brake Seat Leon 5D 2012 Service Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2012, Model line: Leon 5D, Model: Seat Leon 5D 2012Pages: 289, PDF Size: 3.81 MB

Page 202 of 289

201

Care and cleaning

Windows

Clear vision is an essential safety factor.

The windscreen must not be cleaned with insect remover or wax, otherwise

the windscreen wipers will not function properly (juddering).

Traces of rubber, oil, grease or silicone can be removed with a window

cleaning solution or a silicone remover. Wax residue can only be removed

with a special cleaner. Your SEAT Official Service will be able to provide you

with more detailed information.

The windows should also be cleaned on the inside at regular intervals.

Use a separate cloth or chamois to dry the windows. Cloths used for waxing

and polishing contain residues that will cause smears on the glass.

WARNING

Do not use water-repellent coatings on the windscreen. In bad visibility

conditions (e.g. in the rain, dark or with a low sun), these coatings may

cause dazzle: risk of accident! Such coatings can also cause the wind-

screen wiper blades to make noise.

CAUTION

● Remove snow and ice from windows and exterior mirrors with a plastic

scraper only. To avoid scratches caused by dirt on the glass, the scraper

should only be pushed in one direction and not moved to and fro.

● The heating element for the rear window is located on the inner side of

the window. To avoid damaging them, do not apply stickers to the heating

elements.

● Never use warm or hot water to remove snow and ice from windows and

mirrors. This could cause the glass to crack! Rims

The wheels require regular attention to preserve their appearance. It is im-

portant to remove road salt and brake dust by washing the wheels at regu-

lar intervals, otherwise the finish will be impaired.

After washing, the wheels should only be cleaned with an "acid-free" clean-

ing agent for alloy wheels. This is available from SEAT Official Services and

specialist retailers. Never leave the cleaning agent on the rims for any lon-

ger than specified in the instructions before rinsing it off. If the wheel clean-

er fluid contains acid it can attack the surfaces of the wheel bolts.

Car polish or other abrasive agents should not be used for maintaining the

rims. If the protective coating is damaged, e.g. by stone impact, the dam-

aged area should be touched up immediately.

WARNING

Please note when cleaning the wheels that water, ice and road salt can

impair the effectiveness of the brakes; this can cause an accident.

Exhaust tail pipe

It is important to remove road salt and brake dust by washing the wheels at

regular intervals, otherwise the exhaust tail pipe material could be dam-

aged. To remove impurities, do not use rim, paint or chrome cleaners or oth-

er abrasive products. Clean the exhaust tail pipes with cleaning products

that are suitable for stainless steel.

SEAT Official Services carry stocks of cleaning products that have been tes-

ted and approved for use on your vehicle.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 210 of 289

209

Checking and refilling levels

Note

Diesel vehicles are fitted with a protective device that prevents the insertion

of the wrong fuel hose 1)

. It is only possible to refuel with Diesel nozzles.

● If the pump nozzle is worn, damaged, or if it is very small, it is possible

that it will not be able to open the protective device. Before trying to insert

the pump nozzle by turning it, try a different pump or request specialist

help.

● If you fill the tank from a reserve fuel canister, the protective device will

not open. One way to resolve this is to pour the fuel in very slowly.

Bonnet

Working on components in the engine compartment

Extra caution is necessary when working on components in

the engine compartment. Always be aware of the danger of injury and scalding as well as the risk of

accident or even fire when working in the engine compartment (e.g. when

checking and refilling fluids). Always observe the warnings listed below

and follow all general safety precautions. The engine compartment of the

vehicle is a potentially hazardous area ⇒

.

WARNING

● Switch the ignition off.

● Remove the ignition key.

WARNING (Continued)

● Apply the handbrake.

● If the vehicle has a manual gearbox, place the lever in neutral; if it

has an automatic gearbox, place the selector lever in position P.

● Wait for the engine to cool down.

● Keep children away from the engine compartment.

● Never spill liquids used for vehicle operation on the engine compart-

ment, as these may catch fire (e.g. the antifreeze in coolant).

● Take care not to cause short circuits in the electrical system, especial-

ly when working on the battery.

● If working inside the engine compartment, remember that, even when

the ignition is switched off, the radiator fan may start up automatically,

and therefore there is a risk of injury.

● Do not unscrew the cap on the coolant expansion tank when the en-

gine is hot. The cooling system is under pressure.

● Protect face, hands and arms by covering the cap with a large, thick

rag to protect against escaping coolant and steam.

