lock Seat Exeo 2010 Manual PDF

[x] Cancel search | Manufacturer: SEAT, Model Year: 2010, Model line: Exeo, Model: Seat Exeo 2010Pages: 319, PDF Size: 9.64 MB

Page 225 of 319

Checking and refilling levels223

Safety First

Operating Instructions

Practical Tips

Technical Specifications

BonnetReleasing the bonnet

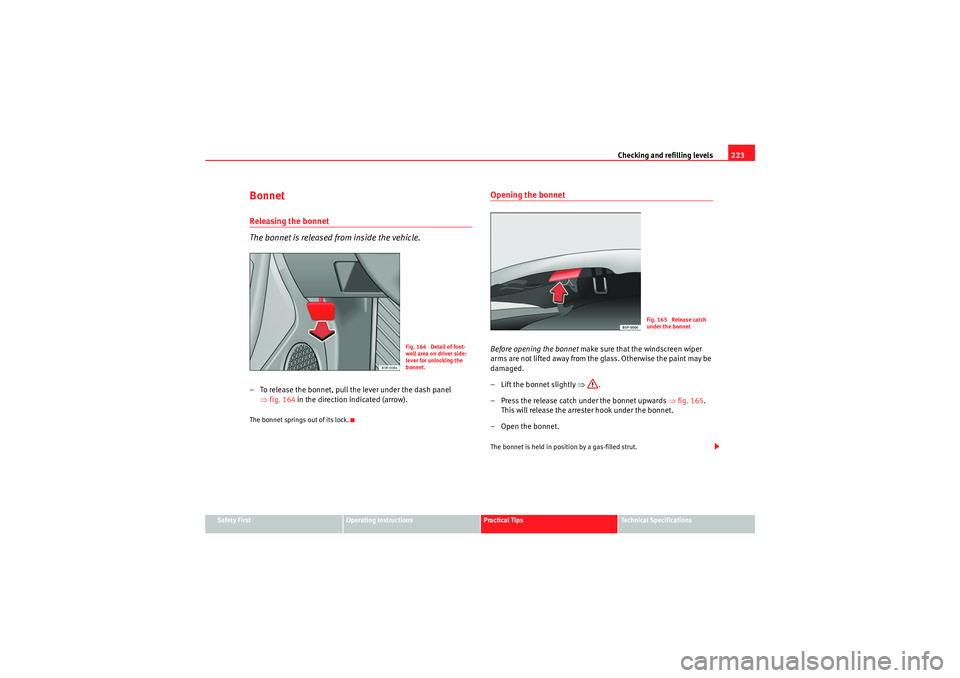

The bonnet is released from inside the vehicle.– To release the bonnet, pull the lever under the dash panel

⇒fig. 164 in the direction indicated (arrow).The bonnet springs out of its lock.

Opening the bonnetBefore opening the bonnet make sure that the windscreen wiper

arms are not lifted away from the glass. Otherwise the paint may be

damaged.

– Lift the bonnet slightly ⇒.

– Press the release catch under the bonnet upwards ⇒fig. 165 .

This will release the arrester hook under the bonnet.

– Open the bonnet.The bonnet is held in position by a gas-filled strut.

Fig. 164 Detail of foot-

well area on driver side:

lever for unlocking the

bonnet.

Fig. 165 Release catch

under the bonnet

exeo_EN.book Seite 223 Montag, 30. August 2010 4:45 16

Page 227 of 319

Checking and refilling levels225

Safety First

Operating Instructions

Practical Tips

Technical Specifications

Note

On right-hand drive vehicles some of the reservoirs mentioned below are

located on the other side of the engine compartment.Closing the bonnet– To close the bonnet, push it down until it overcomes the spring

pressure.

– Let the bonnet engage in the locking part. Do not force it ⇒ .

WARNING

•For safety reasons the bonnet must always be completely closed when

the vehicle is moving. After closing it always check that it is properly

secured. The bonnet must be flush with the adjacent body panels.•Should you notice that the bonnet is not safely secured when the

vehicle is moving, stop the vehicle immediately and close the bonnet.

Failure to do so could result in an accident.

