technical specifications Seat Exeo 2010 Owner's manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2010, Model line: Exeo, Model: Seat Exeo 2010Pages: 319, PDF Size: 9.64 MB

Page 243 of 319

Wheels and tyres241

Safety First

Operating Instructions

Practical Tips

Technical Specifications

display TMPS (Tyre Pressure Monitoring System). Please contact the nearest

qualified workshop as soon as possible.

The tyre pressure warning lamp

�~ lights up if the tyre pressure on one or

more wheels is significantly lower than the tyre pressure setting which was

confirmed by the driver ⇒.

WARNING

•If the tyre pressure warning lamp lights up

�~ you must slow down

immediately and avoid any severe braking or steering manoeuvres. Stop

the vehicle as soon as possible and check the tyres and their pressure.

•The driver is responsible for maintaining correct tyre pressures. There-

fore, the tyre pressure must be regularly checked.•Under certain conditions (e.g. driving at high speeds, on ice and snow

or on poor road surfaces) the tyre pressure warning lamp

�~ may not light

up immediately or not at all.

•Please ask your Dealer or qualified workshop whether run-flat tyres can

be used on your vehicle. Fitting this type of tyre in an undue manner could

lead to your driving licence being taken away from you. Furthermore, it may

led to damage to the vehicle or, under certain circumstances, may cause

accidents.•If you change normal tyres for run-flat tyres or vice versa, the control

unit must be reprogrammed by the Dealer or a qualified workshop.Note

If you did not press the button for the tyre pressure monitoring system to

confirm a new tyre pressure setting after making changes to the tyre pres-

sures or changing one or more wheels, the warning lamp

�~ may light up

although the tyre pressures are correct. In this case, stop the vehicle as soon

as possible and, after examining the tyres, press the button for the tyre pres-

sure monitoring system.

