ESP Seat Leon 5D 2012 Repair Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2012, Model line: Leon 5D, Model: Seat Leon 5D 2012Pages: 289, PDF Size: 3.81 MB

Page 216 of 289

215

Checking and refilling levels

Cooling system Engine coolant specifications

The engine cooling system is supplied from the factory with a specially trea-

ted mixture of water and, at least, 40 % of the additive G 13 (TLVW 774 J).

The engine coolant additive is recognisable by its purple colour. This mix-

ture of water and additive gives the necessary frost protection down to

-25°C (-13 F) and protects the light alloy parts of the cooling system against

corrosion. It also prevents scaling and considerably raises the boiling point

of the coolant.

To protect the engine cooling system, the percentage of additive must al-

ways be at least 40 %, even in warm climates where anti-freeze protection is

not required.

If greater frost protection is required in very cold climates, the proportion of

additive can be increased. However, the percentage of additive should not

exceed 60 %, as this would reduce the frost protection and, in turn, de-

crease the cooling capacity.

When the coolant is topped up, use a mixture of distilled water and, at

least, 40 % of the G 13 or G 12 plus-plus (TL-VW 774 G) additive (both are

purple) to obtain an optimum anticorrosion protection ⇒

. The mixture of

G 13 with G 12 plus (TL-VW 774 F), G 12 (red) or G 11 (green-blue) engine

coolants will significantly reduce the anticorrosion protection and should,

therefore be avoided ⇒

.

WARNING

If there is not enough anti-freeze in the coolant system, the engine may

fail leading to serious damage.

● Please make sure that the percentage of additive is correct with re-

spect to the lowest expected ambient temperature in the zone in which

the vehicle is to be used.

● When the outside temperature is very low, the coolant could freeze

and the vehicle would be immobilised. In this case, the heating would

not work either and inadequately dressed passengers could die of cold.

CAUTION

The original additives should never be mixed with coolants which are not

approved by SEAT. Otherwise, you run the risk of causing severe damage to

the engine and the engine cooling system.

● If the fluid in the expansion tank is not purple but is, for example,

brown, this indicates that the G 13 additive has been mixed with an inade-

quate coolant. The coolant must be changed as soon as possible if this is

the case! This could result in serious faults and engine damage.

For the sake of the environment

Coolants and additives can contaminate the environment. If any fluids are

spilled, they should be collected and correctly disposed of, with respect to

the environment.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 218 of 289

217

Checking and refilling levels

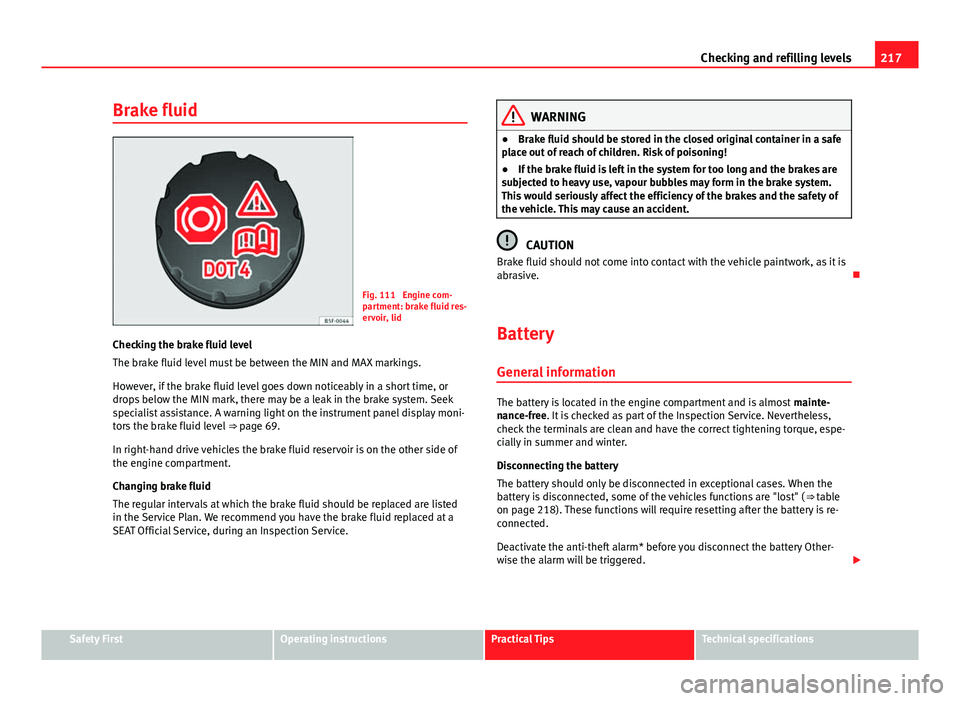

Brake fluid

Fig. 111 Engine com-

partment: brake fluid res-

ervoir, lid

Checking the brake fluid level

The brake fluid level must be between the MIN and MAX markings.

