service Seat Leon 5D 2014 Workshop Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2014, Model line: Leon 5D, Model: Seat Leon 5D 2014Pages: 284, PDF Size: 5.85 MB

Page 216 of 284

Advice

● The vehicle is unbalanced because of a

load

● The wheels on an axle are subject to a

heavier load (e.g. with a heavy load).

● The vehicle is fitted with snow chains

● The temporary spare wheel is fitted

● The wheel on one axle is changed

There may be a delay in the reaction of the

tyre

monitoring indicator or it may not in-

dic

ate anything under certain circumstances

(e.g. sporty driving, snow-covered or un-

paved roads, or when driving with snow

chains).

Calibrating the tyre monitoring

indicator Fig. 180

Glove compartment: tyre control

switch. After changing the tyre pressure or replacing

one or more wheels, the tyre monitoring indi-

cator must be recalibrated. Do the same, for

example, when the front and rear wheels are

swapped.

● Switch the ignition on.

● Store the new tyre pressure in the Easy

Connect system with the button and the

function button Setup

›››

page 17 or us-

ing the switch located in the glove compart-

ment* ››› Fig. 180 .

When driv in

g, the system self-calibrates the

tyre pressure provided by the driver and the

wheels fitted. After a long journey with varied

speeds the programmed values are collected

and monitored.

With the wheels under very heavy loads, the

tyre pressure must be increased to the total

recommended tyre pressure before the cali-

bration ››› page 243

. Note

● The tyre monitoring indicator does not

function when there is a fault in the ESC or

ABS ››› page 143.

● An err oneou

s indication may be given when

snow chains are in use because they increase

the tread of the wheel. Compact temporary spare

wheel

General information Fig. 181

Compact temporary spare wheel:

raised floor panel. The temporary spare wheel has been de-

signed to be used for short periods of time.

Have the tyres checked, and if necessary, re-

placed as soon as possible at a SEAT Official

Service or at a specialised workshop.

Please note the following restrictions when

using the compact temporary spare wheel.

The compact temporary spare wheel is de-

signed specifically for this model. For this

reason, do not use a temporary spare wheel

from a different type of vehicle.

214

Page 217 of 284

Wheels

Removing the temporary spare wheel

– Lift and hold up the floor panel to remove

the temporary spare wheel ››› Fig. 181 .

– Turn the thumb wheel anti-clockwise.

– Take out the temporary spare wheel.

Chains

For technical reasons, snow chains must not

be used on the temporary spare wheel.

If you have a puncture on one of the front

wheels when using snow chains, fit the tem-

porary spare wheel in place of one of the rear

wheels. Fit the snow chains on the rear wheel

that you have removed and replace the punc-

tured front wheel with this wheel. WARNING

● After fitting the temporary spare wheel,

check the tyre pressures as soon as possible.

Failure to do so may cause an accident. The

tyre pressures are listed on the inside of the

fuel tank flap.

● Do not drive at over 80 km/h (50 mph)

when the temporary spare wheel is fitted on

the vehicle: risk of accident!

● Avoid heavy acceleration, hard braking and

fast cornering: risk of accident!

● Never use more than one temporary spare

wheel at the same time, risk of accident. ●

No other type of tyre (normal summer or

winter tyre) may be fitted on the compact

temporary spare wheel rim.

● If you are driving using the spare wheel,

the ACC system could automatically switch

off during the journey. Switch off the system

when starting off. Extraction of the spare wheel in

vehicles with SEAT SOUND 10

speakers (with

subwoofer)* –

Disassemble the subwoofer's

floor panel

(c

arpet) as follows:

– LEON/LEON SC model: first, pull the carpet

in the direction of the backrest and then

pull it upwards to remove it. LEON ST mod-

el: lift and secure the floor storage com-

par

tment as explained in ››› page 121.

– Disconnect the subwoofer's speaker cable.

– Turn the sec

uring wheel anti-clockwise.

– Remove the subwoofer speaker and the

s

pare wheel.

– When replacing the spare wheel, place the

subwoofer speaker in the direction indica-

ted b

y the arrow and with the word

“FRONT” facing forward.