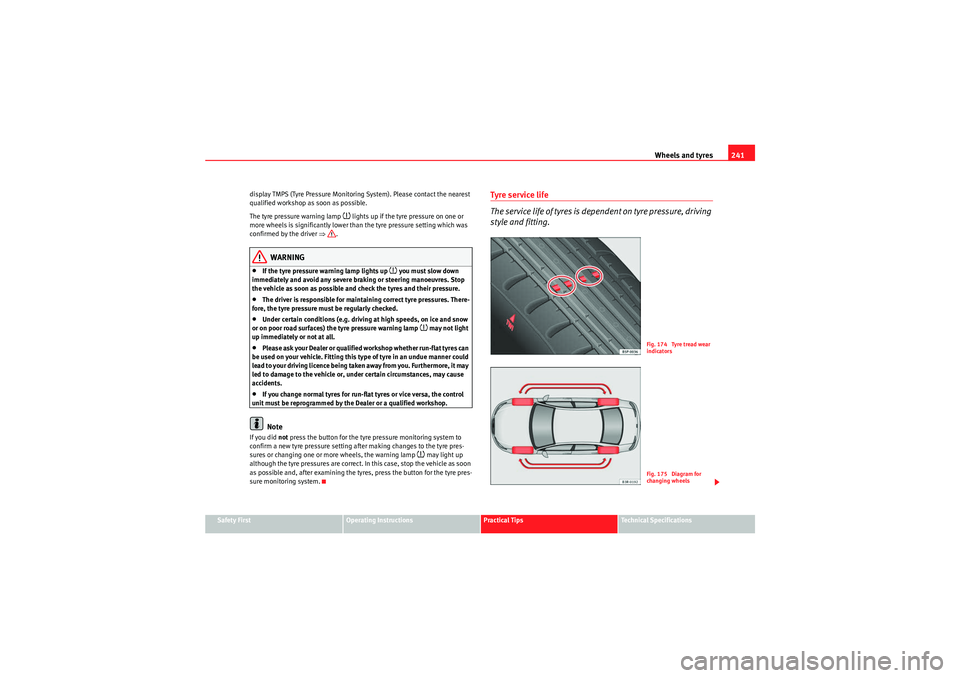

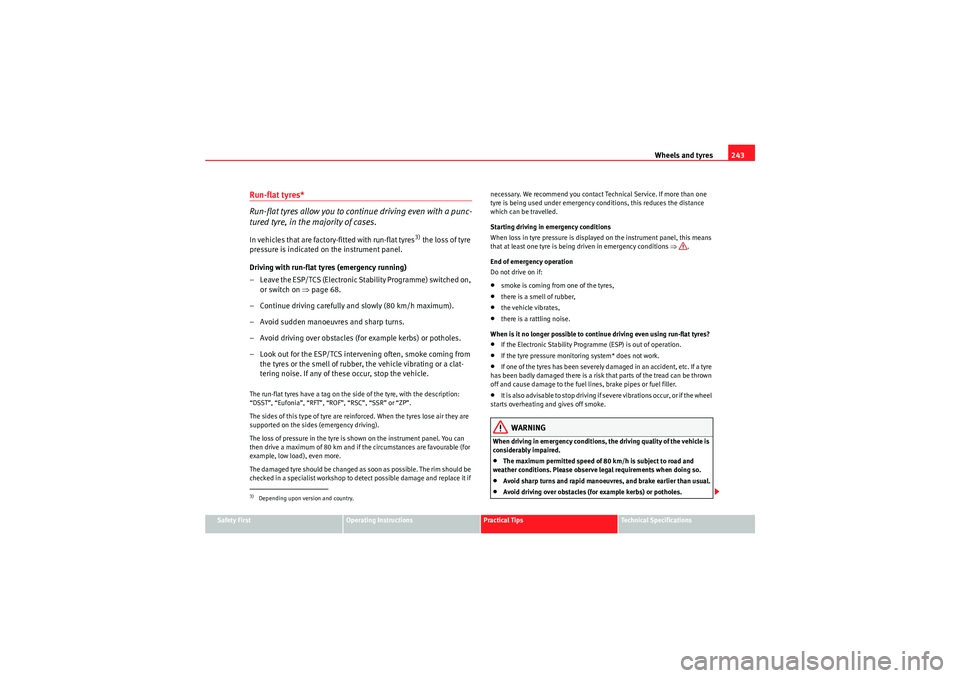

Tyre ser vice life

The service life of tyres is dependent on tyre pressure, driving

style and fitting.

Fig. 174 Tyre tread wear

indicatorsFig. 175 Diagram for

changing wheels

exeo_EN.book Seite 241 Montag, 30. August 2010 4:45 16

Page 245 of 319

Wheels and tyres243

Safety First

Operating Instructions

Practical Tips

Technical Specifications

Run-flat tyres*

Run-flat tyres allow you to cont inue driving even with a punc-

tured tyre, in the majority of cases.In vehicles that are factory-fitted with run-flat tyres

3) the loss of tyre

pressure is indicated on the instrument panel.

Driving with run-flat tyres (emergency running)

– Leave the ESP/TCS (Electronic Stability Programme) switched on, or switch on ⇒page 68.

– Continue driving carefully and slowly (80 km/h maximum).

– Avoid sudden manoeuvres and sharp turns.

– Avoid driving over obstacles (for example kerbs) or potholes.

– Look out for the ESP/TCS intervening often, smoke coming from the tyres or the smell of rubber, the vehicle vibrating or a clat-

tering noise. If any of these occur, stop the vehicle.

The run-flat tyres have a tag on the side of the tyre, with the description:

“DSST”, “Eufonia”, “RFT”, “ROF”, “RSC”, “SSR” or “ZP”.

The sides of this type of tyre are reinforced. When the tyres lose air they are

supported on the sides (emergency driving).

The loss of pressure in the tyre is shown on the instrument panel. You can

then drive a maximum of 80 km and if the circumstances are favourable (for

example, low load), even more.

The damaged tyre should be changed as soon as possible. The rim should be

checked in a specialist workshop to detect possible damage and replace it if necessary. We recommend you contact Technical Service. If more than one

tyre is being used under emergency conditions, this reduces the distance

which can be travelled.

Starting driving in emergency conditions

When loss in tyre pressure is displayed on the instrument panel, this means

that at least one tyre is being driven in emergency conditions

⇒.

