spare wheel Seat Exeo ST 2010 Owner's manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2010, Model line: Exeo ST, Model: Seat Exeo ST 2010Pages: 325, PDF Size: 9.34 MB

Page 6 of 325

Contents

4Economical and environmentally friendly driving

Driving abroad . . . . . . . . . . . . . . . . . . . . . . . . . . . Trailer towing

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trailer towing . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removable towing bracket . . . . . . . . . . . . . . . . .

Vehicle maintenance and cleaning

. . . . . . . .

General notes . . . . . . . . . . . . . . . . . . . . . . . . . . .

Vehicle exterior maintenance . . . . . . . . . . . . . . .

Vehicle interior maintenance . . . . . . . . . . . . . . .

Accessories, parts replacement and

modifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories and spare parts . . . . . . . . . . . . . . . .

Technical modifications . . . . . . . . . . . . . . . . . . .

Mobile phones and two-way radios . . . . . . . . . .

Athermic windscreen* . . . . . . . . . . . . . . . . . . . . .

Checking and refilling levels

. . . . . . . . . . . . . .

Refuelling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Petrol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diesel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bonnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cooling system . . . . . . . . . . . . . . . . . . . . . . . . . .

Washer fluid and windscreen wiper blades . . . .

Brake fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Vehicle battery . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wheels and tyres

. . . . . . . . . . . . . . . . . . . . . . . . .

Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

If and when

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tools, tyre repair kit and spare wheel . . . . . . . .

Changing a wheel . . . . . . . . . . . . . . . . . . . . . . . .

Tyre repairs* (Tyre Mobility System) . . . . . . . . . .

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bulbs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing bulbs. Halogen headlights . . . . . . . .

Changing bulbs. Bi-Xenon AFS headlights . . . . Changing tail light bulbs (on side panel) . . . . .

Changing tail light bulbs (on tailgate) . . . . . . . .

Side turn signals . . . . . . . . . . . . . . . . . . . . . . . . .

Luggage compartment lights . . . . . . . . . . . . . . .

Registration light . . . . . . . . . . . . . . . . . . . . . . . . .

Sun visor light . . . . . . . . . . . . . . . . . . . . . . . . . . .

Jump-starting . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Towing and tow-starting . . . . . . . . . . . . . . . . . . .

Technical Specifications

. . . . . . . . . .

Description of specifications

. . . . . . . . . . . . . .

Important information . . . . . . . . . . . . . . . . . . . . .

Information on fuel consumption . . . . . . . . . . . .

Towing a trailer . . . . . . . . . . . . . . . . . . . . . . . . . .

Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Specifications

. . . . . . . . . . . . . . . . . .

Checking fluid levels . . . . . . . . . . . . . . . . . . . . . .

Petrol engine 1.8 88 kW (120 PS) . . . . . . . . . . .

Petrol engine 1.8 118 kW (160 PS) . . . . . . . . . .

Petrol engine 2.0 147 kW (200 PS) . . . . . . . . . .

Petrol engine 2.0 155 kW (210 PS) . . . . . . . . . .

Diesel engine 2.0 TDI CR 88 kW (120 PS) . . . . .

Diesel engine 2.0 TDI CR 105 kW (143 PS) . . . .

Diesel engine 2.0 TDI CR 125 kW (170 PS) . . . .

Dimensions and capacities . . . . . . . . . . . . . . . .

Index

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

199

201

203

203

206

214

214

215

220

223

223

223

224

224

225

225

226

227

228

230

233

236

240

241

245

245

254

254

257

262

265

267

267

274 280

285

288

289

290

291

291

294

297

297

297

299

299

300

301

301

302

303

304

305

307

308

309

311

313

ExeoST_EN.book Seite 4 Freitag, 3. September 2010 11:41 11

Page 206 of 325

Trailer towing

204Where possible, operate the trailer with the maximum permitted drawbar

load on the ball joint of the towing bracket, but do not exceed the specified

limit.

