heating Seat Leon 5D 2014 Owner's Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2014, Model line: Leon 5D, Model: Seat Leon 5D 2014Pages: 284, PDF Size: 5.85 MB

Page 146 of 284

Operation

Brake assist system

The brake assist system can reduce the re-

quired braking distance. The braking force is

automatically boosted if you press the brake

pedal quickly in an emergency. You must

keep pressing the brake pedal until the dan-

ger has passed.

Traction control system (ASR)

In the event of wheelspin, the traction control

system reduces the engine torque to match

the amount of grip available. This helps the

car to start moving, accelerate or climb a gra-

dient.

Electronic differential lock (EDL)

When the EDL detects wheelspin, it brakes

the spinning wheel and directs the power to

the other driven wheel. This function is active

up to approximately 100 km/h.

To prevent the disc brake of the braked wheel

from overheating, the EDL cuts out automati-

cally if subjected to excessive loads. The ve-

hicle can still be driven. The EDL will switch

on again automatically when the brake has

cooled down.

Tractor-trailer sway mitigation*

If the vehicle is pulling a trailer, it will control

the following: Tractor-trailers tend to sway.

When the swaying of the trailer is felt by the

vehicle and detected by the ESC, it will auto- matically brake the towing vehicle within the

limits of the system and mitigate the sway.

Tractor-trailer sway mitigation is not available

in all countries.

Electronic self-locking*/Selective torque

control*

When driving around bends, an electronic

self-locking intervenes. The front wheel on

the inside of the curve, or the two inside

wheels, respectively, are selectively braked

as required. This minimises the traction of

the front wheels, allowing you to take bends

with greater precision and neutrality. In cer-

tain circumstances, where roads are wet or

snow-covered, the respective system may not

intervene.

Multi-collision brake

In an accident, the multi-collision brake can

help the driver by braking to avoid the risk of

skidding during the accident, which could

lead to further collisions.

The multi-collision brake works for front, side

or rear accidents, when the airbag control

unit records its activation level and the acci-

dent takes place at a speed of over 10 km/h

(6 mph). The ESC automatically brakes the

vehicle, as long as the accident has not dam-

aged the ESC, the brake hydraulics or the on-

board network.

The following actions control automatic brak-

ing during the accident:

●

When the driver presses the accelerator,

the automatic braking does not take place.

● When the braking pressure through press-

ing the brake pedal is greater than the sys-

tem’s braking pressure the vehicle will brake

automatically.

● Multi-collision braking will not be available

if ESC is malfunctioning. WARNING

● The ESC, ABS, ASR, EDL, electronic self-

locking differential or selective torque control

systems cannot exceed the limits imposed by

the laws of physics. Always bear this in mind,

especially on wet or slippery roads. If you no-

tice the systems cutting in, you should re-

duce your speed immediately to suit the road

and traffic conditions. Do not be encouraged

to take risks by the presence of more safety

systems. If you do, an accident may occur.

● Please remember that the accident risk al-

ways increases if you drive fast, especially in

corners or on a slippery road, or if you follow

too close behind the vehicle in front of you.

The ESC, ABS, brake assist, EDL, electronic

self-locking and selective torque control sys-

tems cannot prevent accidents: risk of acci-

dents! 144

Page 182 of 284

Operation

You should always reduce speed immediately

if the trailer shows the slightest sign of snak-

ing . Never try to stop the “snaking” by in-

c r

easing speed.

Always brake in due course. If the trailer has

an overrun brake, apply the brakes gen

tly at

first and then, firmly. This will prevent the

jerking that can be caused by locking of trail-

er wheels. Select a low gear in due course

before going down a steep downhill. This en-

ables you to use the engine braking to slow

down the vehicle.

Reheating

At very high temperatures and during pro-

longed slopes, driving in a low gear and high

engine speed, always monitor the coolant

temperature gauge ››› page 71.

