Seat Leon 5D 2011 Owner's manual

Manufacturer: SEAT, Model Year: 2011, Model line: Leon 5D, Model: Seat Leon 5D 2011Pages: 302, PDF Size: 4.17 MB

Page 261 of 302

259

If and when

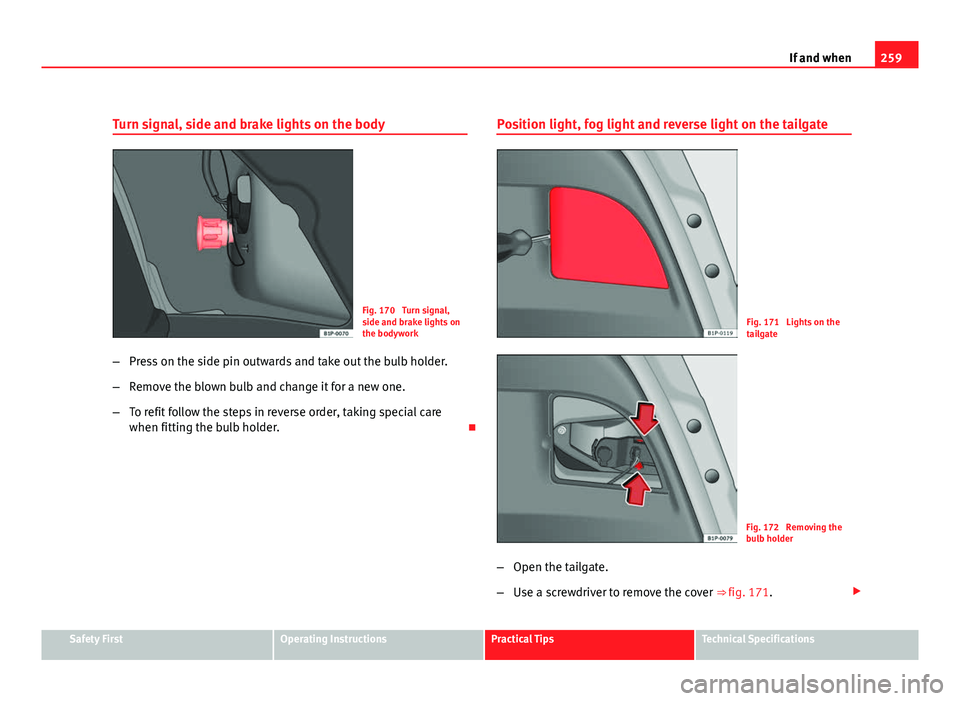

Turn signal, side and brake lights on the body

Fig. 170 Turn signal,

side and brake lights on

the bodywork

– Press on the side pin outwards and take out the bulb holder.

– Remove the blown bulb and change it for a new one.

– To refit follow the steps in reverse order, taking special care

when fitting the bulb holder. Position light, fog light and reverse light on the tailgateFig. 171 Lights on the

tailgate

Fig. 172 Removing the

bulb holder

– Open the tailgate.

– Use a screwdriver to remove the cover ⇒ fig. 171.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 262 of 302

260If and when

–Take the bulbholder out pressing on the securing pins and ex-

tract it outwards ⇒ fig. 172.

– Replace the faulty bulb, rotating it to the left and outwards.

– Installation is done in the reverse order.

WARNING

If a bulb is replaced in a tail light assembly with LED, do not pull too hard

on the bulb holder. This may damage the wiring of the LED module.

