engine Seat Exeo 2008 Repair Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2008, Model line: Exeo, Model: Seat Exeo 2008Pages: 303, PDF Size: 10.02 MB

Page 224 of 303

Checking and refilling levels

222•

To prevent smearing on the windscreen, the wiper blades should be

cleaned regularly using a window cleaner solution. If the wiper blades are

very dirty (e.g. insects etc.), they should be cleaned using a sponge or

cloth. Failure to do so co uld result in an accident.

•

For safety reasons, the wiper blades should be changed once or twice a

year.Caution

•

Damaged or dirty windscreen wipers could scratch the windscreen.

•

Never use fuel, nail varnish remover, paint thinner or similar products to

clean the windows. This could damage the windscreen wiper blades.

•

Never move the windscreen wiper or windscreen wiper arm manually. This

could cause damage.

•

Do not pull the windscreen wipers forward unless they are in the service

position. Otherwise the bonnet could be damaged.Note

•

The wiper arms can be moved to the service position only when the

bonnet is properly closed.

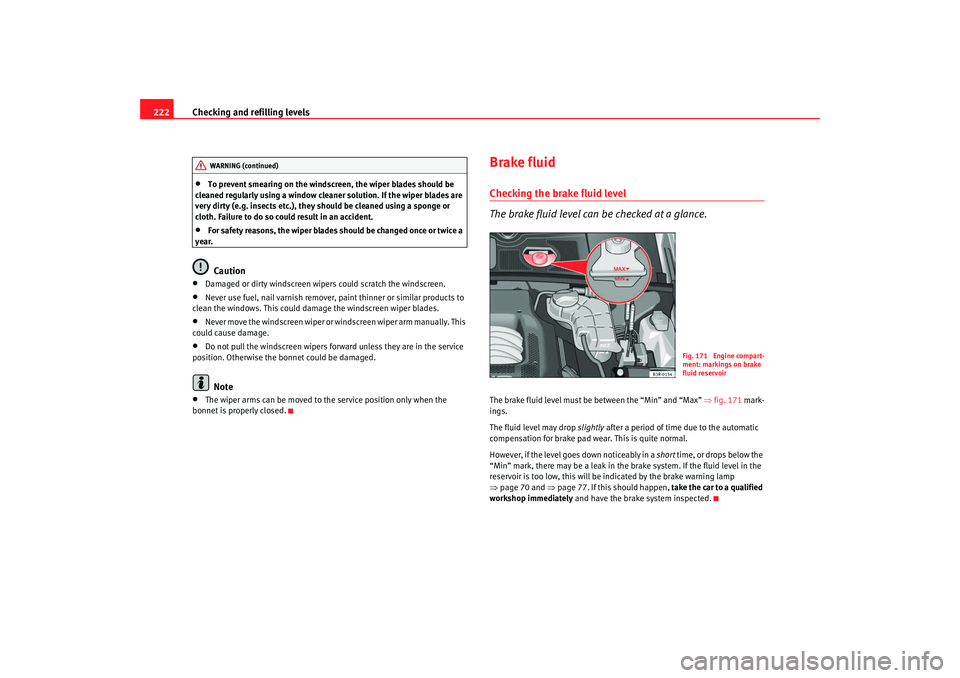

Brake fluidChecking the brake fluid level

The brake fluid level can be checked at a glance.The brake fluid level must be between the “Min” and “Max” ⇒fig. 171 mark-

ings.

The fluid level may drop slightly after a period of time due to the automatic

compensation for brake pad wear. This is quite normal.

However, if the level goes down noticeably in a short time, or drops below the

“Min” mark, there may be a leak in the brake system. If the fluid level in the

reservoir is too low, this will be indicated by the brake warning lamp

⇒ page 70 and ⇒ page 77. If this should happen, take the car to a qualified

workshop immediately and have the brake system inspected.

WARNING (continued)

Fig. 171 Engine compart-

ment: markings on brake

fluid reservoir

Exeo_EN.book Seite 222 Freitag, 17. Oktober 2008 11:24 11

Page 226 of 303

Checking and refilling levels

224Winter operations

The battery is drained more in cold weather, which means that the starting

power is reduced. For this reason, have the battery checked and charged if

necessary before the start of winter.

Replacing the battery

A replacement battery must have the same capacity, voltage and current

rating. It must also have the same dimensions as the original, factory-fitted

battery and have sealed caps. The SEAT batteries which have been specially

developed fulfil the maintenance, performance and safety specifications for

your vehicle.

