light Seat Leon 5D 2014 Owners Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2014, Model line: Leon 5D, Model: Seat Leon 5D 2014Pages: 284, PDF Size: 5.85 MB

Page 197 of 284

Checking and refilling levels

WARNING

Natural gas is a highly explosive, easily flam-

mable substance. Incorrect handling of the

natural gas can cause accidents serious

burns and other injuries.

● Before refuelling with natural gas, engage

the filling mouth correctly. If you can smell

gas, stop refuelling immediately. WARNING

The vehicle is not prepared to use liquefied

natural gas (LNG), and this fuel must not be

added under any circumstances. Liquefied

natural gas can cause the natural gas tank to

explode, resulting in serious injury. Note

● The filling nozzles of natural gas pumps

can differ in the way they are operated. If you

do not know, ask a qualified employee at the

petrol station to do the refuelling.

● Noises heard when refuelling are normal

and do not indicate the presence of a fault in

the system.

● The vehicle natural gas system is prepared

both for refuelling with a small compressor

(slow refuel) and a large compressor (fast re-

fuel) in natural gas service stations. Fuel

Types of petrol The correct grade of petrol is listed inside the

fuel tank flap.

The vehicle is equipped with a catalytic con-

verter and must only be run on

unleaded pet-

rol. The petrol must comply with European

St and

ard EN 228 or German standard DIN

51626-1 and must be unleaded. You can re-

fuel with a maximum ethanol proportion of

10 % (E10). The types of petrol are differenti-

ated by their octane rating (RON).

The f o

llowing titles appear on the corre-

sponding adhesive on the fuel tank flap:

Super unleaded 95 octane or normal 91

octane unleaded petrol

We recommend you use super 95 octane pet-

rol. If this is not available: normal 91 octane

petrol, with a slight decrease in power.

Super unleaded petrol with a minimum of 95

octanes

You should use super petrol with a minimum

of 95 octanes.

If super is not available, in an emergency you

may refuel with normal 91 octane petrol. In

this case only use moderate engine speeds

and a light throttle. Refuel with super as soon

as possible. Super unleaded 98 octane or super 95

octane unleaded petrol

We recommend you use super plus 98 octane

petrol. If this is not available: super 95 oc-

tane petrol, with a slight decrease in power.

If super is not available,

in an emergency you

may refuel with normal 91 octane petrol. In

this case only use moderate engine speeds

and a light throttle. Refuel with super as soon

as possible.

Petrol additives

The quality of the fuel influences the behav-

iour, power and service life of the engine.

This is why the petrol you use should carry

suitable additives already included by the

petrol industry, free of metals. These addi-

tives will help to prevent corrosion, keep the

fuel system clean and prevent deposits from

building up in the engine.

If good-quality petrol with metal-free addi-

tives is not available or engine problems

arise, the necessary additives must be added

when refuelling ››› .

Not all petrol additives have been shown to

be effective. The use of unsuitable petrol ad-

ditives may cause significant damage to the

engine and the catalytic converter. Metal ad-

ditives should never be used. Metal additives

may also be contained in petrol additives for

improving anti-detonation ratings or octane

ratings ››› .

»

195

Technical specifications

Advice

Operation

Safety

The essentials

Page 201 of 284

Checking and refilling levels

●

Take care not to cause short circuits in the

electrical system, especially when working

on the battery.

● If working inside the engine compartment,

remember that, even when the ignition is

switched off, the radiator fan may start up au-

tomatically, and therefore there is a risk of in-

jury.

● Never cover the engine with additional in-

sulating materials such as a blanket. Risk of

fire!

● Do not unscrew the cap on the coolant ex-

pansion tank when the engine is hot. The

cooling system is under pressure.

● Protect face, hands and arms by covering

the cap with a large, thick rag to protect

against escaping coolant and steam.

● If it is necessary to work in the engine com-

partment while the engine is running, the ro-

tating components (for example, poly-V belt,

alternator, radiator fan) and the high voltage

ignition system are an additional hazard.

● Observe the following additional warnings

if work on the fuel system or the electrical

system is necessary:

– Always disconnect the battery from the

on-board network.

– Do not smoke.