However, if the brake fluid level goes down noticeably in a short time, or

drops below the MIN mark, there may be a leak in the brake system. Seek

specialist assistance. A warning light on the instrument panel display moni-

tors the brake fluid level ⇒ page 69.

In right-hand drive vehicles the brake fluid reservoir is on the other side of

the engine compartment.

Changing brake fluid

The regular intervals at which the brake fluid should be replaced are listed

in the Service Plan. We recommend you have the brake fluid replaced at a

SEAT Official Service, during an Inspection Service.

WARNING

● Brake fluid should be stored in the closed original container in a safe

place out of reach of children. Risk of poisoning!

● If the brake fluid is left in the system for too long and the brakes are

subjected to heavy use, vapour bubbles may form in the brake system.

This would seriously affect the efficiency of the brakes and the safety of

the vehicle. This may cause an accident.

CAUTION

Brake fluid should not come into contact with the vehicle paintwork, as it is

abrasive.

Battery General information

The battery is located in the engine compartment and is almost mainte-

nance-free. It is checked as part of the Inspection Service. Nevertheless,

check the terminals are clean and have the correct tightening torque, espe-

cially in summer and winter.

Disconnecting the battery

The battery should only be disconnected in exceptional cases. When the

battery is disconnected, some of the vehicles functions are "lost" ( ⇒ table

on page 218). These functions will require resetting after the battery is re-

connected.

Deactivate the anti-theft alarm* before you disconnect the battery Other-

wise the alarm will be triggered.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 219 of 289

218Checking and refilling levels

FunctionReprogrammingOne-touch function of the electric

windows⇒ page 101, One-touch opening and

closing*

Remote control keyIf the vehicle does not respond to the

key, they should be synchronised

⇒ page 90

Digital clock⇒ page 63

ESC warning lampAfter driving for a few metres, the

warning lamp goes out again.

If the vehicle is not used for long periods

The vehicle has a system for monitoring the current consumption when the

engine is left unused for long periods of time ⇒ page 187. Some functions,

such as the interior lights, or the remote door opening, may be temporarily

disabled to prevent the battery from running flat. These functions will come

back on as soon as the ignition is switched on and the engine started.

Winter conditions

During the winter, the starting power may be reduced, and if necessary, the

battery should be charged ⇒

in Important safety warnings for handling a

vehicle battery on page 218

Important safety warnings for handling a vehicle battery

All work on batteries requires specialist knowledge. Please refer to a SEAT

Official Service or a workshop specialising in batteries: risk of burns or ex-

ploding battery!

The battery must not be opened. Never try to change the fluid level of the

battery. Explosive gas is released from the battery that could cause an ex-

plosion.

Wear eye protection.

Battery acid is very corrosive and caustic. Wear protective gloves

and eye protection. In the event of electrolyte splashes, rinse off

with plenty of water.

Fires, sparks, open flames and smoking are prohibited.

The battery should only be charged in a well-ventilated zone. Risk

of explosion!

Keep children away from acid and batteries!

WARNING

● When repairing or working on the electrical system, proceed as fol-

lows:

● 1. Remove the key from the ignition. The negative cable on the bat-

tery must be disconnected.

● 2. When the repair is finished, reconnect the negative pole of the bat-

tery.

● Switch off all electrical consumers before reconnecting the battery.

Reconnect first the positive cable and then the negative cable. Never re-

verse the polarity of the connections. This could cause an electrical fire.

● Ensure that the vent hose is always connected to the battery.

● Never use damaged batteries. This could cause an explosion! Replace

a damaged battery immediately.

CAUTION

● Never disconnect the battery if the ignition is switched on or if the en-

gine is running. This could damage the electrical system or electronic com-

ponents.

Page 222 of 289

221

Checking and refilling levels

Cleaning and changing the wiper blades of the windscreen

and rear window

Fig. 113 Changing the

windscreen wiper blades

Fig. 114 Changing the

rear wiper blade

The windscreen wiper blades are supplied as standard with a layer of graph-

ite. This layer is responsible for ensuring that the wipe is silent. If the graph- ite layer is damaged, the noise of the water as it is wiped across the wind-

screen will be louder.

Check the condition of the wiper blades regularly.

If the wipers scrape

across the glass they should be changed if they are damaged, or cleaned if

they are dirty ⇒

.