● If it is necessary to work in the engine compartment while the engine

is running, the rotating components (for example, poly-V belt, alternator,

radiator fan) and the high voltage ignition system are an additional haz-

ard.

● Observe the following additional warnings if work on the fuel system

or the electrical system is necessary:

–Always disconnect the battery from the on-board network.

– Do not smoke.

– Never work near naked flames.

– Always keep an approved fire extinguisher immediately available.

1)

according to the country

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 218 of 289

217

Checking and refilling levels

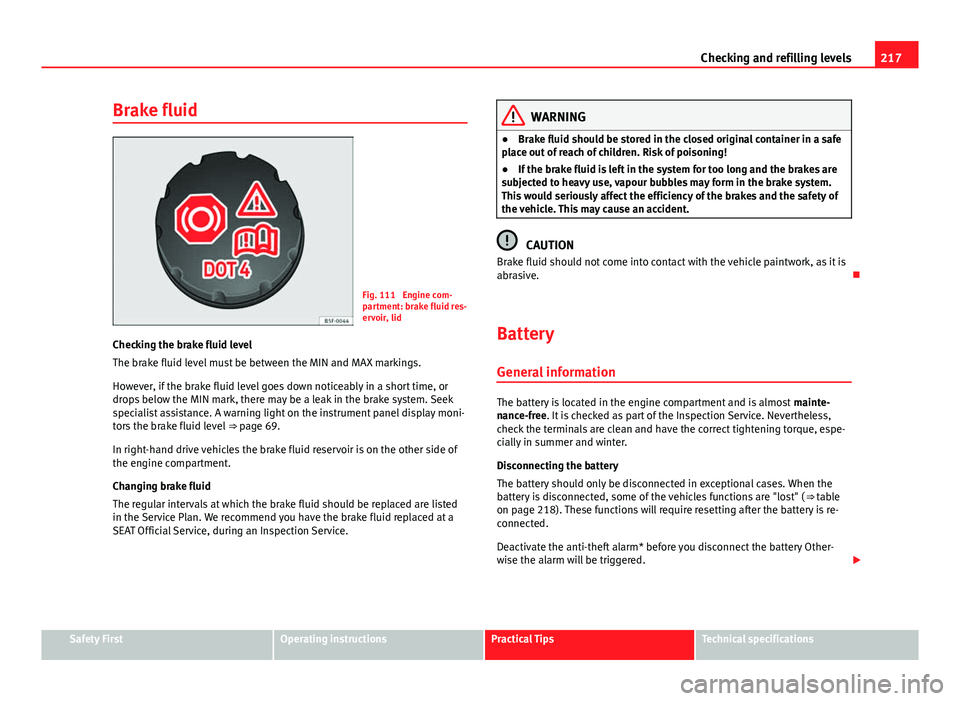

Brake fluid

Fig. 111 Engine com-

partment: brake fluid res-

ervoir, lid

Checking the brake fluid level

The brake fluid level must be between the MIN and MAX markings.

However, if the brake fluid level goes down noticeably in a short time, or

drops below the MIN mark, there may be a leak in the brake system. Seek

specialist assistance. A warning light on the instrument panel display moni-

tors the brake fluid level ⇒ page 69.

In right-hand drive vehicles the brake fluid reservoir is on the other side of

the engine compartment.

Changing brake fluid

The regular intervals at which the brake fluid should be replaced are listed

in the Service Plan. We recommend you have the brake fluid replaced at a

SEAT Official Service, during an Inspection Service.

WARNING

● Brake fluid should be stored in the closed original container in a safe

place out of reach of children. Risk of poisoning!

● If the brake fluid is left in the system for too long and the brakes are

subjected to heavy use, vapour bubbles may form in the brake system.

This would seriously affect the efficiency of the brakes and the safety of

the vehicle. This may cause an accident.

CAUTION

Brake fluid should not come into contact with the vehicle paintwork, as it is

abrasive.

Battery General information

The battery is located in the engine compartment and is almost mainte-

nance-free. It is checked as part of the Inspection Service. Nevertheless,

check the terminals are clean and have the correct tightening torque, espe-

cially in summer and winter.

Disconnecting the battery

The battery should only be disconnected in exceptional cases. When the

battery is disconnected, some of the vehicles functions are "lost" ( ⇒ table

on page 218). These functions will require resetting after the battery is re-

connected.