We recommend you use maintenance-free batteries.

WARNING

•

All work on batteries requires speciali st knowledge. If work is required

on the battery, this should be pe rformed by a Technical Service or

specialist garage. Danger of caustic burns and explosion!

•

The battery must not be opened. Never try to change the battery's

liquid level. Explosive gas is released from the battery that could lead to an

explosion.Caution

•

The battery holder and clamps must always be correctly secured.

•

Before starting any work on the battery, always observe the warnings

listed below ⇒.For the sake of the environment

Batteries contain toxic substances including sulphuric acid and lead.

Therefore, they must be disposed in line with environmental regulations and

must not be disposed of with ordinary household waste. Make sure discon-

nected batteries cannot tip over . Sulphuric acid could be spilt!

Important safety warnings for handling a car batteryThe battery is located at the back of the engine compartment ⇒page 282.

WARNING

Always be aware of the danger of injury and chemical burns as well as the

risk of accident or fire when work ing on the battery and the electrical

system:•

Wear eye protection. Protect your eyes, skin and clothing from acid and

particles containing lead.

•

Battery acid is very corrosive and caustic. Wear protective gloves and

eye protection. Do not tilt the batter ies. This could spill acid through the

vents. Rinse battery acid from eyes immediately for several minutes with

clear water. Then seek medical care immediately. Neutralize any acid

splashes on the skin or clothing with a soapy solution, and rinse off with

plenty of water. If acid is swallowed by mistake, consult a doctor immedi-

ately.

•

Fires, sparks, naked lights and smoking are prohibited. When handling

cables and electrical equipment, avoid causing sparks and electrostatic

charge. Never short the battery terminals. High-energy sparks can cause

injury.

Wear eye protection

Battery acid is very corrosive and caustic. Wear protec-

tive gloves and eye protection!

Fires, sparks, naked lights and smoking are prohibited!

A highly explosive mixture of gases is released when the

battery is under charge.

Keep children away from acid and batteries!

Exeo_EN.book Seite 224 Freitag, 17. Oktober 2008 11:24 11

Page 227 of 303

Checking and refilling levels225

Safety First

Operating instructions

Practical tips

Te c h n i c a l D a t a

•

A highly explosive mixture of gases is released when the battery is

under charge. The batteries should be charged in a well-ventilated room

only.

•

Keep children away from acid and batteries.

•

Before working on the electrical system, you must switch off the

engine, the ignition and all consumers. The negative cable on the battery

must be disconnected. When a light bulb is changed, you need only switch

off the light.

•

Deactivate the anti-theft alarm by unlocking the vehicle before you

disconnect the battery! The alar m will otherwise be triggered.

•

When disconnecting the battery from the vehicle electrical system,

disconnect first the negative cable and then the positive cable.

•

Switch off all electrical consumers before reconnecting the battery.

Reconnect first the positive cable and then the negative cable. Never

reverse the polarity of the connections. This could cause an electrical fire.

•

Never charge a frozen battery, or one which has thawed. This could

result in explosions and chemical burns. Always replace a battery which

has frozen. A flat battery can freeze at temperatures around 0°

•

Ensure that the vent hose is always connected to the battery.

•

Never use a defective battery. This may be fatally explosive. Replace a

damaged battery immediately.Caution

•

Never disconnect the battery if the ignition is switched on or if the engine

is running. This could damage the electrical system or electronic compo-

nents.

•

Do not expose the battery to direct sunlight over a long period of time, as

the intense ultraviolet radiation can damage the battery housing.

•

If the vehicle is left standing in cold conditions for a long period, protect

the battery from frost. If it “freezes” it will be damaged.

Charging the battery

A fully-charged battery is important for reliable starting.– Note the warnings ⇒ in “Important safety warnings for

handling a car battery” on page 224 and ⇒.

– Switch off the ignition and all electrical equipment.

– Only if “fast-charging”: both battery cables must be discon- nected (first the “negative” cabl e, then the “positive” cable).

– Connect the charger cables to the battery terminals, noting the colour code (red is used for “positive”, black or brown for “nega-

tive”).

– Now connect the battery charger to the power point and switch on.

– After charging the battery: switch off the battery charger and disconnect the power point cable.

– Finally disconnect the charger cables from the battery.

