maintenance Seat Leon 5D 2006 Maintenance programme

[x] Cancel search | Manufacturer: SEAT, Model Year: 2006, Model line: Leon 5D, Model: Seat Leon 5D 2006Pages: 292, PDF Size: 8.86 MB

Page 219 of 292

Checking and refilling levels217

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

WARNING

There is a serious danger of accidents if a tyre bursts during driving!•

The tyres must be replaced at the latest when the tread is worn down to

the tread wear indicators. Failure to do so could result in an accident. Worn

tyres do not grip well at high speeds on wet roads. There is also a greater

risk of “aquaplaning”.

•

At continuously high speeds, a tyre with insufficient pressure flexes

more. This causes it to overheat. This can cause tread separation and tyre

blow-out. Risk of accident. Always observe the recommended tyre pres-

sures.

•

If tyres show excessive wear, you should have the running gear checked

by an Authorised Service Centre.

•

Keep chemicals such as oil, fuel and brake fluid away from tyres.

•

Damaged wheels and tyres must be replaced immediately!For the sake of the environment

Under-inflated tyres will increase fuel consumption.Puncture-proof tyres*

Puncture-proof tyres will usually allow the vehicle to continue

even when one of the tyres has a puncture.Vehicles that are factory-fitted with puncture-proof tyres

20)

indicate

on the instrument panel when there is a loss of tyre pressure. Driving on puncture-proof tyres (emergency use)

– Leave the ESP/TCS (electronic stabilisation programme)

switched on, or switch on.

– Drive carefully and at moderate speed (80 km/h maximum).

– Avoid sharp turns and rapid manouevres.

– Avoid driving over obstacles (for example, kerbs) or potholes.

– If the ESP/TCS is frequently activated, check whether there is smoke coming from the tyres or a smell of rubber, or if the vehicle

vibrates or rattles. If this is the case, stop the vehicle.

Puncture-proof tyres are marked on the tyre wall as follows: “DSST”,

“Eufonia”, “RFT”, “ROF”, “RSC”, “SSR” or “ZP”.

The tyre walls of this type of tyre are reinforced. When the tyres lose air, the

tyre walls keep the tyre up (emergency use).

Loss of air pressure in the tyre is shown on the instrument panel. The vehicle

may still be driven for at least 80 km and, under ideal conditions (for example,

no load) further.

The faulty tyre should be replaced as soon as possible. The tyre rim should be

checked for damage at a specialised workshop and replaced as necessary.

We recommend you contact your Authorised Service Centre. If more than one

tyre is being used under emergency co nditions, this reduces the distance

which can be travelled.

Starting driving in emergency conditions

When the loss in tyre pressure is displayed on the instrument panel, this

implies that at least one tyre is being driven in emergency conditions ⇒.

End of emergency operation

Do not drive on if:

20)Depending upon version and country.

leon_ingles Seite 217 Donnerstag, 24. August 2006 1:56 13

Page 221 of 292

Checking and refilling levels219

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

WARNING

•

We recommend that you use only wheels and tyres that have been

approved by SEAT for your model. Fa ilure to do so could impair vehicle

handling. Risk of accident.

•

Avoid running the vehicle on tyres that are more than six years old. If

you have no alternative, you should drive slowly and with extra care at all

times.

•

Never use old tyres or those with an unknown “history of use”.

•

If wheel trims are retrofitted, you must ensure that the flow of air to the

brakes is not restricted. This could cause them to overheat.

•

All four wheels must be fitted with radial tyres of the same type, size

(rolling circumference) and the same tread pattern.For the sake of the environment

Old tyres must be disposed of according to the laws in the country concerned.

Note

•

For technical reasons, it is not generally possible to use the wheels from

other vehicles. This can also apply to wheels of the same model. The use of

wheels or tyres which have not been approved by SEAT for use with your

model may invalidate the vehicle's type approval for use on public roads.

•

If the spare tyre is not the same as the tyres that are mounted on the

vehicle - for example with winter tyres - you should only use the spare tyre for

a short period of time and drive with extra care. Refit the normal road wheel

as soon as possible.

Wheel bolts

Wheel bolts must be tightened to the correct torque.The design of wheel bolts is matched to the rims. If different wheel rims are

fitted, the correct wheel bolts with the right length and correctly shaped bolt

heads must be used. This ensures that wheels are fitted securely and that the

brake system functions correctly.

In certain circumstances, you may not use wheel bolts from a different car -

even if it is the same model ⇒page 191.

WARNING

If the wheel bolts are not tightened correctly, the wheel could become

loose while driving. Risk of accident.•

The wheel bolts must be clean and turn easily. Never apply grease or oil

to them.

•

Use only wheel bolts which belong to the wheel.

