oil Seat Exeo 2008 Owner's Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2008, Model line: Exeo, Model: Seat Exeo 2008Pages: 303, PDF Size: 10.02 MB

Page 219 of 303

Checking and refilling levels217

Safety First

Operating instructions

Practical tips

Te c h n i c a l D a t a

Caution

•

The oil level must never be above area . This could damage the cata-

lytic converter or the engine. Contact a specialist garage to drain the engine

oil if necessary.

•

No additives should be used with engine oil. Any damage caused by the

use of such additives would not be covered by the factory warranty.For the sake of the environment

•

Oil must not be disposed of into the drains or onto the ground.

•

Always observe legal requirements when disposing of empty oil

canisters.

Cooling systemLiquid coolant

The purpose of the liquid coolant is to carry heat away from

the engine. The correct amount of antifreeze is decisive in

preventing the cooling system from freezing in winter.The your vehicle's engine cooling system is filled for life at the factory, so no

coolant needs to be changed. The liquid coolant consists of a mixture of water

and anti-freeze G12++. This is a glycol-b ased antifreeze with anti-corrosion

additives.

Liquid coolant additive

The amount of antifreeze required depends on the temperatures to be

expected in the winter season. If the antifreeze concentration is too low the

coolant can freeze, resulting in failure of the cooling system and heater. The cooling system is filled at the fact

ory with the correct amount of anti-

freeze for the country concerned.

In most cases, the mixture consists of 60% water and 40% anti-freeze. This

mixture gives the required anti-freeze protection at temperatures down to

-25°C and particularly protects the metal parts of the cooling system against

corrosion. It also prevents scaling and significantly raises the boiling point of

the liquid coolant.

Countries with warm climate

The liquid coolant concentration must not be reduced by adding plain water,

even in the summer or in warm climates. The concentration of the anti-freeze

must always be at least 40%.

Countries with cold climate

If greater frost protection is required in very cold climates, the proportion of

the anti-freeze G12++ can be increased. A concentration of 60% offers anti-

freeze protection of temperatures down to approx. -40°C. However,the

concentration of anti-freeze must not exceed 60%, as the anti-freeze protec-

tion would then drop and the performance of the coolant system would suffer.

Vehicles for countries with cold clima tes (e.g. Sweden, Norway and Finland)

have factory-filled anti-freeze protection for temperatures down to -35°C. In

these countries, the concentration of anti-freeze should always be at least

50%.

Caution

•

It is advisable to have the cooling system checked before the winter

season to make sure that the antifreeze concentration is adequate for the

conditions to be expected. This applies particularly if you intend to take the

car into a colder climate zone. If necessary, have the antifreeze concentration

increased to 50 - 60% as required.

•

Use only anti-freeze G12++ , an additive meeting the “TL-VW 774G” spec-

ification. Other anti-freezes may give considerably inferior corrosion protec-

Aa

Exeo_EN.book Seite 217 Freitag, 17. Oktober 2008 11:24 11

Page 220 of 303

Checking and refilling levels

218tion. The damage caused by the use of these anti-freezes may lead to a loss

of liquid coolant, causing serious damage to the engine.•

The anti-freeze G12++ can be mixed on ly with anti-freeze additives G11,

G12 and G12+.