– If necessary, reconnect both battery cables to the battery (first the “positive” cable, then the “negative” cable).When charging with a low current (for instance with a small battery charger)

the battery does not normally have to be disconnected. However, both

battery cables must be disconnected before “ fast-charging” the battery with

a high current. However, always follow th e instructions given by the manufac-

turer of the battery charger.

Fast-charging a battery is dangerous ⇒ in “Important safety warnings for

handling a car battery” on page 224, since it requires a special charger and

WARNING (continued)

Exeo_EN.book Seite 225 Freitag, 17. Oktober 2008 11:24 11

Page 231 of 303

Wheels and tyres229

Safety First

Operating instructions

Practical tips

Te c h n i c a l D a t a

Significant tyre pressure lossThe tyre symbol

is displayed and indicates that the tyre pressure for a least

one tyre is insufficient.

- Stop the vehicle.

- Switch the engine off.

- Check the tyre(s).

- Change the wheel if necessary.

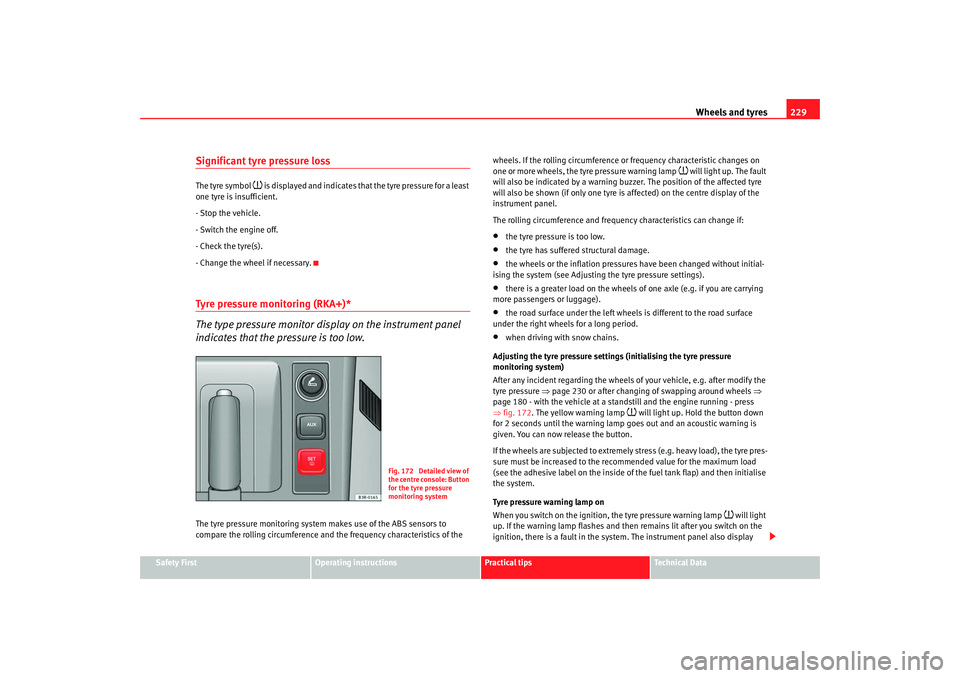

Tyre pressure monitoring (RKA+)*

The type pressure monitor display on the instrument panel

indicates that the pressure is too low.The tyre pressure monitoring system makes use of the ABS sensors to

compare the rolling circumference and the frequency characteristics of the wheels. If the rolling cir

cumference or frequency characteristic changes on

one or more wheels, the tyre pressure warning lamp

will light up. The fault

will also be indicated by a warning buzzer. The position of the affected tyre

will also be shown (if only one tyre is affected) on the centre display of the

instrument panel.

The rolling circumference and frequency characteristics can change if:

•

the tyre pressure is too low.

•

the tyre has suffered structural damage.

•

the wheels or the inflation pressures have been changed without initial-

ising the system (see Adjusting the tyre pressure settings).

•

there is a greater load on the wheels of one axle (e.g. if you are carrying

more passengers or luggage).

•

the road surface under the left wheels is different to the road surface

under the right wheels for a long period.

•

when driving with snow chains.

Adjusting the tyre pressure settings (initialising the tyre pressure

monitoring system)

After any incident regarding the wheels of your vehicle, e.g. after modify the

tyre pressure ⇒page 230 or after changing of swapping around wheels ⇒

page 180 - with the vehicle at a standstill and the engine running - press

⇒ fig. 172 . The yellow warning lamp

will light up. Hold the button down

for 2 seconds until the warning lamp goes out and an acoustic warning is

given. You can now release the button.

