technical specifications Seat Ibiza 5D 2014 Owners Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2014, Model line: Ibiza 5D, Model: Seat Ibiza 5D 2014Pages: 240, PDF Size: 4.89 MB

Page 183 of 240

Emergencies

Note

In some countries, the maximum permitted

speed with snow chains is 50 km/h (31 mph).

The legal requirements of each country must

be followed. Emergencies

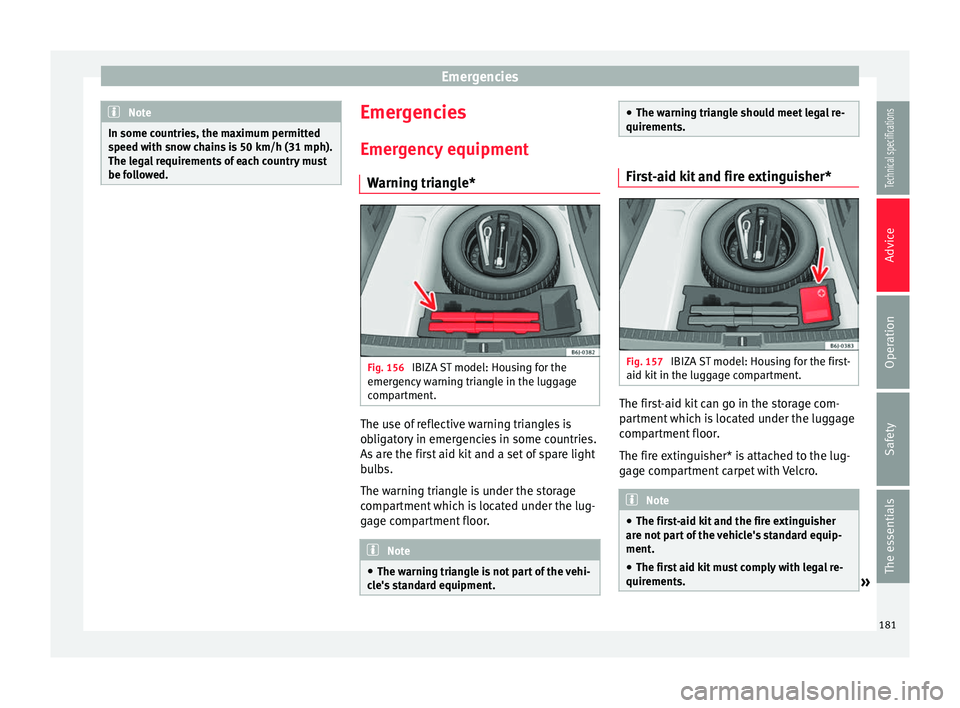

Emergency equipment Warning triangle* Fig. 156

IBIZA ST model: Housing for the

emergency warning triangle in the luggage

compartment. The use of reflective warning triangles is

obligatory in emergencies in some countries.

As are the first aid kit and a set of spare light

bulbs.

The warning triangle is under the storage

compartment which is located under the lug-

gage compartment floor.

Note

● The warning triangle is not part of the vehi-

cle's standard equipment. ●

The warning triangle should meet legal re-

quirements. First-aid kit and fire extinguisher*

Fig. 157

IBIZA ST model: Housing for the first-

aid kit in the luggage compartment. The first-aid kit can go in the storage com-

partment which is located under the luggage

compartment floor.

The fire extinguisher* is attached to the lug-

gage compartment carpet with Velcro.

Note

● The first-aid kit and the fire extinguisher

are not part of the vehicle's standard equip-

ment.

● The first aid kit must comply with legal re-

quirements. » 181Technical specifications

Advice

Operation

Safety

The essentials

Page 185 of 240

Emergencies

Wheel change Preparation work –

If you have a flat tyre or puncture, park the

vehicle as far away from the flow of traffic

as possible. Choose a location that is as

level as possible.

– All vehicle occupants should leave the ve-

hicle. They should wait in a safe area (for

instance behind the roadside crash barri-

er).

– Switch the engine off. Switch the hazard

warning lights on and place the warning tri-

angles in position.

– Apply the handbrake

firmly.

– En g

age the first gear , or put

the selector

lever to position P for those vehicles with

an automatic gearbox.

– If you are towing a trailer, unhitch it from

your vehicle.

– Take the vehicle tools and the spare wheel

out of

the luggage compartment. WARNING

● Switch on the hazard warning lights and

place the warning triangles in position. This

is for your own safety and also warns other

road users. ●

If you change the wheel on a slope, block

the wheel on the opposite side of the car with

a stone or similar to prevent the vehicle from

moving. Changing a wheel

Change the wheel as described below:

– Remove the hub caps or the integral trim .