Electronic stability control*

The ESC* system helps to stabilise the trailer

in case of skidding or rocking. Retrofitting a towing bracket*

Fig. 172

Attachment points for towing brack-

et. If a towing bracket is to be fitted after the ve-

hicle is purchased, this must be completed

according to the instructions of the towing

bracket manufacturer.The attachment points for the towing bracket

A are on the lower part of the vehicle.

The distance between the centre of the ball

coupling and the ground should never be

lower than the indicated value, even with a

fully loaded vehicle and including the maxi-

mum drawbar load.

Elevation values for securing the towing

bracket:

B65 mm (minimum)

C350 mm to 420 mm (fully laden vehicle)

D1040 mm

E317 mm

FLEON/LEON SCLEON ST

319 mm596 mm Fitting a towing bracket

●

Driving with a trailer involves an extra effort

for the vehicle. Therefore, before fitting a

towing bracket, please contact a Technical

Service to check whether your cooling system

needs modification.

● The legal requirements in your country

must be observed (e.g. the fitting of a sepa-

rate control lamp).

● Certain vehicle components, e.g. the rear

bumper, must be removed and reinstalled.

The towing bracket securing bolts must be

180

Page 188 of 284

Advice

Carbon components The carbon parts on your vehicle have a pain-

ted surface. They do not need any special

care and are cleaned just like any other pain-

ted part

››› page 183.

P aint

damage Minor damage to the paint, such as scratches

or stone chips, should be touched up without

delay

before the metal starts to corrode. Suit-

ab l

e touch-up brushes or sprays for your car

can be obtained from a SEAT Official Service.

The number of the original paint finish on the

vehicle is given on the data sticker

››› page 241

.

If corrosion is already visible it must be thor-

oughly removed by a specialised workshop.

Windows Clear vision is an essential safety factor.

The windscreen must not be cleaned with in-

sect remover or wax, otherwise the wind-

screen wipers will not function properly (jud-

dering).

Traces of rubber, oil, grease or silicone can

be removed with a

window cleaning solution

or a silicone remover. Wax residue can only be remo

ved with a special cleaner. Your SEAT

Official Service will be able to provide you

with more detailed information.

The windows should also be cleaned on the

inside at regular intervals.

Use a separate cloth or chamois to dry the

windows. Cloths used for waxing and polish-

ing contain residues that will cause smears

on the glass. WARNING

Do not use water-repellent coatings on the

windscreen. In bad visibility conditions (e.g.

in the rain, dark or with a low sun), these

coatings may cause dazzle: risk of accident!

Such coatings can also cause the windscreen

wiper blades to make noise. CAUTION

● Remove snow and ice from windows and ex-

terior mirrors with a plastic scraper only. To

avoid scratches caused by dirt on the glass,

the scraper should only be pushed in one di-

rection and not moved to and fro.

● The heating element for the rear window is

located on the inner side of the window. To

avoid damaging them, do not apply stickers

to these heating elements.

● Never use warm or hot water to remove

snow and ice from windows and mirrors. This

could cause the glass to crack! Wheels

The wheels require regular attention to pre-

serve their appearance. It is important to re-

move road salt and brake dust by washing

the wheels at regular intervals, otherwise the

finish will be impaired.

After washing, the wheels should only be

cleaned with an "acid-free" cleaning agent

for alloy wheels. This is available from SEAT

Official Services and specialist retailers. Nev-

er leave the cleaning agent on the rims for

any longer than specified in the instructions

before rinsing it off. If the wheel cleaner fluid

contains acid it can attack the surfaces of the

wheel bolts.

Car polish or other abrasive agents should

not be used for maintaining the rims. If the

protective coating is damaged, e.g. by flying

stones, the damaged area should be re-

paired immediately.

WARNING

Please note when cleaning the wheels that

water, ice and road salt can impair the effec-

tiveness of the brakes; this can cause an acci-

dent. Exhaust tail pipe

It is important to remove road salt and brake

dust by washing the wheels at regular

186

Page 195 of 284

Checking and refilling levels

especially if the battery is not fully charged

initially.