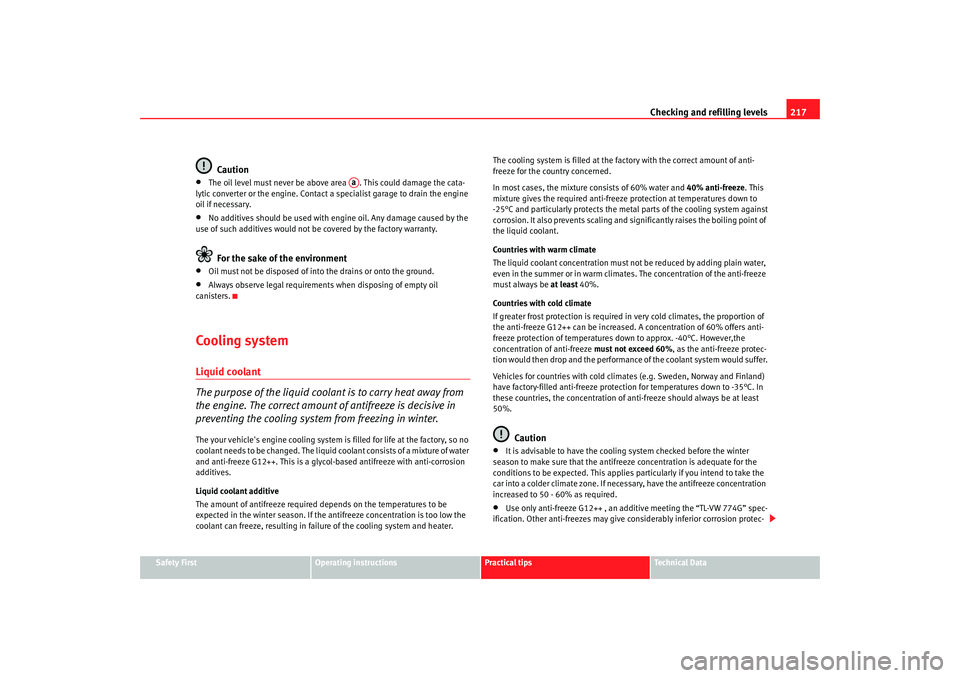

Checking the liquid coolant level

The liquid coolant level can be checked at a glance.– Switch the ignition off.

– Check the coolant level on liquid coolant expansion tank ⇒fig. 167. When the engine is cold, it should be between the

“min” and “max” marks. When the engine is hot, it may be

slightly above the “max” mark.Its location is shown in the correspon ding general overview of the engine

compartment. The liquid coolant level should be checked with the engine switched off.

The liquid coolant level is monitored

by a warning lamp in the instrument

panel ⇒ page 77. However, we recommend that it should be checked occa-

sionally.

Liquid coolant losses

Any loss of liquid coolant normally indicates a leak in the cooling system. In

this case the cooling system should be inspected by a specialist garage

without delay. It is not sufficient merely to top up the liquid coolant.

If there are no leaks in the system, a loss of liquid coolant can only occur if

the coolant boils and is forced out of the system as a result of overheating.

Caution

Radiator sealants must not be added to the liquid coolant. Such additives

could seriously impair the function of the cooling system.Topping up the liquid coolant

Be careful when topping up with liquid coolant.– Switch the engine off.

– Wait for the engine to cool down.

– Cover the cap on the expansion tank ⇒fig. 167 with a cloth, an d

carefully unscrew the cap anti-clockwise ⇒ .

– Add liquid coolant.

– Screw on the cap tightly.

