lock Seat Exeo 2010 Repair Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2010, Model line: Exeo, Model: Seat Exeo 2010Pages: 319, PDF Size: 9.64 MB

Page 201 of 319

Trailer towing199

Safety First

Operating Instructions

Practical Tips

Technical Specifications

Where possible, operate the trailer with the maximum permitted

drawbar

load on the ball joint of the towing bracket, but do not exceed the specified

limit.

Tyre pressure

Check the tyre pressures on your vehicle, and adjust for “full load” conditions

(refer to the sticker listing the tyre pressures on the door pillar). It may also be

necessary to adjust the tyre pressures on the trailer according to the recom-

mendations of the trailer manufacturer.

Exterior mirrors

Check whether you can see enough of the road behind the trailer with the

standard mirrors. If this is not the case you should have additional mirrors

fitted. The two exterior mirrors should be fitted on folding arms. Adjust the

mirrors to give sufficient rear vision.

Headlights

Before starting a journey, check the headlight beam settings with the trailer

hitched up. If necessary, alter the height of the headlight beams by means of

the headlight range control. See ⇒page 119.

Power supply

When you remove the ignition key, the power supply to the trailer is inter-

rupted.

Removable ball joint coupling

Vehicles with a factory-fitted towing bracket are equipped with a removable

ball joint coupling. This is stored in the spare wheel well in the luggage

compartment together with the necessary fitting instructions.

Note

If you frequently tow, we recommend you also have the vehicle serviced

between services.

Notes on towing

Towing a trailer involves additional attention by the driver.Weight distribution

The weight distribution of a loaded trailer with an unladen vehicle is very

unfavourable. However, if this cannot be avoided, drive extra slow to allow for

the unbalanced weight distribution.

Speed

The stability of the vehicle and trailer is reduced with increasing speed. There-

fore, it is advisable not to drive at the maximum permissible speed in unfa-

vourable road, weather or wind condit ions. This especially applies when

driving downhill.

You should always reduce speed immediately if the trailer shows the slightest

sign of swaying . Never try to stabilise the trailer by accelerating.

Anticipate hazards and brake in good time. If towing a trailer with an inertia

brake , first brake gently and then harder. This will prevent brake tapping by

the trailer wheels when they lock. Select a low gear in due course before

going down a steep downhill. This enables you to use the engine braking to

slow down the vehicle.

Swaying and pitching can be reduced by stabiliser aids. We recommend

having stabiliser aids installed when towing trailers with a high trailer weight.

They can be purchased and installed at a Technical Service.

Reheating

When climbing long hills in hot weather with the engine running fast in low

gear, you should keep an eye on the coolant temperature gauge ⇒page 60.

Reduce speed immediately if the needle moves to the right end of the scale.

If the temperature warning lamp

�v in the instrument panel should start

flashing, stop the vehicle and let the engine cool down by running it at idling

speed for a few minutes.

