ESP Seat Ibiza 5D 2007 Service Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2007, Model line: Ibiza 5D, Model: Seat Ibiza 5D 2007Pages: 272, PDF Size: 8.32 MB

Page 180 of 272

Checking and refilling levels

178

− Insert the fuel nozzle into the mouth of the canister as far as

possible.

− If the spare fuel canister is made of metal, the filling nozzle must be

in contact with the canister during filling. This helps prevent an electro-

static charge building up.

− Never spill fuel in the vehicle or in the luggage compartment. Fuel

vapours are explosive. Danger of death.Caution

•

Fuel spills should be removed from the paintwork immediately.

•

Never run the tank completely dry. An irregular fuel supply could cause

misfiring. As a result, unburnt fuel could enter the catalytic converter and

cause damage.For the sake of the environment

Do not try to put in more fuel after the automatic filler nozzle has switched off;

this may cause the fuel to overflow if it becomes warm.PetrolPetrol types

The correct petrol types are listed on a sticker inside the fuel

tank flap.Only unleaded petrol, corresponding to the standard DIN EN 228 , may be

used for vehicles with catalytic converters (EN = “European Norm”). Fuel types are differentiated by the

octane rating, e.g: 91, 95, 98 RON (RON

= “Regulation Octane Number, unit for determining the knock resistance of

petrol”). You may use petrol with a higher octane number than the one recom-

mended for your engine. However, this has no advantage in terms of fuel

consumption and engine power. If, in exceptional circumstances, the correct

octane rating is not available:

•

For engines which require Premium unleaded petrol (95 RON) the

following is valid: Regula r unleaded fuel with 91 RON can also be used. This

can, however, result in a slight loss of power under certain driving conditions.

•

For engines which require Premium unleaded petrol (98 RON) the

following is valid: Premium unleaded fuel with 95 RON can also be used. This

can, however, result in a slight loss of power under certain driving conditions.

– If premium unleaded petrol is not available, the engine can be run on

regular unleaded petrol with 91 RON as an “emergency measure”. In this

case only use moderate engine speeds and a light throttle. Avoid using full

throttle. Fill up with premium petrol as soon as possible.Caution

•

Petrol that follows EN 228 may be mixed with small quantities of ethanol.

However, the so-called “bioethanol fuels” available at commercial establish-

ments with reference E50 or E85, which contain a high percentage of ethanol,

may not be used, as they will damage the fuel system.

•

Even one tankfull of leaded fuel would permanently impair the efficiency

of the catalytic converter.

•

High engine speed and full throttle can damage the engine when using

petrol with an octane rating lower than the correct grade for the engine.For the sake of the environment

Just one full tank of leaded fuel would seriously impair the efficiency of the

catalytic converter.

WARNING (continued)

IBI_ANG_0707 Seite 178 Montag, 6. August 2007 3:59 15

Page 181 of 272

Checking and refilling levels179

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

Petrol additives

Petrol additives improve the quality of the petrol.The quality of the petrol influences running behaviour, performance and

service life of the engine. For this reason you should use good quality petrol

containing additives. These additives will help to prevent corrosion, keep the

fuel system clean and prevent deposits from building up in the engine.

If good quality petrol with additives is not available or engine problems occur,

the required additives must be added during refuelling.DieselDiesel*Diesel fuel must correspond to DIN EN 590 (EN = “European standard”). It

must have a cetane number (CN) of at least 51. The cetane number indicates

the ignition quality of the diesel fuel.

Notes on filling with fuel ⇒page 177.RME fuel*

Only those vehicles fitted with special equipment (number PR

2G0 for biodiesel use) may use biodiesel corresponding to

the standard DIN EN 14214.The biodiesel fuel must comply wit h the DIN EN 14.214 (FAME) Standard.•

Biodiesel is a methylester obtained from rapeseed oil.

•

DIN is a German abbreviation for “Deutsches Institut für Normung e.V.”,

the German standards institute.

•

EN means European Norm.