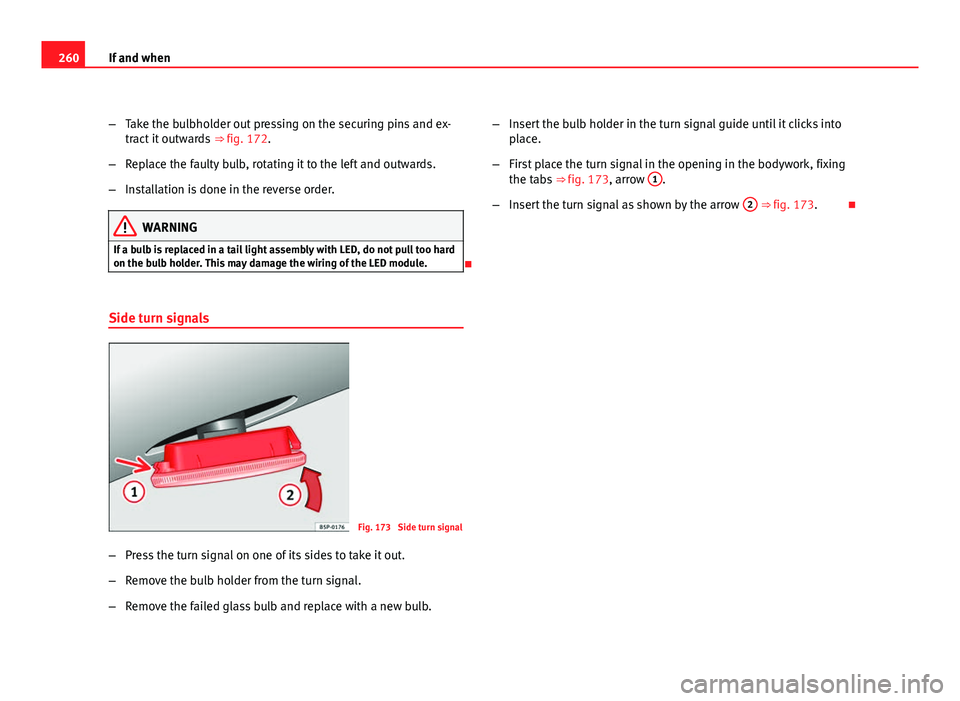

Side turn signals

Fig. 173 Side turn signal

– Press the turn signal on one of its sides to take it out.

– Remove the bulb holder from the turn signal.

– Remove the failed glass bulb and replace with a new bulb. –

Insert the bulb holder in the turn signal guide until it clicks into

place.

– First place the turn signal in the opening in the bodywork, fixing

the tabs ⇒ fig. 173, arrow 1

.

– Insert the turn signal as shown by the arrow 2

⇒ fig. 173.