exeo_EN.book Seite 199 Montag, 30. August 2010 4:45 16

Page 202 of 319

Trailer towing

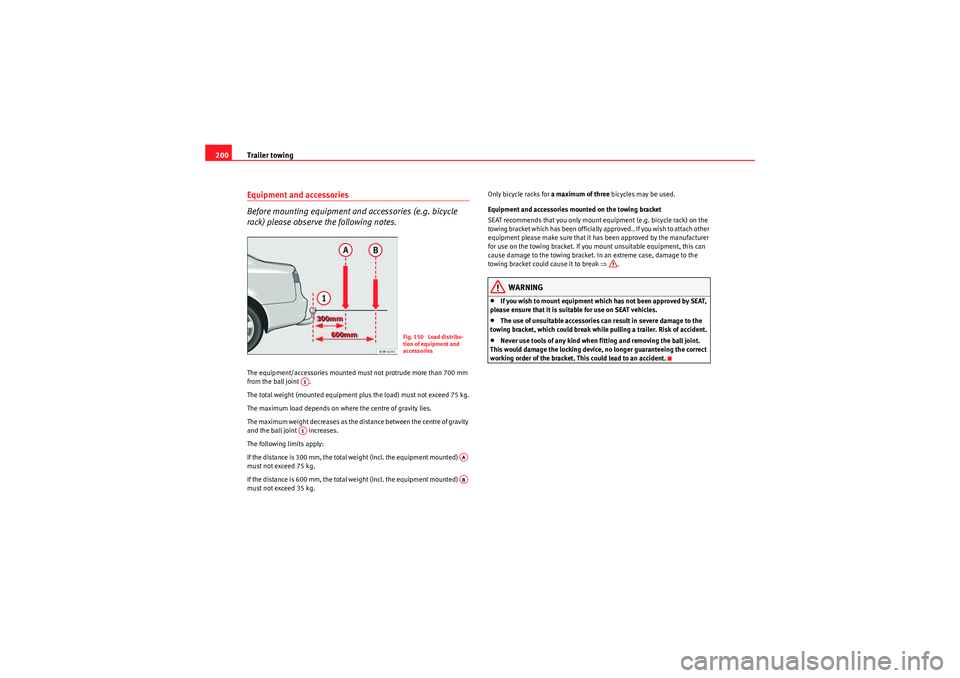

200Equipment and accessories

Before mounting equipment and accessories (e.g. bicycle

rack) please observe the following notes.The equipment/accessories mounted mu st not protrude more than 700 mm

from the ball joint .

The total weight (mounted equipment plus the load) must not exceed 75 kg.

The maximum load depends on where the centre of gravity lies.

The maximum weight decreases as the distance between the centre of gravity

and the ball joint increases.

The following limits apply:

If the distance is 300 mm, the total weight (incl. the equipment mounted)

must not exceed 75 kg.

If the distance is 600 mm, the total weight (incl. the equipment mounted)

must not exceed 35 kg. Only bicycle racks for

a maximum of three bicycles may be used.

Equipment and accessories mounted on the towing bracket

SEAT recommends that you only mount equipment (e.g. bicycle rack) on the

towing bracket which has been officially approved.. If you wish to attach other

equipment please make sure that it has been approved by the manufacturer

for use on the towing bracket. If you mount unsuitable equipment, this can

cause damage to the towing bracket. In an extreme case, damage to the

towing bracket could cause it to break ⇒.

WARNING

•If you wish to mount equipment which has not been approved by SEAT,

please ensure that it is suitable for use on SEAT vehicles.•The use of unsuitable accessories ca n result in severe damage to the

towing bracket, which could break while pulling a trailer. Risk of accident.•Never use tools of any kind when fitting and removing the ball joint.

This would damage the locking device, no longer guaranteeing the correct

working order of the bracket. This could lead to an accident.

