ignition Seat Ibiza ST 2014 Repair Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2014, Model line: Ibiza ST, Model: Seat Ibiza ST 2014Pages: 240, PDF Size: 4.89 MB

Page 160 of 240

Advice

– Rinse the vehicle thoroughly with water.

– Dry the vehicle surface gently with a cha-

mois leather.

– In cold temperature

, dry the rubber seals

and their s

urfaces to prevent them from

freezing. Apply silicone spray to the rubber

seals.

After washing the vehicle – After washing, avoid sudden and sharp

braking. “Dry” the brakes by braking sever-

al times. WARNING

● Wash your vehicle with the ignition switch-

ed off.

● Protect your hands and arms from cuts on

sharp metal edges when cleaning the under-

body, the inside of the wheel housings etc.

Risk of injury.

● Water, ice and salt on the brake system can

reduce braking effectiveness. Risk of acci-

dent. CAUTION

● Never remove dirt, mud or dust if the vehi-

cle surface is dry. Never use a dry cloth or

sponge for cleaning purposes. This could

scratch the paintwork or glass on your vehi-

cle. ●

Washing the vehicle in low temperatures:

when washing the vehicle with a hose, do not

direct water into the lock cylinders or the

gaps around the doors, rear lid, or sunroof.

Risk of freezing. For the sake of the environment

To protect the environment, the vehicle

should be washed only in specially provided

wash bays, to prevent toxic, oil-laden waste

water from entering the sewer system. In

some places, washing vehicles outside wash

bays is prohibited. Note

Do not wash the vehicle in direct sunlight. Washing the vehicle with a high

pressure cleaner

Be particularly careful when using a high

pressure cleaner!

– Always observe the instructions for the

high-pressure cleaner, particularly those

concerning the pressure and the spraying

di s

tance.

– Increase the spraying distance for soft ma-

terials and painted bumpers. –

Do not use a high pressure cleaner to re-

move ice or snow from windows

››› page 159.

– Never u

se concentrated jet nozzles (“rotat-

ing jets”) ››› .

– After washing, avoid sudden and sharp

braking. “Dry” the brakes by braking sever-

al times ››› page 126 . WARNING

● Never wash tyres with a concentrated jet

(“rotating nozzle”). Even at large spraying

distances and short cleaning times, damage

can occur to the tyres. This may cause an ac-

cident.

● Water, ice and salt on the brake system can

reduce braking effectiveness. Risk of acci-

dent. CAUTION

● Do not use water hotter than +60 °C

(+140 °F). This could damage the vehicle.

● To avoid damage to the vehicle, keep a suf-

ficient distance from sensitive materials such

as flexible hoses, plastic, soundproofing ma-

terial, etc. This also applies to bumpers pain-

ted in the colour of the bodywork. The closer

the nozzle is to the surface, the greater the

wear on the material. 158

Page 163 of 240

Care and maintenance

Alloy wheels require regular attention to pre-

serve their appearance. If road salt and brake

dust are not often removed, the aluminium

finish will be impaired.

Always use an acid-free detergent for alloy

wheel rims.

Car polish or other abrasive agents should

not be used for maintaining the rims. If the

protective coating is damaged, e.g. by flying

stones, the damaged area should be re-

paired immediately. WARNING

Observe the safety warnings ››› in Steel

wheel rims on page 160. Underbody protection

The vehicle underbody is coated to protect it

from chemical and mechanical damage.

The protective coating can be damaged when

driving. We recommend that you check the

protective coating under the body and on the

running gear, and retouch it if necessary, be-

fore and after the winter season.

We recommend that you go to your Technical

Service to carry out repair work and addition-

al anti-corrosion work. WARNING

Do not apply underseal or anti-corrosion

coatings to the exhaust pipes, catalytic con-

verter or the heat shields on the exhaust sys-

tem. The heat of the exhaust system or the

engine could cause them to ignite. Risk of

fire. Cleaning the engine compartment

Take special care when cleaning the engine

compartment.

