technical specifications Seat Exeo 2011 Owner's manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2011, Model line: Exeo, Model: Seat Exeo 2011Pages: 313, PDF Size: 5.02 MB

Page 205 of 313

203

Trailer towing

– Check that the knob is directly against the ball joint, so that

there is no gap between the knob and the ball joint -arrow-.

– Check that the ball joint is locked and the key is removed so

that the knob cannot be pulled out ⇒

.

– Check that the ball joint fits tightly in the mounting fixture (try

moving it about to check).

Towing socket

– To plug in the electrical connection for the trailer, pull down the

socket below the bumper ⇒ fig. 158.

If the safety check is not satisfactory, the ball joint must be fitted again

properly.

WARNING

To avoid accidents, the ball joint must meet all the safety requirements

listed in the safety check. The towing bracket must not be used if any one

of these requirements is not met. If this is the case, you should contact a

qualified workshop.

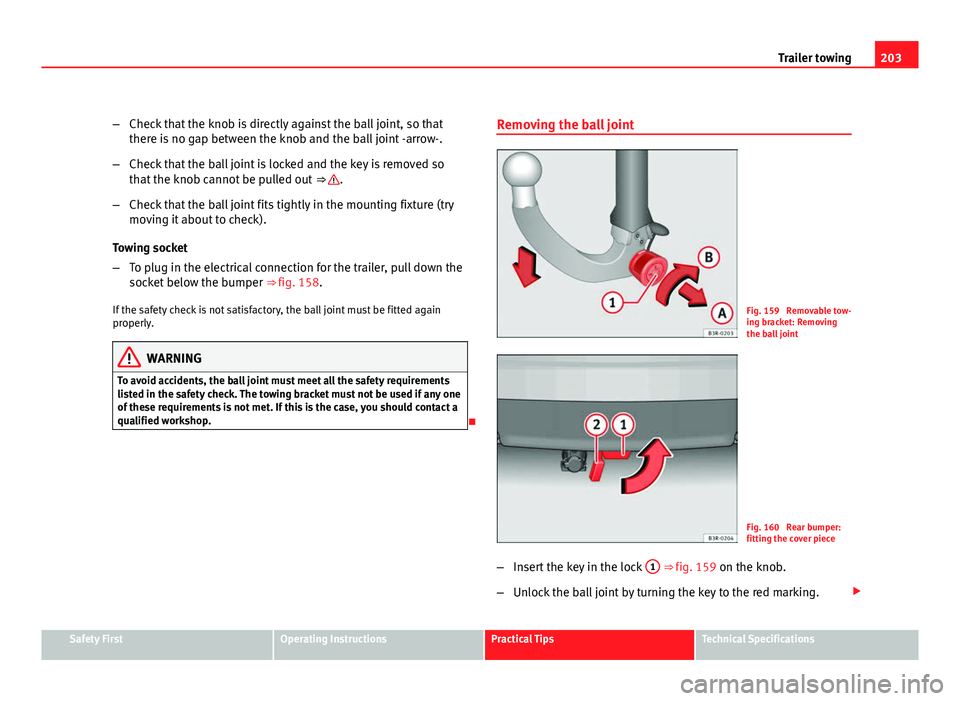

Removing the ball joint

Fig. 159 Removable tow-

ing bracket: Removing

the ball joint

Fig. 160 Rear bumper:

fitting the cover piece

– Insert the key in the lock 1

⇒ fig. 159 on the knob.

– Unlock the ball joint by turning the key to the red marking.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 207 of 313

205

Trailer towing

If a towing bracket is to be fitted after the vehicle is purchased, this must be

completed according to the instructions of the towing bracket manufacturer.

The attachment points for the towing bracket A

are on the lower part of the

vehicle.

The distance between the centre of the ball coupling and the ground should

never be lower than the indicated value, even with a fully loaded vehicle

and including the maximum drawbar load.