Fig. 150 Load distribu-

tion of equipment and

accessories

A1A1

AAAB

exeo_EN.book Seite 200 Montag, 30. August 2010 4:45 16

Page 203 of 319

Trailer towing201

Safety First

Operating Instructions

Practical Tips

Technical Specifications

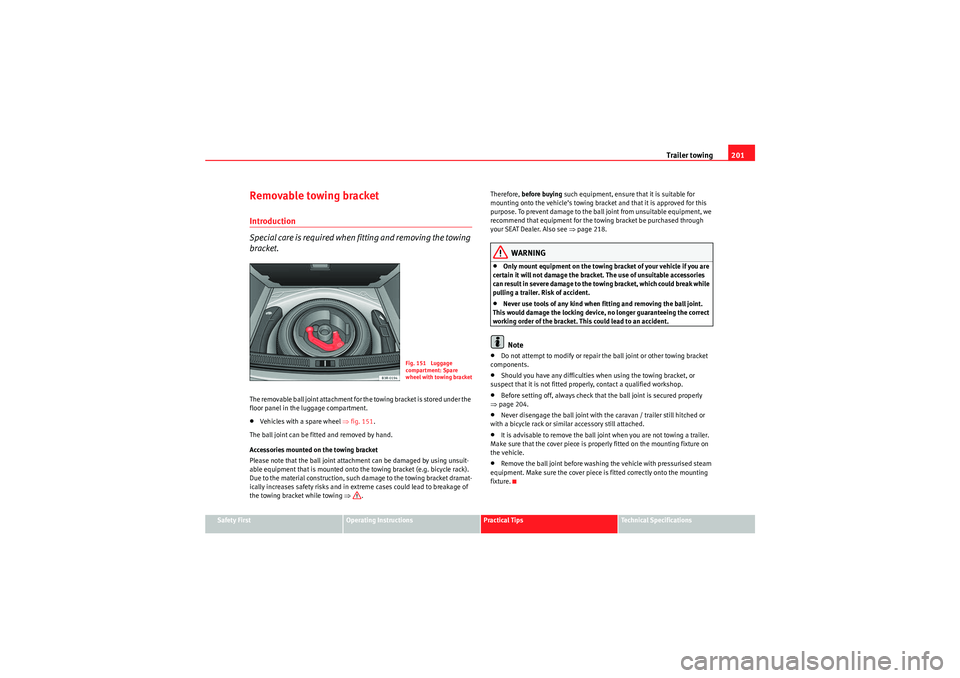

Removable towing bracketIntroduction

Special care is required when fitting and removing the towing

bracket.The removable ball joint attachment for the towing bracket is stored under the

floor panel in the luggage compartment.•Vehicles with a spare wheel ⇒ fig. 151.

The ball joint can be fitted and removed by hand.

Accessories mounted on the towing bracket

Please note that the ball joint attachment can be damaged by using unsuit-

able equipment that is mounted onto the towing bracket (e.g. bicycle rack).

Due to the material construction, such damage to the towing bracket dramat-

ically increases safety risks and in extreme cases could lead to breakage of

the towing bracket while towing ⇒. Therefore,

before buying such equipment, ensure that it is suitable for

mounting onto the vehicle’s towing bracket and that it is approved for this

purpose. To prevent damage to the ball joint from unsuitable equipment, we

recommend that equipment for the towing bracket be purchased through

your SEAT Dealer. Also see ⇒page 218.

WARNING

•Only mount equipment on the towing bracket of your vehicle if you are

certain it will not damage the bracket. The use of unsuitable accessories

can result in severe damage to the towing bracket, which could break while

pulling a trailer. Risk of accident.•Never use tools of any kind when fitting and removing the ball joint.

This would damage the locking device, no longer guaranteeing the correct

working order of the bracket. This could lead to an accident.Note

•Do not attempt to modify or repair the ball joint or other towing bracket

components.•Should you have any difficulties when using the towing bracket, or

suspect that it is not fitted properly, contact a qualified workshop.•Before setting off, always check that the ball joint is secured properly

⇒ page 204.•Never disengage the ball joint with the caravan / trailer still hitched or

with a bicycle rack or similar accessory still attached.•It is advisable to remove the ball joint when you are not towing a trailer.

Make sure that the cover piece is properly fitted on the mounting fixture on

the vehicle.•Remove the ball joint before washing the vehicle with pressurised steam

equipment. Make sure the cover piece is fitted correctly onto the mounting

fixture.