– Never work near naked flames.

– Always keep an approved fire extinguish-

er immediately available. CAUTION

When topping up fluids make sure the correct

fluid is put into the correct filler opening, oth-

erwise this can cause serious malfunctions or

engine damage. For the sake of the environment

Inspect the ground underneath your vehicle

regularly so that any leaks are detected at an

early stage. If you find spots of oil or other

fluids in the area where it was parked, have

your vehicle inspected at the workshop. Note

On right-hand drive vehicles* some of the

containers/reservoirs mentioned below are

located on the other side of the engine com-

partment. Opening the bonnet

Read the additional information carefully

››› page 10

The bonnet is released from inside the vehi-

cle.

Check that the windscreen wiper arms are

not unfolded. Otherwise the paint may be

damaged.

The bonnet can only be unlocked when the

driver door is open. WARNING

Never open the bonnet if you see steam or

drips of coolant being released from the en-

gine compartment. Failure to comply could

result in burns. Wait until no steam or coolant

can be seen before opening the bonnet. Closing the bonnet

–

Slightly lift the bonnet.

– Release the bonnet stay before pressing it

back into its support.

– Carefully close the bonnet.

– Press the bonnet down until it locks into

place.

– Make sure that the bonnet catches onto its

clasp. Do not press down too hard › › › .

WARNING

● For safety reasons the bonnet must always

be completely closed when the vehicle is

moving. Therefore, after closing the bonnet,

always check that the locking element is

properly engaged. This is the case if the bon-

net is flush with the adjacent body panels.

● Should you notice that the bonnet is not

safely secured when the vehicle is moving,

stop the vehicle immediately and close the

bonnet. Failure to follow this instruction

could result in an accident. 199

Technical specifications

Advice

Operation

Safety

The essentials

Page 205 of 284

Checking and refilling levels

Cooling system Engine coolant specifications The engine cooling system is supplied from

the factory with a specially treated mixture of

water and, at least, 40 % of the additive

G 13

(TLVW 774 J). The engine coolant additive is

recognisable by its purple colour. This mix-

ture of water and additive gives the necessa-

ry frost protection down to -25°C (-13°F) and

protects the light alloy parts of the cooling

system against corrosion. It also prevents

scaling and considerably raises the boiling

point of the coolant.

To protect the engine cooling system, the

percentage of additive must always

be at

l e

ast 40 %, even in warm climates where an-

ti-freeze protection is not required.

If greater frost protection is required in very

cold climates, the proportion of additive can

be increased. However, the percentage of ad-

ditive should not exceed 60%, as this would

reduce the frost protection and, in turn, de-

crease the cooling capacity.

When the coolant is topped up, use a mixture

of distilled water and, at least, 40 % of the G

13 or G 12 plu

s-plus (TL-VW 774 G) additive

(both are purple) to obtain an optimum anti-

corrosion protection ››› . The mixture of G

13 with G 12 plus (TL-VW 774 F), G 12 (red) or

G 11 (green-blue) engine coolants will signifi- cantly reduce the anticorrosion protection

and should, therefore be avoided

››› .

WARNING

If there is not enough anti-freeze in the cool-

ant system, the engine may fail leading to se-

rious damage.

● Please make sure that the percentage of

additive is correct with respect to the lowest

expected ambient temperature in the zone in

which the vehicle is to be used.

● When the outside temperature is very low,

the coolant could freeze and the vehicle

would be immobilised. In this case, the heat-

ing would not work either and inadequately

dressed passengers could die of cold. CAUTION

The original additives should never be mixed

with coolants which are not approved by

SEAT. Otherwise, you run the risk of causing

severe damage to the engine and the engine

cooling system. ● If the fluid in the expansion tank is not pur-

ple but is, for example, brown, this indicates

that the G 13 additive has been mixed with

an inadequate coolant. The coolant must be

changed as soon as possible if this is the

case! This could result in serious faults and

engine damage. For the sake of the environment

Coolants and additives can contaminate the

environment. If any fluids are spilled, they

should be collected and correctly disposed

of, with respect to the environment. Topping up coolant

Read the additional information carefully

››› page 32

Top up coolant when the level is below the

MIN (minimum) mark.

