protection Seat Ibiza 2020 Directive 2014/53/EU Bluetooth

[x] Cancel search | Manufacturer: SEAT, Model Year: 2020, Model line: Ibiza, Model: Seat Ibiza 2020Pages: 406, PDF Size: 9.22 MB

Page 139 of 406

Page 29 of 89 Report No. : 60404488 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

B.3.7 Audio amplifier abnormal operating conditions P

B.3.8 Safeguards functional during and after abnorm al

operating conditions ................................ .............. : (See appended table B.3) P

B.4 Simulated single fault conditions

P

B.4.1 General P

B.4.2 Temperature controlling device N/A

B.4.3 Blocked motor test (See appended table B. 4 ) N/A

B.4.4 Functional insulation P

B.4.4.1 Short circuit of clearances for functional insulation P

B.4.4.2 Short circuit of creepage distances for functional

insulation P

B.4.4.3 Short circuit of functional insulation on coated

printed boards N/A

B.4.5 Short - circuit and interruption o f electrodes in tubes

and semiconductors P

B.4.6 Short circuit or disconnection of passive

components P

B.4.7 Continuous operation of components N/A

B.4.8 Compliance during and after single fault conditions

................................ ................................ ............... : (See appended table B.4) P

B.4.9 Battery charging and discharging under single fault

conditions Battery is not provided N/A

C UV RADIATION

N/A

C.1 Protection of materials in equipment from UV radiation

N/A

C.1.2 Requirements N/A

C.1.3 Test method N/A

C.2 UV light conditioning test

N/A

C .2.1 Test apparatus ................................ ....................... : N/A

C.2.2 Mounting of test samples N/A

C.2.3 Carbon - arc light - exposure test N/A

C.2.4 Xenon - arc light - exposure test N/A

D TEST GENERATORS

N/A

D.1 Impulse test generators

N/A

D.2 Antenna interface test generator

N/A

D.3 Elec tronic pulse generator

N/A

Page 142 of 406

Page 32 of 89 Report No. : 60404488 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

h) Protective conductor current exceeding ES2 limits N/A

i) Graphic symbols used on equipment N/A

j) Permanently connected equipment not provid ed

with all - pole mains switch N/A

k) Replaceable components or modules providing

safeguard function N/A

l) Equipment containing insulating liquid N/A

m ) Installation instructions for outdoor equipment N/A

F.5

Instructional safeguards N/A

G COMP ONENTS

N/A

G.1 Switches

N/A

G.1.1 General No such switches are used as

disconnect devices N/A

G.1.2 Ratings, endurance, spacing, maximum load N/A

G.1.3 Test method and compliance N/A

G.2 Relays

N/A

G.2.1 Requirements No such relays are used as

dis connect devices N/A

G.2.2 Overload test N/A

G.2.3 Relay controlling connectors supplying power to

other equipment N/A

G.2.4 Test method and compliance N/A

G.3 Protective devices

N/A

G.3.1 Thermal cut - offs No thermal cut - offs N/A

Thermal cut - outs separately approved according to

IEC 60730 with conditions indicated in a) & b) N/A

Thermal cut - outs tested as part of the equipment as

indicated in c) N/A

G.3.1.2 Test method and compliance N/A

G.3.2 Thermal links No thermal links N/A

G.3.2.1 a) Thermal links tested separately according to IEC

60691 with specifics N/A

b) Thermal links tested as part of the equipment N/A

G.3.2.2 Test method and compliance N/A

G.3.3 PTC thermistors No PTC thermistors N/A

G.3.4 Overcurrent protection device s N/A

Page 143 of 406

Page 33 of 89 Report No. : 60404488 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

G.3.5 Safeguards components not mentioned in G.3.1 to

G.3.4 No such components N/A

G.3.5.1 Non - resettable devices suitably rated and marking

provided N/A

G.3.5.2 Single faults conditions ................................ .......... : N/A