To restore the necessary energy balance, the

system will then temporarily shut off the elec-

trical devices that are using a lot of power, or

reduce the current they are consuming. Heat-

ing systems in particular use a large amount

of electrical power. If you notice, for instance,

that the seat heating* or the rear window

heater is not working, they may have been

temporarily switched off or regulated to a

lower heat output. These systems will be

available again as soon as sufficient electri-

cal power is available.

You may also notice that the engine runs at a

slightly faster idling speed when necessary.

This is quite normal, and no cause for con-

cern. The increased idling speed allows the

alternator to meet the greater power require-

ment and charge the battery at the same

time. Checking and refilling levels

Refuelling Filling the tank Read the additional information carefully

››› page 31

If the automatic filler nozzle is operated cor-

rectly, it will switch itself off as soon as the

fuel tank is “full”. Do not try to put in more

fuel after the nozzle cuts out, as this will fill

the expansion chamber in the fuel tank.

The correct fuel grade for your vehicle is giv-

en on a sticker on the inside of the fuel tank

flap. Further notes on fuel can be found at

››› page 195 .

The c ap

acity of the fuel tank is listed in the

vehicle

technical specifications ›››

page 268. WARNING

Fuel is highly flammable and can cause seri-

ous burns and other injuries.

● Do not smoke when filling the fuel tank or a

canister. Naked flames are forbidden in the

vicinity due to the risk of explosion.

● Observe legislation governing the use,

storage and carrying of a spare fuel canister

in the vehicle.

● For safety reasons we do not recommend

carrying a spare fuel canister in the vehicle. In an accident the canister could be damaged

and could leak.

●

If, in exceptional circumstances, you have

to carry a spare fuel canister, please observe

the following points:

– Never fill fuel into the spare fuel canister

if it is inside or on top of the vehicle. An

electrostatic charge could build up during

filling, causing the fuel vapour to ignite.

Danger of explosion. Always place the

canister on the ground to fill it.

– Insert the filling nozzle as far as possible

into the spare fuel canister.

– If the spare fuel canister is made of met-

al, the filling nozzle must be in contact

with the canister during filling. This

helps prevent an electrostatic charge

building up.

– Never spill fuel in the vehicle or in the

luggage compartment. Fuel vapour is ex-

plosive. Risk of fatal accident! CAUTION

● If any fuel is spilt onto the vehicle, it

should be removed immediately. It could oth-

erwise damage the paintwork.

● Never run the tank completely dry. An irreg-

ular fuel supply could cause misfiring. As a

result, unburnt fuel could enter the exhaust

system and damage the catalytic converter.

● When filling the fuel tank after having run it

completely dry on a vehicle with a diesel en-

gine, the ignition must be switched on for at » 193

Technical specifications

Advice

Operation

Safety

The essentials

Page 196 of 284

Advice

least 30 seconds before starting the engine.

When you then start the engine it may take

longer than normal (up to one minute) to

start firing. This is because air needs to be

bled from the fuel system while starting.

For the sake of the environment

Do not overfill the fuel tank, it may cause the

fuel to overflow if it becomes warm. Note

Diesel vehicles are fitted with a protective de-

vice that prevents the insertion of the wrong

fuel hose 1)

. It is only possible to refuel with

Diesel nozzles.

● If the pump nozzle is worn, damaged, or if

it is very small, it is possible that it will not

be able to open the protective device. Before

trying to insert the pump nozzle by turning it,

try a different pump or request specialist

help.

● If you fill the tank from a reserve fuel canis-

ter, the protective device will not open. One

way to resolve this is to pour the fuel in very

slowly. Refuelling with natural gas

Fig. 173

Tank flap open: gas filler mouth 1 ,

filler mouth retainer 2 Before refuelling, the engine and the igni-

tion, mobile telephone and heating must be

switched off separately

››› .

Read the instructions on how to use the natu-

ral gas pump carefully.

The vehicle is not prepared for refuelling with

liquefied natural gas (LNG) ››› . Before refu-

elling with natural gas, make sure you add

the appropriate type of fuel ››› page 195.

Opening the fuel tank cap

The natural gas filler mouth is behind the fuel

tank cap, next to the petrol filler mouth. ●

Unlock the vehicle with the key or with the

central locking button situated on the driv-

er door ››› page 82 .

● Pr e

ss on the rear area of the flap and open

it.

Refuelling

Things to note: if the ambient temperature is

very high, the natural gas pump protection

against overheating disconnects this auto-

matically.

● Remove the plug from the gas filler mouth

››› Fig. 173 1 .

● Connect the pump filling nozzle to the gas

filler mouth.

● The fuel tank will be full when the pump

c ompr

essor automatically cuts the supply.

● If you wish to finish refuelling in advance,

press the button on the pump to stop the

flow.

Closing the fuel tank cap

● Check that the gas filler mouth retainer 2 is not trapped with the filler nozzle. If neces-

sary, place it in the filler mouth again.

●

Insert the plug in the filler mouth.

● Close the tank flap. Make sure you hear it

click into place. 1)

Depending on country

194

Page 199 of 284

Checking and refilling levels

Liquefied natural gas (LNG) is the result of

heavy cooling of natural gas. Therefore its

volume is considerably reduced compared

with compressed natural gas (CNG). In vehi-

cles with a natural gas engine, liquefied nat-

ural gas cannot be directly refilled, as the gas

would expand excessively in the vehicle gas

tank.

Therefore, vehicles with a natural gas engine

must only be refuelled using compressed

natural gas ››› .

Natural gas quality and consumption

Natural gas is divided into the groups H and

L depending on its quality.

Gas type H has a superior heating power and

inferior nitrogen and carbon dioxide content

than type L. The higher the heating power of

the natural gas, the lower the consumption

will be.

However, the heating power and the propor-

tion of nitrogen and carbon dioxide can fluc-

tuate within the quality groups. Therefore, ve-

hicle consumption can also vary when using

a single type of gas only.

The engine management automatically

adapts to the natural gas used according to

its quality. Therefore, different quality gases

can be mixed in the tank, without the need

for comprehensive draining before applying a

different quality gas. Updated information relating to natural gas

quality is displayed on the instrument panel

››› page 72 .

Nat ur

al gas and safety

If you can smell gas or suspect that there is a

leak ››› :

● Stop the vehicle immediately.

● Switch the ignition off.

● Open the doors to appropriately ventilate

the vehicle.

● Extinguish cigarettes immediately.

● Move away from the vehicle or switch off

objects that may cause sparks or a fire.

● If you continue to smell gas, do not contin-

ue driving!

● Seek specialist assistance. Have the fault

repaired. WARNING

Failure to act when you can smell gas in the

vehicle or when refuelling can cause serious

injuries.

● Carry out the necessary operations.

● Leave the danger zone.

● If necessary, warn the emergency services. WARNING

The vehicle is not prepared to use liquefied

natural gas (LNG) and this fuel must not be

added under any circumstances. Liquefied

natural gas can cause the natural gas tank to

explode, resulting in serious injury. Note

Have the natural gas system checked regular-

ly by a specialised workshop, according to

the Maintenance Programme. 197

Technical specifications

Advice

Operation

Safety

The essentials

Page 206 of 284

Advice

could damage the engine

. If there is no

c

oolant in the expansion tank, do not con-

tinue driving. You should obtain professio-

nal assistance ››› .

– If there is still some coolant in the expan-

sion tank, top up to the upper mark.

– Top up with coolant until the level becomes

stable.

– Screw the cap back on correctly.