Checking coolant level – Park the vehicle in a horizontal position.

– Switch the ignition off.

– Read off the coolant level on coolant ex-

pansion tank. When the engine is cold, the

coolant level should be between the marks.

When the engine is hot, it may be slightly

above the upper mark.

Topping up coolant – Wait for the engine to cool down.

– Cover the coolant expansion tank cap with

a cloth and carefully unscrew it to the left

››› .

– Top up the coolant only if there is still cool-

ant in the expansion tank, otherwise you »

203

Technical specifications

Advice

Operation

Safety

The essentials

Page 206 of 284

Advice

could damage the engine

. If there is no

c

oolant in the expansion tank, do not con-

tinue driving. You should obtain professio-

nal assistance ››› .

– If there is still some coolant in the expan-

sion tank, top up to the upper mark.

– Top up with coolant until the level becomes

stable.

– Screw the cap back on correctly.

Any loss of coolant fluid normally indicates a

leak in the cooling system. Take the vehicle

straight to a specialised workshop to have

the cooling system examined. If there are no

leaks in the engine cooling system, a loss of

coolant can only occur if the coolant boils

and is forced out of the system as a result of

overheating. WARNING

● The cooling system is under pressure. Do

not unscrew the cap on the coolant expan-

sion tank when the engine is hot: risk of

burns!

● The antifreeze and coolant fluid can be a

health hazard. Therefore, the antifreeze

should be stored in the original container in a

safe place out of reach of children. Failure to

comply could result in poisoning.

● If working inside the engine compartment,

remember that, even when the ignition is

switched off, the radiator fan may start up au- tomatically, and therefore there is a risk of in-

jury.

CAUTION

Do not top up the expansion tank with cool-

ant fluid if it is empty! Air could enter the

cooling system. In this case, stop driving.

Seek specialist assistance. Otherwise, there

is a risk of engine damage. Brake fluid

Topping up the brake fluid Read the additional information carefully

››› page 32

Checking the brake fluid level

The brake fluid level must be between the

MIN and MAX markings.

However, if the brake fluid level goes down

noticeably in a short time, or drops below the

MIN mark, there may be a leak in the brake

system. Seek specialist assistance. A warn-

ing light on the instrument panel display

monitors the brake fluid level ››› page 71.

In right-hand drive vehicles the brake fluid

reservoir is on the other side of the engine

compartment. Changing brake fluid

The regular intervals at which the brake fluid

should be replaced are listed in the Mainte-

nance Programme. We recommend you have

it replaced at a SEAT Official Service, during

an Inspection Service.

WARNING

● Brake fluid should be stored in the closed

original container in a safe place out of reach

of children. Risk of poisoning!

● If the brake fluid is left in the system for

too long and the brakes are subjected to

heavy use, vapour bubbles may form in the

brake system. This would seriously affect the

efficiency of the brakes and the safety of the

vehicle. This may cause an accident. CAUTION

Brake fluid should not come into contact with

the vehicle paintwork, as it is abrasive. Windscreen washer reservoir

Checking and topping up the

windscreen washer reservoir with

water Read the additional information carefully

››› page 32

204

Page 207 of 284

Checking and refilling levels

Check the water level in the windscreen

washer reservoir regularly and top up as re-

quired.

The container for the windscreen washer con-

tains the cleaning fluid for the windscreen,

the rear window and the headlight washer

system*.

● Open the bonnet ››› page 198.

● The windscreen washer reservoir is marked

with the symbol on the cap.

● Chec k

there is enough windscreen water in

the reservoir.

Recommended windscreen wipers

● For the hottest seasons we recommend

summer G 052 184 A1 for clear glass. Propor-

tions of the mixture in the washer fluid tank:

1:100 (1 part concentrate per 100 parts wa-

ter).

● All year round, G 052 164 A2 for clear

glass. Approximate proportion of the winter

mixture, up to -18°C (0°F): 1:2 (1 part con-

centrate per 2 parts water); otherwise, a 1:4

proportion of mixture in the washer fluid

tank.

