wheel bolts Seat Leon 5D 2015 Owner's manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2015, Model line: Leon 5D, Model: Seat Leon 5D 2015Pages: 308, PDF Size: 5.93 MB

Page 60 of 308

The essentials

Changing a wheel V ehic

l

e tool kit Fig. 69

See position on page 8 An adapter for the anti-theft wheel bolts*

T

o

wline anc

horage

Box spanner for wheel bolts*

Crank handle for jack

Jack*

Wire hook for pulling off the wheel cov-

ers*/wheel bolt cap clip.

››› in What to do first on page 56

››› page 86 1

2

3

4

5

6 Wheel covers*

Fig. 70

Remove the wheel cover. The wheel covers must be removed for access

t

o the wheel

bo

lts.

Removing ● Remove the wheel cover using the wire

hook ››

› Fig. 70.

● Hook this into one of the cut-outs of the

wheel co

ver.

Fitting

● Fit the wheel cover onto the wheel rim by

pres

sing it firmly.

● Put pressure on the point of the cut-out for

the valv

e.

● Next fit the rest of the wheel cover Wheel bolt caps*

Fig. 71

Wheel: wheel bolts with caps. Removal

● Fit the plastic clip (vehicle tools) over the

c ap u

nti

l it clicks into place ››› Fig. 71.

● Remove the cap with the plastic clip. 58

Page 61 of 308

The essentials

Anti-theft wheel bolts Fig. 72

Anti-theft wheel bolt with cap and

a d

apt

er. ●

Remove the wheel cover* or the cap*.

● Insert the special adapter (vehicle tools)

ont o the anti-thef

t

wheel bolt and push it on

as far as it will go.

● Insert the wheel brace (vehicle tools) onto

the adapt

er as far as it will go.

● Remove the wheel bolt ›››

page 59 . Note

Make a note of the code number of the anti-

theft wheel

bolt and keep it in a safe place,

but not in your vehicle. If you need a new

adapter, you can obtain it from the SEAT Offi-

cial Service, indicating the code number. Loosening the wheel bolts

Fig. 73

Wheel: loosen the wheel bolts. ●

Insert the box spanner (vehicle tools) onto

the wheel bo

lt

as far as it will go. An adapter

is required to unscrew or tighten the anti-

theft wheel bolts ››› page 59.

● Turn the wheel bolt approximately one turn

to the lef

t ››› Fig. 73 (arrow). To apply the re-

quired torque, hold the wheel brace at the

end. If it is not possible to loosen a wheel

bolt, carefully apply pressure with one foot

on the end of the box spanner. Hold on to the

vehicle for support and take care not to slip. WARNING

Slightly loosen the wheel bolts (one turn) be-

for e r

aising the vehicle with the jack*. If not,

an accident may occur. Lifting the vehicle

Fig. 74

Crossbar: marks. Fig. 75

Strut: mounting the jack on the vehi-

c l

e. ●

Place the jack* (vehicle tools) on firm

gr ou

nd. If

necessary use a large, strong

board or similar support. If the surface is slip-

pery (for example tiles) place the jack on a

rubber mat or similar to prevent it from slip-

ping ››› .