Fig. 151 Luggage

compartment: Spare

wheel with towing bracket

exeo_EN.book Seite 201 Montag, 30. August 2010 4:45 16

Page 205 of 319

Trailer towing203

Safety First

Operating Instructions

Practical Tips

Technical Specifications

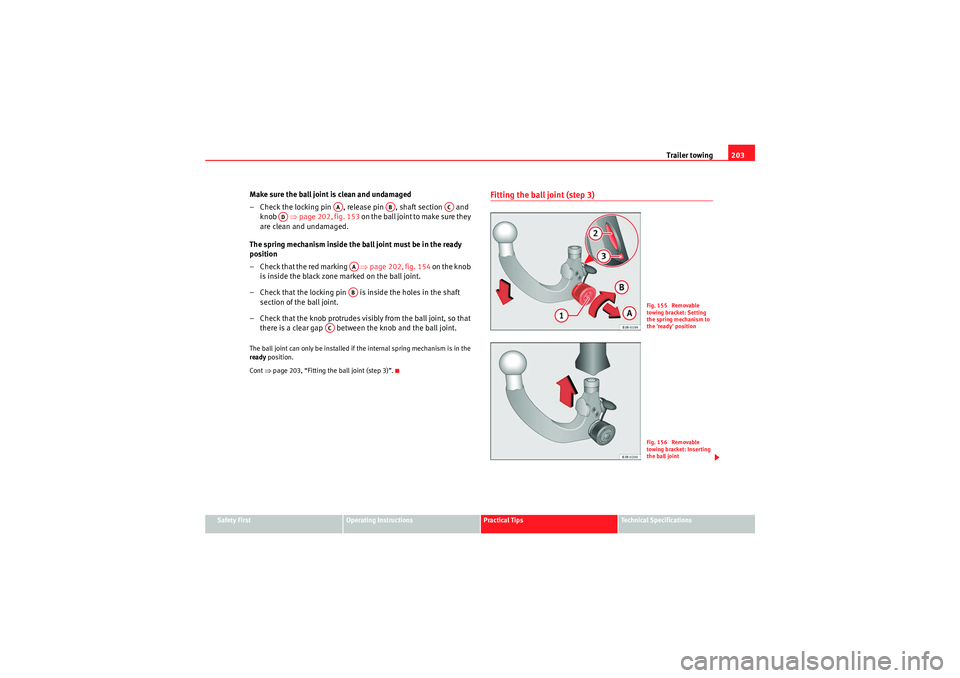

Make sure the ball joint is clean and undamaged

– Check the locking pin , release pin , shaft section and

knob ⇒page 202, fig. 153 on the ball joint to make sure they

are clean and undamaged.

The spring mechanism inside the ball joint must be in the ready

position

– Check that the red marking ⇒page 202, fig. 154 on the knob

is inside the black zone marked on the ball joint.

– Check that the locking pin is inside the holes in the shaft section of the ball joint.

– Check that the knob protrudes visibly from the ball joint, so that there is a clear gap between the knob and the ball joint.The ball joint can only be installed if the internal spring mechanism is in the

ready position.

Cont ⇒page 203, “Fitting the ball joint (step 3)”.

Fitting the ball joint (step 3)

AA

AB

AC

AD

AAAB

AC

Fig. 155 Removable

towing bracket: Setting

the spring mechanism to

the 'ready' positionFig. 156 Removable

towing bracket: Inserting

the ball joint

exeo_EN.book Seite 203 Montag, 30. August 2010 4:45 16

Page 206 of 319

Trailer towing

204

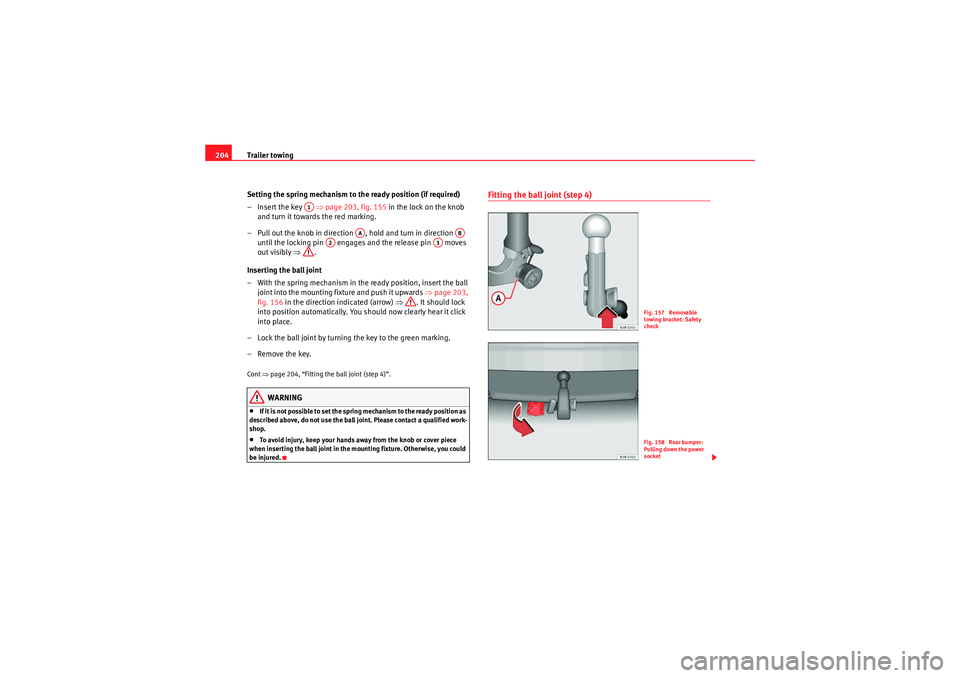

Setting the spring mechanism to the ready position (if required)