•

If the prescribed torque of the wheel bolts is too low, they could loosen

whilst the vehicle is in motion. Risk of accident! If the tightening torque is

too high, the wheel bolts and threads could be damaged.Caution

The prescribed torque for wheel bolts for steel and alloy wheels is 120 Nm.

leon_ingles Seite 219 Donnerstag, 24. August 2006 1:56 13

Page 223 of 292

Checking and refilling levels221

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

Note

In some countries, the speed limit for using snow chains is 50 km/h. The legal

requirements of the country should be followed.

leon_ingles Seite 221 Donnerstag, 24. August 2006 1:56 13

Page 225 of 292

If and when223

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

Compact temporary spare wheel*

The compact temporary spare wheel (spare wheel for vehicles

with no puncture repair kit) should only be used when really

necessary.The temporary spare wheel is stored under the floor panel in the luggage

compartment and is attached by a thumbnut.

How to use the compact temporary spare wheel

Should you ever have a punctured tyre, the compact temporary spare wheel

is only intended for temporary use until you can reach a workshop. The

standard-size road wheel should be replaced as soon as possible.

Please note the following restrictions when using the compact temporary

spare wheel. This spare wheel has been specially designed for your vehicle,

thus, it cannot be changed with th e spare wheel from another vehicle.

No other type of tyre (normal summer or winter tyre) may be fitted on the

compact temporary spare wheel rim. Snow chains

For technical reasons, snow chains must not

be used on the compact tempo-

rary spare wheel.

If you should have a puncture on one of the front wheels when using snow

chains, fit the compact temporary spare in place of one of the rear wheels.

You can then attach the snow chains to the wheel taken from the rear and use

this wheel to replace the punctured front wheel.

WARNING

•

The tyre pressures must be checked and corrected as soon as possible.

The tyre pressure for the spare wheel is 4.2 bar. Failure to do so could result

in an accident.

•

Do not drive faster than 80 km/h. High er speeds can cause an accident.

•

Avoid heavy acceleration, hard braking and fast cornering, risk of acci-

dent.

•

Never use two or more compact spare tyres at the same time, risk of

accident.

•

No other type of tyre (normal summer or winter tyre) may be fitted on

the compact temporary spare wheel rim.Note

•

Emergency wheels must never be used on vehicles fitted with Brembo

brakes. These vehicles are supplied with a tyre repair kit.

Tyre repair kit*

The tyre repair kit (for vehicles not including a spare wheel) is

stored under the floor panel in the luggage compartment.Your vehicle is equipped with the Tyre Mobility System “Tyre repair kit”.

Fig. 153 Luggage

compartment. Access to

the spare wheel

leon_ingles Seite 223 Donnerstag, 24. August 2006 1:56 13

Page 227 of 292

If and when225

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

– Tighten the wheel bolts firmly in diagonal sequence with the box

spanner

–Replace the hub cap.After changing a wheel

After changing the wheel there are still tasks to complete.– Put the tools and jack back in the luggage compartment.

– Place the wheel with the defective tyre in the luggage compart-

ment and secure it.

– Check the tyre pressure of the newly fitted tyre as soon as

possible.

– Have the tightening torque of the wheel bolts checked as soon as possible with a torque wrench. The prescribed torque is 120 Nm.

Note•

If you notice that the wheel bolts are corroded and difficult to turn when

changing a wheel, they must be replaced before having the wheel bolt torque

checked.

•

In the interest of safety, drive at moderate speeds until the wheel bolt

torque has been checked.