Elevation values for securing the towing bracket:

65 mm (minimum)

403

629 mm

1112 mm (vehicle with max. load)

from 350 to 420 mm (vehicle with max. load)

1000 mm

Fitting a towing bracket

● Driving with a trailer involves an extra effort for the vehicle. Therefore,

before fitting a towing bracket, please contact an Authorised Service Centre

to check whether your cooling system needs modification.

● The legal requirements in your country must be observed (e.g. the fitting

of a separate warning lamp).

● Certain vehicle components, e.g. the rear bumper, must be removed and

reinstalled. The towing bracket securing bolts must be tightened using a

torque wrench, and a power socket must be connected to the vehicle's elec-

trical system. This requires specialised knowledge and tools.

● Figures in the illustration show the elevation value and the attachment

points which must be considered if you are retrofitting a towing bracket. B

CDEFG

WARNING

The towing brackets should be fitted at a specialised workshop.

● If the towing bracket is incorrectly installed, there is serious danger

of accident.

● For your own safety, please observe the instructions provided by the

manufacturer of the towing bracket.

CAUTION

● If the power socket is incorrectly installed, this could cause damage to

the vehicle's electrical system.

Note

For the Sport finish, fitting a trailer bracket is not recommended due to the

design of the bumpers.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 209 of 313

207

Vehicle maintenance and cleaning

Care of the vehicle exterior Automatic car wash tunnel

The vehicle can normally be washed without problem in an

automatic car wash.

The vehicle paintwork is so durable that the vehicle can normally be washed

without problems in an automatic car wash tunnel. However, the paintwork

wear depends to a large extent on the kind of the car wash tunnel, the

brushes used, its water filtering and the type of cleaning and preservative

products.

Before going through a vehicle wash, be sure to take the usual precautions

such as closing the windows and sunroof.

If the vehicle has special accessories such as spoilers or a roof rack or two-

way radio aerial, etc., it is advisable to consult the car wash tunnel operator.

After washing, the brakes could take some time to respond as the brake

discs and pads could be wet, or even frozen in winter. Dry the brakes by

braking several times.

WARNING

Water, ice and salt on the brakes can reduce braking efficiency. Risk of

accident.

Washing by hand

Vehicle washing

– First soften the dirt and rinse it off with water. –

Clean your vehicle from top to bottom with a soft sponge, a

glove or a brush. Use very light pressure.

– Rinse the sponge or glove often with clean water.

– Special car shampoo should only be used for very stubborn dirt.

– Leave the wheels, sill panels etc. until last, using a different

sponge or glove.

– Rinse the vehicle thoroughly with water.

– Dry the vehicle surface gently with a chamois leather.

– In cold temperature, dry the rubber seals and their surfaces to

prevent them from freezing. Apply silicone spray to the rubber

seals.

After washing the vehicle

– After washing, avoid sudden and sharp braking. “Dry” the

brakes by braking several times ⇒ page 191, Braking capacity

and braking distance.

WARNING

● Wash your vehicle with the ignition switched off.

● Protect your hands and arms from cuts on sharp metal edges when

cleaning the underbody, the inside of the wheel housings etc. Risk of in-

jury.

● Water, ice and salt on the brakes can reduce braking efficiency. Risk

of accident.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 211 of 313

209

Vehicle maintenance and cleaning

Polishing the paintwork

Polishing brings back gloss to the paintwork. Polishing is only necessary if the paint has lost its shine, and the gloss can-

not be brought back by applying wax. Polishing products can be purchased

in your Authorised Service Centre.

The vehicle must be waxed after polishing if the polish used does not con-

tain wax compounds to seal the paint ⇒ page 208, Vehicle paint mainte-

nance.

CAUTION

To prevent damage to the paintwork:

● Do not use polishes and hard wax on painted parts with a matte finish

or on plastic parts.

● Do not polish your vehicle in a sandy or dusty environment.

Caring for plastic parts

Solvents damage plastic parts.

If normal washing fails to clean plastic parts, clean them with approved sol-

vent-free plastic cleaning and care products.

CAUTION

● The use of liquid air freshener directly over the air vents of the vehicle

may damage the plastic parts if the liquid is accidentally spilled.