•

FAME is the English abbreviation for “ Fatty Acid Methyl Ester”

If the date sticker of the vehicle in cludes the number PR 2G0 optional equip-

ment) this means that that vehicle has been prepared for biodiesel use.

Your Authorised Service Centre or automobile association will be able to

advise on where you can obtain RME biodiesel fuel.

Your Authorised Service Centre can also be consulted to know if the vehicle

has been prepared for biodiesel use.

Things to note about RME fuel (biodiesel)

•

The performance of a vehicle using biodiesel maybe somewhat reduced.

•

Fuel consumption of a vehicle using biodiesel may be slightly higher.

•

RME fuel can be used in winter at temperatures down to approx. -10°C.

•

At outside temperatures below -10° C, we recommend using winter diesel

fuel.Caution

•

RME fuel can damage the fuel system in vehicles which are not suitably

adjusted.

•

If you decide to use biodiesel in your vehicle, please use only RME fuel

which is DIN E 14,214 compliant.

•

If you use biodiesel that does not me et the required standard, the fuel

filter could become clogged.Note

•

In case of low exterior temperatures and a fuel biodiesel percentage of

higher than 50%, an increase in gas emission may occur during operation of

the independent heating.

IBI_ANG_0707 Seite 179 Montag, 6. August 2007 3:59 15

Page 187 of 272

Checking and refilling levels185

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

Note

Before a long trip, we recommend finding an engine oil that conforms to the

corresponding VW specifications and keeping it in the vehicle. This way, the

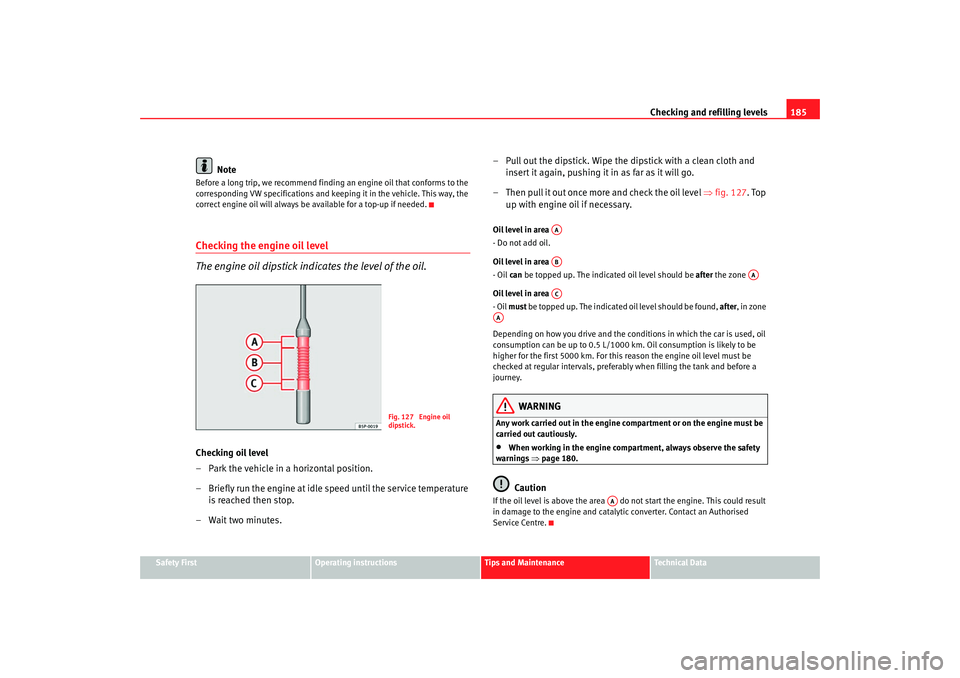

correct engine oil will always be available for a top-up if needed.Checking the engine oil level

The engine oil dipstick indicates the level of the oil.Checking oil level

– Park the vehicle in a horizontal position.

– Briefly run the engine at idle speed until the service temperature

is reached then stop.

– Wait two minutes. – Pull out the dipstick. Wipe the dipstick with a clean cloth and

insert it again, pushing it in as far as it will go.