Deactivate the anti-theft alarm* before you disconnect the battery Other-

wise the alarm will be triggered.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 227 of 289

226Wheels and tyres

To ensure that the wear is equal on all tyres the wheels should be changed

round from time to time according to the system ⇒ Fig. 116. The useful life

of all the tyres will then be about the same time.

Replacing wheels and tyres

It is important to use the correct wheels and tyres when re-

placement is necessary.

– All four wheels must be fitted with tyres of the same type, size

(rolling circumference) and preferably the same tread pattern.

– Tyres should be replaced at least in pairs and not individually

(i.e. both front tyres or both rear tyres together).

– Do not use tyres whose effective size exceeds the dimensions

of the factory-approved makes of tyre.

– If you wish to fit the vehicle with rims or tyres that are different

to those installed in manufacture, it is advisable to consult a

SEAT Official Service before purchasing them.

The tyres and wheel rims are an essential part of the vehicle's design. The

tyres and rims approved by SEAT are specially matched to the characteris-

tics of the vehicle and make a major contribution to good roadholding and

safe handling ⇒

.

The sizes of the rims and tyres approved for your vehicle are listed in the

vehicle documentation (e.g. EC Certificate of Conformity or COC docu-

ment 1)

). The vehicle documentation varies depending on the country of resi-

dence. A knowledge of tyre designations makes it easier to choose the correct

tyres. The following wording can be read on the sides of the tyre:

205/55 R 16 91 V

This contains the following information:

205Tyre width in mm55Height/width ratio in %RTyre construction: Radial16Rim diameter in inches91Load rating codeWSpeed index

The manufacturing date is also indicated on the tyre sidewall (possibly only

on the inner side of the wheel): DOT ... 2212 ...

means that the tyre was produced in the 22nd week of 2012.

Please note that with some types of tyre, the actual tyre size can differ from

the nominal size marked on the tyre (for instance 205/55 R 16 91 W), and

there may be significant differences in the contours of the tyres, even

though the tyres are marked with the same nominal size designation.

When replacing the tyres, it is therefore important to make sure that the

actual size of the new tyres does not exceed the dimensions of the factory-

approved makes of tyre.

Failure to observe this requirement can affect the clearance needed for the

tyres. This could result in contact between the tyres and suspension com-

ponents or bodywork causing damage. The brake lines could also be dam-

aged and vehicle safety could be severely impaired ⇒

.

1)

COC = certificate of conformity

Page 228 of 289

227

Wheels and tyres

If you use tyres that are approved by SEAT you can be sure that the actual

tyre dimensions will be correct for your vehicle. If you decide to fit a differ-

ent type of tyre, you must obtain the appropriate manufacturer's certificate

from the tyre retailer to confirm that the tyres are suitable for your vehicle.

Keep this certificate in a safe place.

Your SEAT Official Service will be able to advise you on which tyres may be

fitted to your vehicle.

It is best to have all servicing of wheels and tyres performed by a special-

ised workshop. They are familiar with the procedure and have the necessary

special tools and spare parts as well as the proper facilities for disposing of

the old tyres.

WARNING

● It is very important to ensure that the tyres you have chosen have ad-

equate clearance. When selecting replacement tyres, do not rely entirely

on the nominal tyre size marked on the tyre; with some makes of tyre the

effective tyre size can differ significantly from the nominal dimensions,

even though the tyres have the same size designation. Inadequate tyre

clearance can result in damage to the tyres or the vehicle, causing a seri-

ous safety risk. It may also invalidate the vehicle's registration for use on

public roads.

● Avoid running the vehicle on tyres that are more than 6 years old. If

you have no alternative, you should drive slowly and with extra care at all

times.

● If wheel trims are fitted after the car is purchased, ensure that there

is an adequate flow of air for cooling the brake system.

For the sake of the environment

Old tyres must be disposed of according to the laws in the country con-

cerned.

Note

● Never mount used tyres if you are not sure of their “previous history”.

● For technical reasons, it is not generally possible to use the wheels from

other vehicles. In some cases, this may also be true for the same model of

wheel.

Wheel bolts

The wheel bolts are designed to suit the rims on your car.

The wheel bolts are matched to the rims. When installing different wheels

(for instance alloy wheels or wheels with winter tyres) it is important to use

the correct wheel bolts with the right length and correctly shaped bolt

heads. This ensures that wheels are fitted securely and that the brake sys-

tem functions correctly.

The wheel bolts must be clean and turn easily.

A special adapter is required to turn the anti-theft wheel bolts*

⇒ page 237.