Engine oilGeneral notesThe engine comes with a special, high quality, multi grade oil that can be

used in all seasons of the year except for those regions affected by extreme

cold. As the use of good quality oil is necessary for the correct operation and long

service life of the engine, when it becomes necessary to replenish or change

the oil, always use an oil that complies to the VW standards.

The specifications (VW standards) set out in the following page should

appear on the container of the service oil; when the container displays the

specific standards for petrol and diesel

engines together, it means that the

oil can be used for both types of engines.

We recommend that the oil change, indicated in the Maintenance

Programme, be performed by an Authorised Service Centre or a qualified

workshop.

The correct oil specifications for your engine are listed in ⇒page 226, “Oil

properties”.

Service intervals

Service intervals can be flexible (LongLife service) or fixed (dependent on

time/distance travelled).

If the PR code that appears on the back of the Maintenance Programme

booklet is QG1, this means that your vehicle has the LongLife service

programmed. If it has the codes QG0 or QG2 the interval service is dependent

on time/distance travelled.

Flexible service intervals (LongLife*)

Special oils and processes have been developed which, depending on the

characteristics and individual driving profiles, allow to extend the oil change

service (LongLife service intervals).

Because this oil is essential for extending the service intervals, it must only

be used observing the following indications:

•Avoid mixing it with oil for fixed service intervals.•Only in exceptional circumstances, if the engine oil level is too low

⇒ page 226 and LongLife oil is not available, it is permitted to top up (once)

with oil for fixed service intervals (up to a maximum of 0.5 litres).

exeo_EN.book Seite 225 Montag, 30. August 2010 4:45 16

Page 231 of 319

Checking and refilling levels229

Safety First

Operating Instructions

Practical Tips

Technical Specifications

tion. The damage caused by the use of these antifreezes may lead to a loss of

coolant fluid, causing serious damage to the engine.

•G12++ antifreeze can be mixed only with antifreeze additives G11, G12

and G12+.Checking the coolant level

The coolant level can be checked visually.– Switch the ignition off.

– Check the coolant level on coolant fluid expansion tank ⇒fig. 168 . When the engine is cold, it should be between the

“min” and “max” marks. When the engine is hot, it may be

slightly above the “max” mark.Its location is shown in the corresponding general overview of the engine

compartment. The coolant level should be checked with the engine switched off.

The coolant level is monitored by a warning lamp on the instrument panel

display

⇒page 78. However, we recommend that it should be checked occa-

sionally.

Coolant fluid loss

Any loss of coolant fluid normally indicates a leak in the cooling system. In

this case the cooling system should be inspected by a qualified workshop

without delay. It is not sufficient merely to top up the coolant fluid.

If there are no leaks in the system, a loss of coolant fluid can only occur if the

coolant boils and is forced out of the system as a result of overheating.

Caution

Radiator sealants must not be added to the coolant fluid. Such additives

could seriously impair the function of the cooling system.To p p i n g u p t h e c o o l a n t f l u i d

Be careful when topping up with coolant fluid.– Switch the engine off.

– Wait for the engine to cool down.

– Cover the cap on the expansion tank ⇒fig. 168 with a cloth, and

carefully unscrew the cap anti-clockwise ⇒.

– Add coolant fluid.

– Screw on the cap tightly.

Fig. 168 Engine compart-

ment: Coolant fluid

deposit

exeo_EN.book Seite 229 Montag, 30. August 2010 4:45 16

Page 238 of 319

Checking and refilling levels

236•A highly explosive mixture of gases is released when the battery is

under charge. The batteries should be charged in a well-ventilated room

only.•Keep children away from acid and batteries.•Before working on the electrical system, you must switch off the

engine, the ignition and all consumers. The negative cable on the battery

must be disconnected. When a light bulb is changed, you need only switch

off the light.•Deactivate the anti-theft alarm by unlocking the vehicle before you

disconnect the battery! The alarm will otherwise be triggered.•When disconnecting the battery from the vehicle electrical system,

disconnect first the negative cable and then the positive cable.•Switch off all electrical consumers before reconnecting the battery.