If the wheels are subjected to extremely stress (e.g. heavy load), the tyre pres-

sure must be increased to the recommended value for the maximum load

(see the adhesive label on the inside of the fuel tank flap) and then initialise

the system.

Tyre pressure warning lamp on

When you switch on the ignition, the tyre pressure warning lamp

will light

up. If the warning lamp flashes and then remains lit after you switch on the

ignition, there is a fault in the system. The instrument panel also display

Fig. 172 Detailed view of

the centre console: Button

for the tyre pressure

monitoring system

Exeo_EN.book Seite 229 Freitag, 17. Oktober 2008 11:24 11

Page 238 of 303

If and when

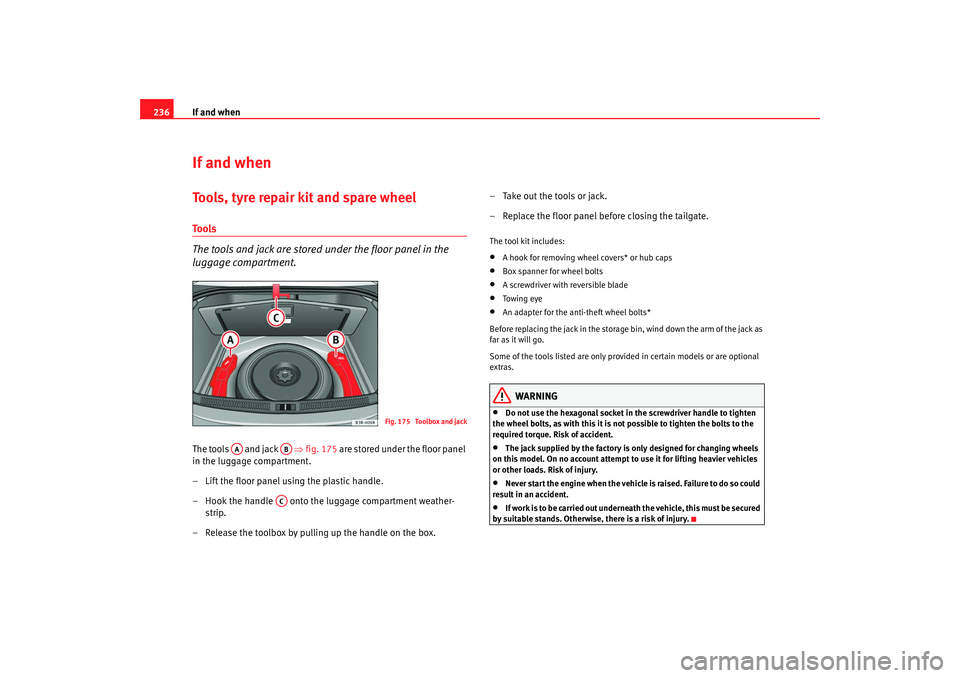

236If and whenTools, tyre repair kit and spare wheelTools

The tools and jack are stored under the floor panel in the

luggage compartment.The tools and jack ⇒fig. 175 are stored under the floor panel

in the luggage compartment.

– Lift the floor panel using the plastic handle.

– Hook the handle onto the luggage compartment weather- strip.

– Release the toolbox by pulling up the handle on the box. – Take out the tools or jack.

– Replace the floor panel before closing the tailgate.

The tool kit includes:•

A hook for removing wheel covers* or hub caps

•

Box spanner for wheel bolts

•

A screwdriver with reversible blade

•

Towing eye

•

An adapter for the anti-theft wheel bolts*

Before replacing the jack in the storage bin, wind down the arm of the jack as

far as it will go.

Some of the tools listed are only provid ed in certain models or are optional

extras.

WARNING

•

Do not use the hexagonal socket in the screwdriver handle to tighten

the wheel bolts, as with this it is not possible to tighten the bolts to the

required torque. Risk of accident.

•

The jack supplied by the factory is only designed for changing wheels

on this model. On no account attempt to use it for lifting heavier vehicles

or other loads. Risk of injury.

•

Never start the engine when the vehicle is raised. Failure to do so could

result in an accident.