Page 263 of 302

261

If and when

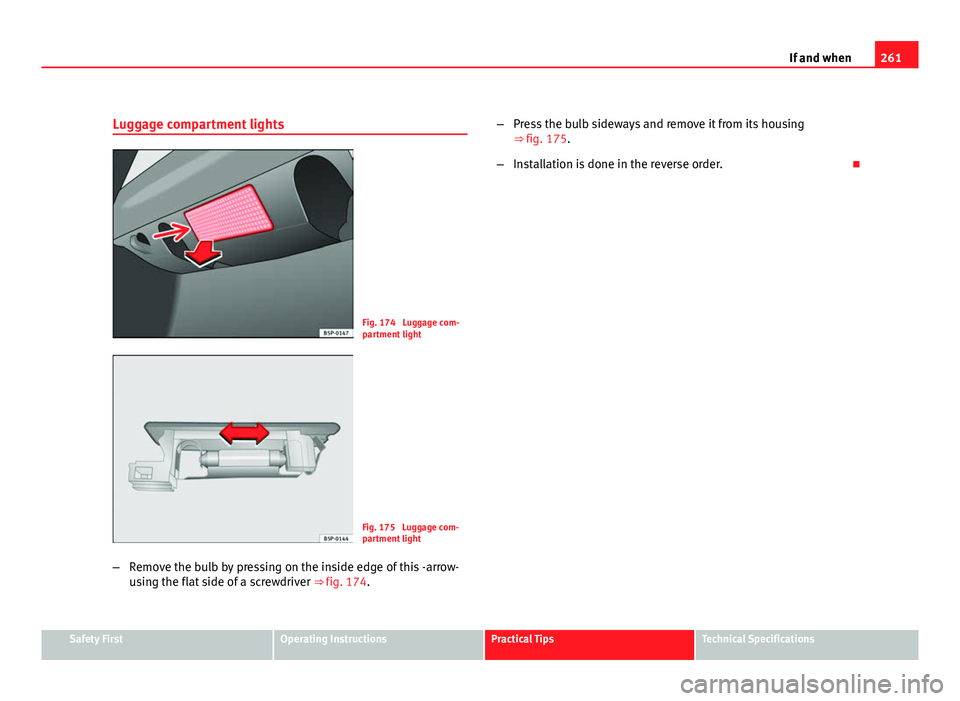

Luggage compartment lights

Fig. 174 Luggage com-

partment light

Fig. 175 Luggage com-

partment light

– Remove the bulb by pressing on the inside edge of this -arrow-

using the flat side of a screwdriver ⇒ fig. 174.–

Press the bulb sideways and remove it from its housing

⇒ fig. 175.

– Installation is done in the reverse order.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 264 of 302

262If and when

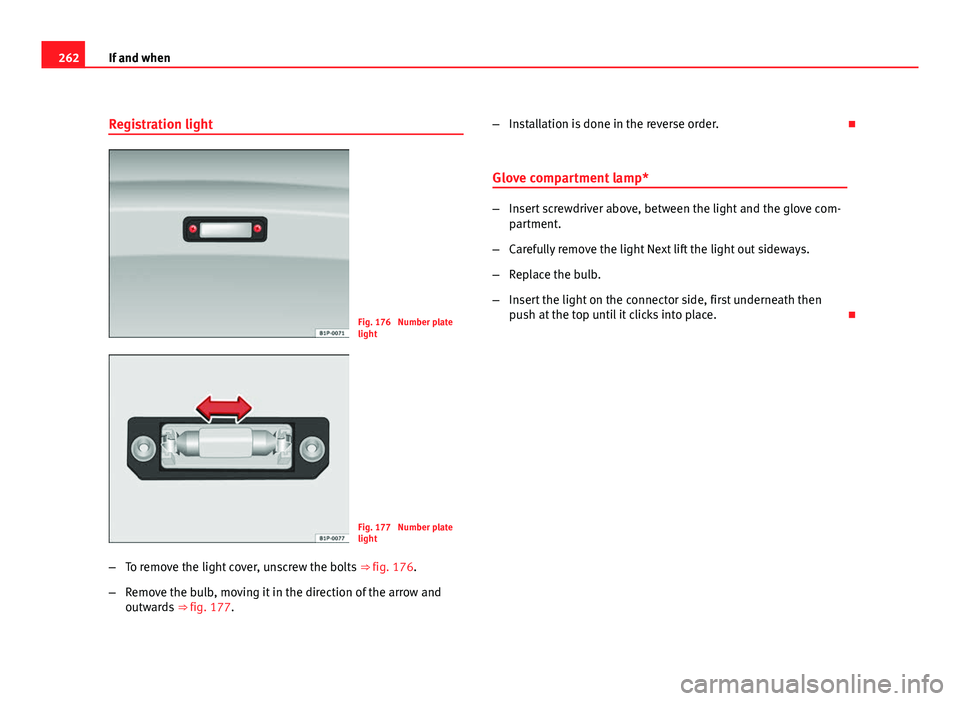

Registration light

Fig. 176 Number plate

light

Fig. 177 Number plate

light

– To remove the light cover, unscrew the bolts ⇒ fig. 176.

– Remove the bulb, moving it in the direction of the arrow and

outwards ⇒ fig. 177. –

Installation is done in the reverse order.

Glove compartment lamp*

– Insert screwdriver above, between the light and the glove com-

partment.