– Then pull it out once more and check the oil level ⇒fig. 127. Top

up with engine oil if necessary.

Oil level in area

- Do not add oil.

Oil level in area

- Oil can be topped up. The indi cated oil level should be after the zone

Oil level in area

- Oil must be topped up. The indicated oil level should be found, after, in zone

Depending on how you drive and the conditions in which the car is used, oil

consumption can be up to 0.5 L/1000 km. Oil consumption is likely to be

higher for the first 5000 km. For this reason the engine oil level must be

checked at regular intervals, preferably when filling the tank and before a

journey.

WARNING

Any work carried out in the engine compartment or on the engine must be

carried out cautiously.•

When working in the engine compartm ent, always observe the safety

warnings ⇒page 180.Caution

If the oil level is above the area do not start the engine. This could result

in damage to the engine and catalytic converter. Contact an Authorised

Service Centre.

Fig. 127 Engine oil

dipstick.

AAAB

AA

AC

AA

AA

IBI_ANG_0707 Seite 185 Montag, 6. August 2007 3:59 15

Page 188 of 272

Checking and refilling levels

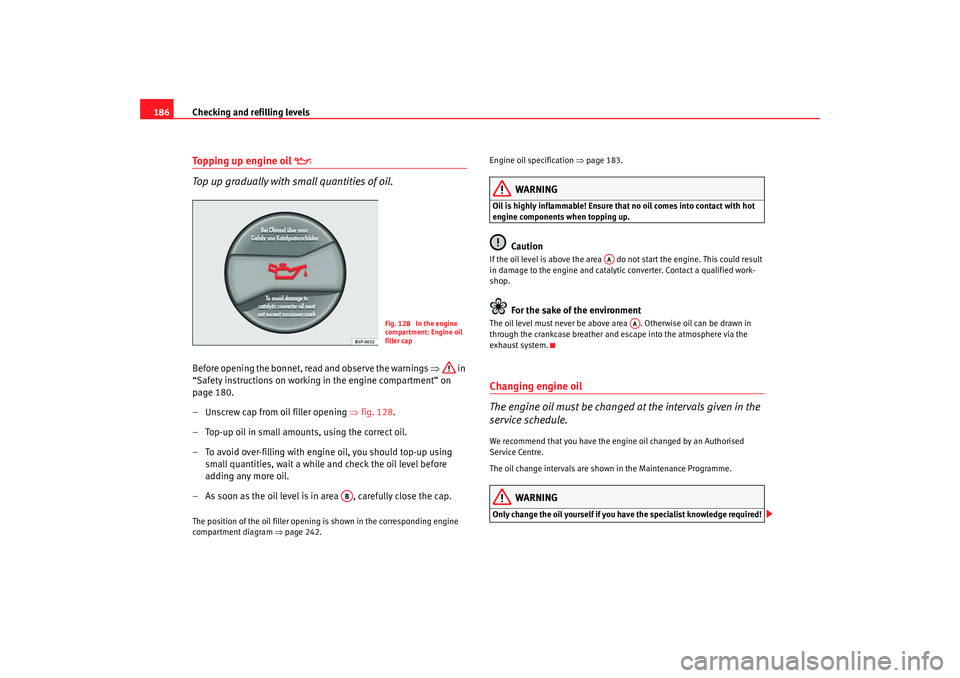

186Topping up engine oil

Top up gradually with small quantities of oil.

Before opening the bonnet, read and observe the warnings ⇒ in

“Safety instructions on working in the engine compartment” on

page 180.

– Unscrew cap from oil filler opening ⇒ fig. 128.

– Top-up oil in small amounts, using the correct oil.

– To avoid over-filling with engine oil, you should top-up using small quantities, wait a while and check the oil level before

adding any more oil.

– As soon as the oil level is in area , carefully close the cap.The position of the oil filler openi ng is shown in the corresponding engine

compartment diagram ⇒ page 242. Engine oil specification

⇒page 183.

WARNING

Oil is highly inflammable! Ensure that no oil comes into contact with hot

engine components when topping up.