G.4 Connectors

N/A

G.4.1 Spacings N/A

G.4.2 Mai ns connector configuration .............................. : N/A

G.4.3 Plug is shaped that insertion into mains socket -

outlets or appliance coupler is unlikely N/A

G.5 Wound components

N/A

G.5.1 Wire insulation in wound components N/A

G.5.1.2 Protection against mechanical stress N/A

G.5.2 Endurance test N/A

G.5.2.1 General test requirements N/A

G.5.2.2 Heat run test N/A

Test time (days per cycle) ................................ ..... :

Test temperature ( C) ................................ ............ :

G.5.2.3 Wound components supplied from the mains N/A

G.5.2.4 No insulation breakdown N/A

G.5.3 Transformers No transformers is used N/A

G.5.3.1 Compliance method ................................ ............... : N/A

Position ................................ ................................ .. : N/A

Method of protection ................................ .............. : N/A

G.5.3.2 Insulation N/A

Protection from displacement of windings ............. :

G.5.3.3 Transformer overload tests N/A

G.5.3.3.1 T est conditions N/A

G.5.3.3.2 Winding temperatures N/A

G.5.3.3.3 Winding temperatures - alternative test method N/A

G.5.3.4 Transformers using FIW N/A

G.5.3.4.1 General N/A

FIW wire nominal diameter ................................ .... :

G.5.3.4.2 Transformers with basic insulat ion only N/A

Page 145 of 406

Page 35 of 89 Report No. : 60404488 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

G.7.3.2.1 Requirements N/A

Strain relief test force (N) ................................ ...... : N/A

G.7.3.2.2 Strain relief mechanism failure N/A

G.7.3.2.3 Cord sheath or jacket position, distance (mm) ...... : N/A

G.7.3.2.4 Strain relief and cord anchorage material N /A

G.7.4 Cord Entry N/A

G.7.5 Non - detachable cord bend protection N/A

G.7.5.1 Requirements N/A

G.7.5.2 Test method and compliance N/A

Overall diameter or minor overall dimension, D

(mm) ................................ ................................ ...... :

Radius of curvature after test (mm) ....................... :

G.7.6 Sup ply wiring space N/A

G.7.6.1 General requirements N/A

G.7.6.2 Stranded wire N/A

G.7.6.2.1 Requirements N/A

G.7.6.2.2 Test with 8 mm strand N/A

G.8 Varistors

N/A

G.8.1 General requirements N/A

G.8.2 Safeguards against fire N/A

G.8.2.1 General N/A

G.8.2.2 Varistor overload test N/A

G.8.2.3 Temporary overvoltage test N/A

G.9 Integrated circuit (IC) current limiters

N/A

G.9.1 Requirements N/A

IC limiter output current (max. 5A) ........................ :

Manufacturers’ defined drift ................................ .. :

G.9.2 Test Progr am N/A

G.9.3 Compliance N/A

G.10 Resistors

N/A

G.10.1 General N/A

G.10.2 Conditioning N/A

G.10.3 Resistor test N/A

Page 149 of 406

Page 39 of 89 Report No. : 60404488 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

Instructional safeguard ................................ .......... : N/A

M EQUIPMENT CONTAINING BATTERIES AND THEIR PROTECTION CIRCUITS

N/A

M.1 General requirements

N/A

M.2 Safety of batteries and their cells

N/A

M.2.1 Batteries and their cells comply with relevant IEC

standards ................................ ............................... : Batteries is not provided N/A

M.3 Protection circuits for batteries provided within

the equipment N/A

M.3.1 Requi rements N/A

M.3.2 Test method N/A

Overcharging of a rechargeable battery N/A

Excessive discharging N/A

Unintentional charging of a non - rechargeable

battery N/A

Reverse charging of a rechargeable battery N/A

M.3.3 Compliance N/A

M.4 Addit ional safeguards for equipment containing a portable secondary lithium

battery N/A

M.4.1 General N/A

M.4.2 Charging safeguards N/A

M.4.2.1 Requirements N/A

M.4.2.2 Compliance ................................ ............................ : N/A

M.4.3 Fire enclosure ................................ ........................ : N/A