– Reconnect the speaker cable and firmly ro-

tate the securing wheel clockwise so that the subwoofer system and wheel are firmly

in place.

Winter service Winter tyres –

Winter tyres must be fitted on all four

wheels.

– Only use winter tyres that are approved for

your vehicle.

– Please note that the maximum permissible

speed for winter tyres may be lower than

for summer tyres.

– Also note that winter tyres are no longer ef-

fective when the tread is worn down.

– Af

ter fitting the wheels you must always

check the tyre pressures. The correct tyre

pressures are listed on the sticker on the

inside of the fuel tank flap ›››

page 208.

In winter road conditions winter tyres will

considerably improve vehicle handling. The

design of summer tyres (width, rubber com-

pound, tread pattern) gives less grip on ice

and snow. This applies particularly to vehi-

cles equipped with wide section tyres or with

high speed tyres (code letters H, V or Y on

the sidew

all). »

215

Technical specifications

Advice

Operation

Safety

The essentials

Page 218 of 284

Advice

Only use winter tyres of the correct type ap-

proved for your vehicle. The sizes of these

tyres are specified in the vehicle's docu-

ments (e.g. EC Certificate of Conformity or

COC 1)

). The vehicle documentation varies de-

pending on the country of residence. See al-

so ››› page 210 .

W int

er tyres lose a great deal of their proper-

ties when the tread

is worn down to a depth

of 4 mm.

The performance of winter tyres is also se-

verely impaired by ageing, even if the tread is

still much deeper than 4 mm.

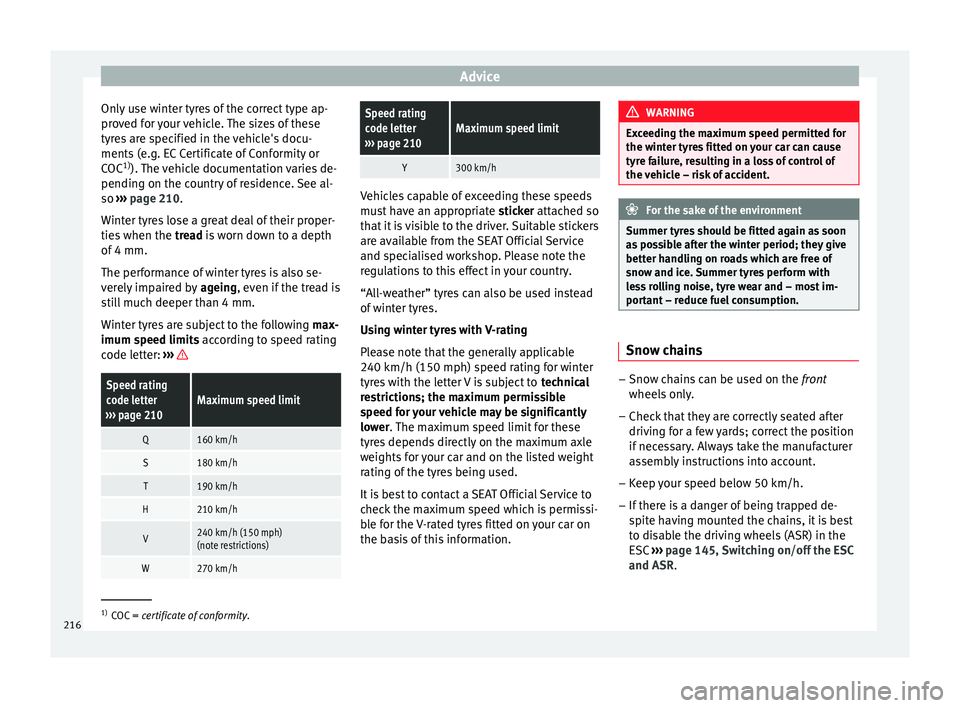

Winter tyres are subject to the following max-

imum speed limits according to speed rating

code l

etter: ›››

Speed rating

code letter

››› page 210Maximum speed limit

Q160 km/h

S180 km/h

T190 km/h

H210 km/h

V240 km/h (150 mph)

(note restrictions)

W270 km/h

Speed rating

code letter

››› page 210Maximum speed limit

Y300 km/h Vehicles capable of exceeding these speeds

must have an appropriate

sticker attached so

that it is visible to the driver. Suitable stickers

are available from the SEAT Official Service

and specialised workshop. Please note the

regulations to this effect in your country.

“All-weather” tyres can also be used instead

of winter tyres.

Using winter tyres with V-rating

Please note that the generally applicable

240 km/h (150 mph) speed rating for winter

tyres with the letter V is subject to technical

restrictions; the maximum permissible

speed for your vehicle may be significantly

lower . The maximum speed limit for these

ty r

es depends directly on the maximum axle

weights for your car and on the listed weight

rating of the tyres being used.

It is best to contact a SEAT Official Service to

check the maximum speed which is permissi-

ble for the V-rated tyres fitted on your car on

the basis of this information. WARNING

Exceeding the maximum speed permitted for

the winter tyres fitted on your car can cause

tyre failure, resulting in a loss of control of

the vehicle – risk of accident. For the sake of the environment

Summer tyres should be fitted again as soon

as possible after the winter period; they give

better handling on roads which are free of

snow and ice. Summer tyres perform with

less rolling noise, tyre wear and – most im-

portant – reduce fuel consumption. Snow chains

–

Snow chains can be used on the front

wheels only.

– Check that they are correctly seated after

driving for a few yards; correct the position

if necessary. Always take the manufacturer

assembly instructions into account.

– Keep your speed below 50 km/h.

– If there is a danger of being trapped de-

spite having mounted the chains, it is best

to disable the driving wheels (ASR) in the

ESC ›››

page 145, Switching on/off the ESC

and ASR . 1)

COC = certificate of conformity.

216

Page 220 of 284

Advice

Fitting

– Fit the wheel cover onto the wheel rim by

pressing it firmly. Put pressure initially on

the point of the cut-out for the valve. Next

fit the rest of the hubcap

Wheel bolt caps* Fig. 183

Wheel: wheel bolts with caps. Removal

– Fit the plastic clip (vehicle tools) over the

cap until it clicks into place ››› Fig. 183.

– Remove the cap with the plastic clip. Anti-theft wheel bolts

Fig. 184

Anti-theft wheel bolt with cap and

adapter. A special adapter (vehicle tools) is required

to remove the anti-theft wheel bolts.

–

Remove the wheel cover* or the cap*.

– Insert the adapter onto the anti-theft wheel

bolt and push it on as far as it will go.

– Insert the wheel brace (vehicle tools) onto

the adapter as far as it will go.

– Remove the wheel bolt ››› page 218. Note

Make a note of the code number of the anti-

theft wheel bolt and keep it in a safe place,

but not in your vehicle. If you need a new

adapter, you can obtain it from the SEAT Offi-

cial Service, indicating the code number. Loosening the wheel bolts

Fig. 185

Wheel: loosen the wheel bolts. –

Insert the box spanner (vehicle tools) onto

the wheel bolt as far as it will go. An adapt-

er is required to unscrew or tighten the an-

ti-theft wheel bolts ››› page 218.

– Turn the wheel bolt approximately one turn

to the left ››› Fig. 185 (arrow). To apply the

r equir

ed torque, hold the wheel brace at

the end. If it is not possible to loosen a

wheel bolt, carefully apply pressure with

one foot on the end of the box spanner.