•

I f wo r k is t o b e ca r r i e d o u t un d e r n ea th the vehicle, this must be secured

by suitable stands. Otherwise, there is a risk of injury.

Fig. 175 Toolbox and jac

k

AA

ABAC

Exeo_EN.book Seite 236 Freitag, 17. Oktober 2008 11:24 11

Page 251 of 303

If and when249

Safety First

Operating instructions

Practical tips

Te c h n i c a l D a t a

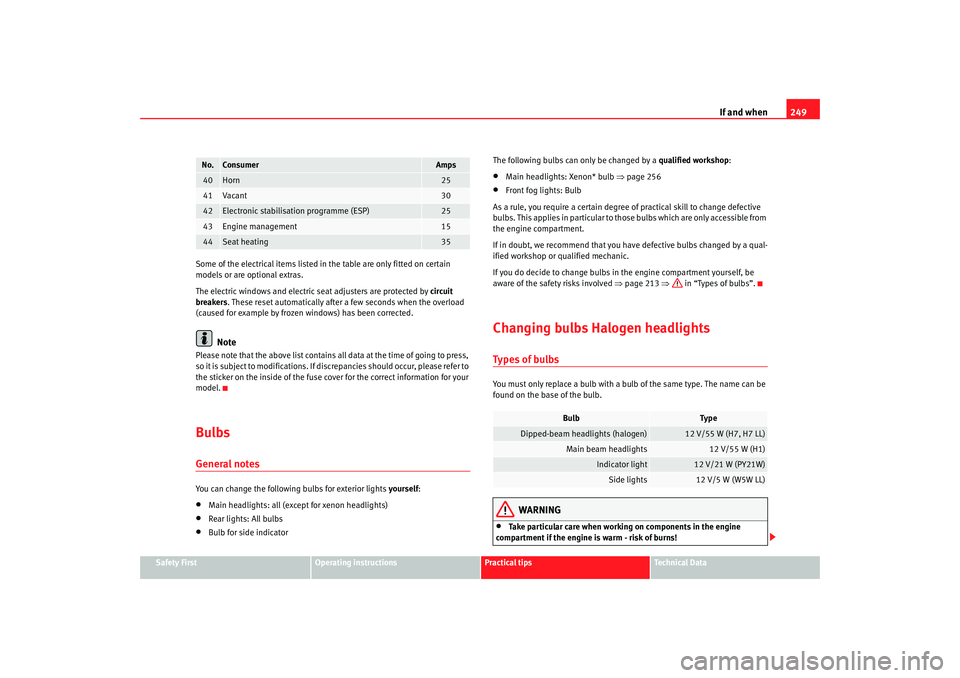

Some of the electrical items listed in

the table are only fitted on certain

models or are optional extras.

The electric windows and electric seat adjusters are protected by circuit

breakers. These reset automatically after a few seconds when the overload

(caused for example by frozen windows) has been corrected.

Note

Please note that the above list contains all data at the time of going to press,

so it is subject to modifications. If discrepancies should occur, please refer to

the sticker on the inside of the fuse cover for the correct information for your

model.BulbsGeneral notesYou can change the following bulbs for exterior lights yourself:•

Main headlights: all (exc ept for xenon headlights)

•

Rear lights: All bulbs

•

Bulb for side indicator The following bulbs can only be changed by a

qualified workshop:

•

Main headlights: Xenon* bulb ⇒page 256

•

Front fog lights: Bulb

As a rule, you require a certain degree of practical skill to change defective

bulbs. This applies in particular to those bulbs which are only accessible from

the engine compartment.

If in doubt, we recommend that you have defective bulbs changed by a qual-

ified workshop or qualified mechanic.

If you do decide to change bulbs in the engine compartment yourself, be

aware of the safety risks involved ⇒page 213 ⇒ in “Types of bulbs”.

Changing bulbs Halogen headlightsTypes of bulbsYou must only replace a bulb with a bu lb of the same type. The name can be

found on the base of the bulb.

WARNING

•

Take particular care when working on components in the engine

compartment if the engine is warm - risk of burns!

40

Horn

25

41

Va ca n t

30

42

Electronic stabilisation programme (ESP)

25

43

Engine management

15

44

Seat heating

35

No.