Damaged wiper blades should be replaced immediately. Wiper blades are

available from specialised workshops.

Raising/lowering windscreen wiper arms

For windscreen wipers, please note: the wiper should be in service position

before being lowering ⇒ page 119. When raising or lowering an arm, it should only be held at the blade fasten-

ing point.

Cleaning windscreen wiper blades

● Raising the wiper arms.

● Use a soft cloth to remove dust and dirt from the windscreen wiper

blades.

● If the blades are very dirty, a sponge or damp cloth may be used ⇒

.

Changing the windscreen wiper blades

● Raising/lowering wiper arms

● Hold down the release button ⇒ Fig. 113 1

while gently pulling the

blade in the direction of the arrow.

● Fit a new wiper blade of the same length and design on to the wiper arm

and hook it into place.

● Rest the wiper arms back onto the windscreen.

Changing the rear wiper blade

● Raising/lowering the wiper arm.

● Turn the blade slightly ⇒ Fig. 114 (arrow A

).

● Hold down the release button 1 while gently pulling the blade in the

direction of the arrow B.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 224 of 289

223

Wheels and tyres

Wheels and tyres

Wheels

General notes

– When driving with new tyres, be especially careful during the

first 500 km (300 miles).

– If you have to drive over a kerb or similar obstacle, drive very

slowly and as near as possible at a right angle to the obstacle.

– Check from time to time if the tyres are damaged (punctures,

cuts, cracks or dents). Remove any foreign objects embedded in

the treads.

– Damaged wheels and tyres must be replaced immediately.

– Keep grease, oil and fuel off the tyres.

– Replace any missing valve caps as soon as possible.

– Mark the wheels before taking them off so that they rotate in

the same direction when put back.

– When removed, the wheels or tyres should be stored in a cool,

dry and preferably dark place.

New tyres

New tyres do not give maximum grip straight away and should therefore be

“run in” by driving carefully and at moderate speeds for about the first 500

km (300 miles). This will also increase the useful life of the tyres. The tread depth of new tyres may

vary, according to the type and make of

tyre and the tread pattern.

Concealed damage

Damage to tyres and rims is often not readily visible. If you notice unusual

vibration or the car pulling to one side, this may indicate that one of the

tyres is damaged. Reduce speed immediately if there is any reason to sus-

pect that damage may have occurred. Inspect the tyres for damage. If no ex-

ternal damage is visible, drive slowly and carefully to the nearest special-

ised workshop and have the car inspected.

Tyres with directional tread pattern

An arrow on the tyre sidewall indicates the direction of rotation on single

drive tyres. Always note the direction of rotation indicated when mounting

the wheel. This guarantees optimum grip and helps to avoid aquaplaning,

excessive noise and wear.

Retrofitting Accessories

If you wish to change or fit wheels, rims or wheel trims, we recommend that

you consult with a SEAT Official Service centre for advice regarding current

techniques.

Useful life of tyres

Correct inflation pressures and sensible driving habits will

increase the useful life of your tyres.

– Check tyre pressure at least once a month, and also prior to any

long trip.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 225 of 289

224Wheels and tyres

–The tyre pressure should only be checked when the tyres are

cold. The slightly raised pressures of warm tyres must not be re-

duced.

– Adjust tyre pressure to the load being carried by the vehicle.

– In vehicles with a tyre pressure indicator, save the pressure of

modified tyres ⇒ page 175, ⇒ page 223.

– Avoid fast cornering and hard acceleration.

– Inspect the tyres for irregular wear from time to time.

The useful life of your tyres depends on the following factors:

Tyre pressure

Tyre pressure values are indicated on the inside of the fuel tank flap.

Insufficient or excessive pressure greatly reduces the useful life of the tyres

and adversely affects vehicle performance and ride. Correct inflation pres-

sures are very important, especially at high speeds.

If you want a more comfortable ride, you can inflate tyres to the pressure

corresponding to the normal vehicle load (up to 3 people) if the vehicle is

carrying a normal load. If the vehicle is going to carry the maximum load,

the tyre pressure should be increased to maximum value indicated.

The tyre pressure must be adjusted according to the load the vehicle is car-

rying. We recommend adhering to the tyre pressure specifications for a max-

imum load.

Do not forget the spare wheel when checking the tyre pressures: Keep the

spare wheel inflated to the highest pressure required for the road wheels.

In the case of a minimised temporary spare wheel (125/70 R16 or 125/70

R18) inflate to a pressure of 4.2 bar as indicated on the tyre pressure label

on the fuel tank flap. Driving style

Fast cornering, heavy acceleration and hard braking (squealing tyres) all in-

crease tyre wear.