● Cleaning products which contain solvents will damage the material. Cleaning windows and exterior mirrors

Cleaning windows

–

Moisten the windows with commercially available, alcohol

based glass cleaner.

– Dry the windows with a clean chamois leather or a lint-free

cloth.

Removing snow

– Use a small brush to remove snow from the windows and mir-

rors.

Removing ice

– Use a de-icer spray.

Use a clean cloth or chamois leather to dry the windows. The chamois leath-

ers used on painted surfaces are not suitable to clean windows because

they are soiled with wax deposits which could smear the windows.

If possible, use a de-icing spray to remove ice. If you use an ice scraper,

push it in one direction only without swinging it.

Use window cleaner or a silicone remover to clean rubber, oil, grease and

silicone deposits off.

Wax deposits can be removed with a special cleaner available in your Au-

thorised Service Centre. Wax deposits on the windscreen could cause the

wiper blades to judder. Adding a window cleaner that dissolves wax to the

windscreen washer fluid prevents wiper blades from juddering, but wax de-

posits are not removed.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 213 of 313

211

Vehicle maintenance and cleaning

Use an industrial cleaner to remove brake dust. Any damage to the paint on

steel wheel rims should be repaired before starting to rust.

WARNING

● Never wash tyres with a cylindrical jet. Even at large spraying distan-

ces and short cleaning times, visible and invisible damage can occur to

the tyres. This may cause an accident.

● Water, ice and salt on the brakes can reduce braking efficiency. Risk

of accident. Directly after washing, avoid sudden and sharp braking.

“Dry” the brakes by braking several times ⇒ page 191.

Alloy wheel rims

Every two weeks

– Wash salt and brake dust from alloy wheels.

– Use an acid free detergent to clean the wheel rims.

Every three months

– Apply a hard wax compound to the wheels.

Alloy wheels require regular attention to preserve their appearance. If road

salt and brake dust are not often removed, the aluminium finish will be im-

paired.

Always use an acid-free detergent for alloy wheel rims.

Car polish or other abrasive agents should not be used. If the protective

coating is damaged, e.g. by flying stones, the damaged area should be re-

paired immediately.

WARNING

● Never wash tyres with a cylindrical jet. Even at large spraying distan-

ces and short cleaning times, visible and invisible damage can occur to

the tyres. This may cause an accident.

● Water, ice and salt on the brakes can reduce braking efficiency. Risk

of accident. Directly after washing, avoid sudden and sharp braking.

“Dry” the brakes by braking several times ⇒ page 191.

Underbody protection

The vehicle underbody is coated to protect it from chemical

and mechanical damage.

The protective coating can be damaged when driving. We recommend you

to check the protective coating under the body and on the running gear, and

reinstated if necessary, before and after the winter season.

We recommend you to go to your Authorised Service Centre to carry out re-

pair work and additional anti-corrosion work.

WARNING

Do not apply underseal or anti-corrosion coatings to the exhaust pipes,

catalytic converter or the heat shields on the exhaust system. The heat of

the exhaust system or the engine could cause them to ignite. Risk of fire.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 215 of 313

213

Vehicle maintenance and cleaning

CAUTION

Cleaning products which contain solvents will damage the material.

Wooden trim cleaning*

– Clean the wooden trim with a water-moistened clean cloth.

– If this does not provide satisfactory results, use a gentle soap

solution.

CAUTION

Cleaning products which contain solvents will damage the material.

Cloth seat covers and fabric trim cleaning

Cloth seat covers and fabric trim on the doors, headlining etc. can be

cleaned with a special interior cleaner or with dry foam and a soft brush.

Leather cleaning*

Normal cleaning

– Moisten a cotton or woollen cloth with water and wipe over the

leather surfaces. Cleaning stubborn stains

–

More stubborn dirt can be removed using a mild soap solution

(pure liquid soap; two tablespoons diluted in one litre of water)

and a cloth.

– Do not let the water soak through the leather or soak into the

seams.

– Then wipe off with a soft, dry cloth.