Any loss of coolant fluid normally indicates a

leak in the cooling system. Take the vehicle

straight to a specialised workshop to have

the cooling system examined. If there are no

leaks in the engine cooling system, a loss of

coolant can only occur if the coolant boils

and is forced out of the system as a result of

overheating. WARNING

● The cooling system is under pressure. Do

not unscrew the cap on the coolant expan-

sion tank when the engine is hot: risk of

burns!

● The antifreeze and coolant fluid can be a

health hazard. Therefore, the antifreeze

should be stored in the original container in a

safe place out of reach of children. Failure to

comply could result in poisoning.

● If working inside the engine compartment,

remember that, even when the ignition is

switched off, the radiator fan may start up au- tomatically, and therefore there is a risk of in-

jury.

CAUTION

Do not top up the expansion tank with cool-

ant fluid if it is empty! Air could enter the

cooling system. In this case, stop driving.

Seek specialist assistance. Otherwise, there

is a risk of engine damage. Brake fluid

Topping up the brake fluid Read the additional information carefully

››› page 32

Checking the brake fluid level

The brake fluid level must be between the

MIN and MAX markings.

However, if the brake fluid level goes down

noticeably in a short time, or drops below the

MIN mark, there may be a leak in the brake

system. Seek specialist assistance. A warn-

ing light on the instrument panel display

monitors the brake fluid level ››› page 71.

In right-hand drive vehicles the brake fluid

reservoir is on the other side of the engine

compartment. Changing brake fluid

The regular intervals at which the brake fluid

should be replaced are listed in the Mainte-

nance Programme. We recommend you have

it replaced at a SEAT Official Service, during

an Inspection Service.

WARNING

● Brake fluid should be stored in the closed

original container in a safe place out of reach

of children. Risk of poisoning!

● If the brake fluid is left in the system for

too long and the brakes are subjected to

heavy use, vapour bubbles may form in the

brake system. This would seriously affect the

efficiency of the brakes and the safety of the

vehicle. This may cause an accident. CAUTION

Brake fluid should not come into contact with

the vehicle paintwork, as it is abrasive. Windscreen washer reservoir

Checking and topping up the

windscreen washer reservoir with

water Read the additional information carefully

››› page 32

204

Page 211 of 284

Wheels

Depending on the vehicle, tyre pressure can

be adjusted (“comfort” tyre pressure) to in-

crease driving comfort. When driving with

comfort tyre pressure fuel consumption may

increase slightly.

The tyre pressure must be adjusted according

to the load the vehicle is carrying. If the vehi-

cle is going to carry the maximum load, the

tyre pressure should be increased to maxi-

mum value indicated on the sticker on the in-

side of the fuel tank flap.

Do not forget the spare wheel when checking

the tyre pressures: Keep this spare wheel in-

flated to the highest pressure required for the

road wheels.

In the case of a minimised temporary spare

wheel (125/70 R16 or 125/70 R18) inflate to

a pressure of 4.2 bar as indicated on the tyre

pressure label on the fuel tank flap.

Driving style

Fast cornering, heavy acceleration and hard

braking (squealing tyres) all increase tyre

wear.

Wheel balance

The wheels on new vehicles are balanced.

However, certain circumstances may lead to

imbalance (run-out), which is detected as vi-

brations in the steering wheel. Unbalanced wheels should be rebalanced, as

they otherwise cause excessive wear on

steering, suspension and tyres. A wheel must

also be rebalanced when a new tyre is fitted

or if a tyre is repaired.

Incorrect wheel alignment

Incorrect wheel alignment causes excessive

tyre wear, impairing the safety of the vehicle.

If you notice excessive tyre wear, you should

check wheel alignment at a SEAT Official

Service.

WARNING

● Always adapt the tyre pressure accordingly

when the vehicle load changes.

● A tyre with low air pressure has to flex a lot

more when the vehicle is heavily loaded or at

high speeds, therefore causing overheating

to occur. Under these conditions, the tyre

bead may be released or the tyre may burst.

Risk of accident! For the sake of the environment

Under-inflated tyres will increase fuel con-

sumption. Wear indicators

Fig. 177

Tyre tread: tread wear indicators Tread wear indicators indicate if a tyre is

worn.