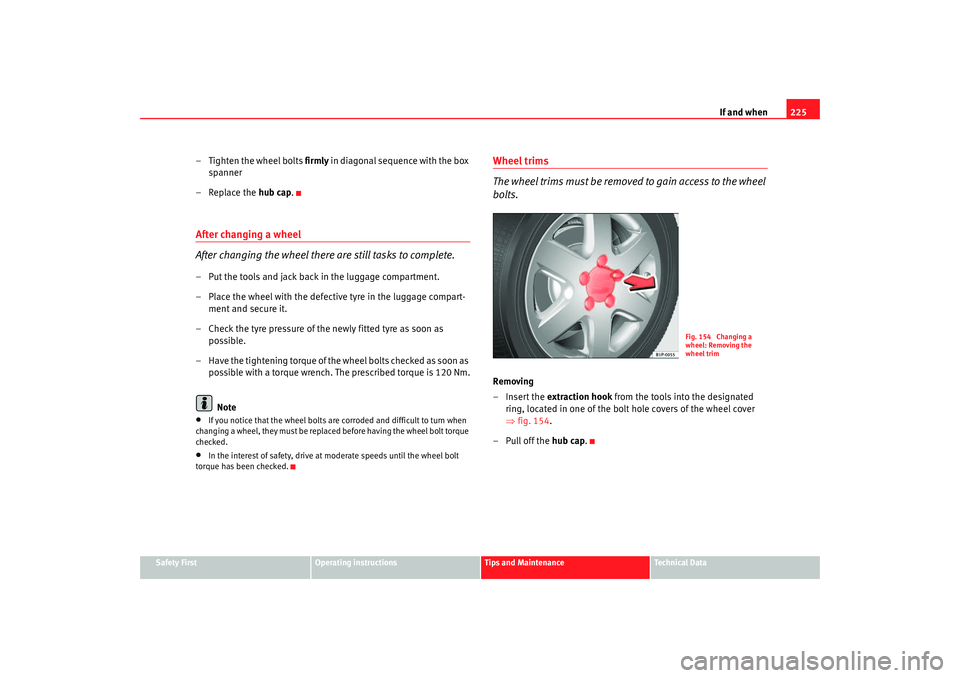

Wheel trims

The wheel trims must be removed to gain access to the wheel

bolts.Removing

–Insert the extraction hook from the tools into the designated ring, located in one of the bolt hole covers of the wheel cover

⇒fig. 154.

–Pull off the hub cap .

Fig. 154 Changing a

wheel: Removing the

wheel trim

leon_ingles Seite 225 Donnerstag, 24. August 2006 1:56 13

Page 229 of 292

If and when227

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

WARNING

Loosen the wheel bolts only about one tu rn before raising the vehicle with

the jack, loosening the wheel bolts more than one turn can result in an acci-

dent.

Note

•

Do not use the hexagonal socket in th e screwdriver handle to loosen or

tighten the wheel bolts.

•

If the wheel bolt is very tight, you may be able to loosen it by pushing

down the end of the spanner carefully with your foot. Hold on to the vehicle

for support and take care not to slip.

leon_ingles Seite 227 Donnerstag, 24. August 2006 1:56 13

Page 231 of 292

If and when229

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

Removing and fitting the wheel

For removing and fitting the wheel, the following tasks must

be completed.Change the wheel as described below after loosening the wheel

bolts and raising the vehicle with the jack.

Removing a wheel

– Unscrew the bolts using the hexagonal tool in the handle of the

screwdriver (vehicle tool) and place them on a clean surface

⇒ fig. 158 .

Fitting a wheel

– Screw in the wheel bolts and tighten them lightly using the hexagonal socket in the screwdriver handle.

The wheel bolts should be clean and turn easily. Before fitting the spare

wheel, inspect the condition of the wheel and hub mounting surfaces. These

surfaces must be clean before fitting the wheel.

The hexagonal socket in the screwdriver handle makes it easier to turn the

wheel bolts when they are loose. The reversible screwdriver blade should be

removed when the tool is used for this purpose.

If tyres with a specific direction of ro tation are fitted, note the direction of

rotation.

Note

Do not use the hexagonal socket in the screwdriver handle to loosen or

tighten the wheel bolts.Anti-theft wheel bolts

A special adapter is required to turn the anti-theft wheel

bolts.

Fig. 158 Wheel change:

Hexagon socket in screw-

driver handle to turn the

wheel bolts after they

have been loosened

Fig. 159 Anti-theft wheel

bolt

leon_ingles Seite 229 Donnerstag, 24. August 2006 1:56 13

Page 233 of 292

If and when231

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

Note

Seek professional assistance if the repair of a tyre puncture is not possible

with the sealing compound.Preparation work

What you must do before changing a wheel.– If you have a flat tyre or puncture, park the vehicle as far away

from the flow of traffic as possible.

–Apply the handbrake firmly.

–Engage the first gear, or put the selector lever to position P for

those vehicles with an automatic gearbox.

– All passengers must leave the vehicle. They should wait in a safe

area (for instance behind the roadside crash barrier).

– Check whether the puncture can be mended using the Tyre Mobility System “General observations and safety advice.”

– Unscrew cap from the valve of the affected wheel.

–Take the tyre repair kit from the luggage compartment.

WARNING

Put the hazard warning lights on and place the warning triangle in position.

This is for your own safety and also warns other road users.

Caution

Take the utmost caution when repairing a flat tyre on a gradient.

Note

Please observe legal requirements when doing so.Repairing the puncture

To repair the puncture, once the preliminary tasks are done,

follow these steps.Apply the sealant

– The instructions for using the sealant correctly are on the pack-

aging

Inflate the tyres.

– Remove the compressor and hose.

– Tighten the fastening nut onto the tyre valve.

– Connect the compressor power supply to the 12 Volt socket.

– Connect the compressor and chec k the tyre pressure with the

pressure gauge.

Finish the repair

– Remove the compressor hose from the valve.

– Check the cap on the tyre valve.