Fig. 167 Engine compart-

ment: Liquid coolant

deposit

Exeo_EN.book Seite 218 Freitag, 17. Oktober 2008 11:24 11

Page 223 of 303

Checking and refilling levels221

Safety First

Operating instructions

Practical tips

Te c h n i c a l D a t a

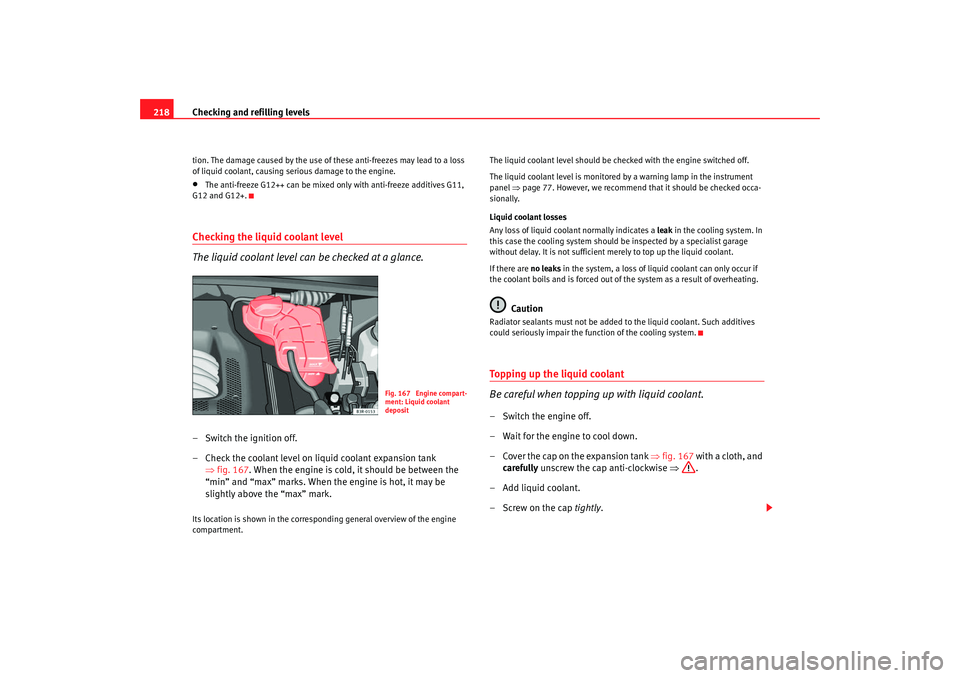

Changing windscreen wiper blades

If the windscreen wiper blades are in perfect condition, you

will benefit from an improved visibility. Damaged wiper

blades should be replaced immediately.

Removing the wiper blade

– Lift the wiper arm away from the windscreen.

– Slide the retainer catch on the wiper blade in the direction indi-

cated ⇒fig. 169 . Hold onto the wiper blade at the same time.

– Pull the wiper blade out of its mounting on the wiper arm.

Fitting the wiper blade

– Slide back the retainer catch on the new wiper blade. The mounting on the wiper blade should now be visible.

– Fit the new wiper blade into the mounting on the wiper arm

⇒ fig. 170 .

– Slide the retainer catch on the wiper blade in direction so that it clicks into place on the wiper arm.

– Fold the wiper arm back down onto the glass.If the windscreen wipers smear , they should be replaced if they are damaged,

or cleaned if they are soiled.

If this does not produce the desired results, the setting angle of the wind-

screen wiper arms might be incorrect. Th ey should be checked by a qualified

workshop and corrected if necessary.

WARNING

Do not drive unless you have good visibility through all windows!•

The ignition must not be switched on while the front wiper arms are in

a raised position. The wipers would return to their park position and

damage the paintwork on the bonnet.

Fig. 169 Removing the

wiper bladeFig. 170 Fitting the wiper

blade

AAAB

AC

AD

Exeo_EN.book Seite 221 Freitag, 17. Oktober 2008 11:24 11

Page 225 of 303

Checking and refilling levels223

Safety First

Operating instructions

Practical tips

Te c h n i c a l D a t a

Topping up and changing the brake fluid

It is best to have the brake fluid changed by a professional.Brake fluid absorbs damp. Therefore, in the course of time it will absorb water

from the ambient air. If the water content in the brake fluid is too high, the

brake system could corrode. In addition, the boiling point of the brake fluid

will be considerably reduced. This could adversely affect the braking ability in

certain circumstances.

For this reason the brake fluid must be changed periodically.

Your vehicle's Service Schedule will tell you when the brake fluid has to be

renewed.

We recommend you have the brake fluid changed as part of a regular Inspec-

tion Service at your garage. They are familiar with the procedure and have the

necessary special tools and spare parts as well as the proper facilities for

disposing of the old fluid.

Use only the genuine brake fluid specified by the factory Specialist garages

know that the brake fluid -DOT 4- is factory approved. The brake fluid must be

new.

WARNING

•

Therefore, it must always be kept closed in its original container. Keep

out of the reach of children. Failure to comply could result in poisoning.

•

Heavy use of the brakes may cause a vapour lock if the brake fluid is left

in the system for too long. This would seriously affect the efficiency of the

brakes and the safety of the car, leading to the risk of accident.Caution

Please note that brake fluid will attack the paintwork on contact.

For the sake of the environment

If the fluid has to be drained out of the brake system, use an appropriate

container to catch the used brake fluid and dispose of it in the proper

manner.BatteryGeneral notes

All work on batteries requires specialist knowledge.The battery is virtually maintenance-free and is checked in the Inspection

Services.