End of emergency operation

Do not drive on if:

•smoke is coming from one of the tyres,•there is a smell of rubber,•the vehicle vibrates,•there is a rattling noise.

When is it no longer possible to continue driving even using run-flat tyres?•If the Electronic Stability Programme (ESP) is out of operation.•If the tyre pressure monitoring system* does not work.•If one of the tyres has been severely damaged in an accident, etc. If a tyre

has been badly damaged there is a risk that parts of the tread can be thrown

off and cause damage to the fuel lines, brake pipes or fuel filler.•It is also advisable to stop driving if severe vibrations occur, or if the wheel

starts overheating and gives off smoke.WARNING

When driving in emergency conditions, the driving quality of the vehicle is

considerably impaired.•The maximum permitted speed of 80 km/h is subject to road and

weather conditions. Please observe legal requirements when doing so.•Avoid sharp turns and rapid manoeuvres, and brake earlier than usual.•Avoid driving over obstacles (for example kerbs) or potholes.

3)Depending upon version and country.

exeo_EN.book Seite 243 Montag, 30. August 2010 4:45 16

Page 247 of 319

Wheels and tyres245

Safety First

Operating Instructions

Practical Tips

Technical Specifications

For the sake of the environment

Old tyres must be disposed of according to the laws in the country concerned.

Note

•For technical reasons, it is not generally possible to use the wheels from

other vehicles. This can also apply to wheels of the same model. The use of

wheels or tyres which have not been approved by SEAT for use with your

model may invalidate the vehicle’s type approval for use on public roads.•If the spare tyre is not the same as the tyres that are mounted on the

vehicle - for example with winter tyres - you should only use the spare tyre for

a short period of time and drive with extra care. Refit the normal road wheel

as soon as possible.Wheel bolts

Wheel bolts must be tightened to the correct torque.The design of wheel bolts is matched to the rims. If different wheel rims are

fitted, the correct wheel bolts with the right length and correctly shaped bolt

heads must be used. This ensures that wheels are fitted securely and that the

brake system functions correctly.

In certain circumstances, you should not use wheel bolts from a different

vehicle, even if it is the same model ⇒page 218.

After the wheels have been changed, the tightening torque of the wheel bolts

s ho uld b e ch ecke d as so on as possi ble wi th a to rq ue wre nch. ⇒ The tight-

ening torque for steel and alloy wheels is 120 Nm.

WARNING

If the wheel bolts are not tightened correctly, the wheel could become

loose while driving. Risk of accident.•The wheel bolts must be clean and turn easily. Never apply grease or oil

to them.•Use only wheel bolts which belong to the wheel.•If the torque of the wheel bolts is too low, they could loosen whilst the

vehicle is in motion. Risk of accident! If the tightening torque is too high,

the wheel bolts and threads can be damaged.Caution

The prescribed tightening torque for wheel bolts for steel and alloy wheels is

120 Nm.Winter tyres

Winter tyres will improve the vehicles handling on snow and

ice.In winter conditions winter tyres will considerably improve the vehicle’s

handling. The design of summer tyre s (width, rubber compound, tread

pattern) gives less grip on ice and snow.

Winter tyres must be inflated to a pressure 0.2 bar higher than the pressures

specified for summer tyres (see sticker on tank flap).

Winter tyres must be fitted on all four wheels.

Information on permitted winter tyre sizes can be found in the vehicle’s regis-

tration documents. Use only radial winter tyres. All tyre sizes listed in the

vehicle documentation also apply to winter tyres.

exeo_EN.book Seite 245 Montag, 30. August 2010 4:45 16

Page 249 of 319

If and when247

Safety First

Operating Instructions

Practical Tips

Technical Specifications

If and whenTools, tyre repair kit and spare wheelTools

The tools and jack are stored under the floor panel in the

luggage compartment.The tools and jack ⇒fig. 176 are stored under the floor panel

in the luggage compartment.

– Lift the floor panel using the plastic handle.

– Hook the handle onto the luggage compartment weather

strip.

– Release the toolbox by pulling up the handle on the box. – Take out the tools or jack.

– Replace the floor panel before closing the tailgate.