M.4.4 Drop test of equipment containi ng a secondary

lithium battery N/A

M.4.4.2 Preparation and procedure for the drop test N/A

M.4.4.3 Drop, Voltage on reference and dropped batteries

(V); voltage difference during 24 h period (%): .... : N/A

M.4.4.4 Check of the charge/discharge function N/A

M.4.4.5 Charge / discharge cycle test N/A

M.4.4.6 Compliance N/A

M.5 Risk of burn due to short - circuit during carrying

N/A

M.5.1 Requirement N/A

M.5.2 Test method and compliance N/A

M.6 Safeguards against short - circuits

N/A

Page 150 of 406

Page 40 of 89 Report No. : 60404488 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

M.6.1 External a nd internal faults N/A

M.6.2 Compliance N/A

M.7 Risk of explosion from lead acid and NiCd batteries

N/A

M.7.1 Ventilation preventing explosive gas concentration N/A

Calculated hydrogen generation rate .................... : N/A

M.7.2 Test method and compliance N/A

Minimum air flow rate, Q (m 3

/h) ............................. :

N/A

M.7.3 Ventilation tests N/A

M.7.3.1 General N/A

M.7.3.2 Ventilation test – alternative 1 N/A

Hydrogen gas concentration (%) ........................... : N/A

M.7.3.3 Ventilation test – alternative 2 N/A

Obtained hydrogen generation rate ....................... : N/A

M.7.3.4 Ventilation test – alternative 3 N/A

Hydrogen gas concentration (%) ........................... : N/A

M.7.4 Marking ................................ ................................ .. : N/A

M.8 Protection against internal ignition from external spark sources of batteries

with aqueous electrolyte N/A

M.8.1 General N/A

M .8.2 Test method N/A

M.8.2.1 General N/A

M.8.2.2 Estimation of hypothetical volume V

Z (m 3

/s) ......... :

M.8.2.3 Correction factors ................................ .................. :

M.8.2.4 Calculation of distance d (mm) ............................. :

M.9 Preventing electrolyte spillage

N/A

M.9.1 Protection from electrolyte spillage N/A

M.9.2 Tray for preventing electrolyte spillage N/A

M.10

Instructions to prevent reasonably foreseeable

misuse N/A

Instructional safeguard ................................ .......... : N/A

N ELECTROCHEMICAL POTENTIALS

N/A

Material (s) used ................................ ..................... :

Page 153 of 406

Page 43 of 89 Report No. : 60404488 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

Mounting of samples ................................ ............ :

Wall thickness (mm) ................................ .............. :

S.4 Flammability classification of materials

N/A

S.5 Flammability test for fire enclosures and fire barrier materials of equipment

where the steady state power exceedi ng 4 000 W N/A

Samples, material ................................ .................. :

Wall thickness (mm) ................................ .............. :

Conditioning ( C) ................................ ................... :

T MECHANICAL STRENGTH TESTS

P

T.1 General

P

T.2 Steady force test, 10 N ................................ ....... :

N/A

T.3 Steady force test, 30 N ................................ ....... :

N/A

T.4 Steady force test, 100 N ................................ ..... :

N/A

T.5 Steady force test, 250 N ................................ ..... :

N/A

T.6 Enclosure impact test

P

Fall test P

Swing test N/A

T.7 Drop test ................................ .............................. :

N/A

T.8 Stress relief test ................................ ................... :

(See appended table T.8) P

T.9 Glass Impact Test ................................ ................... :

N/A

T.10 Glass fragmentation test

N/A

Number of parti cles counted ................................ .... : N/A

T.11 Test for telescoping or rod antennas

N/A

Torque value (Nm) ................................ ................ : N/A

U MECHANICAL STRENGTH OF CATHODE RAY TUBES (CRT) AND

PROTECTION AGAINST THE EFFECTS OF IMPLOSION N/A

U.1 General

N/A

Instructional safeguard :

