warning Seat Leon 5D 2012 Owner's manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2012, Model line: Leon 5D, Model: Seat Leon 5D 2012Pages: 289, PDF Size: 3.81 MB

Page 231 of 289

230Accessories and modifications to the vehicle

Accessories and modifications to the vehicle

Accessories, replacement parts and repairs

Always ask your dealer or specialist retailer for advice be-

fore purchasing accessories and replacement parts.

Your vehicle is designed to offer a high standard of active and passive safe-

ty. For this reason, we recommend that you ask a SEAT Official Service for

advice before fitting accessories or replacement parts. Your SEAT Official

Service has the latest information from the manufacturer and can recom-

mend accessories and replacement parts which are suitable for your re-

quirements. They can also answer any questions you might have regarding

official regulations.

We recommend you to use only SEAT accessories and Genuine SEAT parts ®

.

SEAT has tested these parts and accessories for suitability, reliability and

safety. SEAT Official Services have the necessary experience and facilities to

ensure that the parts are installed correctly and professionally.

Any retro-fitted equipment which has a direct effect on the vehicle and/or

the way it is driven (e.g. cruise control system or electronically-controlled

suspension) must be approved for use in your vehicle and bear the e mark

(the European Union's authorisation symbol).

If any additional electrical components are fitted which do not serve to con-

trol the vehicle itself (for instance a refrigerator box, laptop or ventilator fan,

etc.), these must bear the mark (manufacturer conformity declaration in

the European Union).

WARNING

Accessories, for example telephone holders or cup holders, should never

be fitted on the covers, or within the working range of the airbags. Other-

wise, there is a danger of injury if the airbag is triggered in an accident.

Technical modifications

Modifications must always be carried out according to our

specifications.

Unauthorised modifications to the electronic components, software, wiring

or data transfer in the vehicle may cause malfunctioning. Due to the way the

electronic components are linked together in networks, other indirect sys-

tems may be affected by the faults. This can seriously impair safety, lead to

excessive wear of components, and also invalidate your vehicle registration

documents.

You will appreciate that your SEAT dealership cannot be held liable for any

damage caused by modifications and/or work performed incorrectly.

We recommend that all work should be performed by a SEAT Official Service

using Genuine SEAT parts

®

.

WARNING

Incorrectly performed modifications or other work on your vehicle can

lead to malfunctions and cause accidents.

Radio transmitters and business equipment

Radio transmitters (fixed installation)

Any retrofit installations of radio transmitters in the vehicle require prior ap-

proval. SEAT generally authorises in-vehicle installations of approved types

of radio transmitters provided that:

Page 232 of 289

231

Accessories and modifications to the vehicle

● the aerial is installed correctly.

● the aerial is installed on the exterior of the vehicle (and shielded cables

are used together with non-reflective aerial trimming).

● the effective transmitting power does not exceed 10 Watts at the aerial

base.

A SEAT Official Service and specialised workshop will be able to inform you

about options for installing and operating radio transmitters with a higher

transmitting power.

Mobile radio transmitters

Commercial mobile telephones or radio equipment might interfere with the

electronics of your vehicle and cause malfunctions. This may be due to:

● no external aerial

● external aerial incorrectly installed

● transmitting power more than 10 W

You must, therefore, do not operate portable mobile telephones or radio

equipment inside the vehicle without a properly installed external aerial

⇒

.

Please note also that the maximum range of the equipment can only be ach-

ieved with an external aerial.

Business equipment

Retrofit installation of business or private equipment in the vehicle is per-

mitted, provided the equipment cannot interfere with the driver's immedi-

ate control of the vehicle and that any such equipment carries the mark.

Any retrofit equipment that could influence the driver's control of the vehi-

cle must have a type approval for your vehicle and must carry the e mark.

WARNING

Mobile telephones or radio equipment which is operated inside the vehi-

cle without a properly installed external aerial can create excessive mag-

netic fields that could cause a health hazard.