The tool kit includes:•A hook for removing wheel covers* or hub caps•Box spanner for wheel bolts•A screwdriver with reversible blade•Towing eye•An adapter for the anti-theft wheel bolts*

Before replacing the jack in the storage bin, wind down the arm of the jack as

far as it will go.

Some of the tools listed are only provided in certain models or are optional

extras.WARNING

•Do not use the hexagonal socket in the screwdriver handle to tighten

the wheel bolts, as with this it is not possible to tighten the bolts to the

required torque. Risk of accident.•The factory-supplied jack is only designed for changing wheels on this

model. On no account attempt to use it for lifting heavier vehicles or other

loads. Risk of injury.•Never start the engine when the vehicle is raised. Failure to do so could

result in an accident.•I f w o r k is t o b e ca r r ie d o u t un d e r n ea t h t h e v e h ic l e , t h is m u s t be s e cu re d

by suitable stands. Otherwise, there is a risk of injury.

Fig. 176 Toolbox and jac

k

AA

ABAC

exeo_EN.book Seite 247 Montag, 30. August 2010 4:45 16

Page 251 of 319

If and when249

Safety First

Operating Instructions

Practical Tips

Technical Specifications

Your vehicle can be factory-equipped with a spare steel wheel. The spare

wheel does

not usually meet the same performance standards as the wheels

fitted on the vehicle because of the wheel/tyre dimensions, rubber composi-

tion, tread pattern, etc. Therefore, note the following restrictions:

•The spare steel wheel is designed only for your vehicle model. Do not

attempt to mount the wheel on any vehicle but your own.•Your vehicle will have different driving characteristics when the spare

steel rim wheel is mounted ⇒.•The spare wheel is only intended for temporary use after having a flat tyre.

Replace the spare wheel with a normal wheel that has the proper tyre dimen-

sions as soon as possible.•If the size of the spare steel rim wheel is different to that of the other

wheels, it is unlikely that snow chains suitable for the other wheels will fit it.WARNING

•After mounting the spare steel rim wheel, the tyre pressure must be

checked and corrected as soon as possible. The tyre pressure must corre-

spond to the vehicle load (consult th e table containing the inflation pres-

sures). Otherwise there is danger of causing an accident. Use the highest

tyre pressure as indicated in the table.•Do not drive faster than 80 km/h, as higher speeds can cause an acci-

dent.•Avoid heavy acceleration, hard braking and fast cornering, as this could

cause an accident.

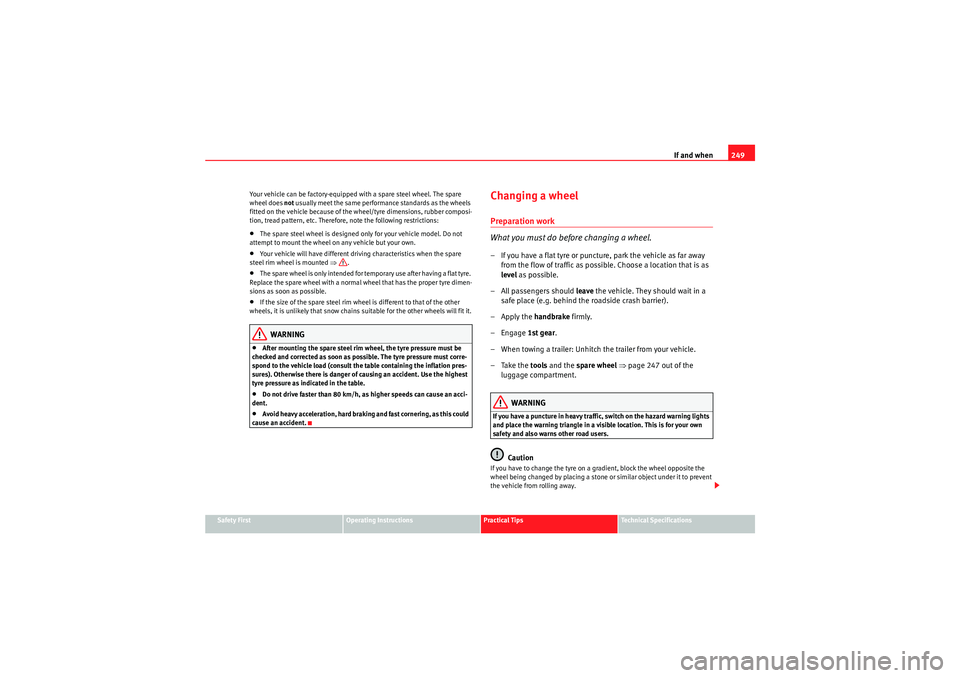

Changing a wheelPreparation work

What you must do before changing a wheel.– If you have a flat tyre or puncture, park the vehicle as far away from the flow of traffic as possible. Choose a location that is as

level as possible.