– Insert the key ⇒page 203, fig. 155 in the lock on the knob

and turn it towards the red marking.

– Pull out the knob in direction , hold and turn in direction

until the locking pin engages and the release pin moves

out visibly ⇒.

Inserting the ball joint

– With the spring mechanism in the ready position, insert the ball joint into the mounting fixture and push it upwards ⇒page 203,

fig. 156 in the direction indicated (arrow) ⇒. It should lock

into position automatically. You should now clearly hear it click

into place.

– Lock the ball joint by turning the key to the green marking.

– Remove the key.Cont ⇒page 204, “Fitting the ball joint (step 4)”.

WARNING

•If it is not possible to set the spring mechanism to the ready position as

described above, do not use the ball joint. Please contact a qualified work-

shop.•To avoid injury, keep your hands away from the knob or cover piece

when inserting the ball joint in the mounting fixture. Otherwise, you could

be injured.

Fitting the ball joint (step 4)

A1

AA

AB

A2

A3

Fig. 157 Removable

towing bracket: Safety

checkFig. 158 Rear bumper:

Pulling down the power

socket

exeo_EN.book Seite 204 Montag, 30. August 2010 4:45 16

Page 207 of 319

Trailer towing205

Safety First

Operating Instructions

Practical Tips

Technical Specifications

Safety check

– Check that the green marking ⇒page 204, fig. 157 on the

knob is inside the black zone marked on the ball joint.

– Check that the knob is directly against the ball joint, so that there is no gap between the knob and the ball joint -arrow-.

– Check that the ball joint is locked and the key is removed so that the knob cannot be pulled out ⇒.

– Check that the ball joint fits tightly in the mounting fixture (try moving it about to check).

To w i n g s o c k e t

– To plug in the electrical connection for the trailer, pull down the socket below the bumper ⇒page 204, fig. 158 .If the safety check is not satisfactory, the ball joint must be fitted again prop-

erly.

WARNING

To avoid accidents, the ball joint must meet all the safety requirements

listed in the safety check. The towing bracket must not be used if any one

of these requirements is not met. If this is the case, you should contact a

qualified workshop.