Note

● The posterior fitting of electric and electronic equipment in this vehicle

affects its licence type and could lead to the withdrawal of the vehicle regis-

tration document under certain circumstances.

● Please use the mobile telephone/radio operating instructions.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 233 of 289

232Emergencies

Emergencies

General information

– If you have a flat tyre or puncture, park the car as far away from

the flow of traffic as possible in a safe place. If you have a punc-

ture, stop the vehicle on a horizontal surface. If you are on a

slope, take extra care.

– Apply the handbrake.

– Switch on the hazard warning lights.

– Always wear a reflective vest ⇒ page 232.

– Set up the warning triangle.

– All vehicle occupants should leave the car. They should wait in

a safe place (for instance behind the roadside crash barrier).

WARNING

Always observe the above steps and protect yourself and other road

users.

Equipment

Reflective vests

Wearing a reflective vest makes you more visible to other road

users.

Note

● Always wear a reflective vest when you get out of the vehicle in moving

traffic (for example, in the event of breakdown or to load/unload the vehi-

cle).

● Observe the applicable legislation for each country.

Vehicle tools/Tyre repair kit/Compressor*

The vehicle tools, the tyre repair kit and the compressor* are stor-

ed under the floor panel in the luggage compartment.

To access the vehicle tools:

– Lift up the floor panel by the plastic handle until it is fastened to

the tabs on both sides.

Depending on the vehicle equipment, you will find the tyre repair set and

the compressor* under the floor panel cover.

Page 234 of 289

233

Emergencies

Tyre repair kit

What to do first

– Please observe the important safety notes ⇒ page 232.

– Apply the handbrake.

– Manual gearbox: Select first gear.

– Automatic gearbox: Move the selector lever to P.

– Check whether a repair is possible using the tyre repair kit

⇒ page 233.

Using the tyre repair kit

Fig. 117 Tyre: irrepara-

ble damage The tyre repair kit is designed to repair your tyre provisionally only. The dam-

aged tyre should be replaced as soon as possible

⇒

.

If the tyre has been damaged by a nail, for example, remove the nail from

the tyre.

The tyre repair kit can be used at outside temperatures of up to -20 °C

(-4 °F).

The tyre repair kit must NOT be used:

● on cuts and punctures larger than 4 mm 1

⇒ Fig. 117

● If the wheel rim has been damaged 2

●

if you have been driving with very low pressure or a completely flat tyre

3.

If necessary, request assistance from specialised personnel.

WARNING

● Remember that the tyre repair kit cannot always be used, and that it

only serves to provide a provisional repair.

● Do not allow the sealing product to come into contact with your eyes,

skin or clothing.

● If you do come into contact with the sealing product immediately

rinse the eyes or skin affected with clean water.

● Do not inhale vapours.

● If any of the sealing product is accidentally ingested, immediately

rinse the mouth thoroughly and drink lots of water. Do not induce vomit-

ing. Seek medical advice immediately.

● Change clothing immediately if it becomes soiled with the sealing

product.

● If any allergic reactions should occur get medical help immediately.

● Keep the sealing product away from children.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 235 of 289

234Emergencies

Note

● If sealing product should leak out, leave it to dry. This way you can pull it

off like a piece of foil.

● Observe the expiry date stated on the sealing compound can. Have the

sealing compound changed by a specialised workshop or SEAT Service.

● Please observe legal requirements when doing so.

Repairing tyres

Fig. 118 Tyre: top up

Important: have the tyre repair kit ready ⇒

page 232.

Filling the tyre

– Before filling the tyre, shake the bottle of sealing product thor-

oughly.

– Screw the enclosed filling hose onto the sealant can as far as it

will go. This will pierce the foil sealing on the can. –

Take the valve cap off the tyre valve and use a screwdriver

⇒ Fig. 118 to unscrew the valve insert.

– Place the valve insert onto a clean surface.