» 59

Page 62 of 308

The essentials

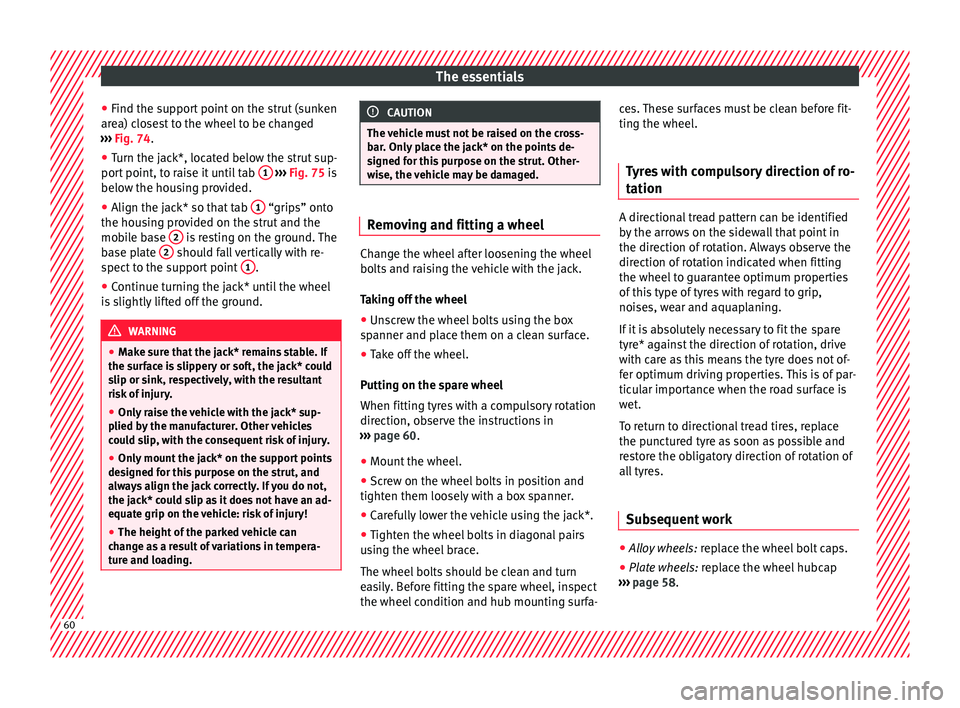

● Find the s up

por

t point on the strut (sunken

area) closest to the wheel to be changed

››› Fig. 74.

● Turn the jack*, located below the strut sup-

port point, t

o raise it until tab 1

› ››

Fig. 75

is

below the housing provided.

● Align the jack* so that tab 1 “grips” onto

the hou s

in

g provided on the strut and the

mobile base 2 is resting on the ground. The

b a

se p

late 2 should fall vertically with re-

s pect

t

o the support point 1 .

● Continue turning the jack* until the wheel

i s

s

lightly lifted off the ground. WARNING

● Mak e s

ure that the jack* remains stable. If

the surface is slippery or soft, the jack* could

slip or sink, respectively, with the resultant

risk of injury.

● Only raise the vehicle with the jack* sup-

plied by

the manufacturer. Other vehicles

could slip, with the consequent risk of injury.

● Only mount the jack* on the support points

designed f

or this purpose on the strut, and

always align the jack correctly. If you do not,

the jack* could slip as it does not have an ad-

equate grip on the vehicle: risk of injury!

● The height of the parked vehicle can

chan

ge as a result of variations in tempera-

ture and loading. CAUTION

The vehicle must not be raised on the cross-

bar . On

ly place the jack* on the points de-

signed for this purpose on the strut. Other-

wise, the vehicle may be damaged. Removing and fitting a wheel

Change the wheel after loosening the wheel

bolts

and r

aising the vehicle with the jack.

Taking off the wheel ● Unscrew the wheel bolts using the box

sp anner and p

lace them on a clean surface.

● Take off the wheel.

Putting on the s

pare wheel

When fitting tyres with a compulsory rotation

direction, observe the instructions in

››› page 60.

● Mount the wheel.

● Screw on the wheel bolts in position and

tighten them loosely

with a box spanner.

● Carefully lower the vehicle using the jack*.

● Tighten the wheel bolts in diagonal pairs

usin

g the wheel brace.

The wheel bolts should be clean and turn

easily. Before fitting the spare wheel, inspect

the wheel condition and hub mounting surfa- ces. These surfaces must be clean before fit-

ting the wheel.

T

yres with compulsory direction of ro-

tation A directional tread pattern can be identified

by

the arr

ows on the sidewall that point in

the direction of rotation. Always observe the

direction of rotation indicated when fitting

the wheel to guarantee optimum properties

of this type of tyres with regard to grip,

noises, wear and aquaplaning.

If it is absolutely necessary to fit the spare

tyre* against the direction of rotation, drive

with care as this means the tyre does not of-

fer optimum driving properties. This is of par-

ticular importance when the road surface is

wet.