We recommend that you replace a battery once it is older than 5 years.

Disconnecting the battery

If the battery is disconnected, some of the vehicle's functions will become

inoperative (e.g. electric windows). These functions will require resetting

after the battery is reconnected. For th is reason, the battery should only be

disconnected from the vehicle's electr ical system when absolutely necessary.

Long periods of non-use

The battery will gradually lose its charge because certain electrical equip-

ment continues to draw current even when the ignition is off. If you park the

vehicle for long periods of time in winter you should take the battery out of

the vehicle and keep it in a frost-proof room. Store the battery in a place

where it cannot “freeze up” and become damaged. At warm outside temper-

atures it is sufficient to disconnect the negative terminal of the battery. Even

when the battery is not connected you should charge it from time to time.

Exeo_EN.book Seite 223 Freitag, 17. Oktober 2008 11:24 11

Page 229 of 303

Wheels and tyres227

Safety First

Operating instructions

Practical tips

Te c h n i c a l D a t a

Wheels and tyresWheelsGeneral notesAvoiding damage

– If you have to drive over a kerb or similar obstacle, drive very

slowly and as near as possible at a right angle to the kerb.

– Keep grease, oil and fuel off the tyres.

– Inspect the tyres regularly for damage (cuts, cracks or blisters, etc.). Remove any foreign objects embedded in the treads.

Storing tyres

– Mark tyres when you remove them to indicate the direction of rotation. This ensures you will be able to install them correctly

when you replace them.

– When removed, the wheels and/or tyres should be stored in a cool, dry and preferably dark location.

– Store tyres in a vertical position if they are not fitted on wheel rims.New tyres

New tyres have to be run in ⇒page 181.

The tread depth of new tyres may vary, according to the type and make of tyre

and the tread pattern. Concealed damage

Damage to tyres and rims is often not readily visible. If you notice unusual

vibrations or the car pulling to one side, this may indicate that one of the tyres

is damaged. The tyres should be checked immediately by an Authorised

Service Centre.

Tyres with directional tread pattern

An arrow on the tyre sidewall indicates the direction of rotation on tyres with

directional tread. Always observe the direction of rotation indicated when

fitting the wheel. This guarantees optimum grip and helps to avoid aqua-

planing, excessive noise and wear.

WARNING

•

New tyres do not have maximum grip in the first 500 km. Drive particu-

larly carefully to avoid risk of accident.

•

Never drive with damaged tyres. This may cause an accident.

•

If you notice unusual vibration or if the vehicle pulls to one side when

driving, stop the vehicle immediately and check the tyres for damage.

Checking tyre pressure

The correct tyre pressure can be seen on the sticker on the

inside of the tank flap.1. Read the required ty re inflation pressure from the sticker. The

values refer to Summer tyres. For Winter tyres, you must add 0.2

bar to the values given on the sticker.

Exeo_EN.book Seite 227 Freitag, 17. Oktober 2008 11:24 11

Page 233 of 303

Wheels and tyres231

Safety First

Operating instructions

Practical tips

Te c h n i c a l D a t a

Wear indicators

The original tyres on your vehicle have 1.6 mm high “tread wear indicators”

⇒

page 230, fig. 173 , running across the tread. Depending on the make,

there will be six to eight of them evenly spaced around the tyre. Markings on

the tyre sidewall (for instance the letters “TWI” or other symbols) indicate the

positions of the tread wear indicators. The minimum tread depth required by

law is 1.6 mm (measured in the tread grooves next to the tread wear indica-

tors). Worn tyres must be replaced. Different figures may apply in export

countries ⇒.

Tyre pressure

Under-inflation or over-inflation will reduce the life of the tyres considerably

and also impair the car's handling. The inflation pressures are listed on a

sticker on the inside of the fuel tank flap.

Correct inflation pressures are very important, especially at high speeds. The

pressure should therefore be checked at least once a month and before

starting any long journey.