– Remove the sealing plug from the filling hose and insert the

hose into the tyre valve.

– Hold the bottle upside down and insert the contents in the tyre

until the bottle is empty.

– Then disconnect the hose and screw the valve insert back onto

the tyre valve.

Inflating the tyre

– Screw the compressor filling hose (tyre repair kit) onto the tyre

valve and plug the connector into the 12V connection.

– Pump the tyre up to 2.0 to 2.5 bar and monitor the pressure

shown on the pressure gauge.

– If the tyre does not reach this pressure, move the car forwards

or backwards 10 metres to allow the sealing compound to

spread all around the tyre.WARNING

● Please observe the manufacturer's safety notes on the compressor

and the instructions supplied with the tyre sealant can.

● If, after six minutes of trying to inflate the tyre, it is not possible get

up to a pressure of 2.0 bar, this indicates that the tyre is too severely

damaged for repair with the kit. Do not carry on driving!

● If the tyre cannot be repaired with the sealing compound, seek pro-

fessional assistance.

Page 236 of 289

235

Emergencies

Note

Do not use the compressor for longer than 6 minutes at a time, as it could

overheat. Once it has cooled down, the compressor may be used again.

After changing a wheel

– Attach the "max. 80 km/h (50 mph)" adhesive label from the

tyre repair kit on the instrument panel, clearly within view of the

driver.

– Stop the vehicle after 10 minutes driving and check the tyre

pressure.

– If tyre pressure is less than 1.3 bar, the tyre is too badly dam-

aged. Do not carry on driving!

WARNING

After repairing a tyre please note the following points:

● Do not drive faster than 80 km/h (50 mph).

● Avoid heavy acceleration, hard braking and fast cornering.

● Vehicle handling could be impaired.

● If the tyre is very damaged, seek professional assistance.

For the sake of the environment

You can dispose of the used bottle of sealing compound at a SEAT Official

Service.

Note

After repairing a tyre, remember to purchase a new bottle of sealing com-

pound from a SEAT Official Service or a specialised workshop.

Changing a wheel What to do first

Before changing the wheel, the following preliminary steps

are required. – Please observe the important safety notes ⇒ page 232.

– Apply the handbrake.

– Manual gearbox: Select first gear.

– Automatic gearbox: Move the selector lever to P.

– When towing a trailer: Unhitch the trailer from your vehicle.

– Have the vehicle tool kit ⇒ page 232 and the spare wheel ready

⇒ page 240.

WARNING

If you change the wheel on a slope, block the wheel on the opposite side

of the car with a stone or similar to prevent the vehicle from moving.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 239 of 289

