to the

front

wheels .

C on

sult the section “wheels” of this manual. Wheel bolts

After the wheels have been changed, the

tightening torque

of the wheel bolts should

be checked as soon as possible with a torque

wrench ››› . The tightening torque for steel

and alloy wheels is 140 Nm. WARNING

● Check the tyre pressure at least once per

month. Checking the tyre pressure is very im-

portant. If the tyre pressure is too high or too

low, there is an increased danger of accidents

- particularly at high speeds.

● If the tightening torque of the wheel bolts

is too low, they could loosen while the vehi-

cle is in motion. Risk of accident! If the tight-

ening torque is too high, the wheel bolts and

threads can be damaged. Note

We recommend that you ask your Technical

Service for information about appropriate

wheel, tyre and snow chain size. 276