Leather maintenance

– The leather should be treated twice a year with a special leath-

er-care product, available in your Authorised Service Centre.

– Apply these products very sparingly.

– Then wipe off with a soft, dry cloth.

SEAT does everything possible to preserve the genuine qualities of this nat-

ural product. Due to the natural properties of the specially selected hides

employed, the finished leather has a certain sensitivity to grease and dirt,

etc. so a degree of care is required in everyday use and when looking after

the leather.

Dust and grit in the pores and seams can scratch and damage the surface. If

the vehicle is under solar radiation for long periods, the leather should be

protected to prevent it from fading. However, slight colour variations in

high-quality natural leather are normal.

CAUTION

● Do not use solvents, wax polish, shoe cream, spot removers or similar

products on leather.

● To avoid damage, stubborn stains should be removed by a specialised

workshop.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 217 of 313

215

Accessories, parts replacement and modifications

Accessories, parts replacement and modifications Accessories and spare parts

Always consult an Authorised Service Centre before purchas-

ing accessories and parts.Your vehicle is designed to offer a high standard of active and passive safe-

ty.

Before purchasing accessories and parts, and before making technical

changes to your vehicle, we recommend you to consult your Authorised

Service Centre.

SEAT dealerships will be happy to provide you with the latest information

about the use, legal requirements and recommendations from the manufac-

turer regarding accessories and parts.

We recommend you use only SEAT Approved Accessories®

and SEAT Ap-

proved Spare Parts ®

. This way, SEAT can guarantee that the product in

question is suitable, reliable and safe. SEAT Authorised Service Centres

have the necessary experience and facilities to ensure that parts are correct-

ly and professionally installed.

Despite a continuous observation of the market, SEAT is not able to assess

the reliability, safety and suitability of those parts SEAT has not approved.

For this reason, SEAT cannot assume responsibility for any non-genuine

parts used, even if these parts have been approved by an official testing

agency or are covered by an official approval certificate.

Any equipment subsequently installed which has a direct effect on the driv-

er's control of the vehicle (e.g. cruise control system or electronically-con-

trolled suspension) must be approved by SEAT and bear the e mark (the Eu-

ropean Union's authorisation symbol). If any

additional electrical components are fitted which do not serve to con-

trol the vehicle itself (e.g. refrigerator box, laptop or ventilator fan), these

must bear the CE mark (European Union manufacturer conformity declara-

tion).

WARNING

Accessories, for example telephone holders or cup holders, should never

be fitted on the covers, or within the working range, of the airbags. Oth-

erwise, there is a danger of injury if the airbag is triggered in an accident.

Technical modifications

Modifications must always be carried out according to our

specifications.

Unauthorised modifications to the electronic components or software in the

vehicle may cause malfunctions. Due to the way the electronic components

are linked together in networks, other indirect systems may be affected by

the faults. This can seriously impair safety, lead to excessive wear of compo-

nents, and also invalidate your vehicle registration documents.

SEAT Authorised Service Centres cannot be held liable for any damage

caused by modifications and/or work incorrectly performed.

For this reason, we recommend having all work performed by a SEAT Author-

ised Technical Service using Genuine SEAT®

Spare Parts.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 219 of 313

217

Checking and refilling levels

Checking and refilling levels Refuelling

The tank flap is released manually. The tank holds approxi-

mately 70 litres.

Fig. 163 Fuel tank flap

with tank cap attached

The flap that covers the tank cap is unlocked and locked automati-

cally by the central locking.

Unscrewing the tank cap

– Press the right side of the flap to open it.

– Unscrew the fuel tank cap anti-clockwise.

– Hook the cap onto the support fitted to the open tank flap

⇒ fig. 163. Closing the tank cap

–

Screw the tank cap clockwise into the filler opening until it you

hear it click into position.

– Close the tank flap.

The tank flap is at the rear of the vehicle on the right.

If the automatic filler nozzle is operated correctly, it will switch itself off as

soon as the tank is “full”. Never attempt to fill beyond this point, as this will

fill the expansion chamber. Fuel may leak out if ambient conditions are

warm.