Wheel balance

The wheels on new vehicles are balanced. However, certain circumstances

may lead to imbalance (run-out), which is detected as vibrations in the

steering wheel.

Unbalanced wheels should be rebalanced, as they otherwise cause exces-

sive wear on steering, suspension and tyres. A wheel must also be reba-

lanced when a new tyre is fitted or if a tyre is repaired.

Incorrect wheel alignment

Incorrect wheel alignment causes excessive tyre wear, impairing the safety

of the vehicle. If you notice excessive tyre wear, you should check wheel

alignment at a SEAT Official Service.

WARNING

● Always adapt the tyre pressure accordingly when the vehicle load

changes.

● A tyre with low air pressure has to flex a lot more when the vehicle is

heavily loaded or at high speeds, therefore causing overheating to occur.

Under these conditions, the tyre bead may be released or the tyre may

burst. Risk of accident!

For the sake of the environment

Under-inflated tyres will increase fuel consumption.

Page 226 of 289

225

Wheels and tyres

Indications of wear

Tread wear indicators indicate if a tyre is worn.

Fig. 115 Tyre tread:

tread wear indicators

The original tyres on your vehicle have 1.6 mm high “tread wear indicators”

running across the tread. Depending on the manufacturer, there will be 6 to

8 of them spaced at equal distances around the tyre. Markings on the tyre

sidewall (for instance the letters “TWI” or a triangle) indicate the positions

of the tread wear indicators.

The minimum tread depth required by law is 1.6 mm (measured in the tread

grooves next to the tread wear indicators). (Different figures may apply in

other countries.)

WARNING

The tyres must be replaced at the latest when the tread is worn down to

the tread wear indicators. Failure to do so could result in an accident.

● Especially in difficult driving conditions such as wet or icy roads, it is

important that the tyres have sufficient tread depth. The tread depth

should same on the tyres of both the front and the rear axles.

● The decrease in driving safety due to insufficient tread depth is par-

ticularly evident in vehicle handling, when there is a risk of aquaplaning

in deep puddles of water and when driving through corners. Braking is

also adversely affected.

● The speed has to be adapted accordingly, otherwise there is a risk of

losing control over the vehicle.

Changing wheels

Fig. 116 Changing

wheels around

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 230 of 289

229

Wheels and tyres

For the sake of the environment

Summer tyres should be fitted again as soon as possible; they give better

handling on roads which are free of snow and ice. Summer tyres perform

with less rolling noise, tyre wear and – most important – reduce fuel con-

sumption.

Snow chains

Snow chains will improve vehicle handling on snow-covered

roads.

– Snow chains can be used on the front wheels only.

– Check that the snow chains are correctly seated after driving for

a few yards. Always take the manufacturer assembly instruc-

tions into account.

– Keep your speed below 50 km/h (30 mph).

– If there is a danger of being trapped despite having mounted

the chains, it is best to disable the driving wheels (ASR) in the

ESC ⇒ page 184, Switching on/off the ESC and ASR.

Snow chains will improve braking ability as well as traction in winter condi-

tions.

For technical reasons snow chains may only be used with the following

wheel rim/tyre combination.

195/65 R15Chains with links of maximum 15 mm205/55 R16Chains with links of maximum 15 mm225/45 R17Chains with links of maximum 9 mm225/40 R18Chains with links of maximum 9 mm

Only use snow chains with fine-pitch links. The links must not protrude

more than 13.5 mm from the tyres (including tensioner).

Remove wheel covers and trim rings before fitting snow chains.

Remove the chains when roads are free of snow. Otherwise they will impair

handling, damage the tyres and wear out very quickly.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 239 of 289