Reconnect first the positive cable and then the negative cable. Never

reverse the polarity of the connections. This could cause an electrical fire.•Never charge a frozen battery, or one which has thawed. This could

result in explosions and chemical burns. Always replace a battery which

has frozen. A flat battery can freeze at temperatures around 0°C.•Ensure that the vent hose is always connected to the battery.•Never use a defective battery. This could cause an explosion. Replace a

damaged battery immediately.Caution

•Never disconnect the battery if the ignition is switched on or if the engine

is running. This could damage the electrical system or electronic compo-

nents.•Do not expose the battery to direct sunlight over a long period of time, as

the intense ultraviolet radiation can damage the battery housing.•If the vehicle is left standing in cold conditions for a long period, protect

the battery from frost. If it freezes it will be damaged.

Charging the battery

A fully-charged battery is important for reliable starting.– Note the warnings ⇒ in “Important safety warnings for

handling a vehicle battery” on page 235 and ⇒.

– Switch off the ignition and all electrical equipment.

– Only if fast-charging: both battery cables must be disconnected (first the negative cable, then the positive cable).

– Connect the charger cables to the battery terminals, noting the colour code (red = positive; black or brown = negative).

– Now connect the battery charger to the power socket and switch on.

– After charging the battery: switch off the battery charger and disconnect the power point cable.

– Finally disconnect the charger cables from the battery.

– If necessary, reconnect both battery cables to the battery (first the positive cable, then the negative cable).When charging with a low current (for instance with a small battery charger)

the battery does not normally have to be disconnected. However, both

battery cables must be disconnected before fast-charging the battery with a

high current. However, always follow the instructions given by the manufac-

turer of the battery charger.

The fast-charging procedure for a battery is dangerous ⇒ in “Important

safety warnings for handling a vehicle battery” on page 235, as it requires a

special charger and the corresponding level of knowledge. We therefore

recommend that this work should only be performed by a qualified workshop.

WARNING (continued)

exeo_EN.book Seite 236 Montag, 30. August 2010 4:45 16

Page 250 of 319

If and when

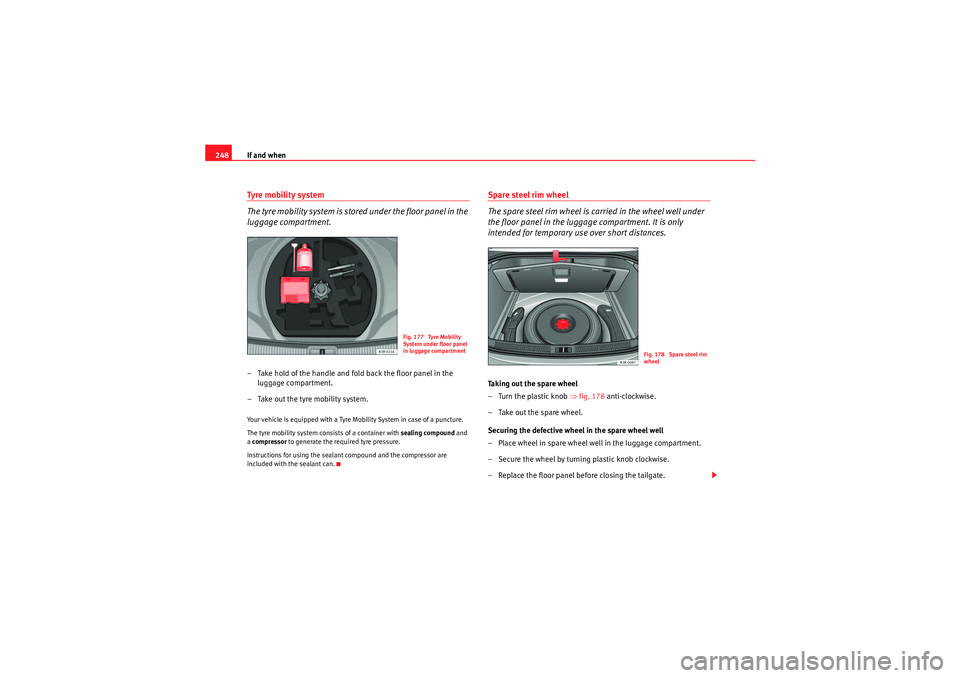

248Tyre mobility system

The tyre mobility system is stor ed under the floor panel in the

luggage compartment.– Take hold of the handle and fold back the floor panel in the

luggage compartment.