– Sl ac

ken the wheel bolts .

– Rai

se the vehicle with the jack at the corre-

s pondin

g area.

– Remove the wheel and put on the spare

one.

– Lower the vehicle.

– Tighten the wheel

bolts firmly with the box

sp

anner.

– Replace the hub cap.

Aft

er changing a wheel –

Put the tools back in their storage location.

– Place the wheel with the defective tyre in

the luggage compartment and secure it.

– Check the tyre pressure of the newly fitted

tyre as soon as possible. –

Have the tightening torque of the wheel

bolts checked as soon as possible with a

torque wrench. The prescribed torque must

be 120 Nm. Note

● If you notice that the wheel bolts are corro-

ded and difficult to turn when changing a

wheel, they must be replaced before having

the wheel bolt tightening torque checked.

● For safety reasons, drive at moderate

speeds until the wheel bolt tightening torque

has been checked. Wheel covers*

Fig. 158

Remove the wheel cover. The wheel covers must be removed for access

to the wheel bolts.

»

183

Technical specifications

Advice

Operation

Safety

The essentials

Page 187 of 240

Emergencies

– Place the jack under the jacking point and

turn the crank until the arm of the jack is di-

rectly below the vertical rib under the door

sill.

– Align the jack so that the arm of the jack

fits around the rib under the door sill and

the movable base plate of the jack is flat on

the ground ››› Fig. 161 .

– Rai

se the vehicle until the defective wheel

is just clear of the ground.

Recesses at the front and rear of the door

sills mark the jacking points ››› Fig. 160.

There i

s only one jacking point for each

wheel. Do not fit the jack anywhere else.

An

unstable surface under the jack may

cause the vehicle to slip off the jack. There-

fore, it must be fitted on solid ground offer-

ing good support. Use a large and stable

base, if necessary. On a hard, slippery sur-

face (such as tile) use a rubber mat or similar

to prevent the jack from slipping. WARNING

● Take all precautions so that the base of the

jack does not slip. Failure to follow this in-

struction could result in an accident.

● The vehicle can be damaged if the jack is

not applied at the correct jacking points.

There is also a risk of injury since the jack can

slip off suddenly if it is not properly engaged. Removing and fitting the wheel

Change the wheel as described below after

loosening the wheel bolts and raising the ve-

hicle with the jack.

Removing a wheel

– Unscrew the wheel bolts using the box

spanner and place them on a clean surface.

Fitting a wheel

– Screw on the wheel bolts in position and

tighten them loosely with a box spanner.

The wheel bolts should be clean and easily

screwed. Before fitting the spare wheel, in-

spect the wheel condition and hub mounting

surfaces. These surfaces must be clean be-

fore fitting the wheel.

