tow Seat Ibiza SC 2012 Owner's Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2012, Model line: Ibiza SC, Model: Seat Ibiza SC 2012Pages: 280, PDF Size: 3.67 MB

Page 169 of 280

167

Driving and the environment

Driving and the environment

Running-in Running in a new engine

The engine needs to be run in over the first 1500 km (1000

miles).

Up to 1000 kilometres (600 miles)

– Do not drive at speeds of more than 2/3 the maximum speed.

– Do not accelerate hard.

– Avoid high engine revolutions.

– Do not tow a trailer.

From 1000 to 1500 kilometres (600 to 900 miles)

– Speeds can be gradually increased to the maximum road speed

or maximum permissible engine speed (rpm).

During its first few hours of running, the internal friction in the engine is

greater than later on, when all the moving parts have bedded in.

For the sake of the environment

If the engine is run in gently, its life will be increased and its oil consump-

tion reduced. Braking capacity and braking distance

The braking capacity and braking distance are influenced by

driving situations and road conditions.

The efficiency of the brakes depends directly on the

brake pad wear. The

rate of wear of the brake pads depends to a great extent on the conditions

under which the vehicle is operated and the way the vehicle is driven. If you

often drive in town, drive short distances or have a sporty driving style, we

recommend that you have the thickness of your brake pads checked by a

Technical Service more frequently than recommended in the Maintenance

Programme.

If you drive with wet brakes, for example, after crossing areas of water, in

heavy rainfall or even after washing the vehicle, the effect of the brakes is

lessened as the brake discs are wet or even frozen (in winter). In this case

the brakes should be dried by pressing the brake pedal several times.

WARNING

Longer braking distances and faults in the brake system increase the risk

of accidents.

● New brake pads must be run in and do not have the correct friction

during the first 200 km (120 miles). However, the reduced braking ca-

pacity may be compensated by pressing on the brake pedal a little hard-

er. This also applies when the brake pads have to be changed further on.

● If brakes are wet or frozen, or if you are driving on roads which have

been salted, braking power may be lower than normal.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 170 of 280

168Driving and the environment

WARNING (Continued)

● On steep slopes, if brakes are excessively used, they will overheat.

Before driving down a long steep slope, it is advisable to reduce speed

and change down into a lower gear or range (depending on the type of

transmission). This makes use of engine braking and relieves the brakes.

● Never let the brakes “drag” by applying light pressure. Continuous

braking will cause the brakes to overheat and the braking distance will

increase. Apply and then release the brakes alternately.

● Never let the vehicle run with the engine switched off. The braking

distance is increased considerably when the brake servo is not active.

● If the brake fluid loses its viscosity and is subjected to heavy use, va-

pour bubbles can form in the brake system. This reduces the efficiency of

the brakes.

● Non-standard or damaged front spoilers could restrict the airflow to

the brakes and cause them to overheat. Before purchasing accessories

please observe the relevant instructions ⇒ page 183, Technical modifi-

cations.

● If a brake system circuit fails, the braking distance will be increased

considerably. Contact a specialised workshop immediately and avoid un-

necessary journeys.

Exhaust gas purification system Catalytic converter*

To maintain the useful life of the catalytic converter

– Use only unleaded petrol with petrol engines, as lead damages

the catalytic converter.

– Do not let the fuel get too low in the tank. –

For engine oil changes, do not replenish with too much engine

oil ⇒ page 199, Topping up engine oil .

– Never tow the vehicle to start it, use jump leads if necessary

⇒ page 241.

If you notice misfiring, uneven running or loss of power when the vehicle is

moving, reduce speed immediately and have the vehicle inspected at the

nearest specialised workshop. In general, the exhaust gas warning lamp

will light up when any of the described symptoms occur ⇒ page 63. If this

happens, unburnt fuel can enter the exhaust system and escape into the en-

vironment. The catalytic converter can also be damaged by overheating.

WARNING

The catalytic converter reaches very high temperatures! Risk of fire!

● Never park where the catalytic converter could come into contact with

dry grass or flammable materials under the vehicle.