238Emergencies

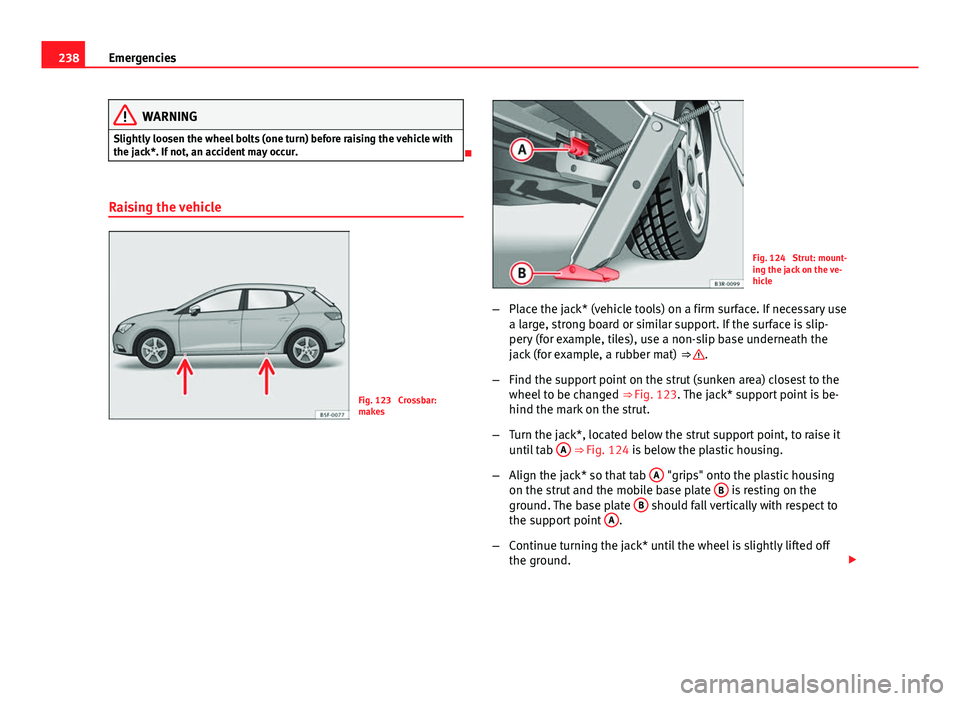

WARNING

Slightly loosen the wheel bolts (one turn) before raising the vehicle with

the jack*. If not, an accident may occur.

Raising the vehicle

Fig. 123 Crossbar:

makes

Fig. 124 Strut: mount-

ing the jack on the ve-

hicle

– Place the jack* (vehicle tools) on a firm surface. If necessary use

a large, strong board or similar support. If the surface is slip-

pery (for example, tiles), use a non-slip base underneath the

jack (for example, a rubber mat) ⇒

.

– Find the support point on the strut (sunken area) closest to the

wheel to be changed ⇒ Fig. 123. The jack* support point is be-

hind the mark on the strut.

– Turn the jack*, located below the strut support point, to raise it

until tab A

⇒ Fig. 124 is below the plastic housing.

– Align the jack* so that tab A

"grips" onto the plastic housing

on the strut and the mobile base plate B is resting on the

ground. The base plate B should fall vertically with respect to

the support point A.

– Continue turning the jack* until the wheel is slightly lifted off

the ground.

Page 240 of 289

239

Emergencies

WARNING

● Make sure that the jack* remains stable. If the surface is slippery or

soft, the jack* could slip or sink, respectively, with the resultant risk of

injury.

● Only raise the vehicle with the jack* supplied by the manufacturer.

Other vehicles could slip, with the consequent risk of injury.

● Only mount the jack* on the support points designed for this purpose

on the strut, and always align the jack correctly. If you do not, the jack*

could slip as it does not have an adequate grip on the vehicle: risk of in-

jury!

● The height of the parked vehicle can change as a result of variations

in temperature and loading.

CAUTION

The vehicle must not be raised on the crossbar. Only place the jack* on the

points designed for this purpose on the strut. Otherwise, the vehicle may be

damaged.

Removing and fitting a wheel

After loosening the wheel bolts and raising the vehicle with the

jack, change the wheel as described below:

Taking off the wheel

– Unscrew the wheel bolts using the box spanner and place them

on a clean surface.

– Take off the wheel ⇒

. Putting on the spare wheel

When fitting tyres with a compulsory rotation direction, observe

the instructions in

⇒ page 239.

– Mount the wheel.

– Screw on the wheel bolts in position and tighten them loosely

with a box spanner.

– Carefully lower the vehicle using the jack*.

– Tighten the wheel bolts in diagonal pairs using the wheel

brace.

The wheel bolts should be clean and turn easily. Before fitting the spare

wheel, inspect the wheel condition and hub mounting surfaces. These sur-

faces must be clean before fitting the wheel.

CAUTION

When removing/fitting the wheel, the rim may hit and damage the brake

disc. For this reason, please take care and get a second person to assist

you.

Tyres with compulsory direction of rotation

A directional tread pattern can be identified by arrows on the sidewall that

point in the direction of rotation. Always observe the direction of rotation in-

dicated when mounting the wheel. This is important so that these tyres can

give maximum grip and avoid excessive noise, tread wear and aquaplaning.