If tyres with a specific direction of rotation

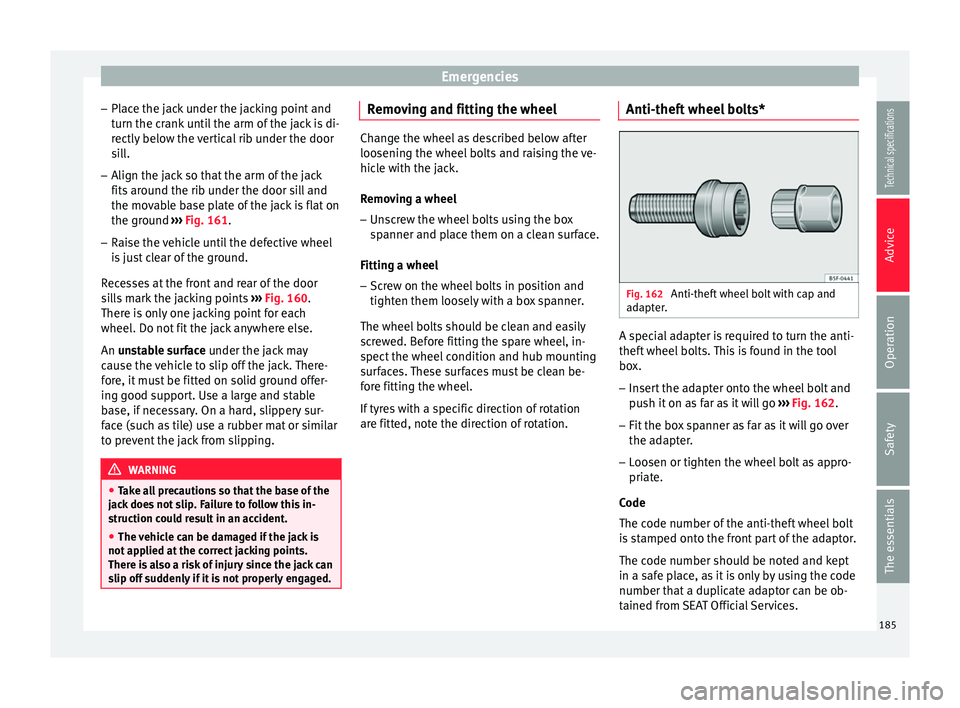

are fitted, note the direction of rotation. Anti-theft wheel bolts* Fig. 162

Anti-theft wheel bolt with cap and

adapter. A special adapter is required to turn the anti-

theft wheel bolts. This is found in the tool

box.

– Insert the adapter onto the wheel bolt and

push it on as far as it will go ››› Fig. 162 .

– Fit the bo

x spanner as far as it will go over

the adapter.

– Loosen or tighten the wheel bolt as appro-

priate.

Code

The code number of the anti-theft wheel bolt

is stamped onto the front part of the adaptor.

The code number should be noted and kept

in a safe place, as it is only by using the code

number that a duplicate adaptor can be ob-

tained from SEAT Official Services. 185

Technical specifications

Advice

Operation

Safety

The essentials

Page 189 of 240

Emergencies

●

Avoid heavy acceleration, hard braking and

fast cornering.

● Drive for only 10 minutes at a maximum

speed of 80 km/h (50 mph) and then check

the tyre. For the sake of the environment

Dispose of used or expired sealant observing

any legal requirements. Note

● A new bottle of sealant can be purchased at

SEAT dealerships.

● Take into account the separate instruction

manual of the tyre mobility set* manufactur-

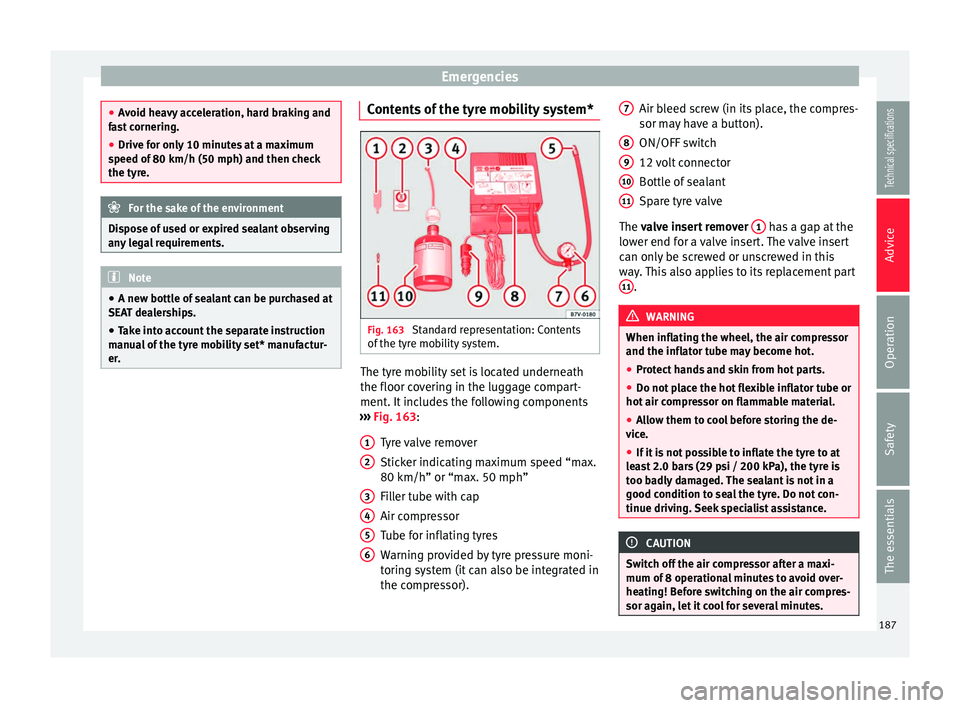

er. Contents of the tyre mobility system*

Fig. 163

Standard representation: Contents

of the tyre mobility system. The tyre mobility set is located underneath

the floor covering in the luggage compart-

ment. It includes the following components

››› Fig. 163 :

T y

re valve remover

Sticker indicating maximum speed “max.