● Do not apply additional underseal or anti-corrosion coatings to the

exhaust pipes, catalytic converter or the heat shields on the exhaust sys-

tem. These materials could catch fire when the vehicle is being driven.

CAUTION

Never run the fuel tank completely dry because the irregularity of the fuel

supply may cause ignition problems. This allows unburnt fuel to enter the

exhaust system, which could cause overheating and damage the catalytic

converter.

For the sake of the environment

Even when the emission control system is working perfectly, there may be a

smell of sulphur from the exhaust gas under some conditions. This depends

on the sulphur content of the fuel used. Quite often the problem can be

solved by changing to another brand of fuel.

Page 174 of 280

172Driving and the environment

SEAT importers and distributors will gladly provide information about the

technical preparations that you vehicle requires and also about necessary

maintenance and repair possibilities.

Adhesive strips for headlights

If you have to drive a right-hand drive vehicle in a left-hand drive country, or

vice versa, the asymmetric dipped beam headlights will dazzle oncoming

traffic.

To prevent dazzling, you must apply stickers to certain parts of the head-

light lenses. Further information is available at your Technical Service.

In vehicles with adaptive headlights, the rotation system must previously be

disconnected. To do this, please go to a specialised workshop.

Trailer towing What do you need to bear in mind when towing a trailer?

Your vehicle may be used to tow a trailer when fitted with the correct equip-

ment.

If the vehicle is supplied with a factory-fitted towing bracket it will already

have the necessary technical modifications and meet the statutory require-

ments for towing a trailer. If you wish to retrofit a towing bracket, consult

⇒ page 185.

Connectors

Your vehicle is fitted with a 12-pin connector for the electrical connection

between the trailer and the vehicle. If the trailer has a

7-pin plug you will need to use an adapter cable. This is

available in any Technical Service.

Trailer weight/drawbar load

Never exceed the authorised trailer weight. If you do not load the trailer up

to the maximum permitted trailer weight, you can then climb correspond-

ingly steeper slopes.

The maximum trailer weights listed are only applicable for altitudes up to

1000 m above sea level. With increasing altitude the engine power and

therefore the vehicle climbing ability are impaired because of the reduced

air density. The maximum trailer weight has to be reduced accordingly. The

weight of the vehicle and trailer combination must be reduced by 10% for

every further 1000 m (or part thereof). The gross combination weight is the

actual weight of the laden vehicle plus the actual weight of the laden trailer.

When possible, operate the trailer with the maximum permitted drawbar

load on the ball joint of the towing bracket, but do not exceed the specified

limit.

The figures for trailer weights and drawbar loads that are given on the data

plate of the towing bracket are for certification purposes only. The correct

figures for your specific model, which may be lower than these figures for

the towing bracket, are given in the vehicle documentation or in ⇒ chap-

ter Technical Data.

Distributing the load

Distribute loads in the trailer so that heavy objects are as near to the axle as

possible. Loads carried in the trailer must be secured to prevent them mov-

ing.

Tyre pressure

Set tyre pressure to the maximum permissible pressure shown on the stick-

er on the inside of the fuel tank flap. Set the tyre pressure of the trailer tyres

in accordance with the trailer manufacturer's recommendations.

Page 175 of 280

173

Driving and the environment

Exterior mirrors

Check whether you can see enough of the road behind the trailer with the

standard rear vision mirrors. If this is not the case, you should have addi-

tional exterior mirrors fitted. Both exterior mirrors should be mounted on

hinged extension brackets. Adjust the mirrors to give sufficient vision to the

rear.

WARNING

Never transport people in a trailer. This could result in fatal accidents.

Note

● Towing a trailer places additional demands on the vehicle. We recom-

mend additional services between the normal inspection intervals if the ve-

hicle is used frequently for towing a trailer.

● Find out whether special regulations apply to towing a trailer in your

country.

Ball coupling of towing bracket*

The ball coupling is provided with instructions on fitting and removing the

ball coupling of the towing bracket.

WARNING

The towing bracket ball coupling must be stored securely in the luggage

compartment to prevent them being flung through the vehicle and caus-

ing injury.