– Take out the tyre mobility system.Your vehicle is equipped with a Tyre Mobility System in case of a puncture.

The tyre mobility system consists of a container with sealing compound and

a compressor to generate the required tyre pressure.

Instructions for using the sealant compound and the compressor are

included with the sealant can.

Spare steel rim wheel

The spare steel rim wheel is carried in the wheel well under

the floor panel in the luggage compartment. It is only

intended for temporary use over short distances.Taking out the spare wheel

–Turn the plastic knob ⇒fig. 178 anti-clockwise.

– Take out the spare wheel.

Securing the defective wheel in the spare wheel well

– Place wheel in spare wheel well in the luggage compartment.

– Secure the wheel by turning plastic knob clockwise.

– Replace the floor panel before closing the tailgate.

Fig. 177 Tyre Mobility

System under floor panel

in luggage compartment

Fig. 178 Spare steel rim

wheel

exeo_EN.book Seite 248 Montag, 30. August 2010 4:45 16

Page 251 of 319

If and when249

Safety First

Operating Instructions

Practical Tips

Technical Specifications

Your vehicle can be factory-equipped with a spare steel wheel. The spare

wheel does

not usually meet the same performance standards as the wheels

fitted on the vehicle because of the wheel/tyre dimensions, rubber composi-

tion, tread pattern, etc. Therefore, note the following restrictions:

•The spare steel wheel is designed only for your vehicle model. Do not

attempt to mount the wheel on any vehicle but your own.•Your vehicle will have different driving characteristics when the spare

steel rim wheel is mounted ⇒.•The spare wheel is only intended for temporary use after having a flat tyre.

Replace the spare wheel with a normal wheel that has the proper tyre dimen-

sions as soon as possible.•If the size of the spare steel rim wheel is different to that of the other

wheels, it is unlikely that snow chains suitable for the other wheels will fit it.WARNING

•After mounting the spare steel rim wheel, the tyre pressure must be

checked and corrected as soon as possible. The tyre pressure must corre-

spond to the vehicle load (consult th e table containing the inflation pres-

sures). Otherwise there is danger of causing an accident. Use the highest

tyre pressure as indicated in the table.•Do not drive faster than 80 km/h, as higher speeds can cause an acci-

dent.•Avoid heavy acceleration, hard braking and fast cornering, as this could

cause an accident.

Changing a wheelPreparation work

What you must do before changing a wheel.– If you have a flat tyre or puncture, park the vehicle as far away from the flow of traffic as possible. Choose a location that is as

level as possible.

–All passengers should leave the vehicle. They should wait in a

safe place (e.g. behind the roadside crash barrier).

–Apply the handbrake firmly.

– Engage 1st gear .

– When towing a trailer: Unhitch the trailer from your vehicle.

– Take the tools and the spare wheel ⇒ page 247 out of the

luggage compartment.

WARNING

If you have a puncture in heavy traffic, switch on the hazard warning lights

and place the warning triangle in a visible location. This is for your own

safety and also warns other road users.

Caution

If you have to change the tyre on a gradient, block the wheel opposite the

wheel being changed by placing a stone or similar object under it to prevent

the vehicle from rolling away.