–All passengers should leave the vehicle. They should wait in a

safe place (e.g. behind the roadside crash barrier).

–Apply the handbrake firmly.

– Engage 1st gear .

– When towing a trailer: Unhitch the trailer from your vehicle.

– Take the tools and the spare wheel ⇒ page 247 out of the

luggage compartment.

WARNING

If you have a puncture in heavy traffic, switch on the hazard warning lights

and place the warning triangle in a visible location. This is for your own

safety and also warns other road users.

Caution

If you have to change the tyre on a gradient, block the wheel opposite the

wheel being changed by placing a stone or similar object under it to prevent

the vehicle from rolling away.

exeo_EN.book Seite 249 Montag, 30. August 2010 4:45 16

Page 253 of 319

If and when251

Safety First

Operating Instructions

Practical Tips

Technical Specifications

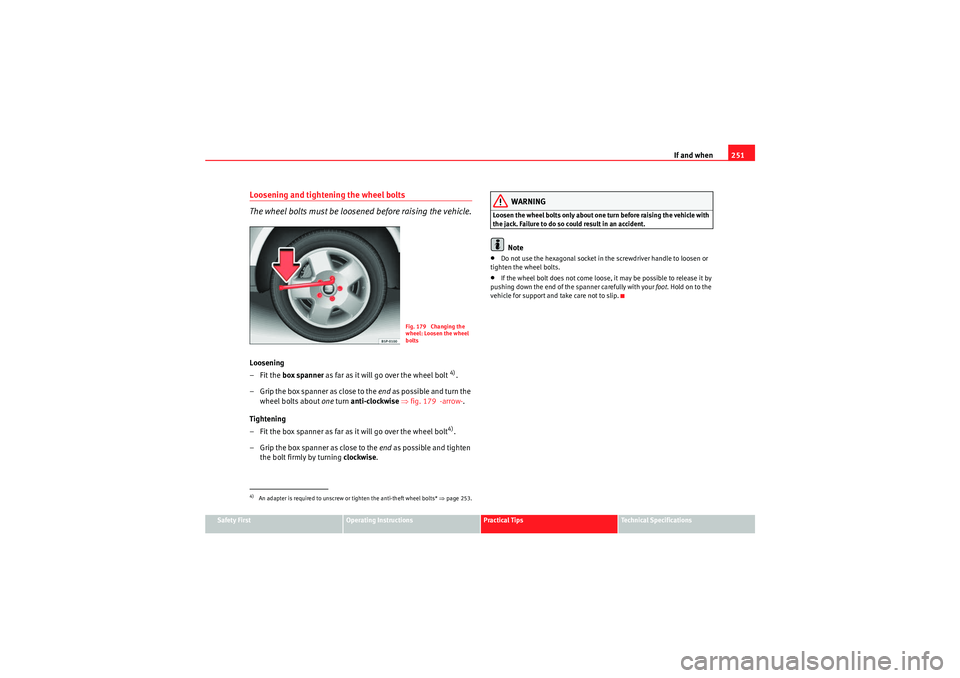

Loosening and tightening the wheel bolts

The wheel bolts must be loosened before raising the vehicle.Loosening

–Fit the box spanner as far as it will go over the wheel bolt

4).

– Grip the box spanner as close to the end as possible and turn the

wheel bolts about one turn anti-clockwise ⇒ fig. 179 -arrow- .

Tightening

– Fit the box spanner as far as it will go over the wheel bolt4).

– Grip the box spanner as close to the end as possible and tighten

the bolt firmly by turning clockwise.