Note

● By law, the ball coupling must be removed if a trailer is not being towed

if it obscures the number plate. Driving tips

Driving with a trailer always requires extra care.

Weight distribution

The weight distribution of a loaded trailer with an unladen vehicle is very

unfavourable. However, if this cannot be avoided, drive extra slowly to allow

for the unbalanced weight distribution.

Speed

The stability of the vehicle and trailer is reduced with increasing speed. For

this reason, it is advisable not to drive at the maximum permissible speed

in an unfavourable road, weather or wind conditions. This applies especially

when driving downhill.

You should always reduce speed immediately if the trailer shows the slight-

est sign of snaking. Never try to stop the “snaking” by increasing speed.

Always brake in due course. If the trailer has an overrun brake, apply the

brakes gently at first and then, firmly. This will prevent the jerking that can

be caused by locking of trailer wheels. Select a low gear in due course be-

fore going down a steep downhill. This enables you to use the engine brak-

ing to slow down the vehicle.

Reheating

At very high temperatures and during prolonged slopes, driving in a low

gear and high engine speed, always monitor the coolant temperature gauge

⇒ page 53.

Electronic Stability Control*

The ESC* system helps to stabilise the trailer in case of skidding or rocking.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 187 of 280

185

Accessories, replacement of parts and modifications

Note

Please observe the operating instructions of your mobile telephone/two-

way radio.

Fitting a towing bracket*

It is possible to fit a towing bracket to the rear of the vehicle.

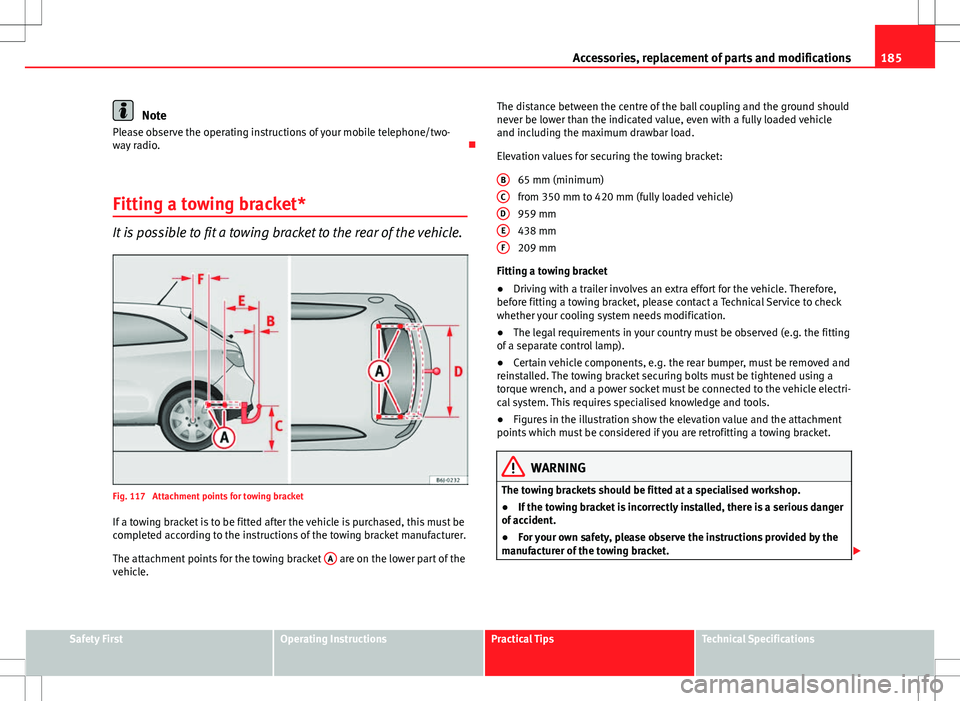

Fig. 117 Attachment points for towing bracket If a towing bracket is to be fitted after the vehicle is purchased, this must be

completed according to the instructions of the towing bracket manufacturer.