Tyre pressure

Check the tyre pressures on your vehicle, and adjust for “full load” conditions

(refer to the sticker listing the tyre pressures on the door pillar). It may also be

necessary to adjust the tyre pressures on the trailer according to the recom-

mendations of the trailer manufacturer.

Exterior mirrors

Check whether you can see enough of the road behind the trailer with the

standard mirrors. If this is not the case you should have additional mirrors

fitted. The two exterior mirrors should be fitted on folding arms. Adjust the

mirrors to give sufficient rear vision.

Headlights

Before starting a journey, check the headlight beam settings with the trailer

hitched up. If necessary, alter the height of the headlight beams by means of

the headlight range control. See ⇒page 120.

Power supply

When you remove the ignition key, the power supply to the trailer is inter-

rupted.

Removable ball joint coupling

Vehicles with a factory-fitted towing bracket are equipped with a removable

ball joint coupling. This is stored in the spare wheel well in the luggage

compartment together with the necessary fitting instructions.

Note

If you frequently tow, we recommend you also have the vehicle serviced

between services.

Notes on towing

Towing a trailer involves additional attention by the driver.Weight distribution

The weight distribution of a loaded trailer with an unladen vehicle is very

unfavourable. However, if this cannot be avoided, drive extra slow to allow for

the unbalanced weight distribution.

Speed

The stability of the vehicle and trailer is reduced with increasing speed. There-

fore, it is advisable not to drive at the maximum permissible speed in unfa-

vourable road, weather or wind conditions. This especially applies when

driving downhill.

You should always reduce speed immediately if the trailer shows the slightest

sign of swaying . Never try to stabilise the trailer by accelerating.

Anticipate hazards and brake in good time. If towing a trailer with an inertia

brake , first brake gently and then harder. This will prevent brake tapping by

the trailer wheels when they lock. Select a low gear in due course before

going down a steep downhill. This enables you to use the engine braking to

slow down the vehicle.

Swaying and pitching can be reduced by stabiliser aids. We recommend

having stabiliser aids installed when towing trailers with a high trailer weight.

They can be purchased and installed at a Technical Service.

Reheating

When climbing long hills in hot weather with the engine running fast in low

gear, you should keep an eye on the coolant temperature gauge ⇒page 60.

Reduce speed immediately if the needle moves to the right end of the scale.

If the temperature warning lamp

�v in the instrument panel should start

flashing, stop the vehicle and let the engine cool down by running it at idling

speed for a few minutes.