– Carefully remove the light Next lift the light out sideways.

– Replace the bulb.

– Insert the light on the connector side, first underneath then

push at the top until it clicks into place.

Page 265 of 302

263

If and when

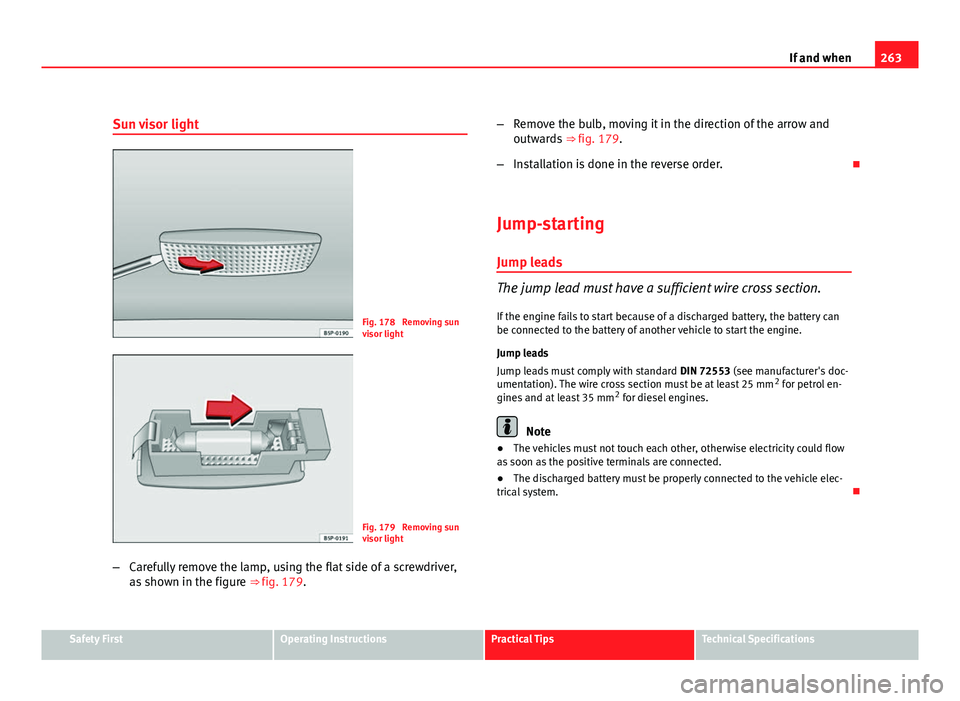

Sun visor light

Fig. 178 Removing sun

visor light

Fig. 179 Removing sun

visor light

– Carefully remove the lamp, using the flat side of a screwdriver,

as shown in the figure ⇒ fig. 179. –

Remove the bulb, moving it in the direction of the arrow and

outwards ⇒ fig. 179.

– Installation is done in the reverse order.

Jump-starting

Jump leads

The jump lead must have a sufficient wire cross section. If the engine fails to start because of a discharged battery, the battery can

be connected to the battery of another vehicle to start the engine.

Jump leads

Jump leads must comply with standard DIN 72553 (see manufacturer's doc-

umentation). The wire cross section must be at least 25 mm 2

for petrol en-

gines and at least 35 mm 2

for diesel engines.

Note

● The vehicles must not touch each other, otherwise electricity could flow

as soon as the positive terminals are connected.

● The discharged battery must be properly connected to the vehicle elec-

trical system.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 266 of 302

264If and when

How to jump start: description

Fig. 180 Diagram for

connecting jump leads if

the vehicle providing as-

sistance the current is

not fitted with the Start-

Stop system: flat battery

A

and battery providing

current B.

Fig. 181 Diagram for

connecting jump leads if

the vehicle providing as-

sistance is fitted with the

Start-Stop system: flat

battery A

and battery

providing current B.