exeo_EN.book Seite 249 Montag, 30. August 2010 4:45 16

Page 253 of 319

If and when251

Safety First

Operating Instructions

Practical Tips

Technical Specifications

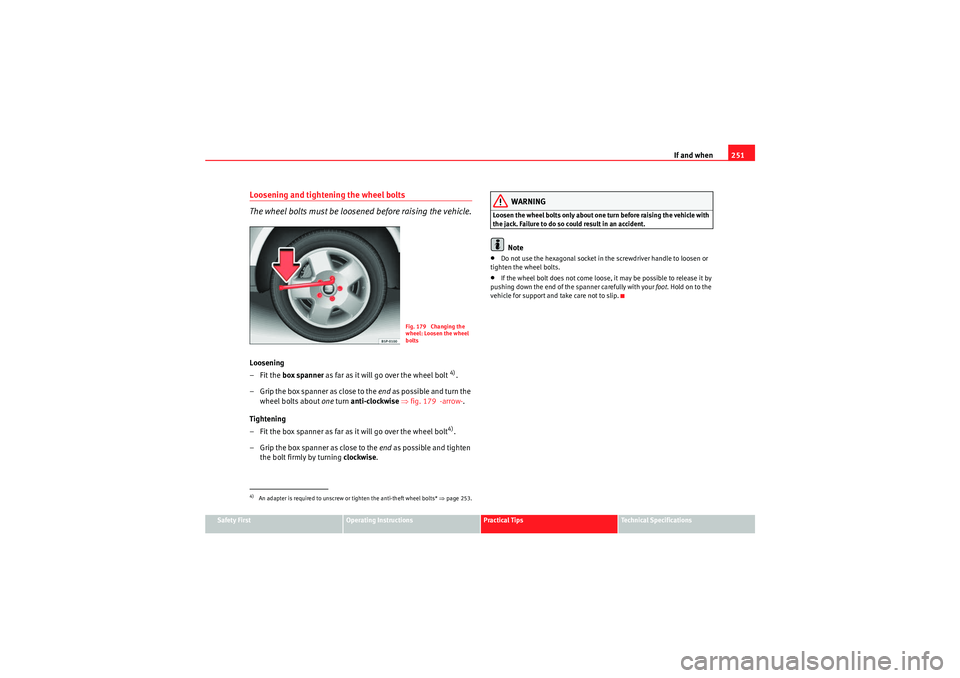

Loosening and tightening the wheel bolts

The wheel bolts must be loosened before raising the vehicle.Loosening

–Fit the box spanner as far as it will go over the wheel bolt

4).

– Grip the box spanner as close to the end as possible and turn the

wheel bolts about one turn anti-clockwise ⇒ fig. 179 -arrow- .

Tightening

– Fit the box spanner as far as it will go over the wheel bolt4).

– Grip the box spanner as close to the end as possible and tighten

the bolt firmly by turning clockwise.

WARNING

Loosen the wheel bolts only about one turn before raising the vehicle with

the jack. Failure to do so could result in an accident.

Note

•Do not use the hexagonal socket in the screwdriver handle to loosen or

tighten the wheel bolts.•If the wheel bolt does not come loose, it may be possible to release it by

pushing down the end of the spanner carefully with your foot. Hold on to the

vehicle for support and take care not to slip.

4)An adapter is required to unscrew or tighten the anti-theft wheel bolts* ⇒page 253.