ExeoST_EN.book Seite 204 Freitag, 3. September 2010 11:41 11

Page 208 of 325

Trailer towing

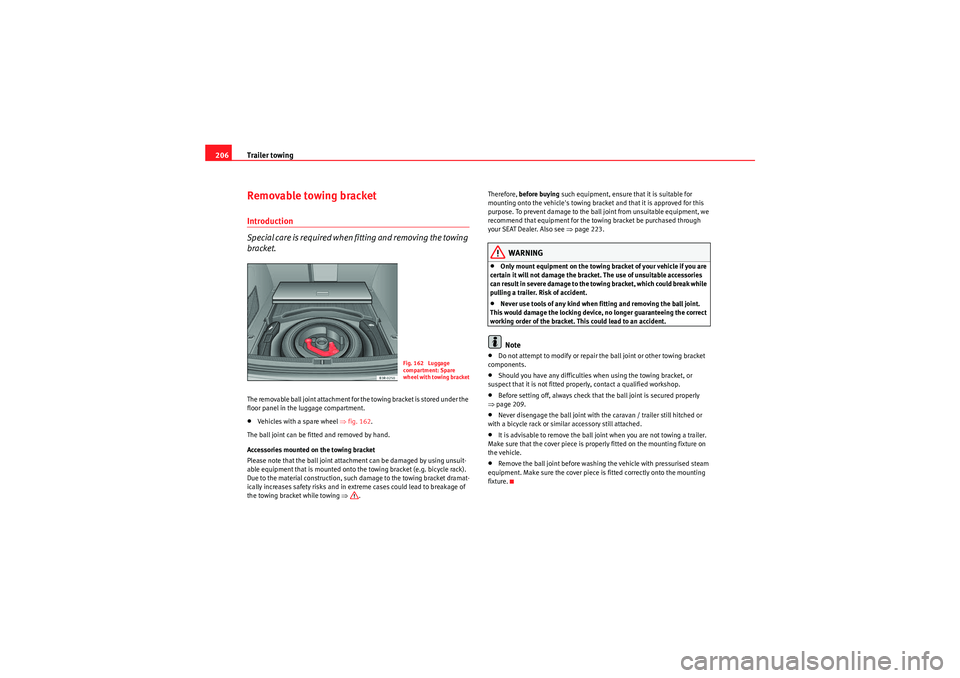

206Removable towing bracketIntroduction

Special care is required when fitting and removing the towing

bracket.The removable ball joint attachment for the towing bracket is stored under the

floor panel in the luggage compartment.•Vehicles with a spare wheel ⇒ fig. 162.

The ball joint can be fitted and removed by hand.

Accessories mounted on the towing bracket

Please note that the ball joint attachment can be damaged by using unsuit-

able equipment that is mounted onto the towing bracket (e.g. bicycle rack).

Due to the material construction, such damage to the towing bracket dramat-

ically increases safety risks and in extreme cases could lead to breakage of

the towing bracket while towing ⇒. Therefore,

before buying such equipment, ensure that it is suitable for

mounting onto the vehicle's towing bracket and that it is approved for this

purpose. To prevent damage to the ball joint from unsuitable equipment, we

recommend that equipment for the towing bracket be purchased through

your SEAT Dealer. Also see ⇒page 223.

WARNING

•Only mount equipment on the towing bracket of your vehicle if you are

certain it will not damage the bracket. The use of unsuitable accessories

can result in severe damage to the towing bracket, which could break while

pulling a trailer. Risk of accident.•Never use tools of any kind when fitting and removing the ball joint.

This would damage the locking device, no longer guaranteeing the correct

working order of the bracket. This could lead to an accident.Note

•Do not attempt to modify or repair the ball joint or other towing bracket

components.•Should you have any difficulties when using the towing bracket, or

suspect that it is not fitted properly, contact a qualified workshop.•Before setting off, always check that the ball joint is secured properly

⇒ page 209.•Never disengage the ball joint with the caravan / trailer still hitched or

with a bicycle rack or similar accessory still attached.•It is advisable to remove the ball joint when you are not towing a trailer.

Make sure that the cover piece is properly fitted on the mounting fixture on

the vehicle.•Remove the ball joint before washing the vehicle with pressurised steam

equipment. Make sure the cover piece is fitted correctly onto the mounting

fixture.

Fig. 162 Luggage

compartment: Spare

wheel with towing bracket

ExeoST_EN.book Seite 206 Freitag, 3. September 2010 11:41 11

Page 253 of 325

Wheels and tyres251

Safety First

Operating Instructions

Practical Tips

Technical Specifications

•If one or more tyres are being driven in emergency conditions, the

driving quality of the vehicle is impaired and there is a risk of accident.Note

•The run-flat tyres do not “deflate” on losing pressure because they are

supported on the reinforced sides. Therefore defects in the tyre cannot be

detected with a visual inspection.•Snow chains must not be used on front tyres used in emergency

conditions.New tyres and wheels

New tyres and wheels have to be run in.The tyres and wheel rims are an essential part of the vehicle's design. The

tyres and rims approved by SEAT are specially matched to the characteristics

of the vehicle and make a major contribution to good road holding and safe

handling ⇒.

Tyres should be replaced at least in pairs and not individually (i.e. both front

tyres or both rear tyres together). A knowledge of tyre designations makes it

easier to choose the correct tyres. Radial tyres have the tyre designations

marked on the sidewall, for example:

195/65 R15 91T

This contains the following information:

195 Tyre width in mm

65 Height/width ratio in %

RTyre construction: Radial

15 Rim diameter in inches 91 Load rating code

TSpeed rating

The tyres could also have the following information:

•A direction of rotation symbol•“Reinforced” denotes heavy-duty tyres.