Jump lead terminal connections

1. Switch off the ignition of both vehicles ⇒

.2. Connect one end of the

red jump lead to the positive terminal

⇒ fig. 180 +

or ⇒

fig. 181 + of the vehicle with the flat bat-

tery A.

3. Connect the other end of the red jump lead to the positive ter-

minal +

in the vehicle providing assistance B.

4. On vehicles with no Start-Stop system , connect one end of the

black jump lead to the negative terminal -

in the vehicle pro-

viding assistance B ⇒ fig. 180.

5. On vehicles with the Start-Stop system , connect one end of the

black jump lead X

to a suitable ground terminal, to a solid

metal part bolted to the engine block or to the engine block it-

self ⇒ fig. 181.

6. Connect the other end of the black jump lead X

to a solid met-

al component bolted to the engine block or to the engine block

itself of the vehicle with the flat battery. Do not connect it to a

point near the battery A

.

7. Position the leads in such a way that they cannot come into contact with any moving parts in the engine compartment.

Starting

8. Start the engine of the vehicle with the boosting battery and let it run at idling speed.

9. Start the engine of the vehicle with the flat battery and wait one or two minutes until the engine is running.

Removing the jump leads

10. Before you remove the jump leads, switch off the headlights (if they are switched on).

Page 267 of 302

265

If and when

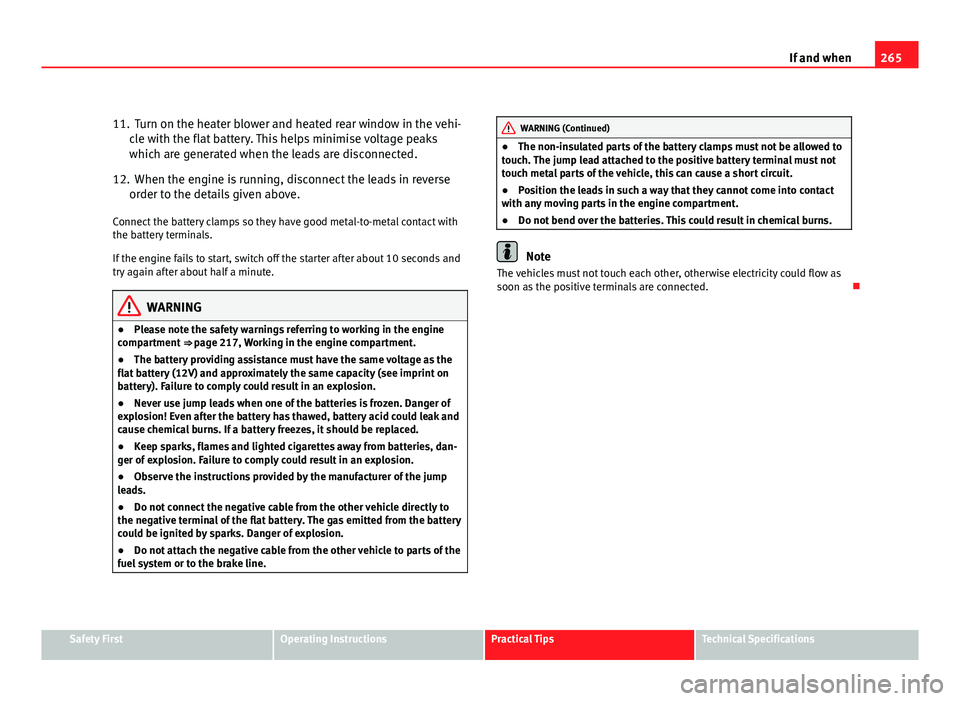

11. Turn on the heater blower and heated rear window in the vehi- cle with the flat battery. This helps minimise voltage peaks

which are generated when the leads are disconnected.

12. When the engine is running, disconnect the leads in reverse order to the details given above.

Connect the battery clamps so they have good metal-to-metal contact with

the battery terminals.