80 km/h” or “max. 50 mph”

Filler tube with cap

Air compressor

Tube for inflating tyres

Warning provided by tyre pressure moni-

toring system (it can also be integrated in

the compressor).

1 2

3

4

5

6 Air bleed screw (in its place, the compres-

sor may have a button).

ON/OFF switch

12 volt connector

Bottle of sealant

Spare tyre valve

The valve insert remover

1 has a gap at the

lower end for a valve insert. The valve insert

can only be screwed or unscrewed in this

way. This also applies to its replacement part 11 .

WARNING

When inflating the wheel, the air compressor

and the inflator tube may become hot.

● Protect hands and skin from hot parts.

● Do not place the hot flexible inflator tube or

hot air compressor on flammable material.

● Allow them to cool before storing the de-

vice.

● If it is not possible to inflate the tyre to at

least 2.0 bars (29 psi / 200 kPa), the tyre is

too badly damaged. The sealant is not in a

good condition to seal the tyre. Do not con-

tinue driving. Seek specialist assistance. CAUTION

Switch off the air compressor after a maxi-

mum of 8 operational minutes to avoid over-

heating! Before switching on the air compres-

sor again, let it cool for several minutes. 7

8

9

10

11

187

Technical specifications

Advice

Operation

Safety

The essentials

Page 191 of 240

Emergencies

2. Connect one end of the red jump lead to

the po s

itive + terminal of the vehicle

with the flat battery A

››› Fig. 164 .

3. C

onnect the other end of the red

jump

lead to the positive terminal + in the ve-

hicle providing assistance B .

4. For vehicles without Start-Stop system:

connect one end of the black jump lead to

the negative terminal – of the vehicle

providing the current B

››› Fig. 164 .

– For

vehicles with Start-Stop system: con-

nect one end of the black jump lead X to a

suitable ground terminal, to a solid piece of

metal in the engine block, or to the engine

block itself ››› Fig. 165 .

5. C

onnect the other end of the black jump

lead X to a solid metal component bolted

to the engine block or to the engine block

itself of the vehicle with the flat battery.

Do not connect it to a point near the bat-

tery A .

6. Position the leads in such a way that they cannot come into contact with any moving

parts in the engine compartment.

Starting

7. Start the engine of the vehicle with the boosting battery and let it run at idling

speed. 8. Start the engine of the vehicle with the flat

battery and wait 2 or 3 minutes until the

engine is “running”.

Removing the jump leads

9. Before you remove the jump leads, switch off the dipped beam headlights (if they

are switched on).

10. Turn on the heater blower and heated rear window in the vehicle with the flat

battery. This helps minimise voltage peaks

which are generated when the leads are

disconnected.

11. When the engine is running, disconnect

the l e

ads in reverse order to the details

given above.

Connect the battery clamps so they have

good metal-to-metal contact with the battery

terminals.

If the engine fails to start, switch off the start-

er after about 10 seconds and try again after

about a minute. WARNING

● Please note the safety warnings referring to

working in the engine compartment

››› page 166, Working in the engine compart-

ment.

● The b att

ery providing assistance must have

the same voltage as the flat battery (12 V)

and approximately the same capacity (see imprint on battery). Failure to comply could

result in an explosion.

●

Never use jump leads when one of the bat-

teries is frozen. Danger of explosion! Even af-

ter the battery has thawed, battery acid could

leak and cause chemical burns. If a battery

freezes, it should be replaced.

● Keep sparks, flames and lighted cigarettes

away from batteries, danger of explosion.

Failure to comply could result in an explo-

sion.

● Observe the instructions provided by the

manufacturer of the jump leads.

● Do not connect the negative cable from the

other vehicle directly to the negative terminal

of the flat battery. The gas emitted from the

battery could be ignited by sparks. Danger of

explosion.

● Do not attach the negative cable from the

other vehicle to parts of the fuel system or to

the brake line.

● The non-insulated parts of the battery

clamps must not be allowed to touch. The

jump lead attached to the positive battery

terminal must not touch metal parts of the ve-

hicle, this can cause a short circuit.

● Position the leads in such a way that they

cannot come into contact with any moving

parts in the engine compartment.

● Do not lean on the batteries. This could re-

sult in chemical burns. » 189

Technical specifications

Advice

Operation

Safety

The essentials

Page 193 of 240

Emergencies

Towing vehicles with an automatic gearbox

● Put the selector lever into position “N”.

● Do not drive faster than 50 km/h (31 mph).

● Do not tow further than 50 km.