The manufacturing date is also indicated on the tyre sidewall (possibly only

on the inner side of the wheel).

“DOT ... 1103...” means, for example, that the tyre was produced in the 11th

week of 2003.

We recommend that work on tyres and wheels be carried out by an Authorised

Service Centre. They are familiar with the procedure and have the necessary

special tools and spare parts as well as the proper facilities for disposing of

the old tyres.

Any Authorised Service Centre has full information on the technical require-

ments when installing or changing tyres, wheels or wheel trims.WARNING

•We recommend that you use only wheels and tyres which have been

approved by SEAT for your model. Failure to do so could impair vehicle

handling. Risk of accident.•Avoid running the vehicle on tyres that are more than six years old. If

you have no alternative, you should drive slowly and with extra care at all

times.•Never use old tyres or those with an unknown history of use.•If wheel trims are retrofitted, you must ensure that the flow of air to the

brakes is not restricted. This could cause them to overheat.•All four wheels must be fitted with radial tyres of the same type, size

(rolling circumference) and the same tread pattern.

WARNING (continued)

ExeoST_EN.book Seite 251 Freitag, 3. September 2010 11:41 11

Page 254 of 325

Wheels and tyres

252

For the sake of the environmentOld tyres must be disposed of according to the laws in the country concerned.

Note

•For technical reasons, it is not generally possible to use the wheels from

other vehicles. This can also apply to wheels of the same model. The use of

wheels or tyres which have not been approved by SEAT for use with your

model may invalidate the vehicle's type approval for use on public roads.•If the spare tyre is not the same as the tyres that are mounted on the

vehicle - for example with winter tyres - you should only use the spare tyre for

a short period of time and drive with extra care. Refit the normal road wheel

as soon as possible.Wheel bolts

Wheel bolts must be tightened to the correct torque.The design of wheel bolts is matched to the rims. If different wheel rims are

fitted, the correct wheel bolts with the right length and correctly shaped bolt

heads must be used. This ensures that wheels are fitted securely and that the

brake system functions correctly.

In certain circumstances, you should not use wheel bolts from a different

vehicle, even if it is the same model ⇒page 223.

After the wheels have been changed, the tightening torque of the wheel bolts

s ho uld b e che cke d as s o on as p ossible wit h a to rqu e w re nch. ⇒ The tight-

ening torque for steel and alloy wheels is 120 Nm.

WARNING

If the wheel bolts are not tightened correctly, the wheel could become

loose while driving. Risk of accident.•The wheel bolts must be clean and turn easily. Never apply grease or oil

to them.•Use only wheel bolts which belong to the wheel.•If the torque of the wheel bolts is too low, they could loosen whilst the

vehicle is in motion. Risk of accident! If the tightening torque is too high,

the wheel bolts and threads can be damaged.Caution

The prescribed tightening torque for wheel bolts for steel and alloy wheels is

120 Nm.Winter tyres

Winter tyres will improve the vehicles handling on snow and

ice.In winter conditions winter tyres will considerably improve the vehicle's

handling. The design of summer tyres (width, rubber compound, tread

pattern) gives less grip on ice and snow.

Winter tyres must be inflated to a pressure 0.2 bar higher than the pressures

specified for summer tyres (see sticker on tank flap).

Winter tyres must be fitted on all four wheels.

Information on permitted winter tyre sizes can be found in the vehicle's regis-

tration documents. Use only radial winter tyres. All tyre sizes listed in the

vehicle documentation also apply to winter tyres.

ExeoST_EN.book Seite 252 Freitag, 3. September 2010 11:41 11

Page 255 of 325

Wheels and tyres253

Safety First

Operating Instructions

Practical Tips

Technical Specifications

Winter tyres lose their effectiveness when the tread is worn down to a depth

of 4 mm.