Hold on to the vehicle for support and take

care not to slip. WARNING

Slightly loosen the wheel bolts (one turn) be-

fore raising the vehicle with the jack*. If not,

an accident may occur. 218

Page 232 of 284

Advice

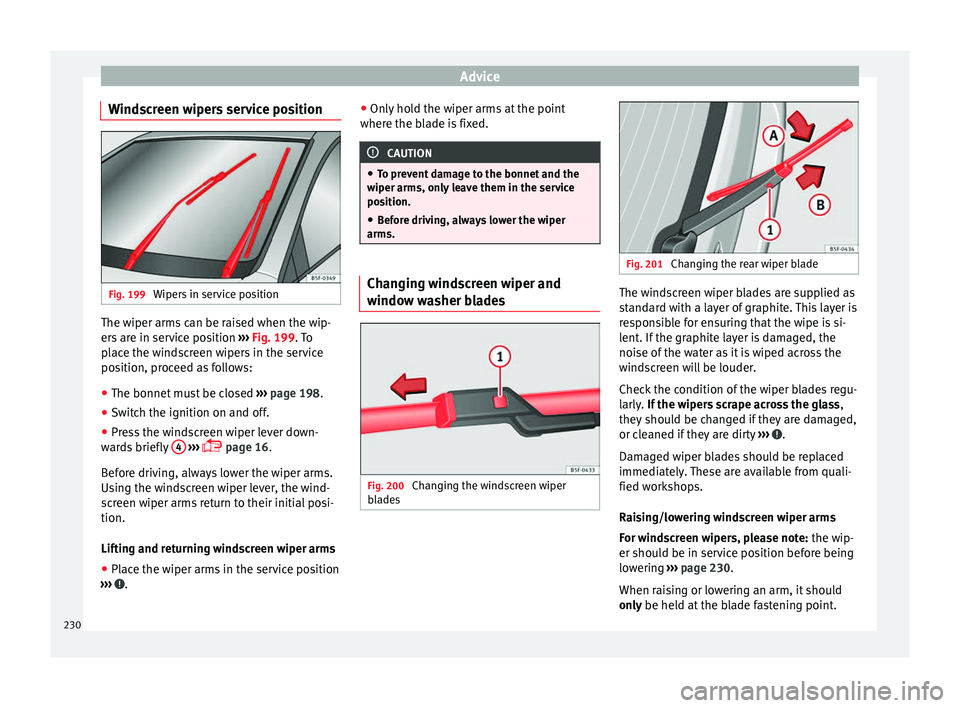

Windscreen wipers service position Fig. 199

Wipers in service position The wiper arms can be raised when the wip-

ers are in service position

››› Fig. 199 . To

p l

ace the windscreen wipers in the service

position, proceed as follows:

● The bonnet must be closed ››› page 198.

● Switch the ignition on and off.

● Press the windscreen wiper lever down-

wards briefly 4

›››

page 16.

Before driving, always lower the wiper arms.

Using the windscreen wiper lever, the wind-

screen wiper arms return to their initial posi-

tion.

Lifting and returning windscreen wiper arms

● Place the wiper arms in the service position

››› . ●

Only hold the wiper arms at the point

where the blade is fixed. CAUTION

● To prevent damage to the bonnet and the

wiper arms, only leave them in the service

position.