The original tyres on your vehicle have

1.6 mm high “tread wear indicators” running

across the tread. Depending on the manufac-

turer, there will be 6 to 8 of them spaced at

equal distances around the tyre. Markings on

the tyre sidewall (for instance the letters

“TWI” or a triangle) indicate the positions of

the tread wear indicators.

The minimum tread depth required by law is

1.6 mm (measured in the tread grooves next

to the tread wear indicators). (Different fig-

ures may apply in other countries.)

»

209Technical specifications

Advice

Operation

Safety

The essentials

Page 214 of 284

Advice

securely and that the brake system functions

correctly.

The wheel bolts must be clean and turn easi-

ly.

A special adapter is required to turn the anti-

theft wheel bolts* ››› page 218.

Tyre monitoring systems Introduction WARNING

Unsuitable handling of the wheels and tyres

may lead to sudden tyre pressure losses, to

tread separation or even to a blow-out.

● Check tyre pressures regularly and ensure

they are maintained at the pressures indica-

ted. Tyre pressure that is too low could cause

overheating, resulting in tread detachment or

even burst tyres.

● Tyre pressure should be that indicated on

the label when the tyres are cold at all times

››› page 243.

● Re

gularly check the cold inflation pressure

of the tyres. If necessary, change the tyre

pressure of the vehicle tyres while they are

cold.

● Regularly check your tyres for damage and

wear. ●

Never exceed the maximum permitted

speed or loads specified for the type of tyre

fitted on your vehicle. For the sake of the environment

Under-inflated tyres lead to increased fuel

consumption and tyre wear. Note

● Driving for the first time with new tyres at a

high speed can cause them to slightly ex-

pand, which could then produce an air pres-

sure warning.

● Only replace used tyres with those author-

ised by SEAT for the corresponding type vehi-

cle.

● Do not only rely on the tyre monitoring sys-

tem. Regularly check your tyres to ensure

that the tyre pressure is correct and that the

tyres are not damaged due to puncture, cuts,

tears and impacts/dents. Remove objects

from the tyres only when they have not

pierced the tyres. Tyre monitor indicator warning lamp

If a light appears

The pressure in one or more tyres has

clearly reduced in comparison to the

tyre pressure set by the driver or the

tyre has structural damage.

Additionally, an audible warning can be heard and a text

message can be seen on the instrument panel display.

Stop the vehicle!

Reduce speed immediately! Stop

the vehicle safely as soon as possible. Avoid sudden

manoeuvres and braking! Check all tyres and pressures.

Replace any damaged tyres. If flashing

System malfunction

The control lamp flashes for approximately one minute

and then lights up permanently.

If tyre pressure is correct, switch the ignition off and on

again. If the control lamp remains lit up, the tyre moni-

toring indicator can be calibrated. Have the system

checked by a specialised workshop.

Several warning and control lamps light up

for a few seconds when the ignition is switch-

ed on while the function is verified. They will

switch off after a few seconds.