● If a breakdown vehicle is used, the vehicle

must be towed with the front wheels raised. Note

● Observe legal requirements when towing or

tow-starting.

● Switch on the hazard warning lights of both

vehicles. However, observe any regulations

to the contrary.

● For technical reasons, vehicles with an au-

tomatic gearbox must not be tow-started.

● If there is no lubricant in the gearbox as the

result of a fault, you must raise the driven

wheels while the vehicle is being towed.

● If the vehicle has to be towed more than

50 km (30 miles), the front wheels should be

raised during towing, and towing should be

carried out by a qualified person.

● The steering wheel is locked when the vehi-

cle has no electrical power. The vehicle must

then be towed with the front wheels raised.

Towing should be carried out by a qualified

person.

● The towline anchorage should always be

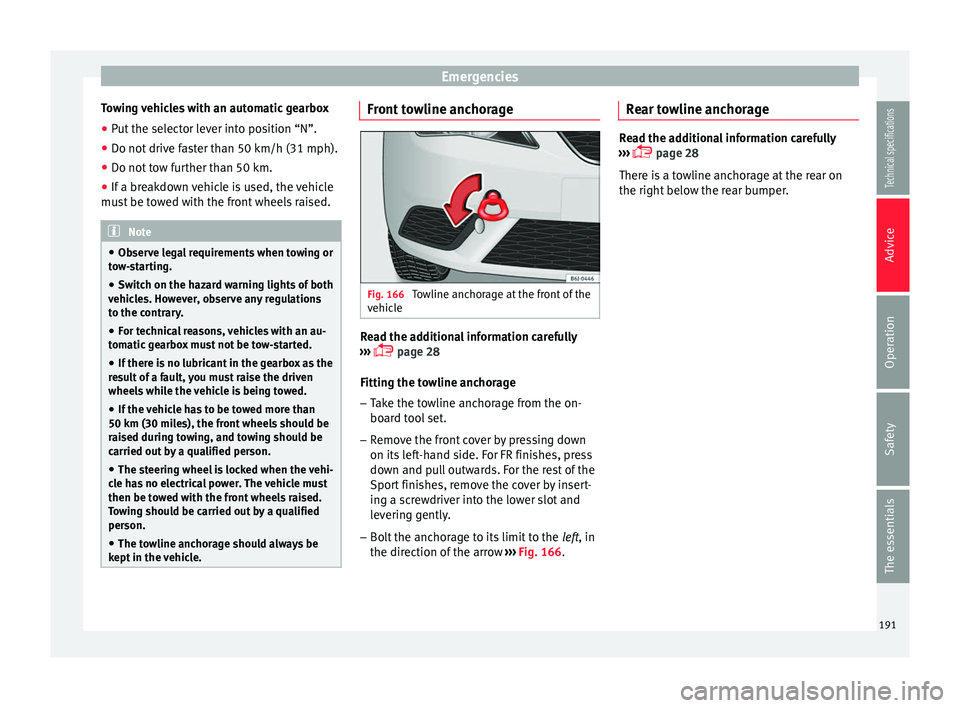

kept in the vehicle. Front towline anchorage

Fig. 166

Towline anchorage at the front of the

vehicle Read the additional information carefully

››› page 28

Fitting the towline anchorage

– Take the towline anchorage from the on-

board tool set.

– Remove the front cover by pressing down

on its left-hand side. For FR finishes, press

down and pull outwards. For the rest of the

Sport finishes, remove the cover by insert-

ing a screwdriver into the lower slot and

levering gently.

– Bolt the anchorage to its limit to the left, in

the dir ection of

the arrow ››› Fig. 166. Rear towline anchorage Read the additional information carefully

››› page 28

There is a towline anchorage at the rear on

the right below the rear bumper.