Tyre pressure monitoring (RKA+)*

Monitoring of the tyre pressures is based on the tyre pressures you have

stored. The tyre pressure monitoring syst em cannot function as intended if

you store tyre pressure settings for a normal load, but then drive with the

vehicle fully laden. The tyre pressure must be adapted to the actual load and

stored accordingly in the tyre pressure monitoring system ⇒page 229.

Driving style

Fast cornering, heavy acceleration and hard braking all increase tyre wear.

Changing wheels around

If the front tyres are worn considerably more than the rear ones it is advisable

to change them around as shown ⇒page 230, fig. 174 . All the tyres will then

last for about the same time. Wheel balance

The wheels on new vehicles are balanced. However, various factors encoun-

tered in normal driving can cause them to become unbalanced, which results

in steering vibration.

Unbalanced wheels should be rebalanced, as they otherwise cause excessive

wear on steering, suspension and tyres. A wheel must also be rebalanced

when a new tyre is fitted.

Incorrect wheel alignment

Incorrect wheel alignment causes excessive tyre wear, impairing the safety of

the vehicle. If tyres show excessive wear, you should have the wheel align-

ment checked by an Authorised Service Centre.

WARNING

There is a serious danger of accidents if a tyre bursts during driving!•

The tyres must be replaced at the latest when the tread is worn down to

the tread wear indicators. Failure to do so could result in an accident. Worn

tyres do not grip well at high speeds on wet roads. There is also a greater

risk of “aquaplaning”

•

At continuously high speeds, a tyre with insufficient pressure flexes

more. This causes it to overheat. This can cause tread separation and tyre

blow-out. Risk of accident. Always observe the recommended tyre pres-

sures.

•

If tyres show excessive wear, you should have the running gear checked

by an Authorised Service Centre.

•

Keep chemicals such as oil, fuel and brake fluid away from tyres.

•

Damaged wheels and tyres must be replaced immediately!For the sake of the environment

Under-inflated tyres will increase fuel consumption.

Exeo_EN.book Seite 231 Freitag, 17. Oktober 2008 11:24 11

Page 236 of 303

Wheels and tyres

234

For the sake of the environmentOld tyres must be disposed of according to the laws in the country concerned.

Note

•

For technical reasons, it is not generally possible to use the wheels from

other vehicles. This can also apply to wheels of the same model. The use of

wheels or tyres which have not been approved by SEAT for use with your

model may invalidate the vehicle's type approval for use on public roads.

•

If the spare tyre is not the same as the tyres that are mounted on the

vehicle - for example with winter tyres - you should only use the spare tyre for

a short period of time and drive with extra care. Refit the normal road wheel

as soon as possible.

Wheel bolts

Wheel bolts must be tightened to the correct torque.The design of wheel bolts is matched to the rims. If different wheel rims are

fitted, the correct wheel bolts with the right length and correctly shaped bolt

heads must be used. This ensures that wheels are fitted securely and that the

brake system functions correctly.

In certain circumstances, you may not use wheel bolts from a different car -

even if it is the same model ⇒page 206.

After the wheels have been changed, the tightening torque of the wheel bolts

should be checked as soon as possible with a torque wrench ⇒. The tight-

ening torque for steel and alloy wheels is 120 Nm.

WARNING

If the wheel bolts are not tightened correctly, the wheel could become

loose while driving. Risk of accident.•

The wheel bolts must be clean and turn easily. Never apply grease or oil

to them.

•

Use only wheel bolts which belong to the wheel.

•

If the torque of the wheel bolts is too low, they could loosen whilst the

vehicle is in motion. Risk of accident! If the tightening torque is too high,

the wheel bolts and threads can be damaged.Caution

The prescribed torque for wheel bolts for steel and alloy wheels is 120 Nm.Winter tyres

Winter tyres will improve the vehicles handling on snow and

ice.In winter conditions winter tyres will considerably improve the vehicles

handling. The design of summer ty res (width, rubber compound, tread

pattern) gives less grip on ice and snow.

Winter tyres must be inflated to a pressure 0.2 bar higher than the pressures

specified for summer tyres (see sticker on tank flap).

Winter tyres must be fitted on all four wheels.