To return to directional tread tires, replace

the punctured tyre as soon as possible and

restore the obligatory direction of rotation of

all tyres.

Subsequent work ●

Alloy wheels: rep

l

ace the wheel bolt caps.

● Plate wheels: rep l

ace the wheel hubcap

››› page 58.60

Page 63 of 308

The essentials

● Ret

urn al

l tools to their proper storing loca-

tion.

● If the replaced wheel does not fit in the

spar

e wheel housing, store it safely in the

luggage compartment ›››

page 148.

● Check the tyre pressure of the newly moun-

ted tyr

e as soon as possible.

● In vehicles fitted with a tyre pressure indi-

cator

, adjust the pressure and store the read-

ing in the radio/Easy Connect system*

››› page 259.

● Have the tightening torque of the wheel

bolts c

hecked as soon as possible with a tor-

que wrench (it should be 120 Nm). Mean-

while, drive carefully.

● Have the flat tyre replaced as quickly as

poss

ible.

Snow chains Use Snow chains should only be used on the

fr

on

t

wheels.

Check that they are correctly seated after

driving for a few yards; correct the position if

necessary, in accordance with the manufac-

turer's fitting instructions. Keep your speed

below 50 km/h. If there is a danger of being trapped despite

havin

g mounted the chains, it is best to disa-

ble the driving wheels (ASR) in the ESC

››› page 180, Switching on/off the ESC

and ASR.

Snow chains will improve braking ability as

well as traction in winter conditions.

For technical reasons snow chains may only

be used with the following wheel rim/tyre

combination.

195/65 R15Chains with links of maximum 15 mm

205/55 R16Chains with links of maximum 15 mm

225/45 R17Chains with links of maximum 9 mm

225/40 R18Chains with links of maximum 9 mm Remove wheel covers and any integral trim

rin

g bef

or

e fitting snow chains.