Caution

If the oil level is above the area do not start the engine. This could result

in damage to the engine and catalytic converter. Contact a qualified work-

shop.

For the sake of the environment

The oil level must never be above area . Otherwise oil can be drawn in

through the crankcase breather and escape into the atmosphere via the

exhaust system.Changing engine oil

The engine oil must be changed at the intervals given in the

service schedule.We recommend that you have the engine oil changed by an Authorised

Service Centre.

The oil change intervals are shown in the Maintenance Programme.

WARNING

Only change the oil yourself if you have the specialist knowledge required!

Fig. 128 In the engine

compartment: Engine oil

filler cap

AB

AA

AA

IBI_ANG_0707 Seite 186 Montag, 6. August 2007 3:59 15

Page 190 of 272

Checking and refilling levels

188

Caution•

Other additives may give considerably inferior corrosion protection. The

resulting corrosion in the cooling system can lead to a loss of coolant,

causing serious damage to the engine.

•

The coolant additive G 12+ (purple) ca n be mixed with the additive G 12

(red) or G 11. Never mix G12 (red colour) with G 11.

Checking the coolant level and topping up

The correct coolant level is important for fault-free func-

tioning of the engine cooling system.Before opening the bonnet, read and observe the warnings ⇒ in

“Safety instructions on working in the engine compartment” on

page 180. Opening the coolant expansion tank

– Switch off the engine and allow it to cool.

– To prevent scalding, cover the cap on the expansion tank with a

thick cloth and carefully unscrew the cap ⇒.

Checking coolant level

– Look into the open coolant expansion tank and read off the coolant level.

– If the level is underneath the “MIN” mark, top up with coolant.

Topping up coolant

–Only use new coolant.

– Do not fill above the “MAX” mark.

Closing the coolant expansion tank

– Screw the cap on again tightly.

The position of the coolant expansion re servoir is shown in the corresponding

engine compartment diagram ⇒page 242.

Make sure that the coolant meets the required specifications ⇒page 187.

Do not use a different type of additive if coolant additive G 12+, is not avail-

able. In this case use only water and bring the coolant concentration back up

to the correct level as soon as possible by putting in the specified additive

⇒ page 187.

Always top up with new coolant.

Do not fill above the “MAX” mark. Otherwise the excess coolant will be forced

out of the cooling system when the engine is hot.

Fig. 129 In the engine

compartment: Coolant

expansion tank cap

IBI_ANG_0707 Seite 188 Montag, 6. August 2007 3:59 15

Page 194 of 272

Checking and refilling levels

192

WARNING

Do not drive unless you have good visibility through all windows!•

Clean the windscreen wiper blades and all windows regularly.

•

The wiper blades should be changed once or twice a year.Caution

•

A damaged or dirty window wiper could scratch the rear window.

•

Never use fuel, nail varnish remover, paint thinner or similar products to

clean the window.

•

Never move the windscreen wiper by hand. This could cause damage.

Brake fluidChecking the brake fluid level

The brake fluid is checked at the intervals given in the service

schedule.– Read off the fluid level at the transparent brake fluid reservoir. It should always be between the “MIN” and “MAX” marks.The position of the brake fluid reservoir is shown in the corresponding engine

compartment diagram ⇒page 242. The brake fluid reservoir has a black and

yellow cap.

The brake fluid level drops slightly when the vehicle is being used as the

brake pads are automatically adjusted as they wear.

Fig. 133 In the engine

compartment: Brake fluid

reservoir cover

IBI_ANG_0707 Seite 192 Montag, 6. August 2007 3:59 15

Page 197 of 272

Checking and refilling levels195

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

•

If the vehicle is left standing in cold conditions for a long period, protect

the battery from frost. If it “freezes” it will be damaged.

Checking the electrolyte level

The electrolyte level should be checked regularly in high-

mileage vehicles, in hot countries and in older batteries.– Open the bonnet and open the battery cover at the front ⇒ in

“Safety instructions on working in the engine compartment” on

page 180 ⇒ in “Warnings on handling the battery” on

page 194.