Fig. 179 Changing the

wheel: Loosen the wheel

bolts

exeo_EN.book Seite 251 Montag, 30. August 2010 4:45 16

Page 265 of 319

If and when263

Safety First

Operating Instructions

Practical Tips

Technical Specifications

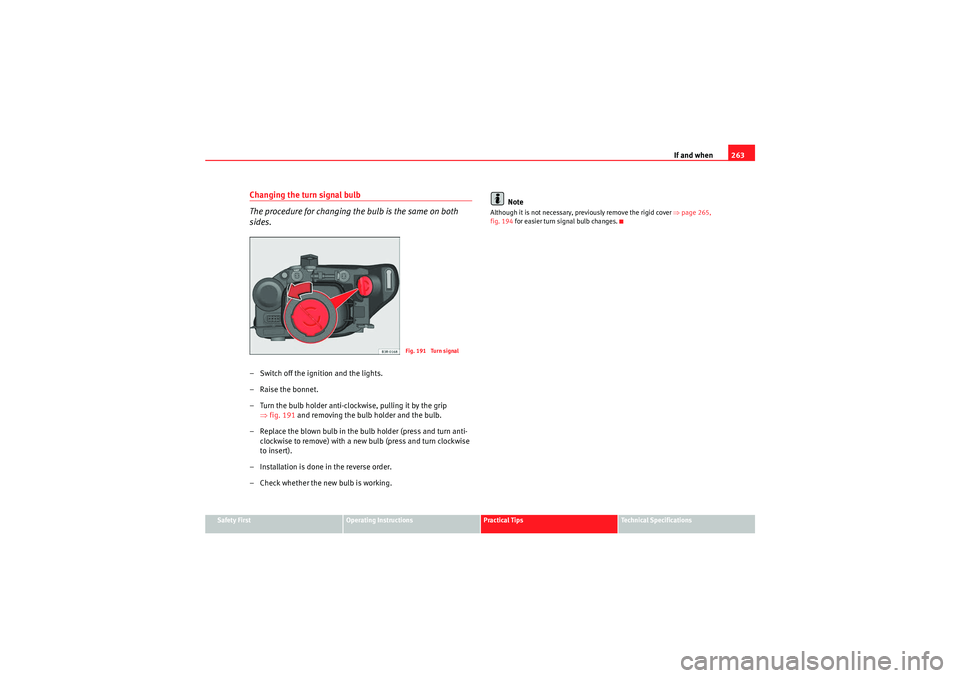

Changing the turn signal bulb

The procedure for changing the bulb is the same on both

sides.– Switch off the ignition and the lights.

– Raise the bonnet.

– Turn the bulb holder anti-clockwise, pulling it by the grip

⇒fig. 191 and removing the bulb holder and the bulb.

– Replace the blown bulb in the bulb holder (press and turn anti- clockwise to remove) with a new bulb (press and turn clockwise

to insert).

– Installation is done in the reverse order.

– Check whether the new bulb is working. Note

Although it is not necessary, previously remove the rigid cover

⇒page 265,

fig. 194 for easier turn signal bulb changes.

Fig. 191 Turn signal

exeo_EN.book Seite 263 Montag, 30. August 2010 4:45 16

Page 267 of 319

If and when265

Safety First

Operating Instructions

Practical Tips

Technical Specifications

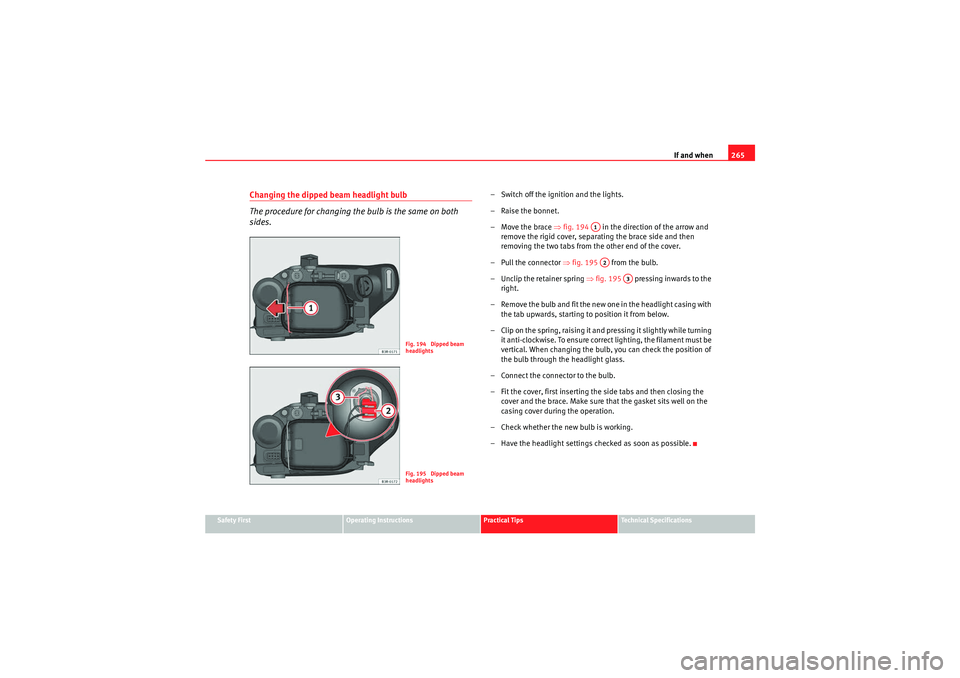

Changing the dipped beam headlight bulb

The procedure for changing the bulb is the same on both

sides.

– Switch off the ignition and the lights.

– Raise the bonnet.

– Move the brace ⇒fig. 194 in the direction of the arrow and

remove the rigid cover, separating the brace side and then

removing the two tabs from the other end of the cover.