Remove the chains when roads are free of

snow. Driving characteristics worsen, and the

wheels become damaged quickly and may

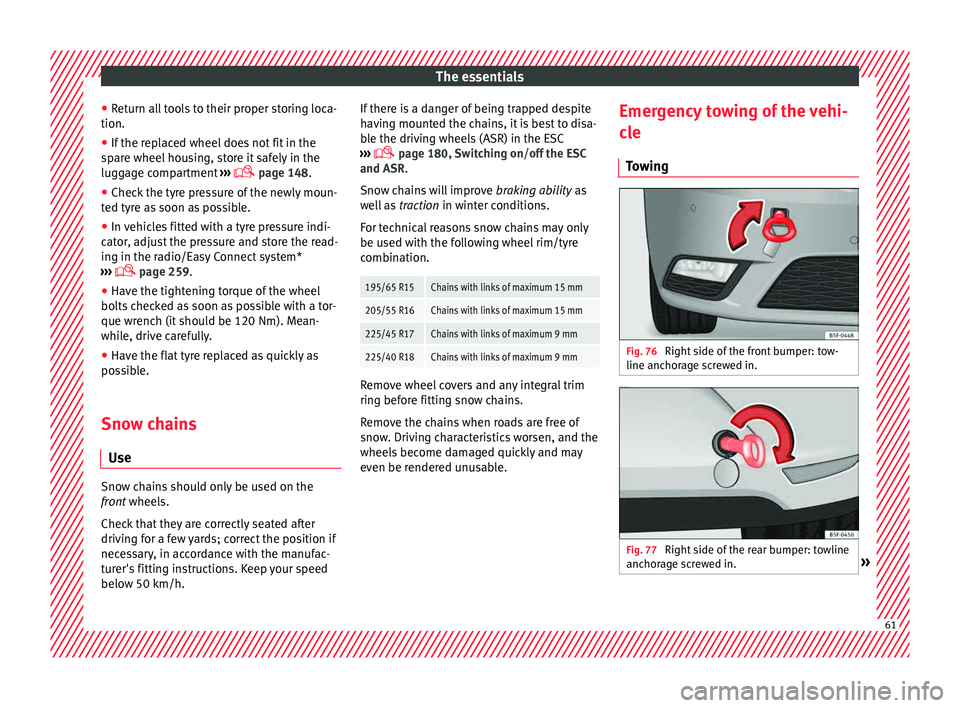

even be rendered unusable. Emergency towing of the vehi-

cle

T

owing Fig. 76

Right side of the front bumper: tow-

line anc hor

ag

e screwed in. Fig. 77

Right side of the rear bumper: towline

anc hor

ag

e screwed in. » 61

Page 88 of 308

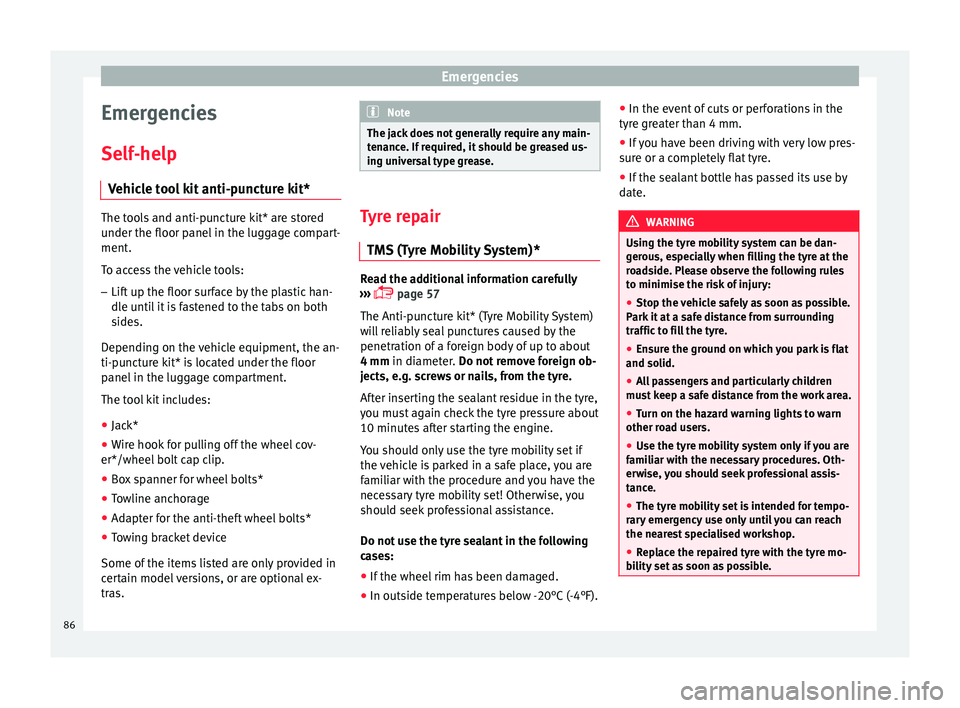

Emergencies

Emergencies

Self -help

V ehic

le tool kit anti-puncture kit* The tools and anti-puncture kit* are stored

under the floor p

anel

in the luggage compart-

ment.

To access the vehicle tools:

– Lift up the floor surface by the plastic han-

dle u nti

l it is fastened to the tabs on both

sides.

Depending on the vehicle equipment, the an-

ti-puncture kit* is located under the floor

panel in the luggage compartment.

The tool kit includes:

● Jack*

● Wire hook for pulling off the wheel cov-

er*/wheel bolt

cap clip.

● Box spanner for wheel bolts*

● Towline anchorage

● Adapter for the anti-theft wheel bolts*

● Towing bracket device

Some of the items

listed are only provided in

certain model versions, or are optional ex-

tras. Note

The jack does not generally require any main-

ten anc

e. If required, it should be greased us-

ing universal type grease. Tyre repair

TMS (T

yre Mobility System)* Read the additional information carefully

›› ›

page 57

The Anti-puncture kit* (Tyre Mobility System)

will reliably seal punctures caused by the

penetration of a foreign body of up to about

4 mm in diameter. Do not remove foreign ob-

jects, e.g. screws or nails, from the tyre.