If, exceptionally, it is necessary to mount the spare wheel* in the opposite

direction of rotation, please drive carefully, as in this case the tyre does not

have optimum conditions of use. This is particularly important when driving

on wet roads.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 242 of 289

241

Emergencies

– Take out the temporary spare wheel.

Chains

For technical reasons, snow chains must not be used on the temporary

spare wheel.

If you have a puncture on one of the front wheels when using snow chains,

fit the temporary spare wheel in place of one of the rear wheels. Fit the snow

chains on the rear wheel that you have removed and replace the punctured

front wheel with this wheel.

WARNING

● After fitting the temporary spare wheel, check the tyre pressures as

soon as possible. Failure to do so may cause an accident. The tyre pres-

sures are listed on the inside of the fuel tank flap.

● Do not drive at over 80 km/h (50 mph) when the temporary spare

wheel is fitted on the vehicle: risk of accident!

● Avoid heavy acceleration, hard braking and fast cornering: risk of ac-

cident!

● Never use more than one temporary spare wheel at the same time,

risk of accident.

● No other type of tyre (normal summer or winter tyre) may be fitted on

the compact temporary spare wheel rim.

Jump starting

Jump leads

The jump lead must have a sufficient wire cross section.

If the engine fails to start because of a discharged battery, the battery can

be connected to the battery of another vehicle to start the engine.

Jump leads

Jump leads must comply with standard DIN 72553 (see cable manufactur-

er's instructions). The wire cross section must be at least 25 mm 2

for petrol

engines and at least 35 mm 2

for diesel engines.

Note

● The vehicles must not touch each other, otherwise electricity could flow

as soon as the positive terminals are connected.

● The discharged battery must be properly connected to the on-board net-

work.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 244 of 289

243

Emergencies

Starting

5. Start the engine of the vehicle with the boosting battery and let it run at idling speed.

6. Start the engine of the vehicle with the flat battery and wait two or three minutes until the engine is “running”.

Removing the jump leads

7. Before you remove the jump leads, switch off the dipped beam headlights (if they are switched on).

8. Turn on the heater blower and heated rear window in the vehi- cle with the flat battery. This helps minimise voltage peaks

which are generated when the leads are disconnected.

9. When the engine is running, disconnect the leads in reverse or- der to the details given above.

Connect the battery clamps so they have good metal-to-metal contact with

the battery terminals.

If the engine fails to start, switch off the starter after about 10 seconds and

try again after about half a minute.

WARNING

● Please note the safety warnings referring to working in the engine

compartment ⇒ page 209.

● The battery providing assistance must have the same voltage as the

flat battery (12V) and approximately the same capacity (see imprint on

battery). Failure to comply could result in an explosion.

WARNING (Continued)

● Never use jump leads when one of the batteries is frozen. Danger of

explosion! Even after the battery has thawed, battery acid could leak and

cause chemical burns. If a battery freezes, it should be replaced.

● Keep sparks, flames and lighted cigarettes away from batteries, dan-

ger of explosion. Failure to comply could result in an explosion.

● Observe the instructions provided by the manufacturer of the jump

leads.

● Do not connect the negative cable from the other vehicle directly to

the negative terminal of the flat battery. The gas emitted from the battery

could be ignited by sparks. Danger of explosion.

● Do not attach the negative cable from the other vehicle to parts of the

fuel system or to the brake line.

● The non-insulated parts of the battery clamps must not be allowed to

touch. The jump lead attached to the positive battery terminal must not

touch metal parts of the vehicle, this can cause a short circuit.

● Position the leads in such a way that they cannot come into contact

with any moving parts in the engine compartment.

● Do not lean on the batteries. This could result in chemical burns.

Note

The vehicles must not touch each other, otherwise electricity could flow as

soon as the positive terminals are connected.

Safety FirstOperating instructionsPractical TipsTechnical specifications