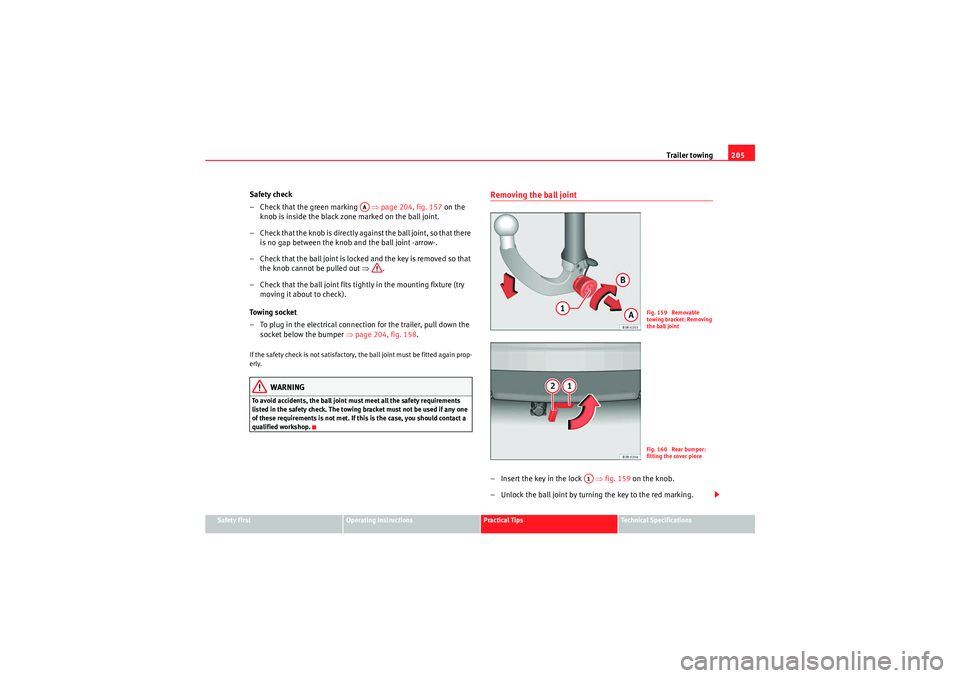

Removing the ball joint– Insert the key in the lock ⇒fig. 159 on the knob.

– Unlock the ball joint by turning the key to the red marking.

AA

Fig. 159 Removable

towing bracket: Removing

the ball jointFig. 160 Rear bumper:

fitting the cover piece

A1

exeo_EN.book Seite 205 Montag, 30. August 2010 4:45 16

Page 208 of 319

Trailer towing

206

– Take hold of the ball joint and pull out the knob in direction .

– Keep hold of the knob and turn it as far as it will go in direction

.

– Release the knob. The spring mechanism will remain in the ready position ⇒.

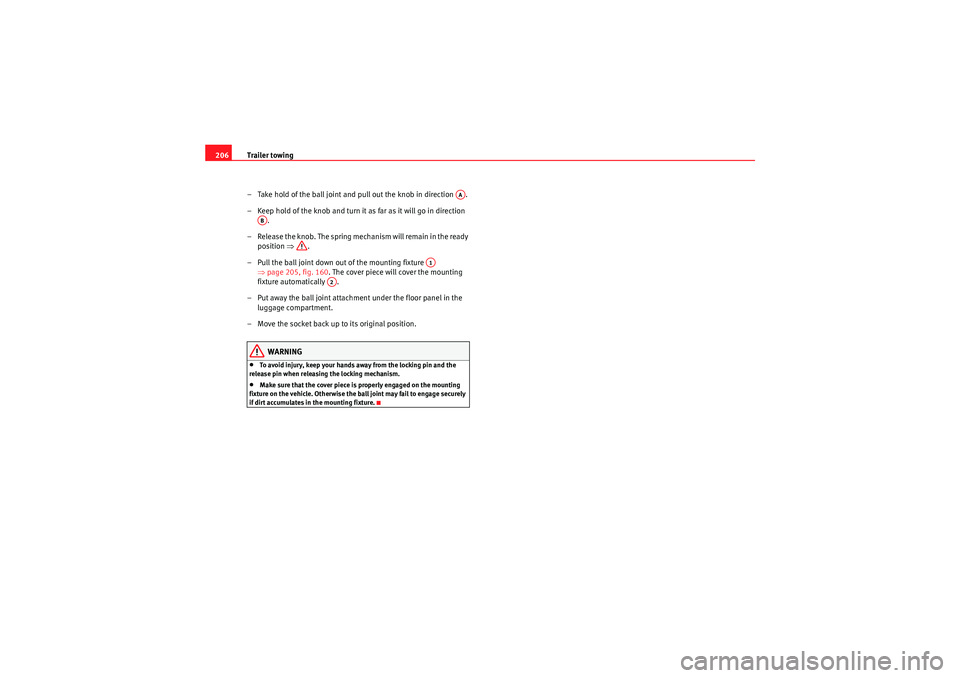

– Pull the ball joint down out of the mounting fixture ⇒page 205, fig. 160. The cover piece will cover the mounting

fixture automatically .

– Put away the ball joint attachment under the floor panel in the luggage compartment.

– Move the socket back up to its original position.

WARNING

•To avoid injury, keep your hands away from the locking pin and the

release pin when releasing the locking mechanism.•Make sure that the cover piece is properly engaged on the mounting

fixture on the vehicle. Otherwise the ball joint may fail to engage securely

if dirt accumulates in the mounting fixture.

AA

AB

A1

A2

exeo_EN.book Seite 206 Montag, 30. August 2010 4:45 16

Page 213 of 319

Vehicle maintenance and cleaning211

Safety First

Operating Instructions

Practical Tips

Technical Specifications

Caution

•Never remove dirt, mud or dust if the vehicle surface is dry. Never use a

dry cloth or sponge for cleaning purposes. This could scratch the paintwork

or glass on your vehicle.•Washing the vehicle in low temperatures: when washing the vehicle with

a hose, do not direct water into the lock cylinders or the gaps around the

doors, tailgate, or sunroof. Risk of freezing.For the sake of the environment

To protect environment, the vehicle should be washed only in specially

provided wash bays. This prevents toxic, oil-laden waste water entering the

sewerage system. In some places, washing vehicles outside wash bays is

prohibited.

Note

Do not wash the vehicle in direct sunlight.Washing the vehicle with a high pressure cleaner

Be particularly careful when using a high pressure cleaner!– Always observe the instructions for the high-pressure cleaner, particularly those concerning the pressure and the spraying

distance.

– Increase the spraying distance for soft materials and painted

bumpers.

– Do not use a high pressure cleaner to remove ice or snow from windows ⇒page 212. – Never use concentrated jet nozzles (“rotating jets”)

⇒.

– After washing, avoid sudden and sharp braking. Dry the brakes by braking several times ⇒page 192.

WARNING

•Never wash tyres with a concentrated jet (“rotating nozzle”). Even at

large spraying distances and short cleaning times, visible and invisible

damage can occur to the tyres. This may cause an accident.•Water, ice and salt on the brakes can reduce braking efficiency. Risk of

accident.Caution

•Do not use water hotter than 60°C. This could damage the vehicle.•To avoid damage to the vehicle, keep a sufficient distance from sensitive

materials such as flexible hoses, plastic, soundproofing material, etc. This is

also important for bumpers painted in the colour of the bodywork. The closer

the nozzle is to the surface, the greater the wear on the material.Vehicle paint maintenance

Regular waxing protects the paintwork.You need to apply wax to your vehicle if water does not form small drops and

run off the paintwork when it is clean.

Good quality hard wax products are available at your Authorised Service

Centre.

exeo_EN.book Seite 211 Montag, 30. August 2010 4:45 16

Page 215 of 319

Vehicle maintenance and cleaning213

Safety First

Operating Instructions

Practical Tips

Technical Specifications

screen washer fluid prevents wiper blades from juddering, but wax deposits

are not removed.

Caution

•Never use warm or hot water to remove snow and ice from windows and

mirrors. This could cause the glass to crack!•The heating element for the rear window is located on the inner side of the

window. To prevent damage, do not put stickers on the heating elements

inside the window.Cleaning windscreen wiper bladesClean wiper blades are essent ial to provide clear vision.

1. Use a soft cloth to remove dust and dirt from the windscreen wiper blades.

2. Use window cleaner to clean the windscreen wiper blades. Use a sponge or a cloth to remove stubborn dirt.Rubber seals maintenance

If rubber seals are well looked after, they will not freeze so

quickly.1. Use a soft cloth to remove dust and dirt from the rubber seals.

2. Apply a specialist care product to the rubber seals.

The rubber strips on the doors, windows, bonnet and tailgate will remain

pliable and last longer if they are treated with a suitable care product (for

example silicone spray).

Caring for rubber seals will also prevent premature ageing and leaks. The

doors will be easier to open. If rubber seals are well looked after, they will not

freeze so quickly in winter.Door lock cylinders

The door lock cylinders can freeze up in winter.To de-ice the lock cylinders you should only use spray with lubricating and

anti-corrosive properties.Cleaning chrome parts1. Clean chrome parts with a damp cloth.

2. Polish chrome parts with a soft, dry cloth.If this does not provide satisfying results, use a specialist chrome cleaning

product . Chrome cleaning products will remove stains from the surface.

Caution

To prevent scratching chrome surfaces:•Never use an abrasive cleaning product on chrome.•Do not clean or polish chrome parts in a sandy or dusty environment.

exeo_EN.book Seite 213 Montag, 30. August 2010 4:45 16

Page 222 of 319

Checking and refilling levels

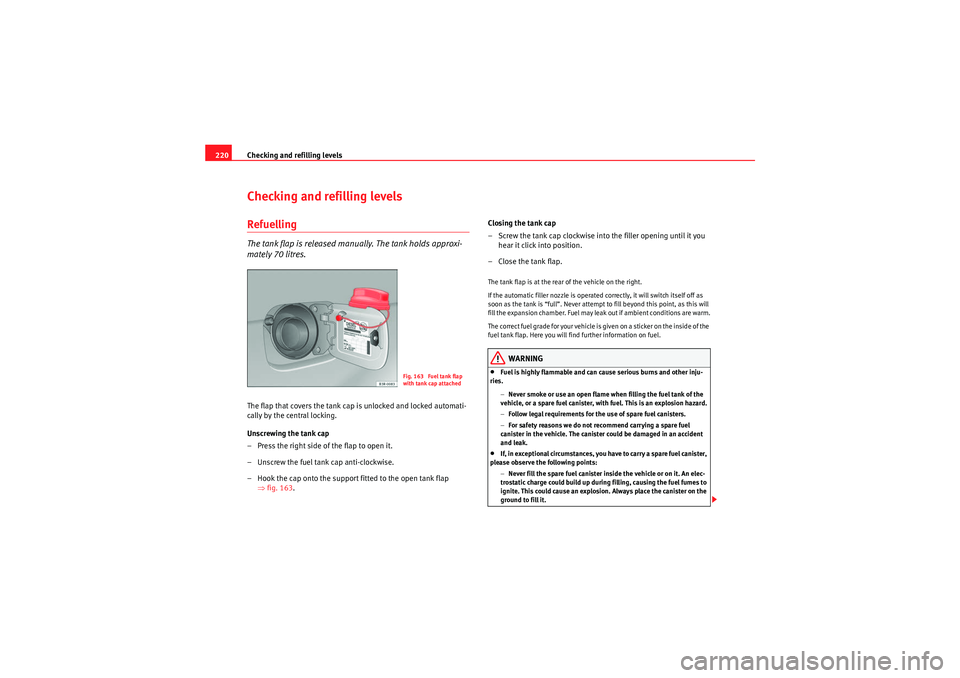

220Checking and refilling levelsRefuellingThe tank flap is released manually. The tank holds approxi-

mately 70 litres.The flap that covers the tank cap is unlocked and locked automati-

cally by the central locking.

Unscrewing the tank cap

– Press the right side of the flap to open it.

– Unscrew the fuel tank cap anti-clockwise.

– Hook the cap onto the support fitted to the open tank flap

⇒fig. 163 . Closing the tank cap

– Screw the tank cap clockwise into the filler opening until it you

hear it click into position.

– Close the tank flap.

The tank flap is at the rear of the vehicle on the right.

If the automatic filler nozzle is operated correctly, it will switch itself off as

soon as the tank is “full”. Never attempt to fill beyond this point, as this will

fill the expansion chamber. Fuel may leak out if ambient conditions are warm.

T he co rr ec t fu el g rad e fo r you r v eh icle is giv en on a sti cker o n th e i nsid e of the

fuel tank flap. Here you will find further information on fuel.

WARNING

•Fuel is highly flammable and can cause serious burns and other inju-

ries.

−Never smoke or use an open flame when filling the fuel tank of the

vehicle, or a spare fuel canister, with fuel. This is an explosion hazard.

− Follow legal requirements for the use of spare fuel canisters.

− For safety reasons we do not recommend carrying a spare fuel

canister in the vehicle. The canister could be damaged in an accident

and leak.•If, in exceptional circumstances, you have to carry a spare fuel canister,

please observe the following points:

−Never fill the spare fuel canister inside the vehicle or on it. An elec-

trostatic charge could build up during filling, causing the fuel fumes to

ignite. This could cause an explosion. Always place the canister on the

ground to fill it.

Fig. 163 Fuel tank flap

with tank cap attached

exeo_EN.book Seite 220 Montag, 30. August 2010 4:45 16