The attachment points for the towing bracket A

are on the lower part of the

vehicle. The distance between the centre of the ball coupling and the ground should

never be lower than the indicated value, even with a fully loaded vehicle

and including the maximum drawbar load.

Elevation values for securing the towing bracket:

65 mm (minimum)

from 350 mm to 420 mm (fully loaded vehicle)

959 mm

438 mm

209 mm

Fitting a towing bracket

● Driving with a trailer involves an extra effort for the vehicle. Therefore,

before fitting a towing bracket, please contact a Technical Service to check

whether your cooling system needs modification.

● The legal requirements in your country must be observed (e.g. the fitting

of a separate control lamp).

● Certain vehicle components, e.g. the rear bumper, must be removed and

reinstalled. The towing bracket securing bolts must be tightened using a

torque wrench, and a power socket must be connected to the vehicle electri-

cal system. This requires specialised knowledge and tools.

● Figures in the illustration show the elevation value and the attachment

points which must be considered if you are retrofitting a towing bracket.

WARNING

The towing brackets should be fitted at a specialised workshop.

● If the towing bracket is incorrectly installed, there is a serious danger

of accident.

● For your own safety, please observe the instructions provided by the

manufacturer of the towing bracket.

BCDEF

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 188 of 280

186Accessories, replacement of parts and modifications

CAUTION

● If the power socket is incorrectly installed, this could cause damage to

the vehicle electrical system.

Note

● SEAT recommends that the towing hooks be fitted at a specialised work-

shop. In certain versions this may entail fitting a heat insulating plate,

which is why it is recommended that you go to a SEAT dealership. In the

event that the plate is not installed correctly, SEAT is exempt from any liabil-

ity.

● Due to the specific design of the exhaust, the fitting of a conventional

towing hook is not recommended for some sportier versions. Please consult

your Technical Service.

Page 218 of 280

216If and when

If and when

Vehicle tools, spare wheel

Vehicle Tools

The vehicle tools are located under the floor panel in the

luggage compartment. – Lift luggage compartment floor panel.

– Take the vehicle tools out of the vehicle.

The vehicle tool kit includes:

● Jack*

● Hook to remove integral* trim and screw caps.

● Box spanner for wheel bolts*

● Towline anchorage*

● Adapter for the anti-theft wheel bolts*

Some of the items listed are only provided in certain model versions, or are

optional extras.

WARNING

● The factory-supplied jack is only designed for changing wheels on

this model. On no account attempt to use it for lifting heavier vehicles or

other loads. Risk of injury.

● Use the jack only on a firm, level ground.

WARNING (Continued)

● Never start the engine when the vehicle is on the jack. Risk of acci-

dent.

● If work is to be carried out underneath the vehicle, this must be se-

cured by suitable means. Otherwise, there is a risk of injury.

Spare wheel (temporary spare wheel)*

The spare wheel (temporary spare wheel) must only be used

for the minimum necessary time.

The temporary spare wheel is stored under the floor panel in the luggage

compartment and is attached by a thumbnut.

How to use the temporary spare wheel

If you ever have a punctured tyre or loss of pressure, the temporary spare

wheel is only intended for temporary use until you reach a workshop.

Change it for a duty wheel as soon as possible.

Please note the following restrictions when using the temporary spare

wheel. This temporary spare wheel has been specially designed for your ve-

hicle, thus, it cannot be changed with the temporary spare wheel from an-

other vehicle.

No other type of tyre (normal summer or winter tyre) may be fitted on the

compact temporary spare wheel rim.

Snow chains

For technical reasons, snow chains must not be used on the compact tem-

porary spare wheel.

Page 219 of 280

217

If and when

If you have a puncture on one of the front wheels when using snow chains,

fit the compact temporary spare wheel in place of one of the rear wheels.

You can then attach the snow chains to the wheel taken from the rear and

use this wheel to replace the punctured front wheel.

WARNING

● The tyre pressures must be checked and corrected as soon as possi-

ble after fitting the temporary spare wheel.

● Do not drive faster than 80 km/h (50 mph). Higher speeds can cause

an accident.

● Avoid heavy acceleration, hard braking and fast cornering. Risk of ac-

cident.