191

Technical specifications

Advice

Operation

Safety

The essentials

Page 195 of 240

Emergencies

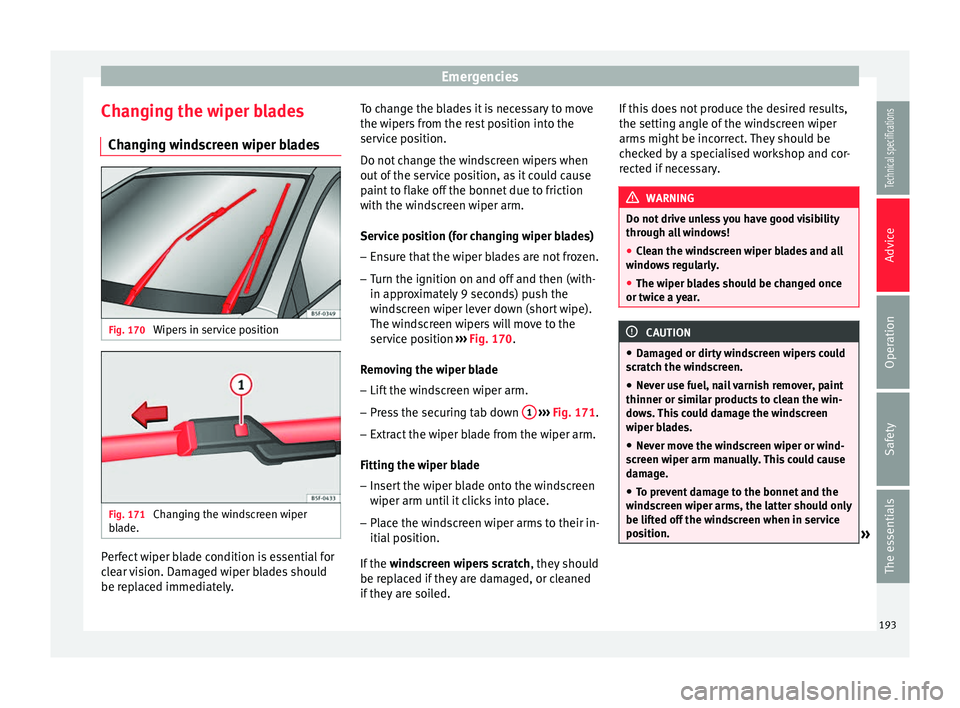

Changing the wiper blades Changing windscreen wiper blades Fig. 170

Wipers in service position Fig. 171

Changing the windscreen wiper

blade. Perfect wiper blade condition is essential for

clear vision. Damaged wiper blades should

be replaced immediately. To change the blades it is necessary to move

the wipers from the rest position into the

service position.

Do not change the windscreen wipers when

out of the service position, as it could cause

paint to flake off the bonnet due to friction

with the windscreen wiper arm.

Service position (for changing wiper blades)

–

Ensure that the wiper blades are not frozen.

– Turn the ignition on and off and then (with-

in approximately 9 seconds) push the

windscreen wiper lever down (short wipe).

The windscreen wipers will move to the

service position ››› Fig. 170 .

R emo

ving the wiper blade

– Lift the windscreen wiper arm.

– Press the securing tab down 1

››› Fig. 171 .

– Extr act

the wiper blade from the wiper arm.

Fitting the wiper blade – Insert the wiper blade onto the windscreen

wiper arm until it clicks into place.

– Place the windscreen wiper arms to their in-

itial position.

If the windscreen wipers scratch , they should

be replaced if they are damaged, or cleaned

if they are soiled. If this does not produce the desired results,

the setting angle of the windscreen wiper

arms might be incorrect. They should be

checked by a specialised workshop and cor-

rected if necessary.

WARNING

Do not drive unless you have good visibility

through all windows!

● Clean the windscreen wiper blades and all

windows regularly.

● The wiper blades should be changed once

or twice a year. CAUTION

● Damaged or dirty windscreen wipers could

scratch the windscreen.

● Never use fuel, nail varnish remover, paint

thinner or similar products to clean the win-

dows. This could damage the windscreen

wiper blades.

● Never move the windscreen wiper or wind-

screen wiper arm manually. This could cause

damage.

● To prevent damage to the bonnet and the

windscreen wiper arms, the latter should only

be lifted off the windscreen when in service

position. » 193

Technical specifications

Advice

Operation

Safety

The essentials

Page 197 of 240

Fuses and bulbs

Fuses and bulbs Fuses Introduction Due to the constant updating of vehicles,

fuse assignments based on equipment and

the use of the same fuse for various electrical

components, it is not possible to provide an

up-to-date summary of the fuse positions for

the electrical components at the time this

manual was printed. For detailed information

about the fuse positions, please consult a

technical service.

In general, a fuse can be assigned to various

electrical components. Likewise, an electrical

component can be protected by several

fuses.

Only replace fuses when the cause of the

problem has been solved. If a newly inserted

fuse blows after a short time, you must have

the electrical system checked by a special-

ised workshop as soon as possible.

Additional information and warnings:

● Working in the engine compartment

››› page 166 . WARNING

The high voltages in the electrical system can

give serious electrical shocks, causing burns

and even death!

● Never touch the electrical wiring of the igni-

tion system.