– Check the colour display in the "magic eye" on the top of the battery.

– If there are air bubbles in the window, tap the window gently until they disperse.The position of the battery is shown in the corresponding engine compart-

ment diagram ⇒page 242.

The round window (“magic eye”) on the top of the battery changes colour,

depending on the charge level and electrolyte level of the battery.

If the colour in the window is colourless or bright yellow, the electrolyte level

of the battery is too low. Have the battery checked by a qualified workshop.

The colours green and black are used by the workshops for diagnostic

purposes.

Charging and changing the vehicle battery

The battery is maintenance-free and is checked during the

inspection service. All work on the vehicle battery requires

specialist knowledge.If you often drive short distances or if the vehicle is not driven for long

periods, the battery should be checked by a qualified workshop between the

scheduled services.

If the battery has discharged and you have problems starting the vehicle, the

battery might be damaged. If this happens, we recommend you have the

vehicle battery checked by an Authorised Service Centre where it will be re-

charged or replaced.

Charging the battery

The vehicle battery should be charged by a qualified workshop only, as

batteries using special technology have been installed and they must be

charged in a controlled environment.

Replacing a vehicle battery

The battery has been developed to suit the conditions of its location and has

special safety features.

Genuine SEAT batteries fulfil the maintenance, performance and safety spec-

ifications of your vehicle.

WARNING

•

We recommend you use only maintenance-free or cycle free leak-proof

batteries which comply with the standards T 825 06 and VW 7 50 73. This

standard applies as of 2001.

•

Before starting any work on the batteries, you must read and observe

the warnings ⇒ in “Warnings on handling the battery” on page 194.

IBI_ANG_0707 Seite 195 Montag, 6. August 2007 3:59 15

Page 199 of 272

Checking and refilling levels197

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

Checking tyre pressure

The correct tyre pressure can be seen on the sticker on the

inside of the tank flap.1. Read the required tyre inflation pressure from the sticker. The

values refer to Summer tyres. For Winter tyres, you must add 0.2

bar to the values given on the sticker.

2. The tyre pressures should only be checked when the tyres are cold. The slightly raised pressures of warm tyres must not be

reduced.

3. Adjust the tyre pressure to the load you are carrying.Tyre pressure

The correct tyre pressure is especially important at high speeds. The pressure

should therefore be checked at least once a month and before starting a

journey.

WARNING

A tyre can easily burst if the pressure is too low, causing an accident!•

At continuously high speeds, a tyre with insufficient pressure flexes

more. In this way it becomes too hot, and this can cause tread separation

and tyre blow-out. Always observe the recommended tyre pressures.

•

If the tyre pressure is too low or too high, the tyres will wear prema-

turely and the vehicle will not handle well. Risk of accident!For the sake of the environment

Under-inflated tyres will increase fuel consumption.