WARNING

Loosen the wheel bolts only about one turn before raising the vehicle with

the jack. Failure to do so could result in an accident.

Note

•Do not use the hexagonal socket in the screwdriver handle to loosen or

tighten the wheel bolts.•If the wheel bolt does not come loose, it may be possible to release it by

pushing down the end of the spanner carefully with your foot. Hold on to the

vehicle for support and take care not to slip.

4)An adapter is required to unscrew or tighten the anti-theft wheel bolts* ⇒page 253.

Fig. 179 Changing the

wheel: Loosen the wheel

bolts

exeo_EN.book Seite 251 Montag, 30. August 2010 4:45 16

Page 255 of 319

If and when253

Safety First

Operating Instructions

Practical Tips

Technical Specifications

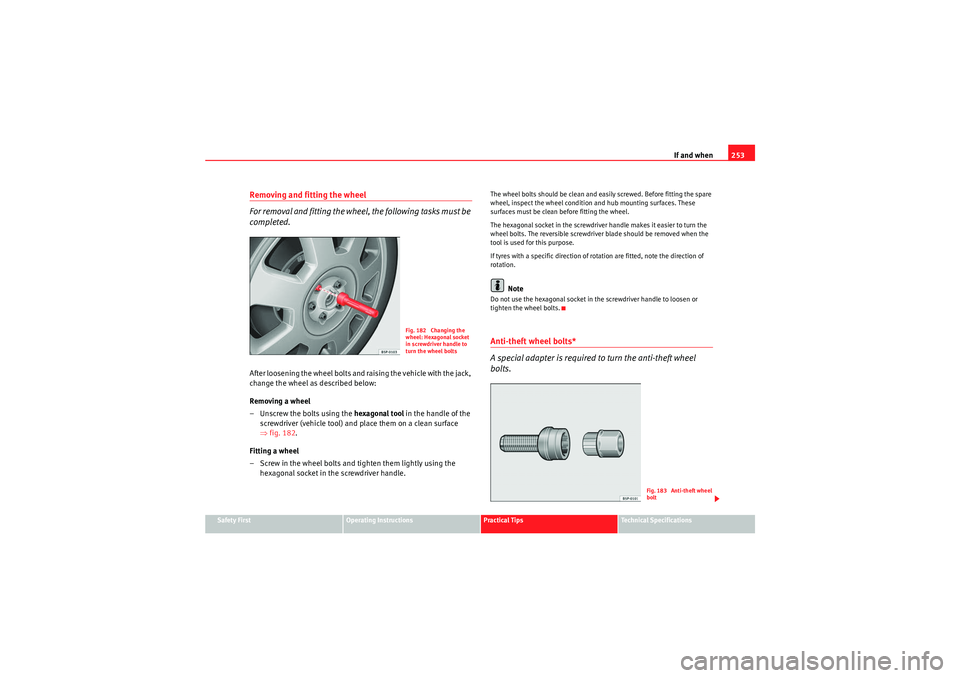

Removing and fitting the wheel

For removal and fitting the wheel, the following tasks must be

completed.After loosening the wheel bolts and raising the vehicle with the jack,

change the wheel as described below:

Removing a wheel

– Unscrew the bolts using the hexagonal tool in the handle of the

screwdriver (vehicle tool) and place them on a clean surface

⇒ fig. 182 .

Fitting a wheel

– Screw in the wheel bolts and tighten them lightly using the hexagonal socket in the screwdriver handle.

The wheel bolts should be clean and easily screwed. Before fitting the spare

wheel, inspect the wheel condition and hub mounting surfaces. These

surfaces must be clean before fitting the wheel.

The hexagonal socket in the screwdriver handle makes it easier to turn the

wheel bolts. The reversible screwdriver blade should be removed when the

tool is used for this purpose.

If tyres with a specific direction of rotation are fitted, note the direction of

rotation.

Note

Do not use the hexagonal socket in the screwdriver handle to loosen or

tighten the wheel bolts.Anti-theft wheel bolts*

A special adapter is required to turn the anti-theft wheel

bolts.