Anti-corrosion treatment

The engine compartment and the surface of

the power unit are given anti-corrosion treat-

ment at the factory.

Good corrosion protection is particularly im-

portant in winter when the vehicle is fre-

quently driven on salted roads. To prevent

the salt corroding the vehicle, the entire en-

gine compartment should be thoroughly

cleaned before and after winter.

Technical Services

have the proper products

for cleaning and preservation as well as the

necessary workshop equipment. For this rea-

son, we recommend having this work per-

formed by them.

The anti-corrosion protection is usually re-

moved if the engine compartment is cleaned

with grease removing solutions, or if you have the engine cleaned. On commissioning

this work, ensure that all surfaces, seams,

joints and components in the engine com-

partment are given anti-corrosion treatment.

WARNING

● When working in the engine compartment,

always observe the safety warnings

››› page 166.

● Bef

ore opening the bonnet, switch the en-

gine off, apply the handbrake firmly and al-

ways remove the key from the ignition.

● Allow the engine to cool before you clean

the engine compartment.

● Do not clean, for example, the vehicle un-

derbody, wheel arches or wheel trims without

protecting your hands and arms. You may cut

yourself on sharp-edged metal parts. Failure

to comply could result in injury.

● Moisture, ice and salt on the brake system

may affect braking effectiveness. Risk of acci-

dent. Directly after washing, avoid sudden

and sharp braking.

● Never touch the radiator fan. It is tempera-

ture-controlled and could start automatically,

even when the key is removed from the igni-

tion! For the sake of the environment

Fuel, grease and oil deposits can be removed

when the engine is washed. The polluted wa-

ter must be cleaned in an oil separator. For

this reason, engine washing should be » 161

Technical specifications

Advice

Operation

Safety

The essentials

Page 166 of 240

Advice

tank is “full”. Never attempt to fill beyond

this point, as this will fill the expansion

chamber. Fuel may leak out if ambient condi-

tions are warm.

The correct fuel grade for your vehicle is giv-

en on a sticker on the inside of the fuel tank

flap. WARNING

● Fuel is highly flammable and can cause se-

rious burns and other injuries.

–Never smoke or come into contact with

sparks when filling the fuel tank of the

vehicle or a spare fuel canister with fuel.

This is an explosion hazard.

– Follow legal requirements for the use of

spare fuel canisters.

– For safety reasons we do not recommend

carrying a spare fuel canister in the vehi-

cle. The canister could be damaged in an

accident and leak.

● If, in exceptional circumstances, you have

to carry a spare fuel canister, please observe

the following:

–Never fill the spare fuel canister inside

the vehicle or on it. An electrostatic

charge could build up during filling, caus-

ing the fuel fumes to ignite. This could

cause an explosion. Always place the

canister on the ground to fill it.

– Insert the fuel nozzle into the mouth of

the canister as far as possible. –

If the spare fuel canister is made of met-

al, the filling nozzle must be in contact

with the canister during filling. This

helps prevent an electrostatic charge

building up.

– Never spill fuel in the vehicle or in the

luggage compartment. Fuel vapours are

explosive. Danger of death. CAUTION

● Fuel spills should be removed from the

paintwork immediately.

● Never run the tank completely dry. Irregular

fuel supply can cause misfiring. As a result,

unburnt fuel could enter the catalytic convert-

er and cause damage.

● When filling the fuel tank after having run it

completely dry on a vehicle with a diesel en-

gine the ignition must be switched on for at

least 30 seconds before starting the engine.

Subsequently, when you start the engine it

may take longer than normal to start firing

(up to one minute). This is due to the fact that

the fuel system has to purge itself of air be-

fore starting. For the sake of the environment

Do not try to put in more fuel after the auto-

matic filler nozzle has switched off; this may

cause the fuel to overflow if it becomes warm. Petrol

Petrol types The correct petrol types are listed on a sticker

inside the fuel tank flap.