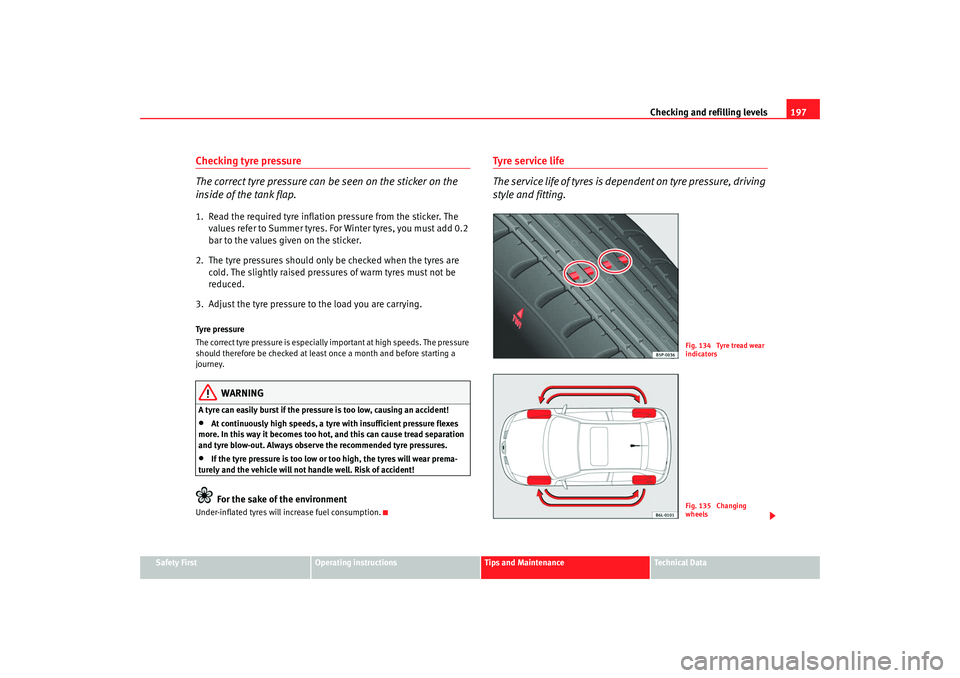

Tyre service life

The service life of tyres is dependent on tyre pressure, driving

style and fitting.

Fig. 134 Tyre tread wear

indicatorsFig. 135 Changing

wheels

IBI_ANG_0707 Seite 197 Montag, 6. August 2007 3:59 15

Page 208 of 272

If and when

206

WARNING

Put the hazard warning lights on and pl ace the warning triangle in position.

This is for your own safety and also warns other road users.

Caution

If you have to change the tyre on a gradient, block the wheel opposite the

wheel being changed by placing a stone or similar object under it to prevent

the vehicle from rolling away.

Note

Please observe legal requirements when doing so.Changing a wheelChange the wheel as described below

– Pull off the hub cap see also ⇒page 207.

–Slacken the wheel bolts.

– Raise the car with the jack in the corresponding zone.

– Ta k e o f f the wheel and then put on the spare wheel.

– Lower the vehicle.

– Tighten the wheel bolts firmly i n d ia go na l s e q u e n ce wi t h t h e b ox

spanner.

–Replace the hub cap.

After changing a wheel

After changing the wheel there are still tasks to complete.– Put the tools and jack back in the luggage compartment.

– Place the wheel with the defective tyre in the luggage compart- ment and secure it.

– Check the tyre pressure of the newly fitted tyre as soon as possible.

– Have the tightening torque of the wheel bolts checked as soon as possible with a torque wrench. The prescribed torque is 120 Nm.

Note•

If you notice that the wheel bolts are corroded and difficult to turn when

changing a wheel, they must be replaced before having the wheel bolt torque

checked.

•

In the interest of safety, drive at moderate speeds until the wheel bolt

torque has been checked.