Winter tyres

Winter tyres will improve the vehicles handling on snow and

ice.

– Winter tyres must be fitted on all four wheels.

– Only use winter tyres that are approved for your vehicle.

– Please note that the maximum permissible speed for winter

tyres may be lower than for summer tyres.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 233 of 289

232Emergencies

Emergencies

General information

– If you have a flat tyre or puncture, park the car as far away from

the flow of traffic as possible in a safe place. If you have a punc-

ture, stop the vehicle on a horizontal surface. If you are on a

slope, take extra care.

– Apply the handbrake.

– Switch on the hazard warning lights.

– Always wear a reflective vest ⇒ page 232.

– Set up the warning triangle.

– All vehicle occupants should leave the car. They should wait in

a safe place (for instance behind the roadside crash barrier).

WARNING

Always observe the above steps and protect yourself and other road

users.

Equipment

Reflective vests

Wearing a reflective vest makes you more visible to other road

users.

Note

● Always wear a reflective vest when you get out of the vehicle in moving

traffic (for example, in the event of breakdown or to load/unload the vehi-

cle).

● Observe the applicable legislation for each country.

Vehicle tools/Tyre repair kit/Compressor*

The vehicle tools, the tyre repair kit and the compressor* are stor-

ed under the floor panel in the luggage compartment.

To access the vehicle tools:

– Lift up the floor panel by the plastic handle until it is fastened to

the tabs on both sides.

Depending on the vehicle equipment, you will find the tyre repair set and

the compressor* under the floor panel cover.

Page 234 of 289

233

Emergencies

Tyre repair kit

What to do first

– Please observe the important safety notes ⇒ page 232.

– Apply the handbrake.

– Manual gearbox: Select first gear.

– Automatic gearbox: Move the selector lever to P.

– Check whether a repair is possible using the tyre repair kit

⇒ page 233.

Using the tyre repair kit

Fig. 117 Tyre: irrepara-

ble damage The tyre repair kit is designed to repair your tyre provisionally only. The dam-

aged tyre should be replaced as soon as possible

⇒

.

If the tyre has been damaged by a nail, for example, remove the nail from

the tyre.

The tyre repair kit can be used at outside temperatures of up to -20 °C

(-4 °F).

The tyre repair kit must NOT be used:

● on cuts and punctures larger than 4 mm 1

⇒ Fig. 117

● If the wheel rim has been damaged 2

●

if you have been driving with very low pressure or a completely flat tyre

3.

If necessary, request assistance from specialised personnel.

WARNING

● Remember that the tyre repair kit cannot always be used, and that it

only serves to provide a provisional repair.

● Do not allow the sealing product to come into contact with your eyes,

skin or clothing.

● If you do come into contact with the sealing product immediately

rinse the eyes or skin affected with clean water.

● Do not inhale vapours.

● If any of the sealing product is accidentally ingested, immediately

rinse the mouth thoroughly and drink lots of water. Do not induce vomit-

ing. Seek medical advice immediately.

● Change clothing immediately if it becomes soiled with the sealing

product.

● If any allergic reactions should occur get medical help immediately.

● Keep the sealing product away from children.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 236 of 289

235

Emergencies

Note

Do not use the compressor for longer than 6 minutes at a time, as it could

overheat. Once it has cooled down, the compressor may be used again.

After changing a wheel

– Attach the "max. 80 km/h (50 mph)" adhesive label from the

tyre repair kit on the instrument panel, clearly within view of the

driver.

– Stop the vehicle after 10 minutes driving and check the tyre

pressure.

– If tyre pressure is less than 1.3 bar, the tyre is too badly dam-

aged. Do not carry on driving!

WARNING

After repairing a tyre please note the following points:

● Do not drive faster than 80 km/h (50 mph).

● Avoid heavy acceleration, hard braking and fast cornering.

● Vehicle handling could be impaired.

● If the tyre is very damaged, seek professional assistance.

For the sake of the environment

You can dispose of the used bottle of sealing compound at a SEAT Official

Service.

Note

After repairing a tyre, remember to purchase a new bottle of sealing com-

pound from a SEAT Official Service or a specialised workshop.

Changing a wheel What to do first

Before changing the wheel, the following preliminary steps

are required. – Please observe the important safety notes ⇒ page 232.

– Apply the handbrake.

– Manual gearbox: Select first gear.

– Automatic gearbox: Move the selector lever to P.

– When towing a trailer: Unhitch the trailer from your vehicle.