● Take care not to cause short circuits in the

electrical system. WARNING

Using unsuitable fuses, repairing fuses or

bridging a current circuit without fuses can

cause a fire and serious injury.

● Never use a fuse with a higher value. Only

replace fuses with a fuse of the same amper-

age (same colour and markings) and size.

● Never repair a fuse.

● Never replace a fuse by a metal strip, staple

or similar. CAUTION

● To prevent damage to the vehicle's electric

system, before replacing a fuse always turn

off the ignition, the lights and all electrical

elements and remove the key from the igni-

tion.

● If you replace a fuse with higher-rating

fuse, you could cause damage to another part

of the electrical system.

● Protect the fuse boxes when open to pre-

vent the entry of dust or humidity as they can

damage the electrical system. Note

● One component may have more than one

fuse.

● Several components may run on a single

fuse. Vehicle fuses

Read the additional information carefully

››› page 25

Only replace fuses with a fuse of the same

amperage (same colour and markings) and

size. »

195Technical specifications

Advice

Operation

Safety

The essentials

Page 199 of 240

Fuses and bulbs

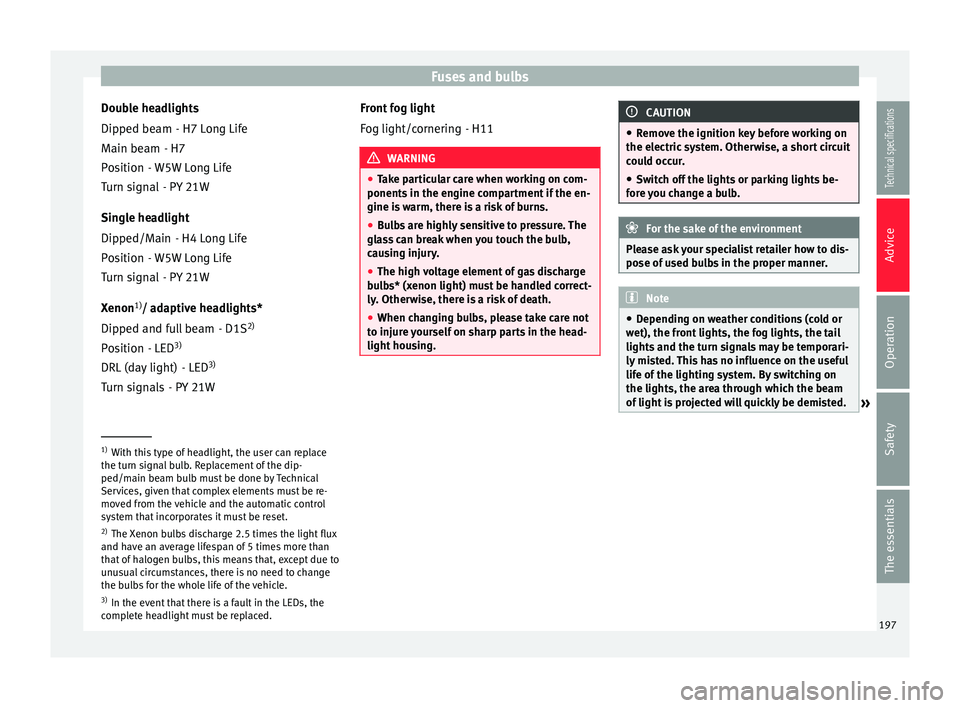

Double headlights - H7 Long Life

- H7

- W5W Long Life - PY 21W

Single headlight - H4 Long Life

- W5W Long Life - PY 21W

Xenon 1)

/ adaptive headlights*

- D1S2)

- LED 3)

- LED 3)

- PY 21W

Dipped beam

Main beam

Position

Turn signal

Dipped/Main

Position

Turn signal

Dipped and full beam

Position

DRL (day light)

Turn signals Front fog light

- H11 WARNING

● Take particular care when working on com-

ponents in the engine compartment if the en-

gine is warm, there is a risk of burns.

● Bulbs are highly sensitive to pressure. The

glass can break when you touch the bulb,

causing injury.

● The high voltage element of gas discharge

bulbs* (xenon light) must be handled correct-

ly. Otherwise, there is a risk of death.

● When changing bulbs, please take care not

to injure yourself on sharp parts in the head-

light housing. Fog light/cornering CAUTION

● Remove the ignition key before working on

the electric system. Otherwise, a short circuit

could occur.