IBI_ANG_0707 Seite 206 Montag, 6. August 2007 3:59 15

Page 209 of 272

If and when207

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

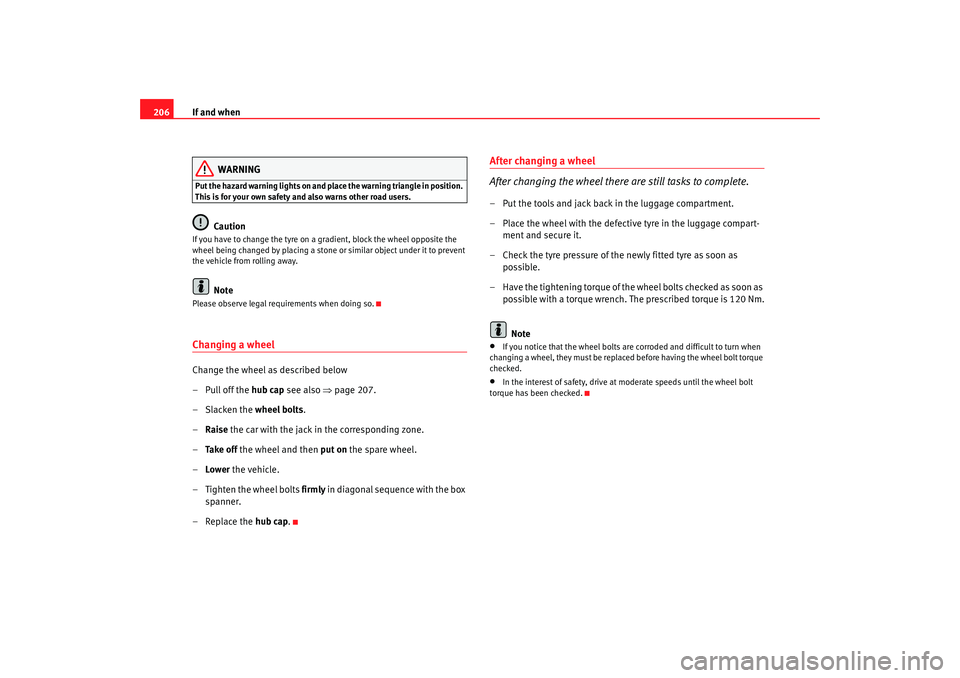

Wheel trims

The wheel trims must be removed to gain access to the wheel

bolts.Dismantle

– Insert the extraction hook from the tools in the corresponding

hole ⇒fig. 139.

– Pull off the hub cap.

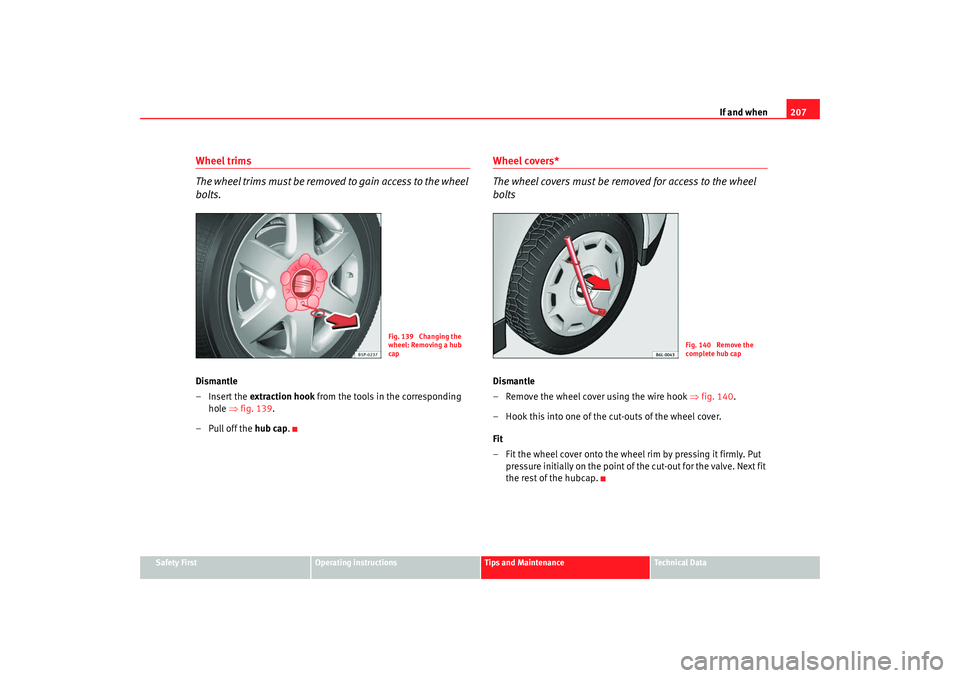

Wheel covers*

The wheel covers must be removed for access to the wheel

boltsDismantle

– Remove the wheel cover using the wire hook ⇒fig. 140.

– Hook this into one of the cut-outs of the wheel cover.

Fit

– Fit the wheel cover onto the wheel rim by pressing it firmly. Put pressure initially on the point of the cut-out for the valve. Next fit

the rest of the hubcap.

Fig. 139 Changing the

wheel: Removing a hub

cap

Fig. 140 Remove the

complete hub cap

IBI_ANG_0707 Seite 207 Montag, 6. August 2007 3:59 15