Only

unleaded petrol conforming to standard

DIN EN 228 may be used for vehicles with

c at

alytic converters (EN = “European Stand-

ard”).

Types of petrol differ from each other accord-

ing to the octane rating , for example: 91, 95,

98 RON (RON = “R

esearch Octane Number”,

unit for determining the knock resistance of

petrol). You may use petrol with a higher oc-

tane number than the one recommended for

your engine. However, this has no advantage

in terms of fuel consumption and engine

power. CAUTION

● Even one tankful of leaded fuel would per-

manently impair the efficiency of the catalyt-

ic converter.

● High engine speed and full throttle can

damage the engine when using petrol with an

octane rating lower than the correct grade for

the engine. 164

Page 167 of 240

Checking and refilling levels

For the sake of the environment

Just one full tank of leaded fuel would seri-

ously impair the efficiency of the catalytic

converter. Petrol additives

The quality of the fuel influences the behav-

iour, power and service life of the engine.

This is why the petrol you use should carry

suitable additives already included by the

petrol industry, free of metals. These addi-

tives will help to prevent corrosion, keep the

fuel system clean and prevent deposits from

building up in the engine.

If good-quality petrol with metal-free addi-

tives is not available or engine problems

arise, the necessary additives must be added

when refuelling.

Not all petrol additives have been shown to

be effective. The use of unsuitable petrol ad-

ditives may cause significant damage to the

engine and the catalytic converter. Metal ad-

ditives should never be used. Metal additives

may also be contained in petrol additives for

improving anti-detonation ratings or octane

ratings.

SEAT recommends “genuine Volkswagen

Group fuel additives for petrol engines”.

These additives can be bought at SEAT deal- ers, where information on how to use them

can also be obtained. CAUTION

Do not refuel if the filler indicates that the

fuel contains metal. LRP (lead replacement

petrol) fuels contain high concentrations of

metal additives. Using them may damage the

engine! Diesel

Diesel* Diesel fuel

must conform to DIN EN 590 (EN =

“European Standard”). It must have a cetane

number (CN) of at least 51. The cetane num-

ber indicates the ignition quality of the diesel

fuel.

Notes on refuelling ›››

page 163.

Biodiesel* CAUTION

● Your vehicle is not designed to use biodie-

sel fuel. Never, under any circumstances re-

fuel with biodiesel. The use of biodiesel fuel

could damage the engine and the fuel sys-

tem. The addition of biodiesel to diesel fuel

by the diesel manufacturer in accordance with standard EN 590 or DIN 51628 is author-

ised and will not cause damage to the engine

or the fuel system.

● The diesel engine has been designed to be

used exclusively with diesel fuel conforming

to standard EN 590. Never refuel or use pet-

rol, kerosene, fuel oil or any other type of

fuel. If you accidentally fill up the vehicle with the wrong type of fuel, do not start the

engine. Seek assistance from specialised per-

sonnel. The composition of these fuels may

severely damage the fuel system and the en-

gine. Winter operation

Winter-grade diesel

When using “summer-grade diesel fuel”, dif-

ficulties may be experienced at temperatures

below 0 °C (+32 °F) because the fuel thickens

due to wax separation. For this reason, “win-

ter-grade diesel fuel” is available in some

countries during the cold months. It can be

used at temperatures as low as -22 °C (-8 ºF).

In countries with different climatic conditions

the diesel fuel generally sold has different

temperature characteristics. Check with the

Technical Services or filling stations in the

country concerned regarding the type of die-

sel fuels available.

»

165Technical specifications

Advice

Operation

Safety

The essentials

Page 168 of 240

Advice

Filter pre-heater

Your vehicle is fitted with a fuel filter glow

plug system, making it well equipped for op-

eration in winter. This ensures that the fuel

system remains operational to approx. -24 °C

(-11 ºF), provided you use winter-grade die-

sel which is safe to -15 °C (+5 °F).