The speed rating code

⇒page 251, “New tyres and wheels” determines the

following speed limits for winter tyres: ⇒

Q max. 160 km/h

S max. 180 km/h

T max. 190 km/h

H max. 210 km/h

In some countries, vehicles which can exceed the speed rating of the fitted

tyre must have an appropriate sticker in the driver's field of view. These

stickers are available from your Authorised Service Centre. The legal require-

ments of each country must be followed.

Do not have winter tyres fitted for unnecessarily long periods. Vehicles with

summer tyres handle better when the roads are free of snow and ice.

If you have a flat tyre, please refer to the notes on the spare wheel

⇒ page 251, “New tyres and wheels”.

WARNING

The maximum speed for the winter tyres must not be exceeded. Otherwise,

this could lead to tyre damage and risk of accident.

For the sake of the environment

Fit your summer tyres again as soon as possible. They are quieter, do not wear

so quickly and reduce fuel consumption.

Snow chainsSnow chains may be fitted only to the front wheels, and only to certain tyre

sizes ⇒page 300.

Remove wheel hub covers and trim rings before fitting snow chains. For safety

reasons cover caps, available in any Authorised Service Centre, must then be

fitted over the wheel bolts.

WARNING

Observe the fitting instructions provid ed by the snow chain manufacturer.

Caution

You must remove the snow chains to drive on roads which are free of snow.

Otherwise they will impair handling, damage the tyres and wear out very

quickly.

Note

•In some countries, the speed limit for using snow chains is 50 km/h. The

legal requirements of the country should be followed.•We recommend that you ask your Authorised Service Centre for informa-

tion about appropriate wheel, tyre and snow chain size.205/55 R16

15 mm chains

225/45 R17

9 mm chains

225/40 R18

7 mm chains

ExeoST_EN.book Seite 253 Freitag, 3. September 2010 11:41 11

Page 256 of 325

If and when

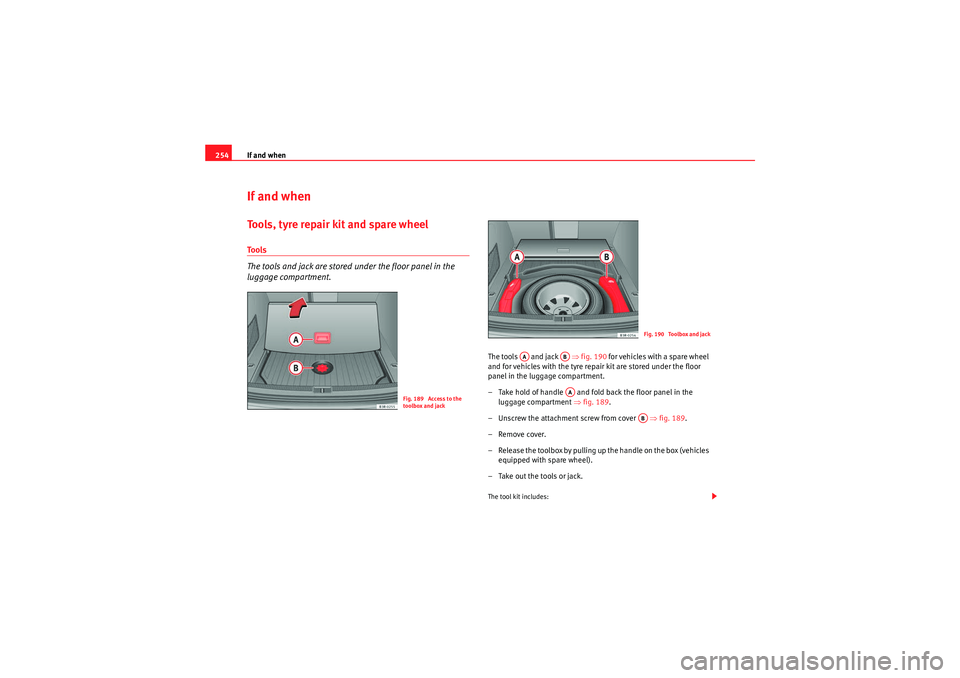

254If and whenTools, tyre repair kit and spare wheelTools

The tools and jack are stored under the floor panel in the

luggage compartment.