– Pull the connector ⇒fig. 195 from the bulb.

– Unclip the retainer spring ⇒fig. 195 pressing inwards to the

right.

– Remove the bulb and fit the new one in the headlight casing with the tab upwards, starting to position it from below.

– Clip on the spring, raising it and pressing it slightly while turning

it anti-clockwise. To ensure correct lighting, the filament must be

vertical. When changing the bulb, you can check the position of

the bulb through the headlight glass.

– Connect the connector to the bulb.

– Fit the cover, first inserting the side tabs and then closing the cover and the brace. Make sure that the gasket sits well on the

casing cover during the operation.

– Check whether the new bulb is working.

– Have the headlight settings checked as soon as possible.

Fig. 194 Dipped beam

headlightsFig. 195 Dipped beam

headlights

A1A2

A3

exeo_EN.book Seite 265 Montag, 30. August 2010 4:45 16

Page 268 of 319

If and when

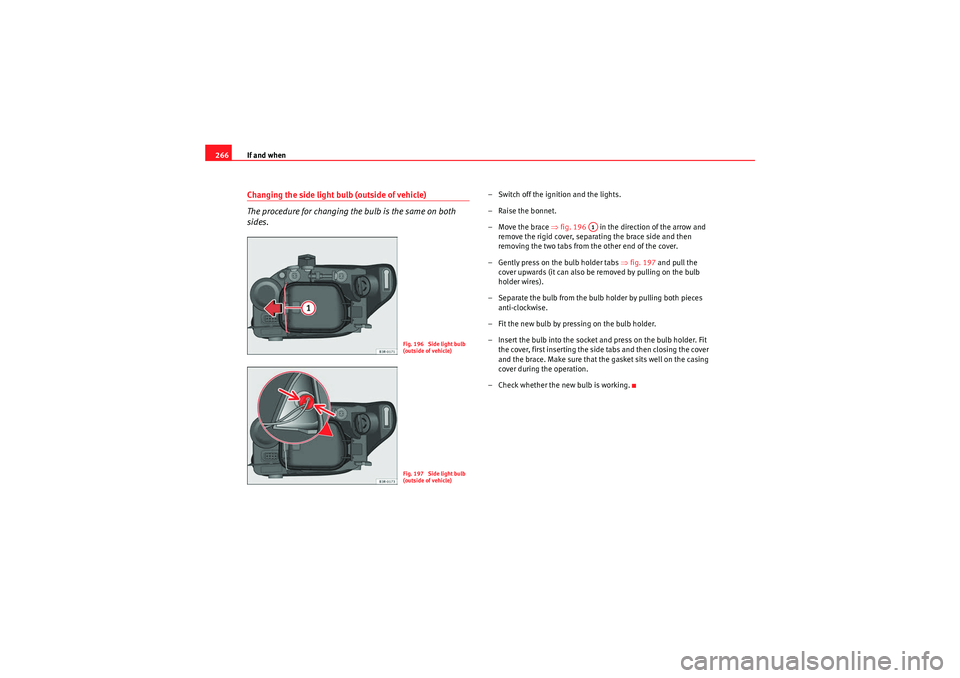

266Changing the side light bulb (outside of vehicle)

The procedure for changing the bulb is the same on both

sides.

– Switch off the ignition and the lights.

– Raise the bonnet.

– Move the brace ⇒ fig. 196 in the direction of the arrow and

remove the rigid cover, separating the brace side and then

removing the two tabs from the other end of the cover.

– Gently press on the bulb holder tabs ⇒fig. 197 and pull the

cover upwards (it can also be removed by pulling on the bulb

holder wires).

– Separate the bulb from the bulb holder by pulling both pieces anti-clockwise.

– Fit the new bulb by pressing on the bulb holder.

– Insert the bulb into the socket and press on the bulb holder. Fit the cover, first inserting the side tabs and then closing the cover

and the brace. Make sure that the gasket sits well on the casing

cover during the operation.

– Check whether the new bulb is working.

Fig. 196 Side light bulb

(outside of vehicle)Fig. 197 Side light bulb

(outside of vehicle)

A1

exeo_EN.book Seite 266 Montag, 30. August 2010 4:45 16