Consumer

Amps

Bulb

Typ e

Dipped-beam headlights (halogen)

12 V/55 W (H7, H7 LL)

Main beam headlights

12 V/55 W (H1)

Indicator light

12 V/21 W (PY21W)

Side lights

12 V/5 W (W5W LL)

Exeo_EN.book Seite 249 Freitag, 17. Oktober 2008 11:24 11

Page 259 of 303

If and when257

Safety First

Operating instructions

Practical tips

Te c h n i c a l D a t a

WARNING

•

Take particular care when working on components in the engine

compartment if the engine is warm - risk of burns!

•

Bulbs are highly sensitive to pressure. The glass can break when you

touch the bulb, causing injury.

•

The high voltage element of gas discharge lamps* (xenon light) must

be handled correctly. Otherwise, there is a risk of death.

•

When changing bulbs, please take care not to injure yourself on sharp

parts in the headlight housing.Caution

•

Remove the ignition key before workin g on the electric system. If not, a

short circuit could occur.

•

Switch off the lights or parking lights before you change a bulb.For the sake of the environment

Please ask your specialist retailer how to dispose of used bulbs in the proper

manner.

Note

•

Depending on the weather conditions (cold, humidity), the front head-

lights and front lights, the rear pilots and the indicators could steam up. This phenomenon has no influence on the life

expectancy of the vehicle lights. If

headlamps are switched on, the area where the light shaft is projected, is

demisted in little time. However, the edges may be steamed up on the inte-

rior.

•

Please check at regular intervals that all lighting (especially the exterior

lighting) on your vehicle is functioning pr operly. This is not only in the interest

of your own safety, but also in that of all other road users.

•

Before changing a bulb, make sure you have the correct new bulb.

•

Do not touch the glass part of the bulb with your bare hands, use a cloth

or paper towel instead. Otherwise, the fingerprints left on the glass will

vaporise as a result of the heat generated by the bulb, be deposited on the

reflector and impair its surface.

Removing the air duct

The air duct has to be removed to gain access to the bulbs for

the right-side headlight.

Bulb

Typ e

Xenon bulbs

12 V/35 W (D1S)

DRL (day light)

12 V/21 W (P21W SLL)

Indicator light

12 V/21 W (PY21W)

Side lights

12 V/5 W (W5W blue LL)

Fig. 199 Air duct on right

side of vehicle

Exeo_EN.book Seite 257 Freitag, 17. Oktober 2008 11:24 11

Page 273 of 303

If and when271

Safety First

Operating instructions

Practical tips

Te c h n i c a l D a t a

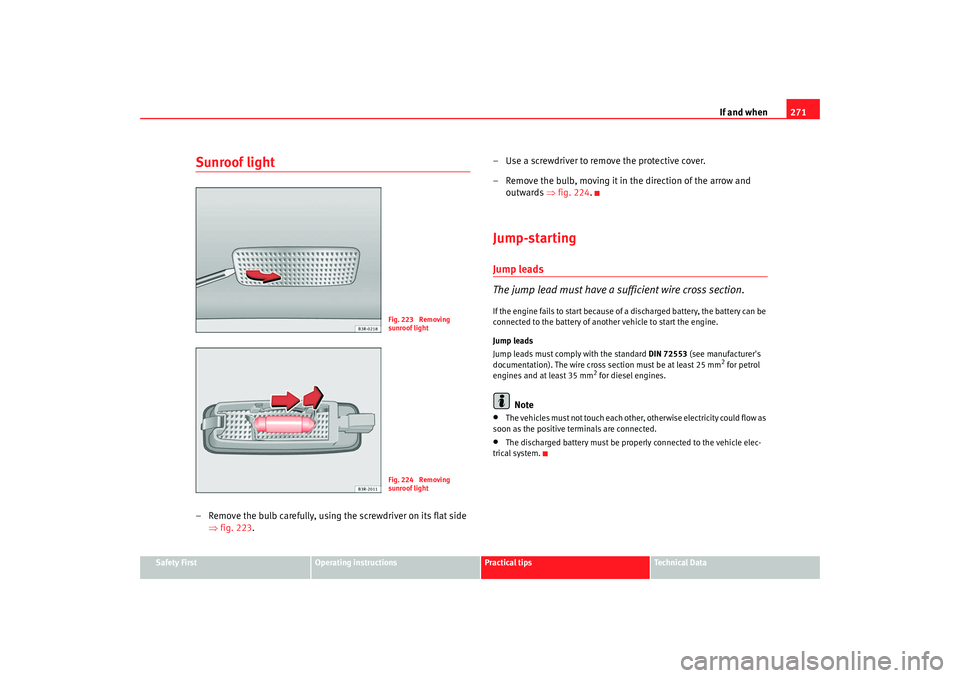

Sunroof light– Remove the bulb carefully, using the screwdriver on its flat side

⇒fig. 223 . – Use a screwdriver to remove the protective cover.