Information on permitted winter tyre sizes can be found in the vehicle's regis-

tration documents. Use only radial winter tyres. All tyre sizes listed in the

vehicle documentation also apply to winter tyres.

Exeo_EN.book Seite 234 Freitag, 17. Oktober 2008 11:24 11

Page 246 of 303

If and when

244The sealing compound must not be used in the following cases:•

On cuts and punctures larger than 4 mm ⇒page 243, fig. 183

•

if the wheel rim has been damaged

•

if you have been driving with very low pressure or a completely flat tyre

How to use the TMS (tyre mobility system) is described in the section

Repairing a tyre ⇒ page 245 and in the instructions supplied with the tyre

sealant can.

The TMS (tyre mobility system) can be used at outside temperatures down to

-20 °C.

WARNING

After repairing a tyre please note the following points:•

Do not drive faster than 80 km/h.

•

Avoid heavy acceleration, hard braking and fast cornering.

•

Vehicle handling could be impaired.

•

Tyres which have been sealed using the Tyre Mobility System are only

suitable for temporary use over a short period.

•

After using the tyre sealant the tyre pressure monitoring system* may

malfunction. Therefore, please drive carefully to the next available quali-

fied workshop.

•

The Tyre Mobility System must NOT be used,

− on cuts and punctures larger than 4 mm

− if the wheel rim has been damaged

− if you have been driving with very low pressure or a completely flat

tyre

•

Seek professional assistance if the repair of a tyre puncture is not

possible with the sealing compound.

•

Do not allow the sealant to come into contact with your eyes, skin or

clothing.

•

If you do come into contact with the sealant immediately rinse the eyes

or skin affected with clean water.

•

Change clothing immediately if it becomes soiled with the tyre sealant.

•

Make sure you do not breathe in the fumes!

•

If any of the tyre sealant is accidentally ingested, immediately rinse the

mouth thoroughly and drink lots of water.

−Do not induce vomiting. Seek medical assistance if needed.

•

If any allergic reactions should occur get medical help immediately.

•

Keep the sealant away from children.For the sake of the environment

Used bottles of sealing compound can be returned to the Technical Service

for disposal.

Note

•

If sealant should leak out, leave it to dry. When it has dried, you can pull

it off like a piece of foil.

•

Observe the expiry date stated on the sealing compound can. Have the

sealing compound exchanged by a qualified workshop.

A1

A2

A3

WARNING (continued)