The tools and jack ⇒fig. 190 for vehicles with a spare wheel

and for vehicles with the tyre repair kit are stored under the floor

panel in the luggage compartment.

– Take hold of handle and fold back the floor panel in the luggage compartment ⇒fig. 189 .

– Unscrew the attachment screw from cover ⇒fig. 189 .

– Remove cover.

– Release the toolbox by pulling up the handle on the box (vehicles equipped with spare wheel).

– Take out the tools or jack.The tool kit includes:

Fig. 189 Access to the

toolbox and jack

Fig. 190 Toolbox and jac

k

AA

ABAA

AB

ExeoST_EN.book Seite 254 Freitag, 3. September 2010 11:41 11

Page 258 of 325

If and when

256Spare steel rim wheel

The spare steel rim wheel is carried in the wheel well under

the floor panel in the luggage compartment. It is only

intended for temporary use over short distances.Taking out the spare wheel

–Turn the plastic knob ⇒fig. 192 anti-clockwise.

– Take out the spare wheel.

Securing the defective wheel in the spare wheel well

– Place wheel in spare wheel well in the luggage compartment.

– Secure the wheel by turning plastic knob clockwise.

– Replace the floor panel before closing the tailgate.

Your vehicle can be factory-equipped with a spare steel wheel. The spare

wheel does not usually meet the same performance standards as the wheels

fitted on the vehicle because of the wheel/tyre dimensions, rubber composi-

tion, tread pattern, etc. Therefore, note the following restrictions:•The spare steel wheel is designed only for your vehicle model. Do not

attempt to mount the wheel on any vehicle but your own.•Your vehicle will have different driving characteristics when the spare

steel rim wheel is mounted ⇒ .•The spare wheel is only intended for temporary use after having a flat tyre.

Replace the spare wheel with a normal wheel that has the proper tyre dimen-

sions as soon as possible.•If the size of the spare steel rim wheel is different to that of the other

wheels, it is unlikely that snow chains suitable for the other wheels will fit it.WARNING

•After mounting the spare steel rim wheel, the tyre pressure must be

checked and corrected as soon as possible. The tyre pressure must corre-

spond to the vehicle load (consult the table containing the inflation pres-

sures). Otherwise there is danger of causing an accident. Use the highest

tyre pressure as indicated in the table.•Do not drive faster than 80 km/h, as higher speeds can cause an acci-

dent.•Avoid heavy acceleration, hard braking and fast cornering, as this could

cause an accident.

Fig. 192 Spare steel rim

wheel

ExeoST_EN.book Seite 256 Freitag, 3. September 2010 11:41 11

Page 259 of 325

If and when257

Safety First

Operating Instructions

Practical Tips

Technical Specifications

Changing a wheelPreparation work

What you must do before changing a wheel.– If you have a flat tyre or puncture, park the vehicle as far away

from the flow of traffic as possible. Choose a location that is as

level as possible.

–All passengers should leave the vehicle. They should wait in a

safe place (e.g. behind the roadside crash barrier).

–Apply the handbrake firmly.

– Engage 1st gear .

– When towing a trailer: Unhitch the trailer from your vehicle.

– Take the tools and the spare wheel ⇒ page 254 out of the

luggage compartment.

WARNING

If you have a puncture in heavy traffic, switch on the hazard warning lights

and place the warning triangle in a visible location. This is for your own

safety and also warns other road users.

Caution

If you have to change the tyre on a gradient, block the wheel opposite the

wheel being changed by placing a stone or similar object under it to prevent

the vehicle from rolling away.

Note

Please observe legal requirements when doing so.Changing a wheel

Change the wheel as described below.– Remove the wheel cover.

–Loosen the wheel bolts ⇒page 258.

– Raise the vehicle with the jack ⇒page 259.