238Emergencies

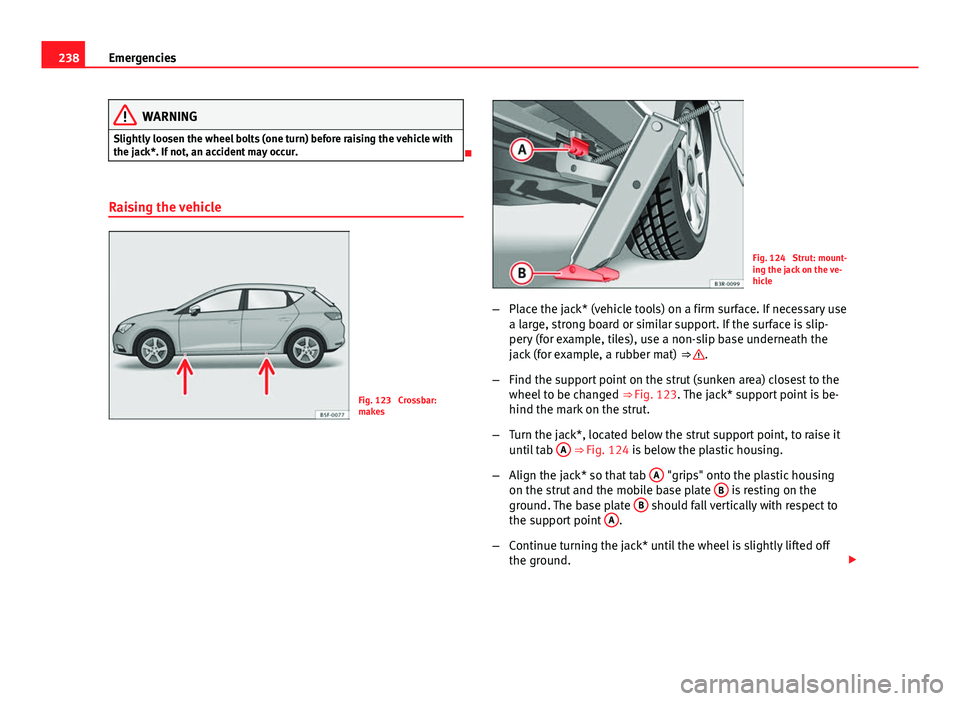

WARNING

Slightly loosen the wheel bolts (one turn) before raising the vehicle with

the jack*. If not, an accident may occur.

Raising the vehicle

Fig. 123 Crossbar:

makes

Fig. 124 Strut: mount-

ing the jack on the ve-

hicle

– Place the jack* (vehicle tools) on a firm surface. If necessary use

a large, strong board or similar support. If the surface is slip-

pery (for example, tiles), use a non-slip base underneath the

jack (for example, a rubber mat) ⇒

.

– Find the support point on the strut (sunken area) closest to the

wheel to be changed ⇒ Fig. 123. The jack* support point is be-

hind the mark on the strut.

– Turn the jack*, located below the strut support point, to raise it

until tab A

⇒ Fig. 124 is below the plastic housing.

– Align the jack* so that tab A

"grips" onto the plastic housing

on the strut and the mobile base plate B is resting on the

ground. The base plate B should fall vertically with respect to

the support point A.

– Continue turning the jack* until the wheel is slightly lifted off

the ground.

Page 240 of 289

239

Emergencies

WARNING

● Make sure that the jack* remains stable. If the surface is slippery or

soft, the jack* could slip or sink, respectively, with the resultant risk of

injury.

● Only raise the vehicle with the jack* supplied by the manufacturer.

Other vehicles could slip, with the consequent risk of injury.

● Only mount the jack* on the support points designed for this purpose

on the strut, and always align the jack correctly. If you do not, the jack*

could slip as it does not have an adequate grip on the vehicle: risk of in-

jury!

● The height of the parked vehicle can change as a result of variations

in temperature and loading.

CAUTION

The vehicle must not be raised on the crossbar. Only place the jack* on the

points designed for this purpose on the strut. Otherwise, the vehicle may be

damaged.

Removing and fitting a wheel

After loosening the wheel bolts and raising the vehicle with the

jack, change the wheel as described below:

Taking off the wheel

– Unscrew the wheel bolts using the box spanner and place them

on a clean surface.

– Take off the wheel ⇒

. Putting on the spare wheel

When fitting tyres with a compulsory rotation direction, observe

the instructions in

⇒ page 239.

– Mount the wheel.

– Screw on the wheel bolts in position and tighten them loosely

with a box spanner.

– Carefully lower the vehicle using the jack*.

– Tighten the wheel bolts in diagonal pairs using the wheel

brace.

The wheel bolts should be clean and turn easily. Before fitting the spare

wheel, inspect the wheel condition and hub mounting surfaces. These sur-

faces must be clean before fitting the wheel.

CAUTION

When removing/fitting the wheel, the rim may hit and damage the brake

disc. For this reason, please take care and get a second person to assist

you.

Tyres with compulsory direction of rotation

A directional tread pattern can be identified by arrows on the sidewall that

point in the direction of rotation. Always observe the direction of rotation in-

dicated when mounting the wheel. This is important so that these tyres can

give maximum grip and avoid excessive noise, tread wear and aquaplaning.

If, exceptionally, it is necessary to mount the spare wheel* in the opposite

direction of rotation, please drive carefully, as in this case the tyre does not

have optimum conditions of use. This is particularly important when driving

on wet roads.

Safety FirstOperating instructionsPractical TipsTechnical specifications