– Disconnect the compressor from the vehicle mains.

leon_ingles Seite 231 Donnerstag, 24. August 2006 1:56 13

Page 235 of 292

If and when233

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

– Take the plastic clip from inside the fuse cover (at left-hand end

of the dash panel), fit it onto the blown fuse and pull the fuse out.

– Replace the blown fuse (which will have a melted metal strip) with a new fuse of the same ampere rating.

– Carefully fit the fuse cover back on to ensure no water can enter the fuse box.The individual electrical circuits are pr otected by fuses. The fuses are located

behind a cover at the left-hand end of the dash panel and on the left-hand

side of the engine compartment.

The electric windows are protected by circuit breakers. These reset automat-

ically after a few seconds when the overload (caused for example by frozen

windows) has been corrected.

Colour coding of fuses

WARNING

Never “repair” damaged fuses and never replace them with fuses with a

higher rating. Failure to comply could re sult in fire. This could also cause

damage to other parts of the electrical system.

Note

•

If a newly replaced fuse blows again after a short time, the electrical

system must be checked by a qualified workshop as soon as possible.

•

If you replace a fuse with a stronger fuse, you could cause damage to

another location in the electrical system.

•

Always keep some spare fuses in the vehicle. These are available from

SEAT dealers.

Colour

Amperes

light brown 5

red 10

blue 15

yellow 20

natural (white) 25

green 30

orange 40

red 50

white 80

blue100

grey 150

violet 200

Colour

Amperes

leon_ingles Seite 233 Donnerstag, 24. August 2006 1:56 13

Page 237 of 292

If and when235

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

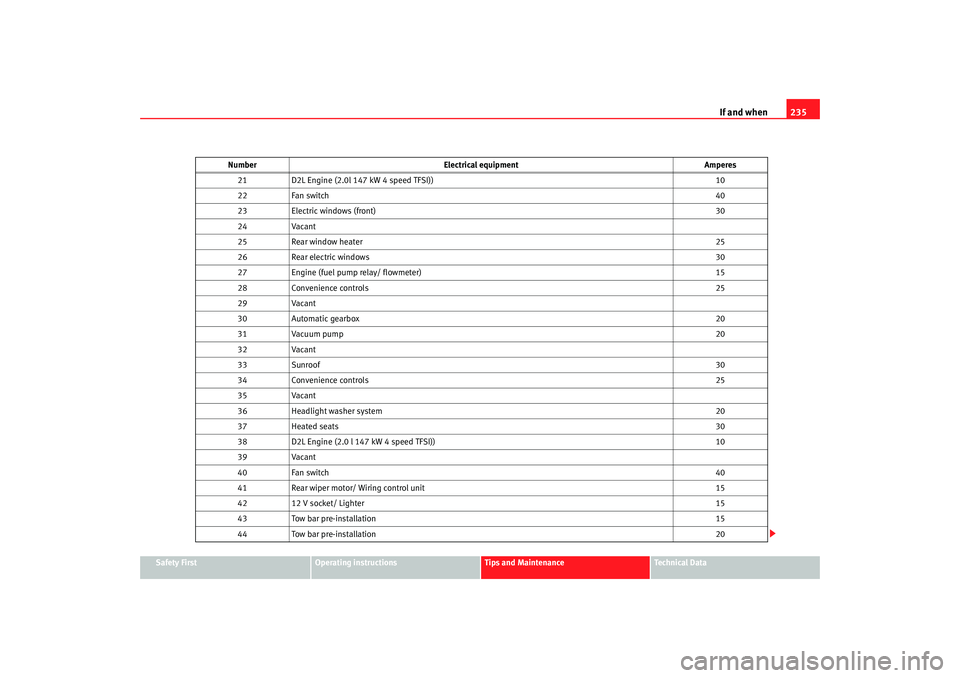

21

D2L Engine (2.0l 147 kW 4 speed TFSI)) 10

22 Fan switch 40

23 Electric windows (front) 30

24 Vacant

25 Rear window heater 25

26 Rear electric windows 30

27 Engine (fuel pump relay/ flowmeter) 15

28 Convenience controls 25

29 Vacant

30 Automatic gearbox 20

31 Vacuum pump 20

32 Vacant

33 Sunroof 30

34 Convenience controls 25

35 Vacant

36 Headlight washer system 20

37 Heated seats 30

38 D2L Engine (2.0 l 147 kW 4 speed TFSI)) 10

39 Vacant

40 Fan switch 40

41 Rear wiper motor/ Wiring control unit 15

42 12 V socket/ Lighter 15

43 Tow bar pre-installation 15

44 Tow bar pre-installation 20

Number

Electrical equipment Amperes

leon_ingles Seite 235 Donnerstag, 24. August 2006 1:56 13