Fig. 182 Changing the

wheel: Hexagonal socket

in screwdriver handle to

turn the wheel bolts

Fig. 183 Anti-theft wheel

bolt

exeo_EN.book Seite 253 Montag, 30. August 2010 4:45 16

Page 257 of 319

If and when255

Safety First

Operating Instructions

Practical Tips

Technical Specifications

The sealing compound must not be used in the following cases:

•On cuts and punctures larger than 4 mm

⇒page 254, fig. 184 •If the wheel rim has been damaged •If you have been driving with ver y low pressure or a com pletely flat tyre

How to use the TMS (tyre mobility system) is described in the section

Repairing a tyre ⇒ page 256 and in the instructions supplied with the tyre

sealant can.

The TMS (tyre mobility system) can be used at outside temperatures down to

-20°C.WARNING

After repairing a tyre please note the following points:•Do not drive faster than 80 km/h.•Avoid heavy acceleration, hard braking and fast cornering.•Vehicle handling could be impaired.•Tyres which have been sealed using the Tyre Mobility System are only

suitable for temporary use over a short period.•After using the tyre sealant the tyre pressure monitoring system* may

malfunction. Therefore, please drive carefully to the next available quali-

fied workshop.•The Tyre Mobility System must NOT be used,

− on cuts and punctures larger than 4 mm

− if the wheel rim has been damaged

− if you have been driving with very low pressure or a completely flat

tyre•Seek professional assistance if the repair of a tyre puncture is not

possible with the sealing compound.•Do not allow the sealant to come into contact with your eyes, skin or

clothing.

•If you do come into contact with the sealant immediately rinse the eyes

or skin affected with clean water.•Change clothing immediately if it becomes soiled with the tyre sealant.•Make sure you do not breathe in the fumes!•If any of the tyre sealant is accidentally ingested, immediately rinse the

mouth thoroughly and drink lots of water.

−Do not induce vomiting. Seek medical assistance if needed.•If any allergic reactions should occur get medical help immediately.•Keep the sealant away from children.For the sake of the environment

If you have to dispose of a sealant can, go to a specialised waste service or to

a SEAT Technical Service, where the product can be recycled in an appropriate

waste container.

Note

•If sealant should leak out, leave it to dry. When it has dried, you can pull

it off like a piece of foil.•Observe the expiry date stated on the sealing compound can. Have the

sealing compound exchanged by a qualified workshop.

A1

A2

A3

WARNING (continued)

exeo_EN.book Seite 255 Montag, 30. August 2010 4:45 16

Page 259 of 319

If and when257

Safety First

Operating Instructions

Practical Tips

Technical Specifications

– If the tyre pressure remains lower than the value specified above

drive the vehicle approx. 10 metres forwards or backwards, so

that the sealant can spread evenly in the tyre. If the pressure is

still lower than the specification the tyre is too badly damaged

and cannot be repaired using the tyre sealant.

Final check

– After about 10 minutes, stop to check the tyre pressure.

– If tyre pressure is less than 1.3 bar, the tyre is too badly damaged. Do not drive on! You should obtain professional

assistance.

WARNING

•If you have a puncture in heavy traffic, switch on the hazard warning

lights and place the warning triangle in a visible location. This is for your

own safety and also warns other road users.•Make sure your pass engers wait in a safe place ( for instance behind t he

roadside crash barrier).•Please observe the manufacturer’s safety notes on the compressor and

the instructions supplied with the tyre sealant can.•If it is not possible to build up a tyre pressure of 2.0 bar within 6

minutes this means that the tyre is too badly damaged. Do not drive on!•Seek professional assistance if the repair of a tyre puncture is not

possible with the sealing compound.•If tyre pressure is less than 1.3 bar after driving about 10 minutes, the

tyre is too badly damaged. Do not drive on! Obtain technical assistance.Caution

Take special care if you have to repair a tyre on a slope.