● Before driving, always lower the wiper

arms. Changing windscreen wiper and

window washer blades

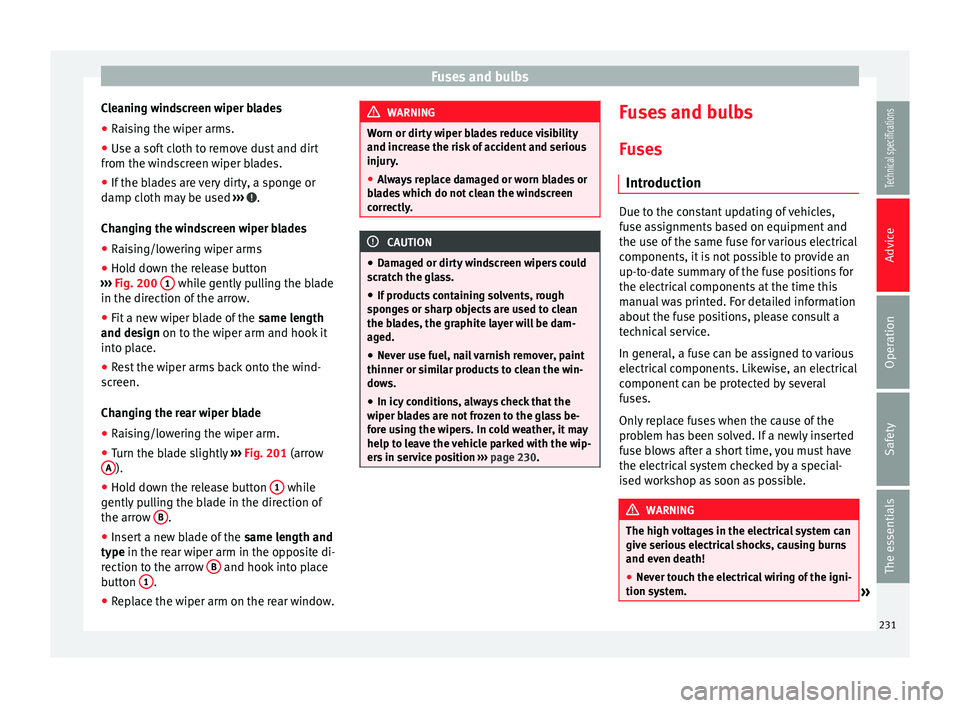

Fig. 200

Changing the windscreen wiper

blades Fig. 201

Changing the rear wiper blade The windscreen wiper blades are supplied as

standard with a layer of graphite. This layer is

responsible for ensuring that the wipe is si-

lent. If the graphite layer is damaged, the

noise of the water as it is wiped across the

windscreen will be louder.

Check the condition of the wiper blades regu-

larly. If the wipers scrape across the glass

,

they shou

ld be changed if they are damaged,

or cleaned if they are dirty ››› .

Damaged wiper blades should be replaced

immediately. These are available from quali-

fied workshops.

Raising/lowering windscreen wiper arms

For windscreen wipers, please note: the wip-

er should be in service position before being

lowering ››› page 230 .

When r ai

sing or lowering an arm, it should

only

be held at the blade fastening point.

230

Page 233 of 284

Fuses and bulbs

Cleaning windscreen wiper blades

● Raising the wiper arms.

● Use a soft cloth to remove dust and dirt

from the windscreen wiper blades.

● If the blades are very dirty, a sponge or

damp cloth may be used ››› .

Changing the windscreen wiper blades

● Raising/lowering wiper arms

● Hold down the release button

››› Fig. 200 1 while gently pulling the blade

in the direction of the arrow.

● Fit a new wiper blade of the same length

and design on to the wiper arm and hook it

int o p

lace.

● Rest the wiper arms back onto the wind-

screen.

Changing the rear wiper blade

● Raising/lowering the wiper arm.

● Turn the blade slightly ››› Fig. 201 (arrow

A ).

● Hold down the release button 1 while

gently pulling the blade in the direction of

the arrow B .

● Insert a new blade of the same length and

type in the rear wiper arm in the opposite di-

r ection t

o the arrow B and hook into place

button 1 .

● Replace the wiper arm on the rear window. WARNING

Worn or dirty wiper blades reduce visibility

and increase the risk of accident and serious

injury.

● Always replace damaged or worn blades or

blades which do not clean the windscreen

correctly. CAUTION

● Damaged or dirty windscreen wipers could

scratch the glass.

● If products containing solvents, rough

sponges or sharp objects are used to clean

the blades, the graphite layer will be dam-

aged.

● Never use fuel, nail varnish remover, paint

thinner or similar products to clean the win-

dows.

● In icy conditions, always check that the

wiper blades are not frozen to the glass be-

fore using the wipers. In cold weather, it may

help to leave the vehicle parked with the wip-

ers in service position ››› page 230. Fuses and bulbs

Fuses Introduction Due to the constant updating of vehicles,

fuse assignments based on equipment and

the use of the same fuse for various electrical

components, it is not possible to provide an

up-to-date summary of the fuse positions for

the electrical components at the time this

manual was printed. For detailed information

about the fuse positions, please consult a

technical service.

In general, a fuse can be assigned to various

electrical components. Likewise, an electrical

component can be protected by several

fuses.

Only replace fuses when the cause of the

problem has been solved. If a newly inserted

fuse blows after a short time, you must have

the electrical system checked by a special-

ised workshop as soon as possible.

WARNING

The high voltages in the electrical system can

give serious electrical shocks, causing burns

and even death!

● Never touch the electrical wiring of the igni-

tion system. » 231

Technical specifications

Advice

Operation

Safety

The essentials

Page 238 of 284

Advice

– Remove the bulb by pressing on the bulb

holder and turning it anti-clockwise at the

same time.

– Installation involves all of the above steps

in reverse sequence.

Main beam headlight bulb Fig. 210

Main beam headlight bulb. Fig. 211

Main beam headlight bulb. –

Raise the bonnet.

– Move the loop ››› Fig. 210 1 in the direc-

tion of the arrow and remove the cover.

– Slide connector ››› Fig. 211 2 to the left or

right and pull.

– Remove the bulb by disconnecting the con-

nector.

– Installation involves all of the above steps

in reverse sequence.

Changing bulb for front fog

light* Front fog light bulb Fig. 212

Front fog light. Fig. 213

Front fog light. –

Remove the bolt ››› Fig. 212 1 from the fog

light grille with a screwdriver.

– Remove the bolts (3x) ››› Fig. 213 2 to re-

move the fog light.

– Remove the fog light. Note

Due to the difficulty of accessing fog light

bulbs, have them replaced at a Technical

Service or specialised workshop. 236

Page 239 of 284

Fuses and bulbs

Fog light, FR version Fig. 214

Fog light: access to the connector

and to the light bulb holder. Fig. 215

Fog light: access to the connector

and to the light bulb holder. –

Remove the 3 bolts 1

››› Fig. 214 from the

in s

ide of the wheel housing and the 2 bot-

tom bolts 2

››› Fig. 214 from the bumper

with the help of a screwdriver. –

Pull the wheel housing 3

››› Fig. 215 ac-

c e

ss the 2 hidden screws 4

››› Fig. 215 of

the b umper

.

– Remove the screws using a screwdriver.

– Pull the bumper to release it from its an-

chorages to access the connector and the

light bulb holder. Note

Due to the difficulty of accessing fog light

bulbs, have them replaced at a Technical

Service or specialised workshop. Remove the bulb holder

Fig. 216

Front fog light. –

Remove connector ››› Fig. 216 1 from the

bulb.

– Turn the bulb holder ››› Fig. 216

2 anti-

clockwise and pull. –

Remove the bulb by pressing on the bulb

holder and turning it anti-clockwise at the

same time.

– Installation involves all of the above steps

in reverse sequence.

– Check that the bulb works properly.

Changing tail light bulbs (on

side panel) Overview of tail lights Rear lights on the side panel

Turn signalPY21W NA LL

Side light and brake lightP21W LL

237

Technical specifications

Advice

Operation

Safety

The essentials

Page 244 of 284

Technical specifications

VIN in the Easy Connect – Select: Function button CAR > control but-

ton (Car)* Systems > Service & Control >

Ch a

ssis number .