Exeo_EN.book Seite 244 Freitag, 17. Oktober 2008 11:24 11

Page 247 of 303

If and when245

Safety First

Operating instructions

Practical tips

Te c h n i c a l D a t a

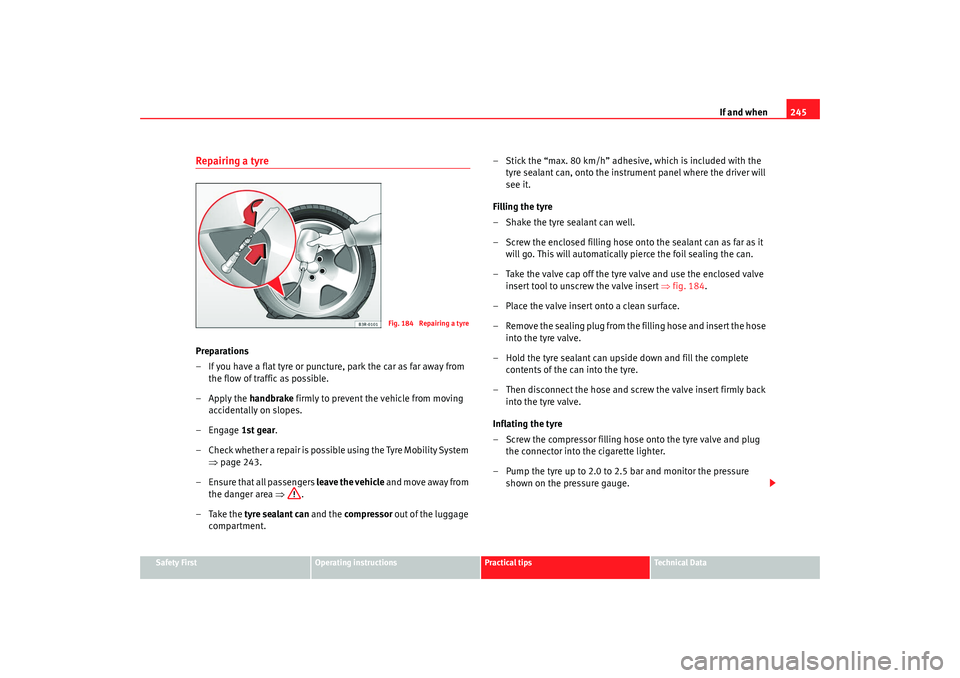

Repairing a tyrePreparations

– If you have a flat tyre or puncture, park the car as far away from

the flow of traffic as possible.

–Apply the handbrake firmly to prevent the vehicle from moving

accidentally on slopes.

–Engage 1st gear.

– Check whether a repair is possible using the Tyre Mobility System ⇒page 243.

– Ensure that all passengers leave the vehicle and move away from

the danger area ⇒.

– Take the tyre sealant can and the compressor out of the luggage

compartment. – Stick the “max. 80 km/h” adhesive, which is included with the

tyre sealant can, onto the instru ment panel where the driver will

see it.

Filling the tyre

– Shake the tyre sealant can well.

– Screw the enclosed filling hose onto the sealant can as far as it will go. This will automatically pierce the foil sealing the can.

– Take the valve cap off the tyre valve and use the enclosed valve insert tool to unscrew the valve insert ⇒fig. 184.

– Place the valve insert onto a clean surface.

– Remove the sealing plug from the filling hose and insert the hose into the tyre valve.

– Hold the tyre sealant can upside down and fill the complete contents of the can into the tyre.

– Then disconnect the hose and screw the valve insert firmly back into the tyre valve.

Inflating the tyre

– Screw the compressor filling hose onto the tyre valve and plug the connector into the cigarette lighter.

– Pump the tyre up to 2.0 to 2.5 bar and monitor the pressure shown on the pressure gauge.

Fig. 184 Repairing a tyre

Exeo_EN.book Seite 245 Freitag, 17. Oktober 2008 11:24 11

Page 248 of 303

If and when

246

– If the tyre pressure remains lower than the value specified above drive the vehicle approx. 10 metres forwards or backwards, so

that the sealant can spread evenly in the tyre. If the pressure is

still lower than the specification the tyre is too badly damaged

and cannot be repaired using the tyre sealant.

Final check

– After about 10 minutes, stop to check the tyre pressure.

– If tyre pressure is less than 1.3 bar, the tyre is too badly damaged. Do not drive on! You should obtain professional

assistance.

WARNING

•

If you have a puncture in heavy traffic, switch on the hazard warning

lights and place the warning triangle in a visible location. This is for your

own safety and also warns other road users.

•

Make sure your passengers wait in a safe place (for instance behind the

roadside crash barrier).

•

Please observe the manufacturers' safety notes on the compressor and

the instructions supplied with the tyre sealant can.

•

If it was not possible to build up a tyre pressure of 2.0 bar within 6

minutes this means that the tyre is too badly damaged. Do not drive on!

•

Seek professional assistance if the repair of a tyre puncture is not

possible with the sealing compound.

•

If tyre pressure is less than 1.3 bar after driving about 10 minutes, the

tyre is too badly damaged. Do not drive on! Obtain technical assistance.Caution

Take special care if you have to repair a tyre on a slope.

Note

•

Do not use the compressor for longer than 6 minutes. Otherwise, it might

overheat. When the compressor has cooled down, you can use it again.

•

If tyre sealant should leak out, leave it to dry and then pull it off like foil.

•

After carrying out a tyre repair remember to buy a new tyre sealant can at

a qualified workshop. This will ensure that the Tyre Mobility System is opera-

tive again.

•

Please observe legal requirements when doing so.

Exeo_EN.book Seite 246 Freitag, 17. Oktober 2008 11:24 11