WARNING

When the tyres are inflated at different pres-

sures or at a pressure that is too low then a

tyre may be damaged resulting in a loss of 212

Page 224 of 284

Advice

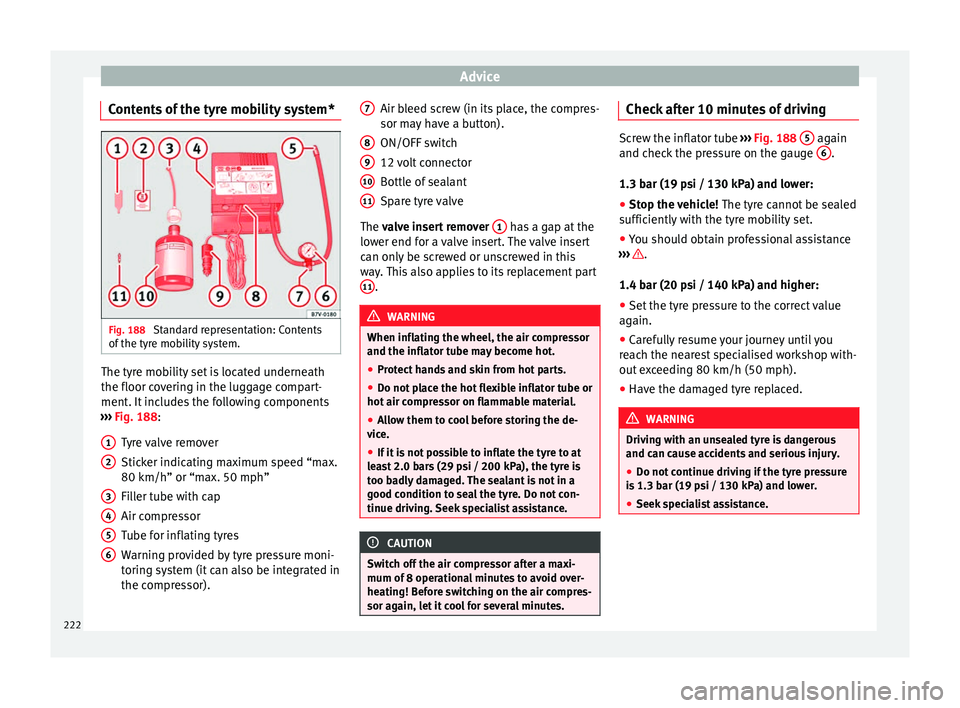

Contents of the tyre mobility system* Fig. 188

Standard representation: Contents

of the tyre mobility system. The tyre mobility set is located underneath

the floor covering in the luggage compart-

ment. It includes the following components

››› Fig. 188 :

T y

re valve remover

Sticker indicating maximum speed “max.

80 km/h” or “max. 50 mph”

Filler tube with cap

Air compressor

Tube for inflating tyres

Warning provided by tyre pressure moni-

toring system (it can also be integrated in

the compressor).

1 2

3

4

5

6 Air bleed screw (in its place, the compres-

sor may have a button).

ON/OFF switch

12 volt connector

Bottle of sealant

Spare tyre valve

The valve insert remover

1 has a gap at the

lower end for a valve insert. The valve insert

can only be screwed or unscrewed in this

way. This also applies to its replacement part 11 .

WARNING

When inflating the wheel, the air compressor

and the inflator tube may become hot.

● Protect hands and skin from hot parts.

● Do not place the hot flexible inflator tube or

hot air compressor on flammable material.

● Allow them to cool before storing the de-

vice.

● If it is not possible to inflate the tyre to at

least 2.0 bars (29 psi / 200 kPa), the tyre is

too badly damaged. The sealant is not in a

good condition to seal the tyre. Do not con-

tinue driving. Seek specialist assistance. CAUTION

Switch off the air compressor after a maxi-

mum of 8 operational minutes to avoid over-

heating! Before switching on the air compres-

sor again, let it cool for several minutes. 7

8

9

10

11 Check after 10 minutes of driving

Screw the inflator tube

››› Fig. 188 5 again

and check the pressure on the gauge 6 .

1.3 bar (19 psi / 130 kPa) and lower:

● Stop the vehicle! The tyre cannot be sealed

sufficiently with the tyre mobility set.

● You should obtain professional assistance

››› .

1.4 bar (20 psi / 140 kPa) and higher:

● Set the tyre pressure to the correct value

again.

● Carefully resume your journey until you

reach the nearest specialised workshop with-

out exceeding 80 km/h (50 mph).

● Have the damaged tyre replaced. WARNING

Driving with an unsealed tyre is dangerous

and can cause accidents and serious injury.

● Do not continue driving if the tyre pressure

is 1.3 bar (19 psi / 130 kPa) and lower.

● Seek specialist assistance. 222