After inserting the sealant residue in the tyre,

you must again check the tyre pressure about

10 minutes after starting the engine.

You should only use the tyre mobility set if

the vehicle is parked in a safe place, you are

familiar with the procedure and you have the

necessary tyre mobility set! Otherwise, you

should seek professional assistance.

Do not use the tyre sealant in the following

cases:

● If the wheel rim has been damaged.

● In outside temperatures below -20°C (-4°F). ●

In the ev ent

of

cuts or perforations in the

tyre greater than 4 mm.

● If you have been driving with very low pres-

sure or a c

ompletely flat tyre.

● If the sealant bottle has passed its use by

date. WARNING

Using the tyre mobility system can be dan-

ger ou

s, especially when filling the tyre at the

roadside. Please observe the following rules

to minimise the risk of injury:

● Stop the vehicle safely as soon as possible.

Park it

at a safe distance from surrounding

traffic to fill the tyre.

● Ensure the ground on which you park is flat

and solid.

● Al

l passengers and particularly children

must

keep a safe distance from the work area.

● Turn on the hazard warning lights to warn

other roa

d users.

● Use the tyre mobility system only if you are

famili

ar with the necessary procedures. Oth-

erwise, you should seek professional assis-

tance.

● The tyre mobility set is intended for tempo-

rary

emergency use only until you can reach

the nearest specialised workshop.

● Replace the repaired tyre with the tyre mo-

bility

set as soon as possible.86

Page 99 of 308

Fuses and bulbs

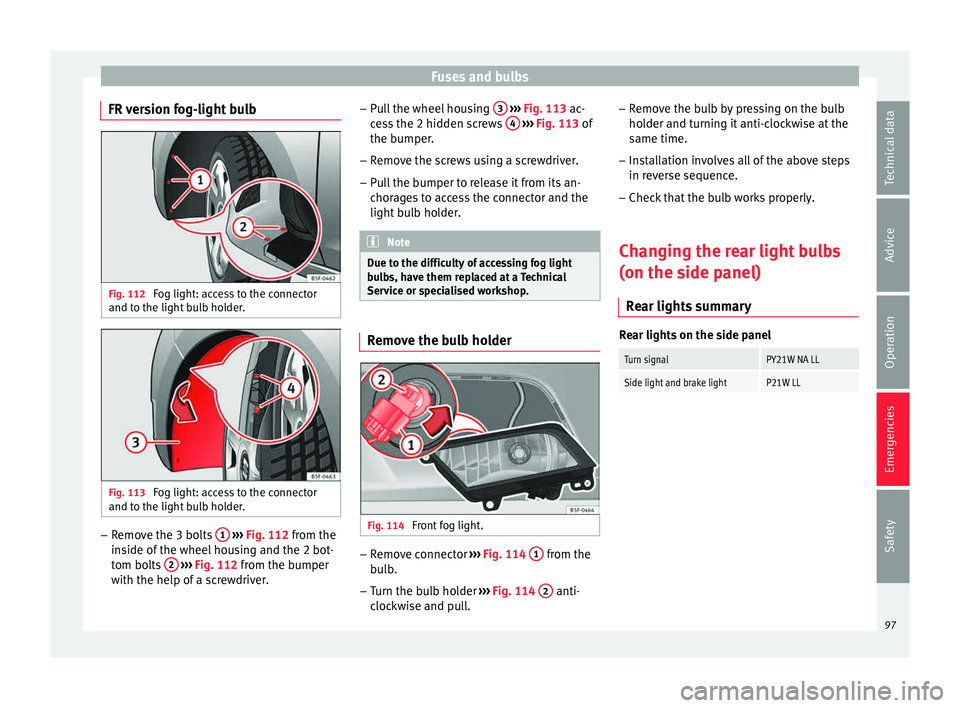

FR version fog-light bulb Fig. 112

Fog light: access to the connector

and t o the light

b

ulb holder. Fig. 113

Fog light: access to the connector

and t o the light

b

ulb holder. –

Remove the 3 bolts 1

› ›

› Fig. 112

from the

inside of the wheel housing and the 2 bot-

tom bolts 2

› ›

› Fig. 112

from the bumper

with the help of a screwdriver. –

Pul

l the wheel housing 3

› ››

Fig. 113

ac -

cess the 2 hidden screws 4

› ››

Fig. 113

of

the b

umper.