If the engine fails to start, switch off the starter after about 10 seconds and

try again after about half a minute.

WARNING

● Please note the safety warnings referring to working in the engine

compartment ⇒ page 217, Working in the engine compartment.

● The battery providing assistance must have the same voltage as the

flat battery (12V) and approximately the same capacity (see imprint on

battery). Failure to comply could result in an explosion.

● Never use jump leads when one of the batteries is frozen. Danger of

explosion! Even after the battery has thawed, battery acid could leak and

cause chemical burns. If a battery freezes, it should be replaced.

● Keep sparks, flames and lighted cigarettes away from batteries, dan-

ger of explosion. Failure to comply could result in an explosion.

● Observe the instructions provided by the manufacturer of the jump

leads.

● Do not connect the negative cable from the other vehicle directly to

the negative terminal of the flat battery. The gas emitted from the battery

could be ignited by sparks. Danger of explosion.

● Do not attach the negative cable from the other vehicle to parts of the

fuel system or to the brake line.

WARNING (Continued)

● The non-insulated parts of the battery clamps must not be allowed to

touch. The jump lead attached to the positive battery terminal must not

touch metal parts of the vehicle, this can cause a short circuit.

● Position the leads in such a way that they cannot come into contact

with any moving parts in the engine compartment.

● Do not bend over the batteries. This could result in chemical burns.

Note

The vehicles must not touch each other, otherwise electricity could flow as

soon as the positive terminals are connected.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 268 of 302

266If and when

Towing and tow-starting

Tow-starting

The use of jump leads is preferable to tow-starting.

We recommend that you do not tow-start your vehicle. Jump-start-

ing is preferable ⇒ page 263.

However, if your vehicle has to be tow-started:

– Engage the 2nd or the 3rd gear.

– Keep the clutch pressed down.

– Switch the ignition on.

– Once both vehicles are moving, release the clutch.

– As soon as the engine starts, press the clutch and move the

gear lever into neutral. This helps to prevent driving into the

towing vehicle.

WARNING

The risk of accidents is high when tow-starting. The vehicle being towed

can easily collide with the towing vehicle.

CAUTION

When tow-starting, fuel could enter the catalytic converter and damage it. Comments

Please observe the following points if you use a tow-rope:

Notes for the driver of the towing vehicle

–

Drive slowly at first until the tow-rope is taut. Then accelerate

gradually.

– Begin and change gears cautiously. If you are driving an auto-

matic vehicle, accelerate gently.

– Remember that the brake servo and power steering are not

working in the vehicle you are towing. Brake sooner than nor-

mal and pressing the pedal gently.

Notes for the driver of the towed vehicle

– Ensure that the tow-rope remains taut at all times when towing.

Tow-rope or tow-bar

It is easier and safer to tow a vehicle with a tow-bar. You should only use a

tow-rope if you do not have a tow-bar.

A tow-rope should be slightly elastic to reduce the loading on both vehicles.

It is advisable to use a tow-rope made of synthetic fibre or similarly elastic

material.

Attach the tow-rope or the tow-bar only to the towing eyes provided or a

towing bracket.

Driving style

Towing requires some experience, especially when using a tow-rope. Both

drivers should be familiar with the technique required for towing. Inexper-

ienced drivers should not attempt to tow.

Page 269 of 302

267

If and when

Do not pull too hard with the towing vehicle and take care to avoid jerking

the tow-rope. When towing on an unpaved road, there is always a risk of

overloading and damaging the anchorage points.

The ignition of the vehicle being towed must be switched on to prevent the

steering wheel from locking and also to allow the use of the turn signals,

horn, windscreen wipers and washers.

As the brake servo does not work if the engine is not running, you must ap-

ply considerably more pressure to the brake pedal than you normally would.

As the power assisted steering does not work if the engine is not running,

you will need more strength to steer than you normally would.

Towing vehicles with an automatic gearbox

● Put the selector lever into position “N”.