Note

•Do not use the compressor for longer than 6 minutes. Otherwise, it might

overheat. When the compressor has cooled down, you can use it again.•If tyre sealant should leak out, leave it to dry and then pull it off like foil.•After carrying out a tyre repair remember to buy a new tyre sealant can at

a qualified workshop. This will ensure that the Tyre Mobility System is opera-

tive again.•Please observe legal requirements when doing so.

exeo_EN.book Seite 257 Montag, 30. August 2010 4:45 16

Page 261 of 319

If and when259

Safety First

Operating Instructions

Practical Tips

Technical Specifications

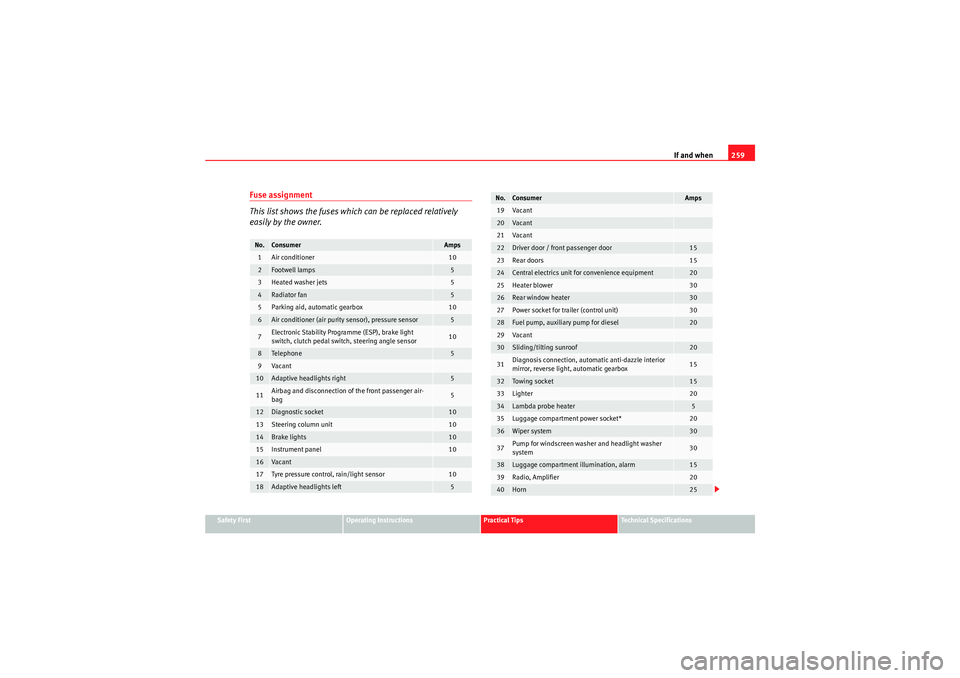

Fuse assignment

This list shows the fuses which can be replaced relatively

easily by the owner.No.

Consumer

Amps

1

Air conditioner

10

2

Footwell lamps

5

3

Heated washer jets

5

4

Radiator fan

5

5

Parking aid, automatic gearbox

10

6

Air conditioner (air purity sensor), pressure sensor

5

7

Electronic Stability Programme (ESP), brake light

switch, clutch pedal switch, steering angle sensor

10

8

Te le p hon e

5

9

Va can t

10

Adaptive headlights right

5

11

Airbag and disconnection of the front passenger air-

bag

5

12

Diagnostic socket

10

13

Steering column unit

10

14

Brake lights

10

15

Instrument panel

10

16

Va can t

17

Tyre pressure control, rain/light sensor

10

18

Adaptive headlights left

5

19

Va can t

20

Va can t

21

Va can t

22

Driver door / front passenger door

15

23

Rear doors

15

24

Central electrics unit for convenience equipment

20

25

Heater blower

30

26

Rear window heater

30

27

Power socket for trailer (control unit)

30

28

Fuel pump, auxiliary pump for diesel

20

29

Va can t

30

Sliding/tilting sunroof

20

31

Diagnosis connection, automatic anti-dazzle interior

mirror, reverse light, automatic gearbox

15

32

Towi ng s ocke t

15

33

Lighter

20

34

Lambda probe heater

5

35

Luggage compartment power socket*

20

36

Wiper system

30

37

Pump for windscreen washer and headlight washer

system

30

38

Luggage compartment illumination, alarm

15

39

Radio, Amplifier

20

40

Horn

25

No.

Consumer

Amps

exeo_EN.book Seite 259 Montag, 30. August 2010 4:45 16