– Remove the bulb, moving it in

the direction of the arrow and

outwards ⇒fig. 224.

Jump-startingJump leads

The jump lead must have a sufficient wire cross section.If the engine fails to start because of a discharged battery, the battery can be

connected to the battery of another vehicle to start the engine.

Jump leads

Jump leads must comply with the standard DIN 72553 (see manufacturer's

documentation). The wire cross section must be at least 25 mm

2 for petrol

engines and at least 35 mm

2 for diesel engines.

Note

•

The vehicles must not touch each othe r, otherwise electricity could flow as

soon as the positive terminals are connected.

•

The discharged battery must be properly connected to the vehicle elec-

trical system.

Fig. 223 Removing

sunroof lightFig. 224 Removing

sunroof light

Exeo_EN.book Seite 271 Freitag, 17. Oktober 2008 11:24 11

Page 274 of 303

If and when

272How to jump start: description⇒ fig. 225 shows the flat battery and the charged battery.

Jump lead terminal connections

– Switch off the ignition on both vehicles ⇒.

1. Connect one end of the red jump lead to the positive ⇒fig. 225

terminal of the vehicle with the flat battery ⇒.

2. Connect the other end of the red jump lead to the positive terminal in the vehicle providing assistance.

3. Connect one end of the black jump lead to the negative terminal on the battery of the vehicle providing assistance. 4. Connect the other end of the black jump lead to a solid metal

component which is bolted on to the engine block, or onto the

engine block itself of the vehicle with the flat battery. Do not

connect it to a point near the battery ⇒.

5. Position the leads in such a way that they cannot come into contact with any moving parts in the engine compartment.

Starting

6. Start the engine of the vehicle with the boosting battery and let it run at idling speed.

7. Start the engine of the car with the flat battery and wait one or two minutes until the engine is “running”.

Removing the jump leads

8. Before you remove the jump leads, switch off the headlights (if they are switched on).

9. Turn on the heater blower and rear window heater in the vehicle with the flat battery. This helps minimise voltage peaks which are

generated when the leads are disconnected.

10. When the engine is running, disconnect the leads in reverse order to the deta ils given above.

Connect the battery clamps so they have good metal-to-metal contact with

the battery terminals.

If the engine fails to start, switch off the starter after about 10 seconds and

try again after about half a minute.

Fig. 225 How to connect

the jump leads

AA

AB

A+

A+

A-

AX

Exeo_EN.book Seite 272 Freitag, 17. Oktober 2008 11:24 11

Page 275 of 303

If and when273

Safety First

Operating instructions

Practical tips

Te c h n i c a l D a t a

WARNING

•

Please note the safety warnings referring to working in the engine

compartment ⇒page 213.

•

The battery providing assistance must have the same voltage as the flat

battery (12V) and approximately the same capacity (see imprint on

battery). Failure to comply could result in an explosion.

•

Never use jump leads when one of the batteries is frozen. Danger of

explosion! Even after the battery has thawed, battery acid could leak and

cause chemical burns. If a battery freezes, it should be replaced.

•

Keep sparks, flames and lighted cigarettes away from batteries, danger

of explosion. Failure to comply could result in an explosion.

•

Observe the instructions provided by the manufacturer of the jump

leads.

•

Do not connect the negative cable from the other vehicle directly to the

negative terminal of the flat battery. The gas emitted from the battery could

be ignited by sparks. Danger of explosion.

•

Do not attach the negative cable from the other vehicle to parts of the

fuel system or to the brake line.

•

The non-insulated parts of the battery clamps must not be allowed to

touch. The jump lead attached to the positive battery terminal must not

touch metal parts of the vehicle, this can cause a short circuit.

•

Position the leads in such a way that they cannot come into contact

with any moving parts in the engine compartment.

•

Do not bend over the batteries. This could result in chemical burns.Note

The vehicles must not touch each other, otherwise electricity could flow as

soon as the positive terminals are connected.

Exeo_EN.book Seite 273 Freitag, 17. Oktober 2008 11:24 11