The correct fuel grade for your vehicle is given on a sticker on the inside of

the fuel tank flap. Here you will find further information on fuel.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 221 of 313

219

Checking and refilling levels

CAUTION

● Petrol with standard EN 228 may be mixed with small quantities of etha-

nol. However, bioethanol fuels available at commercial establishments with

reference E50 or E85, which contain a high percentage of ethanol, may not

be used, as they will damage the fuel system.

● Even one tankful of leaded fuel would permanently impair the efficiency

of the catalytic converter.

● High engine speed and full throttle can damage the engine when using

petrol with an octane rating lower than the correct grade for the engine.

For the sake of the environment

Just one full tank of leaded fuel would seriously impair the efficiency of the

catalytic converter.

Petrol additives

Petrol additives improve the quality of the petrol.

The quality of the petrol influences the performance, power and life of the

engine. For this reason, you should use good quality petrol containing addi-

tives. These additives will help to prevent corrosion, keep the fuel system

clean and prevent deposits from building up in the engine.

If good quality petrol with additives is not available or engine problems oc-

cur, the required additives must be added during refuelling. Diesel

Diesel*

Diesel fuel must conform to DIN EN 590 (EN = “European Standard”). It

must have a cetane number (CN) of at least 51. The cetane number indi-

cates the ignition quality of the diesel fuel.

Notes on refuelling ⇒ page 217.

Biodiesel*

CAUTION

● Your vehicle is not designed to use biodiesel fuel. Never, under any cir-

cumstances refuel with biodiesel. The use of biodiesel fuel could damage

the engine and the fuel system. The addition of biodiesel to diesel fuel by

the diesel manufacturer in accordance with standard EN 590 or DIN 51628

is authorised and will not cause damage to the engine or the fuel system.

● The diesel engine has been designed to be used exclusively with diesel

fuel conforming to standard EN 590. Never refuel or use petrol, kerosene,

fuel oil or any other type of fuel. If you accidentally fill up the vehicle with

the wrong type of fuel, do not start the engine. Seek assistance from speci-

alised personnel. The composition of these fuels may severely damage the

fuel system and the engine.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 223 of 313

221

Checking and refilling levels

Opening the bonnet

Fig. 165 Release catch

under the bonnet

Before opening the bonnet make sure that the windscreen wiper

arms are not lifted away from the glass. Otherwise the paint may

be damaged.

– Lift the bonnet slightly ⇒

.

– Press the release catch under the bonnet upwards ⇒ fig. 165.

This will release the arrester hook under the bonnet.

– Open the bonnet.

The bonnet is held in position by a gas-filled strut.

WARNING

Never open the bonnet if you see steam or drips of coolant being re-

leased from the engine compartment. Failure to comply could result in

burns. Wait until no steam or coolant can be seen before opening the

bonnet.

Work in the engine compartment

Extra caution is necessary when working on components in

the engine compartment.

Always be aware of the danger of injury and scalding as well as the risk of

accident or even fire when working in the engine compartment (e.g. when

checking and refilling fluids). Always observe the warnings listed below

and follow all general safety precautions. The engine compartment of the

vehicle is a potentially hazardous area ⇒

WARNING

● Switch the engine off.

● Remove the ignition key.

● Apply the handbrake firmly.

● If your vehicle is equipped with a manual gearbox, place the gear lev-

er in neutral. If you are driving an automatic vehicle, place the selector

lever in position P.

● Wait for the engine to cool down.

● Children should not be allowed to approach the engine compartment.

● Never spill liquids used for vehicle operation on the engine compart-

ment, as these may catch fire (e.g. coolant).

● Take care not to cause short circuits in the electrical system, especial-

ly when working on the battery.

● Never touch the radiator fan while the engine is hot, as the fan could

start up suddenly.

● Never open the expansion tank when the engine is hot. The cooling

system is under pressure.

● Protect face, hands and arms from any hot steam or hot coolant fluid

released by covering the cap with a large, thick rag when opening the ex-

pansion tank.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications