Seat Leon 5D 2006 Maintenance programme

Manufacturer: SEAT, Model Year: 2006, Model line: Leon 5D, Model: Seat Leon 5D 2006Pages: 292, PDF Size: 8.86 MB

Page 221 of 292

Checking and refilling levels219

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

WARNING

•

We recommend that you use only wheels and tyres that have been

approved by SEAT for your model. Fa ilure to do so could impair vehicle

handling. Risk of accident.

•

Avoid running the vehicle on tyres that are more than six years old. If

you have no alternative, you should drive slowly and with extra care at all

times.

•

Never use old tyres or those with an unknown “history of use”.

•

If wheel trims are retrofitted, you must ensure that the flow of air to the

brakes is not restricted. This could cause them to overheat.

•

All four wheels must be fitted with radial tyres of the same type, size

(rolling circumference) and the same tread pattern.For the sake of the environment

Old tyres must be disposed of according to the laws in the country concerned.

Note

•

For technical reasons, it is not generally possible to use the wheels from

other vehicles. This can also apply to wheels of the same model. The use of

wheels or tyres which have not been approved by SEAT for use with your

model may invalidate the vehicle's type approval for use on public roads.

•

If the spare tyre is not the same as the tyres that are mounted on the

vehicle - for example with winter tyres - you should only use the spare tyre for

a short period of time and drive with extra care. Refit the normal road wheel

as soon as possible.

Wheel bolts

Wheel bolts must be tightened to the correct torque.The design of wheel bolts is matched to the rims. If different wheel rims are

fitted, the correct wheel bolts with the right length and correctly shaped bolt

heads must be used. This ensures that wheels are fitted securely and that the

brake system functions correctly.

In certain circumstances, you may not use wheel bolts from a different car -

even if it is the same model ⇒page 191.

WARNING

If the wheel bolts are not tightened correctly, the wheel could become

loose while driving. Risk of accident.•

The wheel bolts must be clean and turn easily. Never apply grease or oil

to them.

•

Use only wheel bolts which belong to the wheel.

•

If the prescribed torque of the wheel bolts is too low, they could loosen

whilst the vehicle is in motion. Risk of accident! If the tightening torque is

too high, the wheel bolts and threads could be damaged.Caution

The prescribed torque for wheel bolts for steel and alloy wheels is 120 Nm.

leon_ingles Seite 219 Donnerstag, 24. August 2006 1:56 13

Page 222 of 292

Checking and refilling levels

220Winter tyres

Winter tyres will improve the vehicles handling on snow and

ice.In winter conditions winter tyres will considerably improve the vehicles

handling. The design of summer tyres (width, rubber compound, tread

pattern) gives less grip on ice and snow.

Winter tyres must be inflated to a pressure 0.2 bar higher than the pressures

specified for summer tyres (see sticker on tank flap).

Winter tyres must be fitted on all four wheels.

Information on permitted winter tyre sizes can be found in the vehicle's regis-

tration documents. Use only radial winter tyres. All tyre sizes listed in the

vehicle documentation also apply to winter tyres.

Winter tyres lose their effectiveness when the tread is worn down to a depth

of 4 mm.

The speed rating code ⇒page 218, “New tyres and wheels” determines the

following speed limits ⇒ :

Q max. 160 km/h

S max. 180 km/h

T max. 190 km/h

H max. 210 km/h

In some countries, vehicles which can exceed the speed rating of the fitted

tyre must have an appropriate sticker in the driver's field of view. These

stickers are available from your Authorised Service Centre. The legal require-

ments of each country must be followed.

Do not have winter tyres fitted for unnecessarily long periods. Vehicles with

summer tyres handle better when the roads are free of snow and ice.

If you have a flat tyre, please refer to the notes on the spare wheel

⇒ page 218, “New tyres and wheels”.

WARNING

The maximum speed for the winter tyres must not be exceeded. Otherwise,

this could lead to tyre damage and thus, an accident risk.

For the sake of the environment

Fit your summer tyres in good time. They are quieter, do not wear so quickly

and reduce fuel consumption.Snow chainsSnow chains may be fitted only to the front wheels, and only to certain tyre

sizes ⇒page 258.

Snow chains must have fine-pitch link s which do not protrude more that 9

mm, including tension device.

Remove wheel hub covers and trim rings before fitting snow chains. For safety

reasons cover caps, available in any Authorised Service Centre, must then be

fitted over the wheel bolts.

WARNING

Observe the fitting instructions provided by the snow chain manufacturer.

Caution

You must remove the snow chains to drive on roads which are free of snow.

Otherwise they will impair handling, damage the tyres and wear out very

quickly.

leon_ingles Seite 220 Donnerstag, 24. August 2006 1:56 13

Page 223 of 292

Checking and refilling levels221

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

Note

In some countries, the speed limit for using snow chains is 50 km/h. The legal

requirements of the country should be followed.

leon_ingles Seite 221 Donnerstag, 24. August 2006 1:56 13

Page 224 of 292

If and when

222If and whenTools, tyre repair kit and spare wheelVehicle To ols

The vehicle onboard tools are located under the floor panel in

the luggage compartment .– Lift the cover of the luggage compartment, by pulling it up with a

finger in the fitting.

– Take the onboard tools out of the vehicle.The tool kit includes:•

Jack*

•

Hook for removing wheel covers* or hub caps*

•

Box spanner for wheel bolts*

•

Reversible screwdriver with handle (including hexagonal interior) for the

wheel bolts. The screwdriver is a combination tool.

•

To wi ng e ye

•

Adapter for the anti-theft wheel bolts*

Some of the items listed are only prov ided on certain models / model years,

or are optional extras.

WARNING

•

Do not use the hexagonal socket in the screwdriver handle to tighten

the wheel bolts. It is impossible to tighten the bolts with the torque

required, risk of accident.

•

The jack* supplied by the factory is only designed for changing wheels

on this model. On no account attempt to use it for lifting heavier vehicles

or other loads, risk of injury.

•

Use the jack* only on firm, level ground.

•

Never start the engine when the vehicle is on the jack, risk of accident.

•

I f wo r k is t o b e ca r r i e d o u t un d e r n ea th the vehicle, this must be secured

by suitable stands. Otherwise, there is a risk of injury.WARNING (continued)

leon_ingles Seite 222 Donnerstag, 24. August 2006 1:56 13

Page 225 of 292

If and when223

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

Compact temporary spare wheel*

The compact temporary spare wheel (spare wheel for vehicles

with no puncture repair kit) should only be used when really

necessary.The temporary spare wheel is stored under the floor panel in the luggage

compartment and is attached by a thumbnut.

How to use the compact temporary spare wheel

Should you ever have a punctured tyre, the compact temporary spare wheel

is only intended for temporary use until you can reach a workshop. The

standard-size road wheel should be replaced as soon as possible.

Please note the following restrictions when using the compact temporary

spare wheel. This spare wheel has been specially designed for your vehicle,

thus, it cannot be changed with th e spare wheel from another vehicle.

No other type of tyre (normal summer or winter tyre) may be fitted on the

compact temporary spare wheel rim. Snow chains

For technical reasons, snow chains must not

be used on the compact tempo-

rary spare wheel.

If you should have a puncture on one of the front wheels when using snow

chains, fit the compact temporary spare in place of one of the rear wheels.

You can then attach the snow chains to the wheel taken from the rear and use

this wheel to replace the punctured front wheel.

WARNING

•

The tyre pressures must be checked and corrected as soon as possible.

The tyre pressure for the spare wheel is 4.2 bar. Failure to do so could result

in an accident.

•

Do not drive faster than 80 km/h. High er speeds can cause an accident.

•

Avoid heavy acceleration, hard braking and fast cornering, risk of acci-

dent.

•

Never use two or more compact spare tyres at the same time, risk of

accident.

•

No other type of tyre (normal summer or winter tyre) may be fitted on

the compact temporary spare wheel rim.Note

•

Emergency wheels must never be used on vehicles fitted with Brembo

brakes. These vehicles are supplied with a tyre repair kit.

Tyre repair kit*

The tyre repair kit (for vehicles not including a spare wheel) is

stored under the floor panel in the luggage compartment.Your vehicle is equipped with the Tyre Mobility System “Tyre repair kit”.

Fig. 153 Luggage

compartment. Access to

the spare wheel

leon_ingles Seite 223 Donnerstag, 24. August 2006 1:56 13

Page 226 of 292

If and when

224The tyre repair kit consists of a container with sealing compound to repair the

puncture and a compressor to generate the required tyre pressure. The kit will

reliably seal punctures up to a size of about 4 mm caused by the penetration

of a foreign body into the tyre.

Note

•

Seek professional assistance if the repair of a tyre puncture is not

possible with the sealing compound.

Wheel changePreparation work

What you must do before changing a wheel.– If you have a flat tyre or puncture, park the vehicle as far away from the flow of traffic as possible. Choose a location that is as

level as possible.

– All passengers should leave the ve hicle. They should wait in a

safe area (for instance behind the roadside crash barrier).

– Switch off the engine. Switch on the hazard warning lights.

–Apply the handbrake firmly.

– Engage the first gear, or put the selector lever to position P for

those vehicles with an automatic gearbox.

– If you are towing a trailer, unhitch it from your vehicle. –Take the

vehicle tools and the spare wheel out of the luggage

compartment.

WARNING

Put the hazard warning lights on and place the warning triangle in position.

This is for your own safety and also warns other road users.

Caution

If you have to change the wheel on a gradient, block the wheel opposite the

wheel being changed by placing a stone or similar object under it to prevent

the vehicle from rolling away.

Note

Please observe legal requirements when doing so.Changing a wheelChange the wheel as described below

–Pull off the hub cap. See ⇒ page 225, fig. 154.

– Slacken the wheel bolts

– Raise the car with the jack in the corresponding zone

– Ta k e o f f the wheel and then put on the spare wheel

– Lower the vehicle.

leon_ingles Seite 224 Donnerstag, 24. August 2006 1:56 13

Page 227 of 292

If and when225

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

– Tighten the wheel bolts firmly in diagonal sequence with the box

spanner

–Replace the hub cap.After changing a wheel

After changing the wheel there are still tasks to complete.– Put the tools and jack back in the luggage compartment.

– Place the wheel with the defective tyre in the luggage compart-

ment and secure it.

– Check the tyre pressure of the newly fitted tyre as soon as

possible.

– Have the tightening torque of the wheel bolts checked as soon as possible with a torque wrench. The prescribed torque is 120 Nm.

Note•

If you notice that the wheel bolts are corroded and difficult to turn when

changing a wheel, they must be replaced before having the wheel bolt torque

checked.

•

In the interest of safety, drive at moderate speeds until the wheel bolt

torque has been checked.

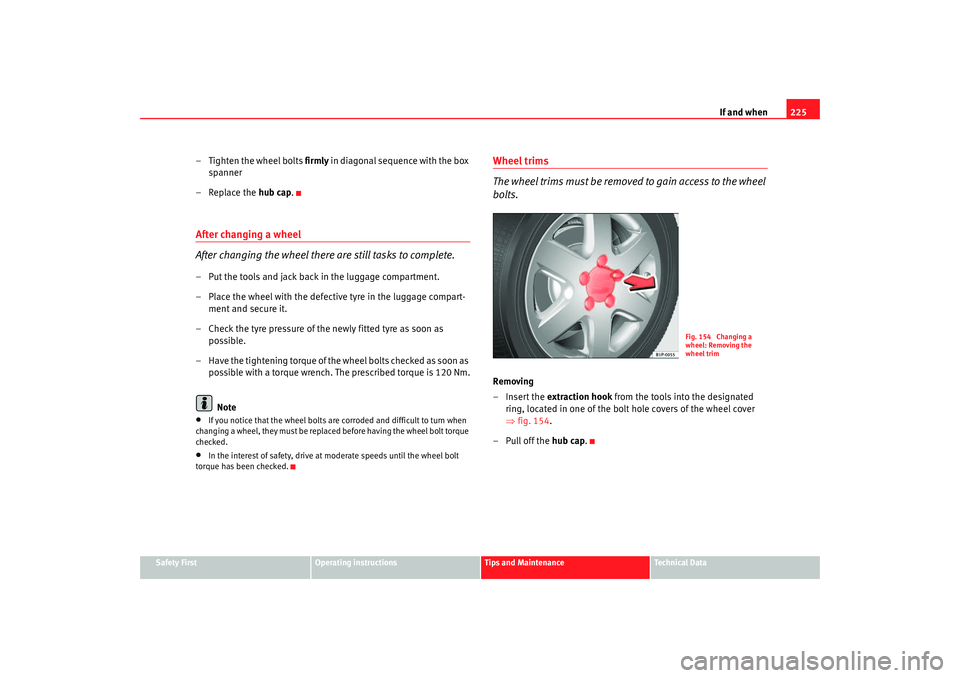

Wheel trims

The wheel trims must be removed to gain access to the wheel

bolts.Removing

–Insert the extraction hook from the tools into the designated ring, located in one of the bolt hole covers of the wheel cover

⇒fig. 154.

–Pull off the hub cap .

Fig. 154 Changing a

wheel: Removing the

wheel trim

leon_ingles Seite 225 Donnerstag, 24. August 2006 1:56 13

Page 228 of 292

If and when

226Wheel covers*

The wheel covers must be removed for access to the wheel

boltsRemoving

– Remove the wheel cover using the wire hook.

– Hook this into one of the cut-outs of the wheel cover.

Fitting

– Fit the wheel cover onto the wheel rim by pressing it firmly. Put

pressure initially on the point of the cut out for the valve. Then

press the wheel cover onto the steel rim so that it engages all

round.

Loosening the wheel bolts

The wheel bolts must be loosened before raising the vehicle.Loosening

–Fit the box spanner as far as it will go over the wheel bolt.

– Grasp the box spanner by the end and turn it about one full turn to

the left ⇒ fig. 155 .

Tigh tening

– Fit the box spanner as far as it will go over the wheel bolt.

– Grasp the box spanner close to the end and turn the bolt to the right until it is secured.

– An adapter is required to unscrew or tighten the anti-theft wheel bolts.

Fig. 155 Changing the

wheel: Loosening the

wheel bolts

leon_ingles Seite 226 Donnerstag, 24. August 2006 1:56 13

Page 229 of 292

If and when227

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

WARNING

Loosen the wheel bolts only about one tu rn before raising the vehicle with

the jack, loosening the wheel bolts more than one turn can result in an acci-

dent.

Note

•

Do not use the hexagonal socket in th e screwdriver handle to loosen or

tighten the wheel bolts.

•

If the wheel bolt is very tight, you may be able to loosen it by pushing

down the end of the spanner carefully with your foot. Hold on to the vehicle

for support and take care not to slip.

leon_ingles Seite 227 Donnerstag, 24. August 2006 1:56 13

Page 230 of 292

If and when

228Raising the vehicle

The vehicle must be raised with a jack to remove the wheel.

– Locate the jacking point under the door sill closest to the wheel

being changed ⇒fig. 156.

– Wind up the jack under the jacking point until the arm of the jack is directly below the vertical rib under the door sill.

– Align the jack so that the arm of the jack fits around the rib under the door sill and the movable base plate of the jack is flat on the

ground ⇒fig. 157.

– Raise the vehicle until the defective wheel is just clear of the ground.Recesses at the front and rear of the door sills mark the jacking points

⇒fig. 156. A position has been made for each wheel. Do not fit the jack

anywhere else.

An unstable surface under the jack may cause the vehicle to slip off the jack.

Therefore, the jack must be fitted on solid ground offering good support. Use

a large and stable base, if necessary. On a hard, slippery surface (such as

tiles) use a rubber mat or similar to prevent the jack from slipping.

WARNING

•

Take all precautions so that the base of the jack does not slip. Failure to

do so could result in an accident.

•

The vehicle can be damaged if the ja ck is not applied at the correct

jacking points. There is also a risk of injury since the jack can slip off

suddenly if it is not properly engaged.

Fig. 156 The jacking

pointsFig. 157 Fitting the jack

leon_ingles Seite 228 Donnerstag, 24. August 2006 1:56 13