No CRT provid ed within the

equipment N/A

U.2 Test method and compliance for non - intrinsically protected CRTs

N/A

U.3 Protective screen

N/A

V DETERMINATION OF ACCESSIBLE PARTS

N/A

V.1 Accessible parts of equipment

N/A

Page 154 of 406

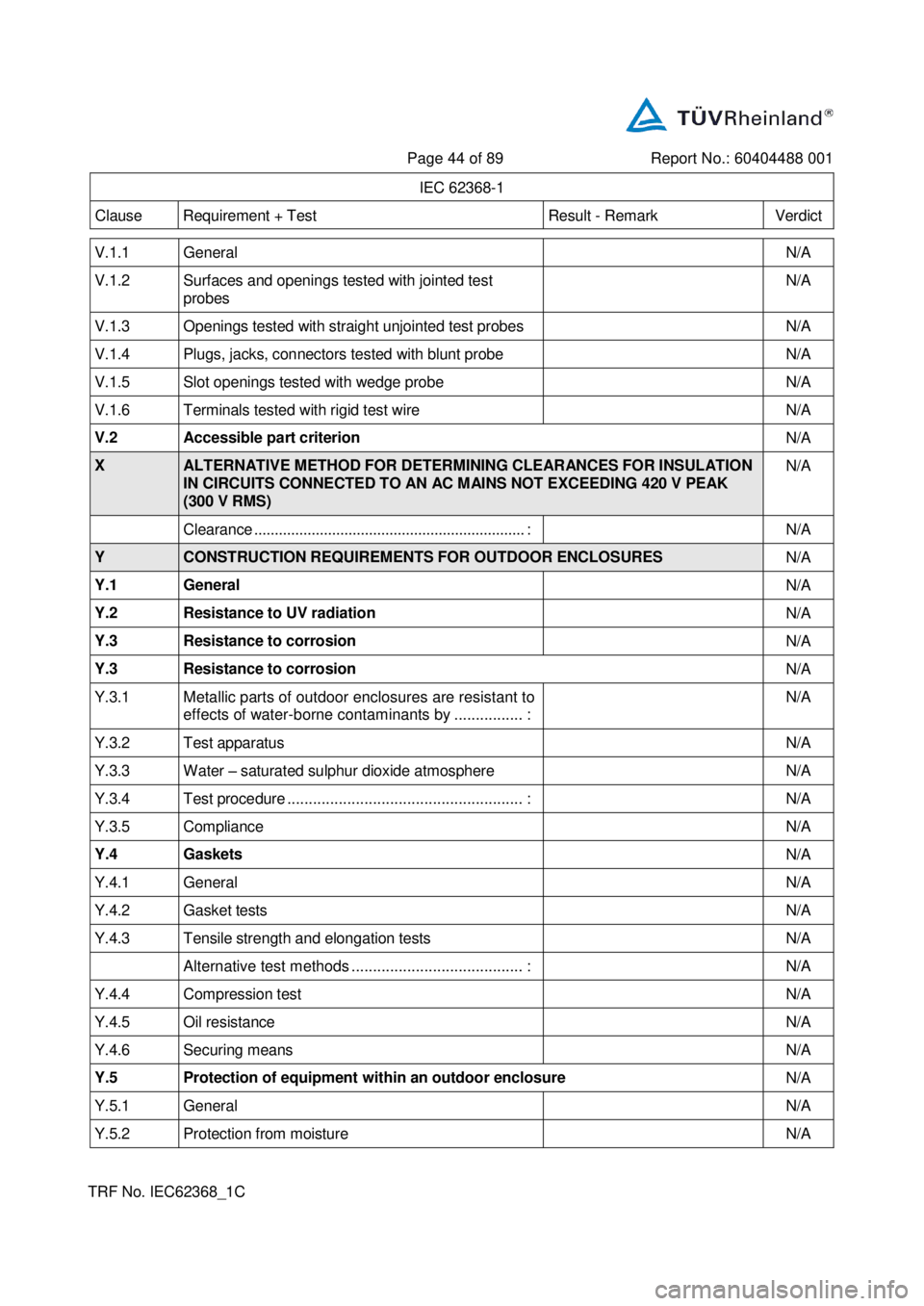

Page 44 of 89 Report No. : 60404488 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