Top-up quantities

The reservoir holds approximately 3 litres in

versions without headlight washer and 5 li-

tres in versions with headlight washer. WARNING

If the water from the windscreen washer does

not contain enough anti-freeze, it may freeze

on the windscreen and rear window, reducing

forward and rear visibility.

● In winter, ensure the windscreen washer

contains enough anti-freeze.

● In cold conditions, you should not use the

windscreen washer system unless you have

warmed the windscreen with the ventilation

system. The antifreeze could freeze on the

windscreen and reduce visibility. WARNING

Never mix an unsuitable antifreeze or other

similar additives with the windscreen washer

water. A greasy layer may be formed on the

windscreen which will impair visibility.

● Use clean water with a window cleaner rec-

ommended by SEAT.

● If necessary, add a suitable antifreeze to

the water in the reservoir. CAUTION

● Do not mix cleaning products recommen-

ded by SEAT with other products. This could

lead to flocculation and may block the wind-

screen washer jets.

● When topping up service fluids, make abso-

lutely certain that you fill the fluids into the

correct reservoirs. Using the wrong fluids could cause serious malfunctions and engine

damage!

● Not having windscreen wiper fluid reduces

visibility through the windscreen, and leads

to loss of visibility in headlights in models

with headlight washer. Battery

General information The battery is located in the engine compart-

ment and is almost

maintenance-free. It is

checked as part of the Inspection Service.

Nevertheless, check the terminals are clean

and have the correct tightening torque, espe-

cially in summer and winter.

Disconnecting the battery

The battery should only be disconnected in

exceptional cases. When the battery is dis-

connected, some of the vehicle's functions

are “lost” ( ››› table on page 206). These

functions will require resetting after the bat-

tery is reconnected.

Deactivate the anti-theft alarm* before you

disconnect the battery Otherwise the alarm

will be triggered. »

205

Technical specifications

Advice

Operation

Safety

The essentials

Page 208 of 284

AdviceFunctionReprogramming

One-touch function of

the electric windows›››

page 92, One-touch

opening and closing*.

Remote control key

If the vehicle does not re-

spond to the key, they

should be synchronised

››› page 87.

Digital clock››› page 68.

ESC warning lampAfter driving for a few me-

tres, the warning lamp goes

out again. If the vehicle is not used for long periods

The vehicle has a system for monitoring the

current consumption when the engine is left

unused for long periods of time

››› page 191.

Some functions, such as the interior lights, or

the remote door opening, may be temporarily

disabled to prevent the battery from running

flat. These functions will come back on as

soon as the ignition is switched on and the

engine started.

Winter conditions

During the winter, the starting power may be

reduced, and if necessary, the battery should

be charged ››› in Important safety warn-

ings for handling a vehicle battery on

page 206 Important safety warnings for

handling a vehicle battery All work on batteries requires specialist

knowledge. Please refer to a SEAT Official

Service or a workshop specialising in batter-

ies: risk of burns or exploding battery!

The battery must not be opened.

Never try to

change the fluid level of the battery. Other-

wise explosive gas is released from the bat-

tery that could cause an explosion.

Wear eye protection.

Battery acid is very corrosive and caustic. Wear

protective gloves and eye protection. In the event

of electrolyte splashes, rinse off with plenty of

water.

Fires, sparks, open flames and smoking are pro-

hibited.

The battery should only be charged in a well-ven-

tilated zone. Risk of explosion!

Keep children away from acid and batteries!

WARNING

● When repairing or working on the electrical

system, proceed as follows:

–1. Remove the key from the ignition. The

negative cable on the battery must be

disconnected.

– 2. When the repair is finished, reconnect

the negative pole of the battery. ●

Switch off all electrical devices before re-

connecting the battery. Reconnect first the

positive cable and then the negative cable.

Never reverse the polarity of the connections.

This could cause an electrical fire.

● Ensure that the vent hose is always connec-

ted to the battery.

● Never use damaged batteries. This could

cause an explosion! Replace a damaged bat-

tery immediately. CAUTION

● Never disconnect the battery if the ignition

is switched on or if the engine is running.

This could damage the electrical system or

electronic components. Charging the battery

Terminals for charging the battery are fitted

in the engine compartment.