● Never use more than one temporary spare wheel at the same time,

risk of accident.

● No other type of tyre (normal summer or winter tyre) may be fitted on

the compact temporary spare wheel rim.

Tyre repair kit*

The tyre repair kit (for vehicles not including a temporary

spare wheel) is stored under the floor panel in the luggage

compartment. In the event of a punctured tyre, your vehicle is equipped with the Tyre Mo-

bility System tyre repair kit.

The tyre repair kit consists of a container with sealing product to repair the

puncture and a compressor to generate the required tyre pressure. The kit

will reliably seal punctures up to a size of about 4 mm caused by the pene-

tration of a foreign body into the tyre.

Note

● Seek professional assistance if the repair of a tyre puncture is not possi-

ble with the sealing product.

Wheel change Preparation work

What you must do before changing a wheel.

– If you have a flat tyre or puncture, park the vehicle as far away

from the flow of traffic as possible. Choose a location that is as

level as possible.

– All vehicle occupants should leave the vehicle. They should

wait in a safe area (for instance behind the roadside crash barri-

er).

– Switch the engine off. Switch the hazard warning lights on and

place the warning triangles in position.

– Apply the handbrake firmly.

– Engage the first gear , or put the selector lever to position P for

those vehicles with an automatic gearbox.

– If you are towing a trailer, unhitch it from your vehicle.

– Take the vehicle tools and the spare wheel out of the luggage

compartment.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 227 of 280

225

If and when

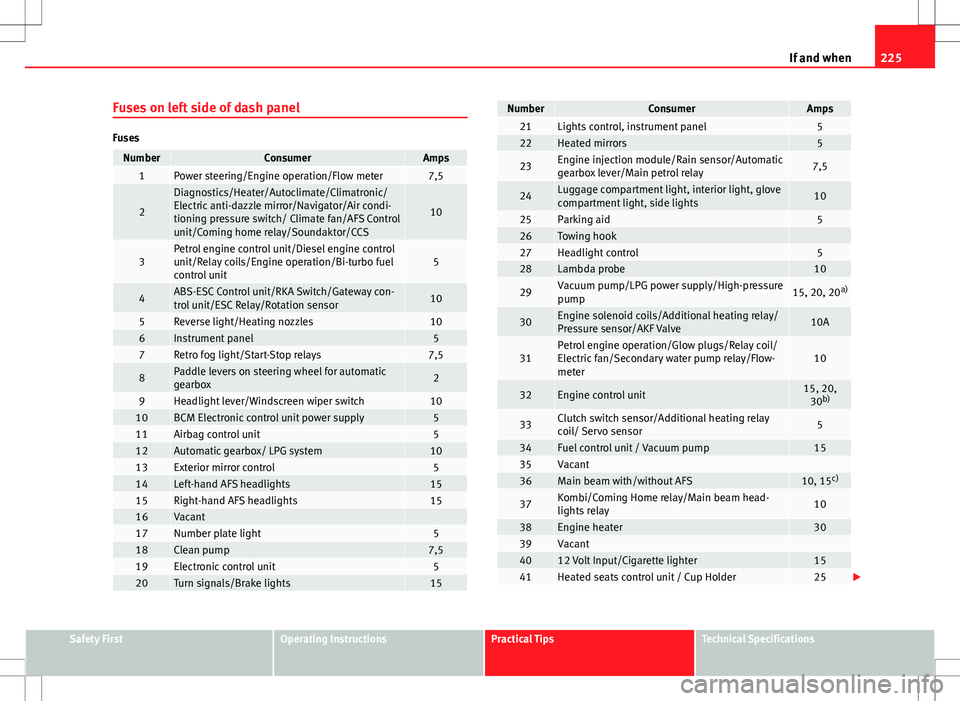

Fuses on left side of dash panel

Fuses

NumberConsumerAmps1Power steering/Engine operation/Flow meter7,5

2

Diagnostics/Heater/Autoclimate/Climatronic/

Electric anti-dazzle mirror/Navigator/Air condi-

tioning pressure switch/ Climate fan/AFS Control

unit/Coming home relay/Soundaktor/CCS

10

3Petrol engine control unit/Diesel engine control

unit/Relay coils/Engine operation/Bi-turbo fuel

control unit5

4ABS-ESC Control unit/RKA Switch/Gateway con-

trol unit/ESC Relay/Rotation sensor10

5Reverse light/Heating nozzles106Instrument panel57Retro fog light/Start-Stop relays7,5