V.1.1 General N/A

V.1.2 Surfaces and opening s tested with jointed test

probes N/A

V.1.3 Openings tested with straight unjointed test probes N/A

V.1.4 Plugs, jacks, connectors tested with blunt probe N/A

V.1.5 Slot openings tested with wedge probe N/A

V.1.6 Terminals tested with rigid test wi re N/A

V.2 Accessible part criterion

N/A

X ALTERNATIVE METHOD FOR DETERMINING CLEARANCES FOR INSULATION

IN CIRCUITS CONNECTED TO AN AC MAINS NOT EXCEEDING 420 V PEAK

(300 V RMS) N/A

Clearance ................................ ................................ .. : N/A

Y CONSTRUCTION REQUIREMENTS FOR OUTDOOR ENCLOSURES

N/A

Y.1 General

N/A

Y.2 Resistance to UV radiation

N/A

Y.3 Resistance to corrosion

N/A

Y.3 Resistance to corrosion

N/A

Y.3.1 Metallic parts of outdoor enclosures are resistant to

effects of water - borne contaminants by ................ : N/A

Y.3.2 Test apparatus N/A

Y.3.3 Water – saturated sulphur dioxide atmosphere N/A

Y.3.4 Test procedure ................................ ....................... : N/A

Y.3.5 Compliance N/A

Y.4 Gaskets

N/A

Y.4.1 General N/A

Y.4.2 Gasket tests N/A

Y.4.3 Tensile strength and elongation tests N/A

Alternative test methods ................................ ........ : N/A

Y.4.4 Compression test N/A

Y.4.5 Oil resistance N/A

Y.4.6 Securing means N/A

Y.5 Protection of equipment within an outdoor enclosure

N/A

Y.5.1 General N/A

Y.5.2 Protection from moisture N/A

Page 155 of 406

Page 45 of 89 Report No. : 60404488 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

Relevant tests of IEC 60529 or Y.5.3 .................... : N/A

Y.5. 3 Water spray test N/A

Y.5.4 Protection from plants and vermin N/A

Y.5.5 Protection from excessive dust N/A

Y.5.5.1 General N/A

Y.5.5.2 IP5X equipment N/A

Y.5.5.3 IP6X equipment N/A

Y.6 Mechanical strength of enclosures

N/A

Y.6.1 General N/A

Y.6.2 Impact test ................................ ............................. : N/A

Page 163 of 406

Page 53 of 89 Report No. : 60404488 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

B.3, B.4 TABLE: Ab normal operating and fault condition tests

P

Ambient temperature T

amb ( C) ................................ ..................... : 2 1 - 2 3

Power source for EUT: Manufacturer, model/type, outputrating .. : -

Component No. Condition Supply

voltage

(V) Test

time Fuse no. Fuse

current

(A) Observation

Ventilati on

openings Block ed 14.4 2 h - - FI : 1.89 A, NO,

CT (Monitor body : 3 8. 1 C,

Power key knob body : 2 6. 9

C, Enclosure near media

button : 29. 9 C, Ambient :

2 2 .6 C, NCD, NH

Speaker output Max. non -

clipped output 14.4 2 h - - FI : 3.14 A, NO,

CT ( Amp I C body (IC163) :

64.8 C , Monitor body : 3 8. 1

C, Power key knob body :

26. 7 C, Enclosure near

media button : 29. 6 C,

Ambient : 2 2.4 C, NCD, NH

Speaker output SC 14.4 1 h - - FI : 0.5 - 1. 27 A , IP , NCD,

NH

IC101(3,8) SC 14.4 1 h - - FI : 0.5 A , CD(IC1 01) , NH

IC902(1,6) SC 14.4 1 h - - FI : 0.5 A , CD(IC902) , NH

Supplementary information:

Abbreviation:

FI – Final Input Current; IP – Internal protection operated; NO – Normal Operated;

CD – Component Damaged (list damaged components); NCD – No Component Damaged;

NH – No Hazard ; CT – Constant temperatures were obtained (list components: temperature;);

NB – No indication of dielectric breakdown; YB – Dielectric breakdown (indicate time and location);

NC – Cheesecloth remained intact; YC – Cheesecloth char red or flamed;