–

Note the warnings ››› in Important safety

warnings for handling a vehicle battery on

page 206 and

›

›› .

– Switch off all electrical devices. Remove the

ignition key.

– Raise the bonnet ››› page 199.

– Open the battery cover.

– Connect the charger clamps as described

to the positive pole of the battery (+)

and

206

Page 211 of 284

Wheels

Depending on the vehicle, tyre pressure can

be adjusted (“comfort” tyre pressure) to in-

crease driving comfort. When driving with

comfort tyre pressure fuel consumption may

increase slightly.

The tyre pressure must be adjusted according

to the load the vehicle is carrying. If the vehi-

cle is going to carry the maximum load, the

tyre pressure should be increased to maxi-

mum value indicated on the sticker on the in-

side of the fuel tank flap.

Do not forget the spare wheel when checking

the tyre pressures: Keep this spare wheel in-

flated to the highest pressure required for the

road wheels.

In the case of a minimised temporary spare

wheel (125/70 R16 or 125/70 R18) inflate to

a pressure of 4.2 bar as indicated on the tyre

pressure label on the fuel tank flap.

Driving style

Fast cornering, heavy acceleration and hard

braking (squealing tyres) all increase tyre

wear.

Wheel balance

The wheels on new vehicles are balanced.

However, certain circumstances may lead to

imbalance (run-out), which is detected as vi-

brations in the steering wheel. Unbalanced wheels should be rebalanced, as

they otherwise cause excessive wear on

steering, suspension and tyres. A wheel must

also be rebalanced when a new tyre is fitted

or if a tyre is repaired.

Incorrect wheel alignment

Incorrect wheel alignment causes excessive

tyre wear, impairing the safety of the vehicle.

If you notice excessive tyre wear, you should

check wheel alignment at a SEAT Official

Service.

WARNING

● Always adapt the tyre pressure accordingly

when the vehicle load changes.

● A tyre with low air pressure has to flex a lot

more when the vehicle is heavily loaded or at

high speeds, therefore causing overheating

to occur. Under these conditions, the tyre

bead may be released or the tyre may burst.

Risk of accident! For the sake of the environment

Under-inflated tyres will increase fuel con-

sumption. Wear indicators

Fig. 177

Tyre tread: tread wear indicators Tread wear indicators indicate if a tyre is

worn.

The original tyres on your vehicle have

1.6 mm high “tread wear indicators” running

across the tread. Depending on the manufac-

turer, there will be 6 to 8 of them spaced at

equal distances around the tyre. Markings on

the tyre sidewall (for instance the letters

“TWI” or a triangle) indicate the positions of

the tread wear indicators.

The minimum tread depth required by law is

1.6 mm (measured in the tread grooves next

to the tread wear indicators). (Different fig-

ures may apply in other countries.)

»

209Technical specifications

Advice

Operation

Safety

The essentials

Page 214 of 284

Advice

securely and that the brake system functions

correctly.

The wheel bolts must be clean and turn easi-

ly.

A special adapter is required to turn the anti-

theft wheel bolts* ››› page 218.

Tyre monitoring systems Introduction WARNING

Unsuitable handling of the wheels and tyres

may lead to sudden tyre pressure losses, to

tread separation or even to a blow-out.

● Check tyre pressures regularly and ensure

they are maintained at the pressures indica-

ted. Tyre pressure that is too low could cause

overheating, resulting in tread detachment or

even burst tyres.

● Tyre pressure should be that indicated on

the label when the tyres are cold at all times

››› page 243.

● Re

gularly check the cold inflation pressure

of the tyres. If necessary, change the tyre

pressure of the vehicle tyres while they are

cold.

● Regularly check your tyres for damage and

wear. ●

Never exceed the maximum permitted

speed or loads specified for the type of tyre

fitted on your vehicle. For the sake of the environment

Under-inflated tyres lead to increased fuel

consumption and tyre wear. Note

● Driving for the first time with new tyres at a

high speed can cause them to slightly ex-

pand, which could then produce an air pres-

sure warning.

● Only replace used tyres with those author-

ised by SEAT for the corresponding type vehi-

cle.