8Paddle levers on steering wheel for automatic

gearbox2

9Headlight lever/Windscreen wiper switch1010BCM Electronic control unit power supply511Airbag control unit512Automatic gearbox/ LPG system1013Exterior mirror control514Left-hand AFS headlights1515Right-hand AFS headlights1516Vacant 17Number plate light518Clean pump7,519Electronic control unit520Turn signals/Brake lights15

NumberConsumerAmps21Lights control, instrument panel522Heated mirrors5

23Engine injection module/Rain sensor/Automatic

gearbox lever/Main petrol relay7,5

24Luggage compartment light, interior light, glove

compartment light, side lights10

25Parking aid526Towing hook 27Headlight control528Lambda probe10

29Vacuum pump/LPG power supply/High-pressure

pump15, 20, 20 a)

30Engine solenoid coils/Additional heating relay/

Pressure sensor/AKF Valve10A

31Petrol engine operation/Glow plugs/Relay coil/

Electric fan/Secondary water pump relay/Flow-

meter10

32Engine control unit15, 20,

30 b)

33Clutch switch sensor/Additional heating relay

coil/ Servo sensor5

34Fuel control unit / Vacuum pump1535Vacant 36Main beam with/without AFS10, 15 c)

37Kombi/Coming Home relay/Main beam head-

lights relay10

38Engine heater3039Vacant 4012 Volt Input/Cigarette lighter1541Heated seats control unit / Cup Holder25

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 230 of 280

228If and when

Xenon 1)

//adaptive headlights*

- D1S2)

- LED 3)

- LED3)

- PY 21W

Fog light - H11

WARNING

● Take particular care when working on components in the engine com-

partment if the engine is warm. Risk of burns.

● Bulbs are highly sensitive to pressure. The glass can break when you

touch the bulb, causing injury.

● The high voltage element of gas discharge bulbs* (xenon light) must

be handled correctly. Otherwise, there is a risk of death.

● When changing bulbs, please take care not to injure yourself on sharp

parts in the headlight housing.

CAUTION

● Remove the ignition key before working on the electric system. Other-

wise, a short circuit could occur.

● Switch off the lights or parking lights before you change a bulb.

Dipped and full beam

Side

DRL (day light)

Turn signals

Fog light/cornering

For the sake of the environment

Please ask your specialist retailer how to dispose of used bulbs in the prop-

er manner.

Note

● Depending on weather conditions (cold or wet), the front lights, the fog

lights, the tail lights and the turn signals may be temporarily misted. This

has no influence on the useful life of the lighting system. By switching on

the lights, the area through which the beam of light is projected will quickly

be demisted. However, the edges may continue to be misted.

● Please check at regular intervals that all lighting (especially the exterior

lighting) on your vehicle is functioning properly. This is not only in the inter-

est of your own safety, but also that of all other road users.

● Before changing a bulb, make sure you have the correct new bulb.

● Do not touch the glass part of the bulb with your bare hands, use a cloth

or paper towel instead. Otherwise, the fingerprints left on the glass will va-

porise as a result of the heat generated by the bulb, they will be deposited

on the reflector and will impair its surface.

1)

With this type of headlight, the user can replace the turn signal bulb. Replacement of the

dipped/main beam bulb must be done by a Technical Service, given that complex elements

must be removed from the vehicle and the automatic control system that incorporates it

must be reset.

2) The Xenon bulbs discharge 2.5 times the light flux and have an average lifespan of 5 times

more than that of halogen bulbs, this means that, except due to unusual circumstances,

there is no need to change the bulbs for the whole life of the vehicle.

3) In the event that there is a fault in the LEDs, the complete headlight must be replaced.