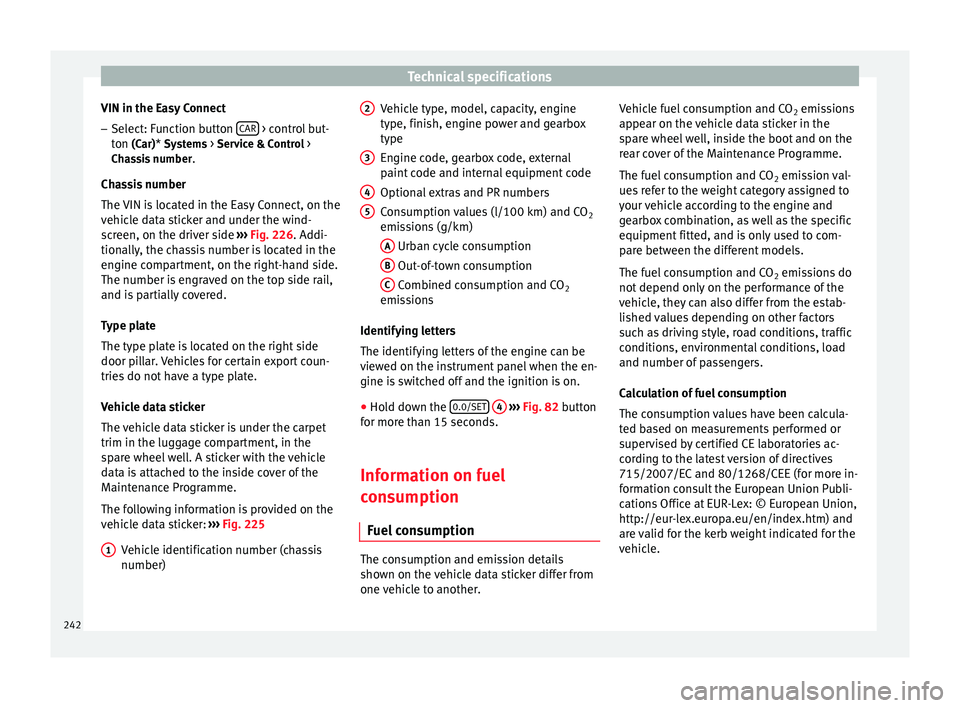

Chassis number

The VIN is located in the Easy Connect, on the

vehicle data sticker and under the wind-

screen, on the driver side ››› Fig. 226. Addi-

tional

ly, the chassis number is located in the

engine compartment, on the right-hand side.

The number is engraved on the top side rail,

and is partially covered.

Type plate

The type plate is located on the right side

door pillar. Vehicles for certain export coun-

tries do not have a type plate.

Vehicle data sticker

The vehicle data sticker is under the carpet

trim in the luggage compartment, in the

spare wheel well. A sticker with the vehicle

data is attached to the inside cover of the

Maintenance Programme.

The following information is provided on the

vehicle data sticker: ››› Fig. 225

Vehicle identification number (chassis

number)

1 Vehicle type, model, capacity, engine

type, finish, engine power and gearbox

type

Engine code, gearbox code, external

paint code and internal equipment code

Optional extras and PR numbers

Consumption values (l/100 km) and CO

2

emissions (g/km)

A Urban cycle consumption

B Out-of-town consumption

C Combined consumption and CO

2

emissions

Identifying letters

The identifying letters of the engine can be

viewed on the instrument panel when the en-

gine is switched off and the ignition is on.

● Hold down the 0.0/SET

4

››› Fig. 82 button

for more than 15 seconds.

Information on fuel

consumption

Fuel consumption The consumption and emission details

shown on the vehicle data sticker differ from

one vehicle to another.2 3

4

5 Vehicle fuel consumption and CO

2 emissions

appear on the vehicle data sticker in the

spare wheel well, inside the boot and on the

rear cover of the Maintenance Programme.

The fuel consumption and CO 2 emission val-

ues refer to the weight category assigned to

your vehicle according to the engine and

gearbox combination, as well as the specific

equipment fitted, and is only used to com-

pare between the different models.

The fuel consumption and CO 2 emissions do

not depend only on the performance of the

vehicle, they can also differ from the estab-

lished values depending on other factors

such as driving style, road conditions, traffic

conditions, environmental conditions, load

and number of passengers.

Calculation of fuel consumption

The consumption values have been calcula-

ted based on measurements performed or

supervised by certified CE laboratories ac-

cording to the latest version of directives

715/2007/EC and 80/1268/CEE (for more in-

formation consult the European Union Publi-

cations Office at EUR-Lex: © European Union,

http://eur-lex.europa.eu/en/index.htm) and

are valid for the kerb weight indicated for the

vehicle.

242

Page 246 of 284

Technical specifications195/65 R15Chains with links of maximum 15 mm

205/55 R16Chains with links of maximum 15 mm

205/50 R17Chains with links of maximum 15 mm

225/45 R17Chains with links of maximum 9 mm

225/40 R18Chains with links of maximum 9 mm

225/35 R19Chains with links of maximum 7 mm

205/55 R17Snow chains are not permitted

225/45 R18Snow chains are not permitted

Wheel bolts

After the wheels have been changed, the

tightening torque

of the wheel bolts should

be c hec

ked as soon as possible with a torque

wrench ››› . The tightening torque for steel

and alloy wheels is 120 Nm. WARNING

● Check the tyre pressure at least once per

month. Checking the tyre pressure is very im-

portant. If the tyre pressure is too high or too

low, there is an increased danger of accidents

- particularly at high speeds.

● If the tightening torque of the wheel bolts

is too low, they could loosen while the vehi-

cle is in motion. Risk of accident! If the tight-

ening torque is too high, the wheel bolts and

threads can be damaged. Note

We recommend that you ask your Technical

Service for information about appropriate

wheel, tyre and snow chain size. 244