● Do not only rely on the tyre monitoring sys-

tem. Regularly check your tyres to ensure

that the tyre pressure is correct and that the

tyres are not damaged due to puncture, cuts,

tears and impacts/dents. Remove objects

from the tyres only when they have not

pierced the tyres. Tyre monitor indicator warning lamp

If a light appears

The pressure in one or more tyres has

clearly reduced in comparison to the

tyre pressure set by the driver or the

tyre has structural damage.

Additionally, an audible warning can be heard and a text

message can be seen on the instrument panel display.

Stop the vehicle!

Reduce speed immediately! Stop

the vehicle safely as soon as possible. Avoid sudden

manoeuvres and braking! Check all tyres and pressures.

Replace any damaged tyres. If flashing

System malfunction

The control lamp flashes for approximately one minute

and then lights up permanently.

If tyre pressure is correct, switch the ignition off and on

again. If the control lamp remains lit up, the tyre moni-

toring indicator can be calibrated. Have the system

checked by a specialised workshop.

Several warning and control lamps light up

for a few seconds when the ignition is switch-

ed on while the function is verified. They will

switch off after a few seconds.

WARNING

When the tyres are inflated at different pres-

sures or at a pressure that is too low then a

tyre may be damaged resulting in a loss of 212

Page 215 of 284

Wheels

control of the vehicle and a serious or fatal

accident.

●

If the warning lamp lights up, stop im-

mediately and check the tyres.

● If the tyres are inflated at different pres-

sures or if a tyre pressure is too low, this will

increase tyre wear, negatively affecting vehi-

cle stability and increasing braking distan-

ces.

● If tyres are inflated at different pressures or

a tyre pressure is too low, a tyre may be dam-

aged and burst resulting in a loss of control

of the vehicle.

● The driver is responsible for ensuring that

all of the vehicle tyres are correctly inflated

to the right pressure. The recommended tyre

pressure is indicated on the label

››› page 243.

● The ty r

e monitoring system can only oper-

ate correctly if all of the tyres are inflated to

the correct pressure when cold.

● Driving with tyres at the wrong pressure

can damage them and result in an accident.

Ensure that the tyre pressures of all the tyres

correspond to the vehicle load.

● Before starting a journey, always inflate

tyres to the correct pressure.

● Tyres with insufficient pressure are subjec-

ted to more flexing. Due to this, the tyre

could become excessively hot, causing tread

separation and also tyre blow-out.

● With an overloaded vehicle at high speed,

the tyres can overheat and burst resulting in

a loss of vehicle control. ●

Tyre pressures which are too high or too

low reduce the useful life of the tyre, affect-

ing vehicle performance.

● If a tyre has not been punctured and it does

not have to be changed immediately, drive to

the nearest specialised workshop at a moder-

ate speed and have the tyre checked and in-

flated to the correct pressure. WARNING

Observe the safety warnings ››› in Control

and warning lamps on page 71. Note

● If excessively low tyre pressure is detected

with the ignition on, an audible warning will

sound. In the event that there is a fault in the

system, an audible warning will sound.

● Driving on dirt tracks for a long period of

time or driving in a sporty style can tempora-

rily deactivate the TPMS. The control lamp

shows a fault, but disappears when road con-

ditions or the driving style change. Tyre monitoring indicator

Fig. 179

Instrument panel: warning of loss of

tyre pressure. The tyre monitor indicator compares wheel

revolutions and, with this information, the

tread of each wheel using the ABS sensors. If

the rolling circumference of one or more

wheels has changed, the tyre monitoring in-

dicator will indicate this on the instrument

panel through a warning lamp and a warning

to the driver

››› Fig. 179 . When only one spe-

c ific

tyre is affected, its position within the

vehicle will be indicated.

Loss of pressure: Check left tyre pressure!

Wheel tread change

The wheel tread changes when: ● Tyre pressure is manually changed

● Tyre pressure is insufficient

● Tyre structure is damaged »

213

Technical specifications

Advice

Operation

Safety

The essentials

Page 219 of 284

Emergencies

Snow chains will improve braking ability as

well as traction in winter conditions.