– Have the vehicle tool kit ⇒ page 232 and the spare wheel ready

⇒ page 240.

WARNING

If you change the wheel on a slope, block the wheel on the opposite side

of the car with a stone or similar to prevent the vehicle from moving.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 240 of 289

239

Emergencies

WARNING

● Make sure that the jack* remains stable. If the surface is slippery or

soft, the jack* could slip or sink, respectively, with the resultant risk of

injury.

● Only raise the vehicle with the jack* supplied by the manufacturer.

Other vehicles could slip, with the consequent risk of injury.

● Only mount the jack* on the support points designed for this purpose

on the strut, and always align the jack correctly. If you do not, the jack*

could slip as it does not have an adequate grip on the vehicle: risk of in-

jury!

● The height of the parked vehicle can change as a result of variations

in temperature and loading.

CAUTION

The vehicle must not be raised on the crossbar. Only place the jack* on the

points designed for this purpose on the strut. Otherwise, the vehicle may be

damaged.

Removing and fitting a wheel

After loosening the wheel bolts and raising the vehicle with the

jack, change the wheel as described below:

Taking off the wheel

– Unscrew the wheel bolts using the box spanner and place them

on a clean surface.

– Take off the wheel ⇒

. Putting on the spare wheel

When fitting tyres with a compulsory rotation direction, observe

the instructions in

⇒ page 239.

– Mount the wheel.

– Screw on the wheel bolts in position and tighten them loosely

with a box spanner.

– Carefully lower the vehicle using the jack*.

– Tighten the wheel bolts in diagonal pairs using the wheel

brace.

The wheel bolts should be clean and turn easily. Before fitting the spare

wheel, inspect the wheel condition and hub mounting surfaces. These sur-

faces must be clean before fitting the wheel.

CAUTION

When removing/fitting the wheel, the rim may hit and damage the brake

disc. For this reason, please take care and get a second person to assist

you.

Tyres with compulsory direction of rotation

A directional tread pattern can be identified by arrows on the sidewall that

point in the direction of rotation. Always observe the direction of rotation in-

dicated when mounting the wheel. This is important so that these tyres can

give maximum grip and avoid excessive noise, tread wear and aquaplaning.

If, exceptionally, it is necessary to mount the spare wheel* in the opposite

direction of rotation, please drive carefully, as in this case the tyre does not

have optimum conditions of use. This is particularly important when driving

on wet roads.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 244 of 289

243

Emergencies

Starting

5. Start the engine of the vehicle with the boosting battery and let it run at idling speed.

6. Start the engine of the vehicle with the flat battery and wait two or three minutes until the engine is “running”.

Removing the jump leads

7. Before you remove the jump leads, switch off the dipped beam headlights (if they are switched on).

8. Turn on the heater blower and heated rear window in the vehi- cle with the flat battery. This helps minimise voltage peaks

which are generated when the leads are disconnected.

9. When the engine is running, disconnect the leads in reverse or- der to the details given above.

Connect the battery clamps so they have good metal-to-metal contact with

the battery terminals.

If the engine fails to start, switch off the starter after about 10 seconds and

try again after about half a minute.

WARNING

● Please note the safety warnings referring to working in the engine

compartment ⇒ page 209.

● The battery providing assistance must have the same voltage as the

flat battery (12V) and approximately the same capacity (see imprint on

battery). Failure to comply could result in an explosion.

WARNING (Continued)

● Never use jump leads when one of the batteries is frozen. Danger of

explosion! Even after the battery has thawed, battery acid could leak and

cause chemical burns. If a battery freezes, it should be replaced.

● Keep sparks, flames and lighted cigarettes away from batteries, dan-

ger of explosion. Failure to comply could result in an explosion.

● Observe the instructions provided by the manufacturer of the jump

leads.

● Do not connect the negative cable from the other vehicle directly to

the negative terminal of the flat battery. The gas emitted from the battery

could be ignited by sparks. Danger of explosion.

● Do not attach the negative cable from the other vehicle to parts of the

fuel system or to the brake line.

● The non-insulated parts of the battery clamps must not be allowed to

touch. The jump lead attached to the positive battery terminal must not

touch metal parts of the vehicle, this can cause a short circuit.

● Position the leads in such a way that they cannot come into contact

with any moving parts in the engine compartment.

● Do not lean on the batteries. This could result in chemical burns.

Note

The vehicles must not touch each other, otherwise electricity could flow as

soon as the positive terminals are connected.

Safety FirstOperating instructionsPractical TipsTechnical specifications