However, if the fuel has waxed to such an ex-

tent that the engine will not start at tempera-

tures of under -24 °C (-11 °F), simply place

the vehicle in a warm place for a while. CAUTION

Do not mix fuel additives, the so-called “thin-

ners”, or similar additives with diesel fuel. Working in the engine

compartment

Safety instructions on working in the

engine compartment Before starting any work on the engine or in

the engine compartment:

1. Switch off the engine and remove the key

from the ignition.

2. Apply the handbrake.

3. Move the gear lever to neutral or the selec- tor lever to position P. 4. Wait for the engine to cool down.

5. Keep children away from the vehicle.

6. Raise the bonnet

››› page 167.

You should not do any work in the engine

compartment unless you know exactly how to

carry out the jobs and have the correct tools!

Have the work carried out by a specialised

workshop if you are uncertain.

All service fluids and consumables, e.g. cool-

ant, engine oil, spark plugs and batteries,

are under constant development. SEAT pro-

vides a constant flow of information to Tech-

nical Services concerning modifications. For

this reason, we recommend you have service

fluids and consumables replaced by a Techni-

cal Service. Please observe the relevant in-

structions ››› page 155 . The engine compart-

ment of

the vehicle is a hazardous area ››› .

WARNING

All work on the engine or in the engine com-

partment, e.g. checking and refilling fluids,

involves the danger of injury and burns, acci-

dents and even fire.

● Never open the bonnet if you see steam,

smoke or coolant escaping from the engine

compartment. Otherwise, there is a risk of

sustaining burns. Wait until no more steam or

coolant is emitted, then allow the engine to

cool before carefully opening the bonnet. ●

Switch off the engine and remove the key

from the ignition.

● Apply the handbrake and move the gear

lever to neutral or selector lever to position P.

● Keep children away from the vehicle.

● Never touch hot engine parts. There is a

risk of burns.

● Never spill liquids on a hot engine or on a

hot exhaust gas system. This is a fire hazard.

● Avoid causing short-circuits in the electri-

cal system, particularly at the points where

the jump leads are attached ››› page 188. The

battery could explode.

● Never touch the radiator fan. It is tempera-

ture controlled and could start automatically,

even when the engine has been switched off

and the key removed from the ignition!

● Never cover the engine with additional in-

sulating materials such as a blanket. Risk of

fire!

● Do not unscrew the cap on the coolant ex-

pansion tank when the engine is hot. If the

coolant is hot, the cooling system will be

pressurised!

● Protect face, hands and arms by covering

the cap with a large, thick cloth to protect

against escaping coolant and steam.

● Always make sure you have not left any ob-

jects, such as cleaning cloths or tools, in the

engine compartment.

● If you have to work underneath the vehicle,

you must use suitable stands additionally to 166

Page 169 of 240

Checking and refilling levels

support the vehicle, there is a risk of acci-

dent!. A hydraulic jack is insufficient for se-

curing the vehicle and there is a risk of injury.

●

If any work has to be performed when the

engine is started or with the engine running,

there is an additional, potentially fatal, safety

risk from the rotating parts, such as the drive

belts, alternator, radiator fan, etc., and from

the high-voltage ignition system. You should

also observe the following:

– Never touch the electrical wiring of the

ignition system.

– Ensure that jewellery, loose clothing and

long hair do not get trapped in rotating

engine parts. Danger of death. Before

starting any work remove jewellery, tie

back and cover hair, and wear tight-fit-

ting clothes.

– Never accelerate with a gear engaged

without taking the necessary precau-

tions. The vehicle could move, even if the

handbrake is applied. Danger of death.

● If work has to be carried out on the fuel

system or on electrical components, you

must observe the following safety notes in

addition to the above warnings:

– Always disconnect the battery from the

on-board network. The vehicle must be

unlocked when this is done, otherwise

the alarm will be triggered.

– Do not smoke.

– Never work near naked flames.

– Always have a fire extinguisher on hand. CAUTION

When topping up service fluids, make sure

not to mistake them. Using the wrong fluids

could cause serious malfunctions and engine

damage! For the sake of the environment

Service fluids leaks are harmful to the envi-

ronment. For this reason you should make

regular checks on the ground underneath

your vehicle. If you find spots of oil or other

fluids, have your vehicle inspected in a speci-

alised workshop. Opening the bonnet

Read the additional information carefully

››› page 10

The bonnet is released from inside the vehi-

cle.

Before opening the bonnet ensure that the

windscreen wipers are in rest position. WARNING

Hot coolant can scald!

● Never open the bonnet if you see steam,

smoke or coolant escaping from the engine

compartment. ●

Wait until no more steam, smoke or coolant

is emitted from the bonnet, then carefully

open the bonnet.

● When working in the engine compartment,

always observe the safety warnings

››› page 166. Closing the bonnet

–

Slightly lift the bonnet.

– Release the bonnet stay and replace it in its

support.

– At a height of approximately 30 cm let it fall

so it locks.

If the bonnet does not close, do not press

downwards. Open it again and let it fall as

mentioned above. WARNING

If the bonnet is not closed properly, it could

open while you are driving and completely

obscure your view of the road. Risk of acci-

dent.

● After closing the bonnet, always check that

it is properly secured. The bonnet must be

flush with the surrounding body panels.

● If you notice that the bonnet latch is not se-

cured when the vehicle is moving, stop the

vehicle immediately and close the bonnet

properly. Risk of accident. 167Technical specifications

Advice

Operation

Safety

The essentials

Page 177 of 240

Checking and refilling levels

●

Fires, sparks, open flames and smoking are

prohibited. When handling cables and electri-

cal equipment, avoid causing sparks and

electrostatic charge. Never short the battery

terminals. High-energy sparks can cause in-

jury.

● A highly explosive mixture of gases is re-

leased when the battery is under charge. The

batteries should be charged in a well-ventila-

ted room only.

● Keep children away from acid and batteries.

● Before working on the electrical system,

you must switch off the engine, the ignition

and all electrical devices. The negative cable

on the battery must be disconnected. When a

light bulb is changed, you need only switch

off the light.

● Deactivate the anti-theft alarm by unlock-

ing the vehicle before you disconnect the bat-

tery! The alarm will otherwise be triggered.

● When disconnecting the battery from the

vehicle on-board network, disconnect first

the negative cable and then the positive ca-

ble.

● Switch off all electrical devices before re-

connecting the battery. Reconnect first the

positive cable and then the negative cable.

Never reverse the polarity of the connections.

This could cause an electrical fire.

● Never charge a frozen battery, or one which

has thawed. This could result in explosions

and chemical burns. Always replace a battery

which has frozen. A flat battery can also

freeze at temperatures close to 0 °C (+32 °F). ●

Ensure that the vent hose is always connec-

ted to the battery.

● Never use a defective battery. This could

cause an explosion. Replace a damaged bat-

tery immediately.

● For vehicles with the battery in the luggage

compartment: Check that the battery gas

ventilation hose is securely attached. CAUTION

● Never disconnect the battery if the ignition

is switched on or if the engine is running.

This could damage the electrical system or

electronic components.

● Do not expose the battery to direct sunlight

over a long period of time, as the intense ul-

traviolet radiation can damage the battery

housing.

● If the vehicle is left standing in cold condi-

tions for a long period, protect the battery

from “freezing”. If it freezes it will be dam-

aged. Checking the electrolyte level

The electrolyte level should be checked regu-

larly in high-mileage vehicles, in hot coun-

tries and in older batteries.

– Open the bonnet and open the battery cov-

er at the front ››› in Safety instructions

on working in the engine compartment on

page 166

›

›› in Warnings on handlingthe battery on page 174. For vehicles with

the battery under the spare wheel, open

the rear lid and lift the floor covering. The

battery is located next to the spare wheel.

– Check the colour display in the "magic eye"

on the top of the battery.

– If there are air bubbles in the window, tap

the window gently until they disperse.

The position of the battery is shown in the

corresponding engine compartment diagram

››› page 168 . The location of the battery in

the lug g

age compartment can be seen in

››› Fig. 152.

The “magic

eye” indicator, located on the top

of the battery changes colour, depending on

the charge state and electrolyte level of the

battery.

There are two different colours:

● Black: correct charge status.

● Transparent/clear yellow: the battery must

be replaced. Contact a specialised workshop.

Charging and changing the vehicle

battery The battery is maintenance-free and is

checked during the inspection service. All

work on the vehicle battery requires special-

ist knowledge.

»

175

Technical specifications

Advice

Operation

Safety

The essentials

Page 190 of 240

Advice

Check after 10 minutes of driving Screw in the inflator tube

››› Fig. 163 5 again and check the pressure on the gauge

6 .

1.3 bar (19 psi / 130 kPa) and lower:

● Stop the vehicle! The tyre cannot be sealed

sufficiently with the tyre mobility set.

● You should obtain professional assistance

››› .

1.4 bar (20 psi / 140 kPa) and higher:

● Set the tyre pressure to the correct value

again.

● Carefully resume your journey until you

reach the nearest specialised workshop with-

out exceeding 80 km/h (50 mph).

● Have the damaged tyre replaced. WARNING

Driving with an unsealed tyre is dangerous

and can cause accidents and serious injury.

● Do not continue driving if the tyre pressure

is 1.3 bar (19 psi / 130 kPa) and lower.

● Seek specialist assistance. Jump-starting

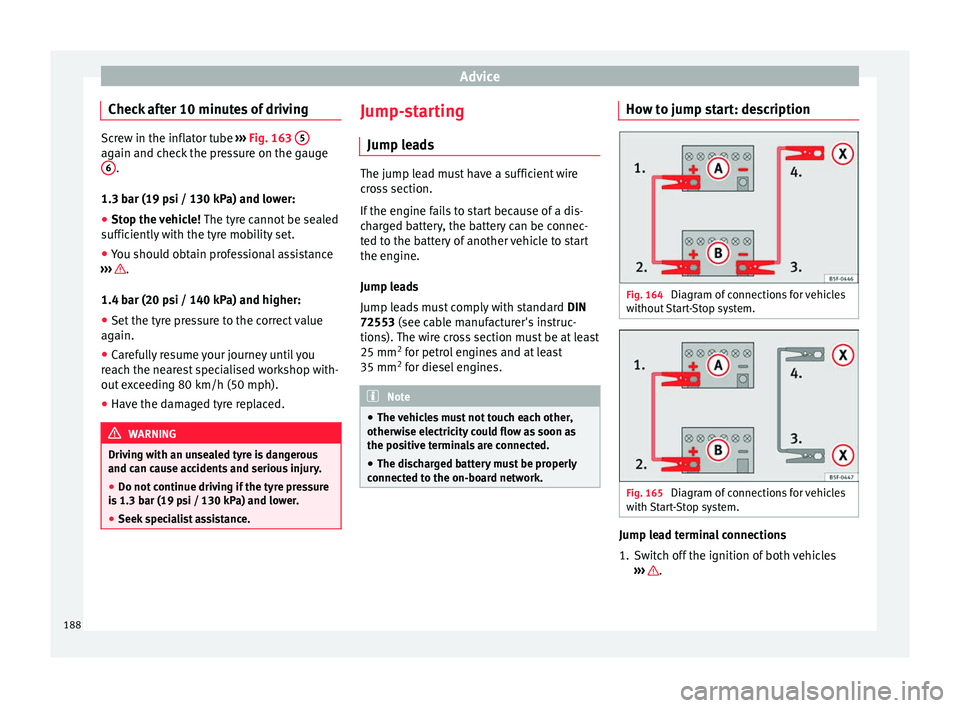

Jump leads The jump lead must have a sufficient wire

cross section.

If the engine fails to start because of a dis-

charged battery, the battery can be connec-

ted to the battery of another vehicle to start

the engine.

Jump leads

Jump leads must comply with standard

DIN

72553 (see cable manufacturer's instruc-

tion s).

The wire cross section must be at least

25 mm 2

for petrol engines and at least

35 mm 2

for diesel engines. Note

● The vehicles must not touch each other,

otherwise electricity could flow as soon as

the positive terminals are connected.

● The discharged battery must be properly

connected to the on-board network. How to jump start: description

Fig. 164

Diagram of connections for vehicles

without Start-Stop system. Fig. 165

Diagram of connections for vehicles

with Start-Stop system. Jump lead terminal connections

1. Switch off the ignition of both vehicles

››› .

188

Page 192 of 240

Advice

Note

The vehicles must not touch each other, oth-

erwise electricity could flow as soon as the

positive terminals are connected. Towing or tow starting

Tow-starting* We recommend that you do

not tow-start your

v ehic

le. Jump-starting is preferable

››› page 188.

Ho w

ever, if your vehicle has to be tow-

started:

– Engage 2 nd

or 3 rd

gear.

– Keep the clutch pressed down.

– Switch the ignition on.

– Once both vehicles are moving, release the

clutch.

– As soon as the engine starts, press the

clutch and move the gear lever into neutral.

This helps to prevent driving into the tow-

ing vehicle. WARNING

The risk of accidents is high when tow-start-

ing. The vehicle being towed can easily col-

lide with the towing vehicle. CAUTION

When tow-starting, fuel could enter the cata-

lytic converter and damage it. Comments

Please observe the following points if you

use a tow rope:

Notes for the driver of the towing vehicle

– Drive slowly at first until the tow rope is

taut. Then accelerate gradually.

– Begin and change gears cautiously. If you

are driving an automatic vehicle, accelerate

gently.

– Remember that the brake servo and power

steering are not working in the vehicle you

are towing. Brake sooner than normal and

pressing the pedal gently.

Notes for the driver of the towed vehicle

– Ensure that the tow rope remains taut at all

times when towing.

Tow rope or tow bar

It is easier and safer for the vehicle to be tow-

ed using a tow bar. You should only use a

tow-rope if you do not have a tow-bar.

A tow rope should be slightly elastic to re-

duce the loading on both vehicles. It is advis- able to use a tow rope made of synthetic fi-

bre or similarly elastic material.

Attach the tow rope or the tow bar only to the

towline anchorages provided or a towing

bracket.

Driving style

Towing requires some experience, especially

when using a tow rope. Both drivers should

be familiar with the technique required for

towing. Inexperienced drivers should not at-

tempt to tow.

Do not pull too hard with the towing vehicle

and take care to avoid jerking the tow rope.

When towing on an unpaved road, there is al-

ways a risk of overloading and damaging the

anchorage points.

The ignition of the vehicle being towed must

be switched on to prevent the steering wheel

from locking and also to allow the use of the

turn signals, horn, windscreen wipers and

washers.

The brake servo only works when the engine

is running. When not running, you must ap-

ply considerably more pressure to the brake

pedal.

As the power assisted steering does not work

if the engine is not running, you will need

more strength to steer than you normally

would.

190

Page 195 of 240

Emergencies

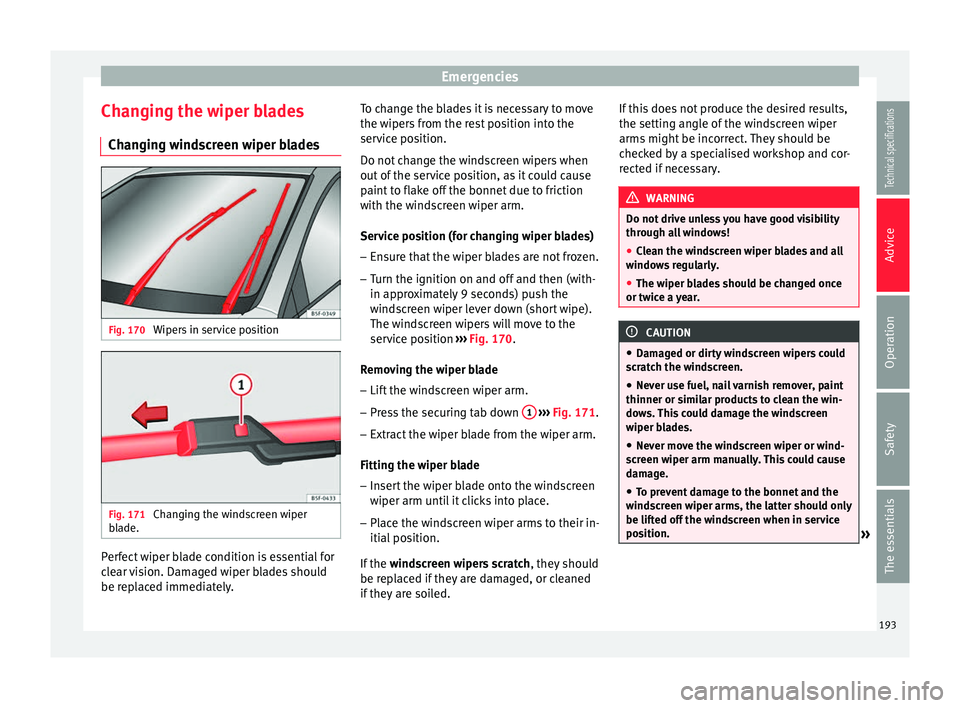

Changing the wiper blades Changing windscreen wiper blades Fig. 170

Wipers in service position Fig. 171

Changing the windscreen wiper

blade. Perfect wiper blade condition is essential for

clear vision. Damaged wiper blades should

be replaced immediately. To change the blades it is necessary to move

the wipers from the rest position into the

service position.

Do not change the windscreen wipers when

out of the service position, as it could cause

paint to flake off the bonnet due to friction

with the windscreen wiper arm.

Service position (for changing wiper blades)

–

Ensure that the wiper blades are not frozen.

– Turn the ignition on and off and then (with-

in approximately 9 seconds) push the

windscreen wiper lever down (short wipe).

The windscreen wipers will move to the

service position ››› Fig. 170 .

R emo

ving the wiper blade

– Lift the windscreen wiper arm.

– Press the securing tab down 1

››› Fig. 171 .

– Extr act

the wiper blade from the wiper arm.

Fitting the wiper blade – Insert the wiper blade onto the windscreen

wiper arm until it clicks into place.

– Place the windscreen wiper arms to their in-

itial position.

If the windscreen wipers scratch , they should

be replaced if they are damaged, or cleaned

if they are soiled. If this does not produce the desired results,

the setting angle of the windscreen wiper

arms might be incorrect. They should be

checked by a specialised workshop and cor-

rected if necessary.

WARNING

Do not drive unless you have good visibility

through all windows!

● Clean the windscreen wiper blades and all

windows regularly.

● The wiper blades should be changed once

or twice a year. CAUTION

● Damaged or dirty windscreen wipers could

scratch the windscreen.

● Never use fuel, nail varnish remover, paint

thinner or similar products to clean the win-

dows. This could damage the windscreen

wiper blades.

● Never move the windscreen wiper or wind-

screen wiper arm manually. This could cause

damage.

● To prevent damage to the bonnet and the

windscreen wiper arms, the latter should only

be lifted off the windscreen when in service

position. » 193

Technical specifications

Advice

Operation

Safety

The essentials