– Ta k e o f f the wheel with the flat tyre and then put on the spare

wheel ⇒page 260.

– Lower the vehicle.

– Tighten the wheel bolts firmly in diagonal sequence with the box

spanner ⇒page 258.

– Replace the cover.After changing a wheel

After changing the wheel, there are still tasks to complete.– Place the wheel with the defective tyre in the spare wheel well

and secure it.

– Put the tools and jack back in the luggage compartment.

ExeoST_EN.book Seite 257 Freitag, 3. September 2010 11:41 11

Page 260 of 325

If and when

258

–The inflation pressure of the newly fitted spare tyre must be

checked as soon as possible.

–Have the tightening torque of the wheel bolts checked as soon

as possible with a torque wrench. It must be 120 Nm (always

when cold)

–Have the flat tyre replaced as quickly as possible.

Note•If you notice that the wheel bolts are rusty and difficult to turn when

changing a wheel, they must be replaced before having the tightening torque

checked.•For your safety, drive at moderate speeds until the wheel bolt tightening

torque has been checked.

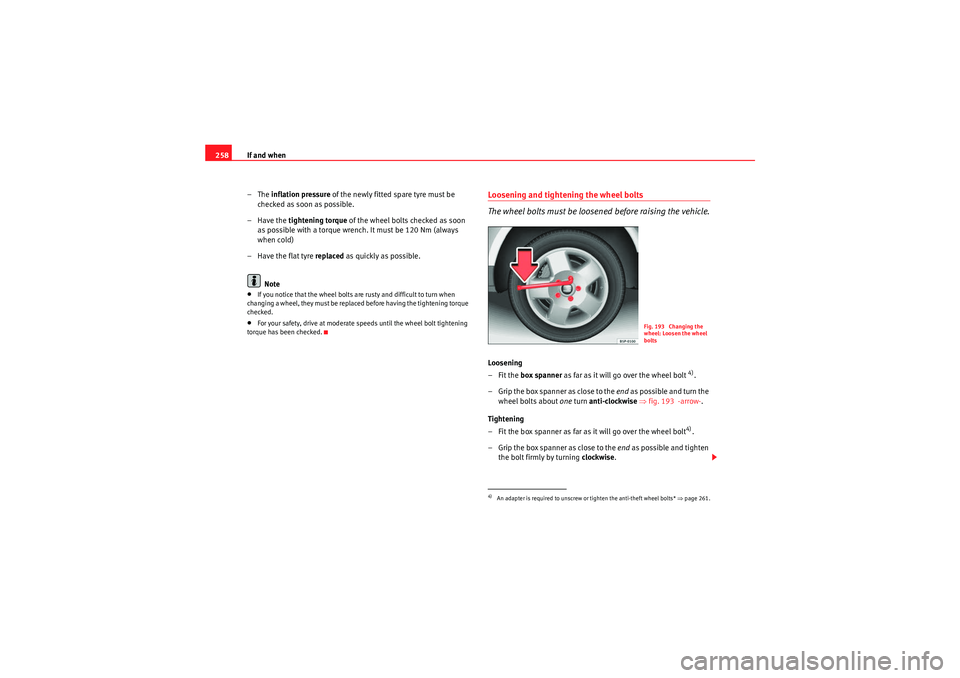

Loosening and tightening the wheel bolts

The wheel bolts must be loosened before raising the vehicle.Loosening

–Fit the box spanner as far as it will go over the wheel bolt

4).

– Grip the box spanner as close to the end as po ssible an d turn t he

wheel bolts about one turn anti-clockwise ⇒ fig. 193 -arrow- .

Tightening

– Fit the box spanner as far as it will go over the wheel bolt4).

– Grip the box spanner as close to the end as possible and tighten

the bolt firmly by turning clockwise.

4)An adapter is required to unscrew or tighten the anti-theft wheel bolts* ⇒page 261.

Fig. 193 Changing the

wheel: Loosen the wheel

bolts

ExeoST_EN.book Seite 258 Freitag, 3. September 2010 11:41 11