F or t

echnical reasons snow chains may only

be used with the following wheel rim/tyre

combination.

195/65 R15Chains with links of maximum 15 mm

205/55 R16Chains with links of maximum 15 mm

225/45 R17Chains with links of maximum 9 mm

225/40 R18Chains with links of maximum 9 mm Remove wheel covers and any

integral trim

ring before fitting snow chains.

R emo

ve the chains when roads are free of

snow

. Otherwise they will impair handling,

damage the tyres and wear out very quickly. Emergencies

Changing a wheel What to do first Read the additional information carefully

››› page 34

– If you have a flat tyre or puncture, park the

car as far away from the flow of traffic as

possible in a safe place. If you have a punc-

ture, stop the vehicle on a horizontal sur-

face. If you are on a slope, take extra care.

– Apply the handbrake.

– Switch on the hazard warning lights.

– Manual gearbox: select the 1st gear.

– Automatic gearbox: move the selector lever

to P.

– When towing a trailer: unhitch the trailer

from your vehicle.

– Have the vehicle tool kit ›››

page 220 and

the spare wheel ready ›››

page 214.

– Observe the applicable legislation for each

country (reflective vest, warning triangles,

etc.).

– All vehicle occupants should leave the car.

They should wait in a safe area (for in-

stance behind the roadside crash barrier). WARNING

● Always observe the above steps and pro-

tect yourself and other road users.

● If you change the wheel on a slope, block

the wheel on the opposite side of the car with

a stone or similar to prevent the vehicle from

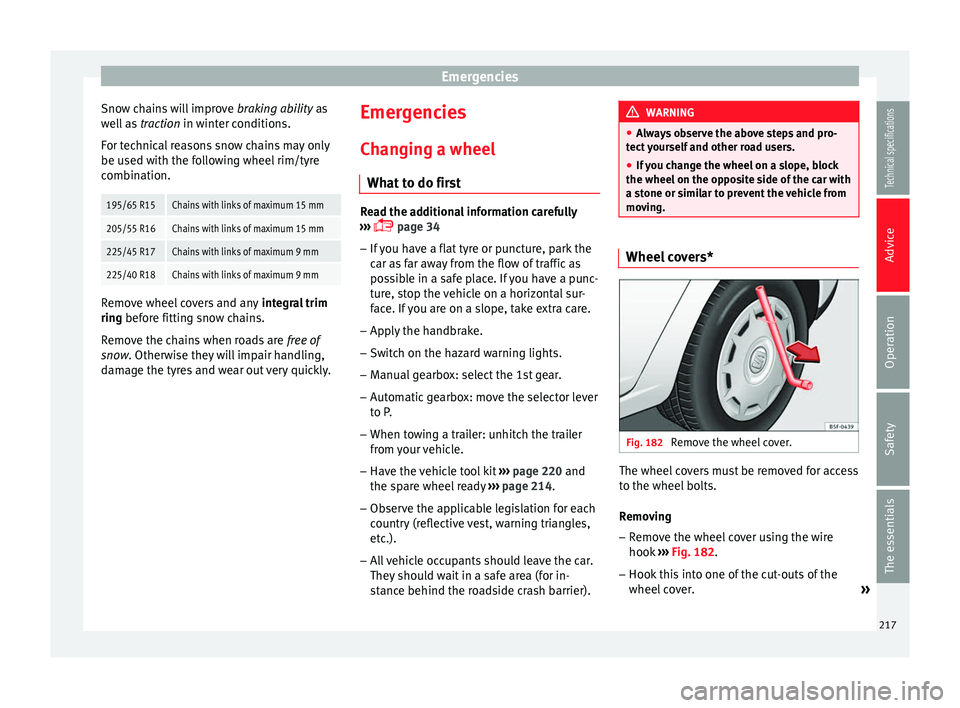

moving. Wheel covers*

Fig. 182

Remove the wheel cover. The wheel covers must be removed for access

to the wheel bolts.

Removing

– Remove the wheel cover using the wire

hook ›››

Fig. 182 .

– Hook thi

s into one of the cut-outs of the

wheel cover. »

217

Technical specifications

Advice

Operation

Safety

The essentials