● Switch off the lights or parking lights be-

fore you change a bulb. For the sake of the environment

Please ask your specialist retailer how to dis-

pose of used bulbs in the proper manner. Note

● Depending on weather conditions (cold or

wet), the front lights, the fog lights, the tail

lights and the turn signals may be temporari-

ly misted. This has no influence on the useful

life of the lighting system. By switching on

the lights, the area through which the beam

of light is projected will quickly be demisted. »1)

With this type of headlight, the user can replace

the turn signal bulb. Replacement of the dip-

ped/main beam bulb must be done by Technical

Services, given that complex elements must be re-

moved from the vehicle and the automatic control

system that incorporates it must be reset.

2) The Xenon bulbs discharge 2.5 times the light flux

and have an average lifespan of 5 times more than

that of halogen bulbs, this means that, except due to

unusual circumstances, there is no need to change

the bulbs for the whole life of the vehicle.

3) In the event that there is a fault in the LEDs, the

complete headlight must be replaced. 197Technical specifications

Advice

Operation

Safety

The essentials

Page 201 of 240

Fuses and bulbs

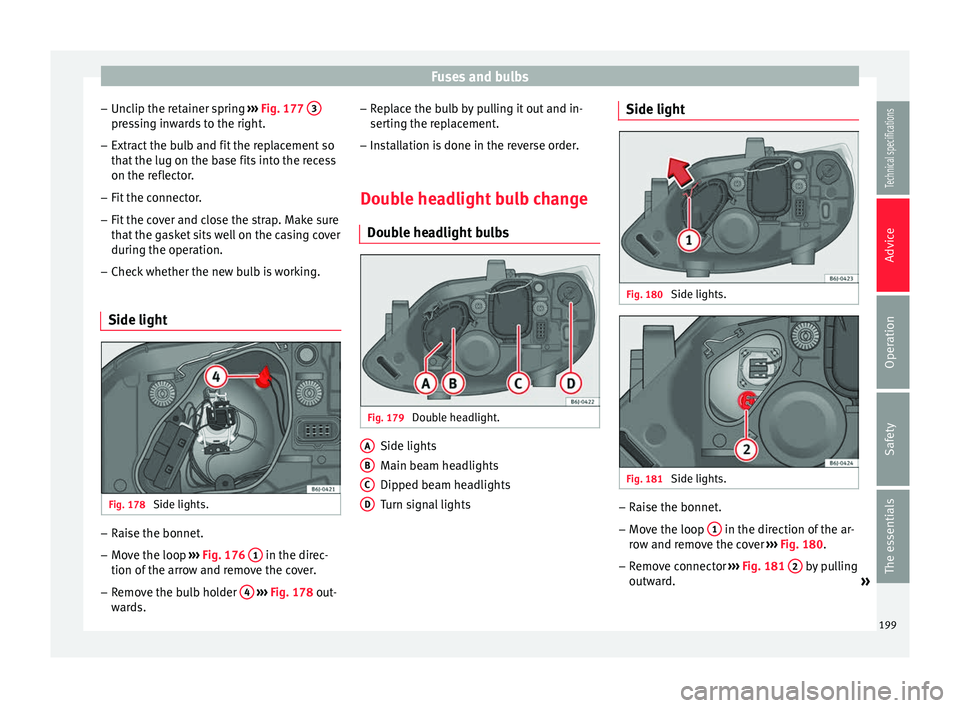

– Unclip the retainer spring ››› Fig. 177 3 pressing inwards to the right.

– Extract the bulb and fit the replacement so

that the lug on the base fits into the recess

on the reflector.

– Fit the connector.

– Fit the cover and close the strap. Make sure

that the gasket sits well on the casing cover

during the operation.

– Check whether the new bulb is working.

Side light Fig. 178

Side lights. –

Raise the bonnet.

– Move the loop ››› Fig. 176 1 in the direc-

tion of the arrow and remove the cover.

– Remove the bulb holder 4

››› Fig. 178 out-

w ar

ds. –

Replace the bulb by pulling it out and in-

serting the replacement.

– Installation is done in the reverse order.

Double headlight bulb change Double headlight bulbs Fig. 179

Double headlight. Side lights

Main beam headlights

Dipped beam headlights

Turn signal lights

A B

C

D Side light

Fig. 180

Side lights. Fig. 181

Side lights. –

Raise the bonnet.

– Move the loop 1 in the direction of the ar-

row and remove the cover ››› Fig. 180 .

– Remo

ve connector ››› Fig. 181 2 by pulling

outward. »

199

Technical specifications

Advice

Operation

Safety

The essentials