● Do not drive faster than 50 km/h.

● Do not tow further than 50 km.

● If a breakdown vehicle is used, the vehicle must be towed with the front

wheels raised.

Note

● Observe legal requirements when towing or tow-starting.

● Switch on the hazard warning lights of both vehicles. However, observe

any regulations to the contrary.

● For technical reasons, vehicles with an automatic gearbox must not be

tow-started.

● If damage to your vehicle means that there is no lubricant in the gear-

box, you must raise the drive wheels while the vehicle is being towed.

● If the vehicle has to be towed more than 50 km, the front wheels should

be raised during towing, and towing should be carried out by a qualified

person. ●

The steering wheel is locked when the vehicle has no electrical power.

The vehicle must then be towed with the front wheels raised. Towing should

be carried out by a qualified person.

● The towing eye should always be kept in the vehicle. Please refer to the

notes on ⇒ page 266.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 270 of 302

268If and when

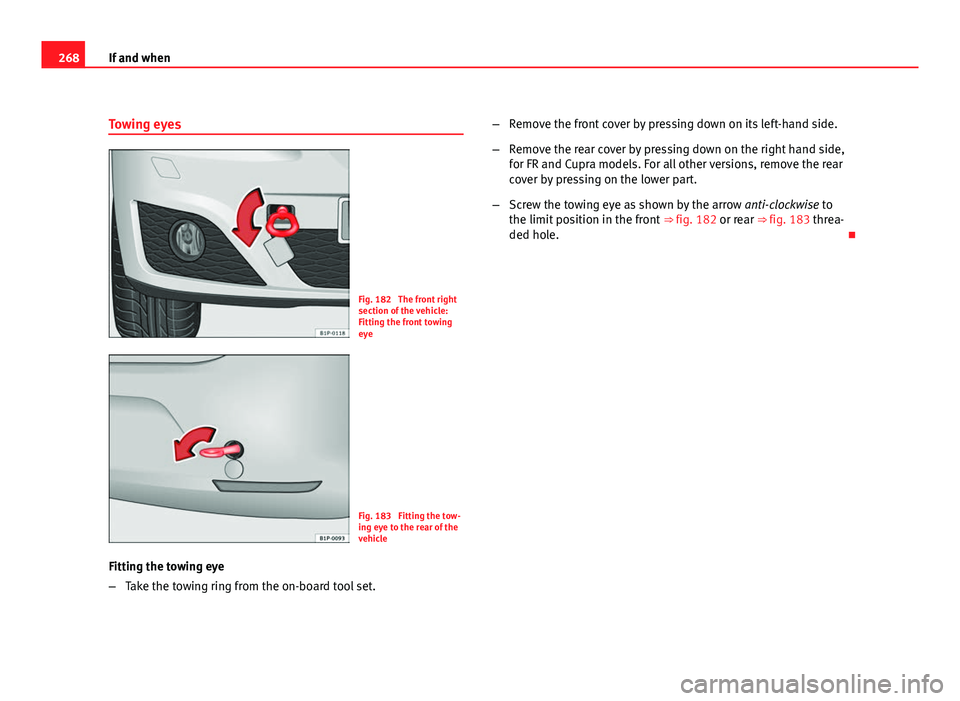

Towing eyes

Fig. 182 The front right

section of the vehicle:

Fitting the front towing

eye

Fig. 183 Fitting the tow-

ing eye to the rear of the

vehicle

Fitting the towing eye

– Take the towing ring from the on-board tool set. –

Remove the front cover by pressing down on its left-hand side.

– Remove the rear cover by pressing down on the right hand side,

for FR and Cupra models. For all other versions, remove the rear

cover by pressing on the lower part.

– Screw the towing eye as shown by the arrow anti-clockwise to

the limit position in the front ⇒ fig. 182 or rear ⇒ fig. 183 threa-

ded hole.