– Remove the screws using a screwdriver.

– Pull the bumper to release it from its an-

chorag

es to access the connector and the

light bulb holder. Note

Due to the difficulty of accessing fog light

bu l

bs, have them replaced at a Technical

Service or specialised workshop. Remove the bulb holder

Fig. 114

Front fog light. –

Remove connector ››

›

Fig. 114 1 from the

b ul

b.

– Turn the bulb holder ›››

Fig. 114 2 anti-

c loc

k

wise and pull. –

Remov

e the bulb by pressing on the bulb

holder and turning it anti-clockwise at the

same time.

– Installation involves all of the above steps

in rever

se sequence.

– Check that the bulb works properly.

Changing the rear light bulbs

(on the side panel) R

ear lights summary Rear lights on the side panel

Turn signalPY21W NA LL

Side light and brake lightP21W LL

97

Technical data

Advice

Operation

Emergencies

Safety

Page 236 of 308

Advice

Carbon parts The carbon parts on your vehicle have a pain-

ted s

ur

face. They do not need any special

care and are cleaned just like any other pain-

ted part ››› page 231.

Paint damage Minor damage to the paint, such as scratches

or st

one c

hips, should be touched up without

delay before the metal starts to corrode. Suit-

able touch-up brushes or sprays for your car

can be obtained from a SEAT Official Service.

The number of the original paint finish on the

vehicle is given on the data sticker

››› page 265.

If corrosion is already visible it must be thor-

oughly removed by a specialised workshop.

Windows Clear vision is an essential safety factor.

The w

ind

s

creen must not be cleaned with in-

sect remover or wax, otherwise the wind-

screen wipers will not function properly (jud-

dering).

Traces of rubber, oil, grease or silicone can

be removed with a window cleaning solution

or a silicone remover. Wax residue can only be removed with a special cleaner. Your SEAT

Offici

al Service will be able to provide you

with more detailed information.

The windows should also be cleaned on the

inside at regular intervals.

Use a separate cloth or chamois to dry the

windows. Cloths used for waxing and polish-

ing contain residues that will cause smears

on the glass. WARNING

Do not use water-repellent coatings on the

wind s

creen. In bad visibility conditions (e.g.

in the rain, dark or with a low sun), these

coatings may cause dazzle: risk of accident!

Such coatings can also cause the windscreen

wiper blades to make noise. CAUTION

● Remo v

e snow and ice from windows and ex-

terior mirrors with a plastic scraper only. To

avoid scratches caused by dirt on the glass,

the scraper should only be pushed in one di-

rection and not moved to and fro.

● The heating element for the rear window is

located on the inner s

ide of the window. To

avoid damaging them, do not apply stickers

to these heating elements.

● Never use warm or hot water to remove

snow and ic

e from windows and mirrors. This

could cause the glass to crack! Wheels

The wheels require regular attention to pre-

serv

e their ap

pearance. It is important to re-

move road salt and brake dust by washing

the wheels at regular intervals, otherwise the

finish will be impaired.

After washing, the wheels should only be

cleaned with an "acid-free" cleaning agent

for alloy wheels. This is available from SEAT

Official Services and specialist retailers. Nev-

er leave the cleaning agent on the rims for

any longer than specified in the instructions

before rinsing it off. If the wheel cleaner fluid

contains acid it can attack the surfaces of the

wheel bolts.

Car polish or other abrasive agents should

not be used for maintaining the rims. If the

protective coating is damaged, e.g. by flying

stones, the damaged area should be re-

paired immediately. WARNING

Please note when cleaning the wheels that

wat er

, ice and road salt can impair the effec-

tiveness of the brakes; this can cause an acci-

dent. Exhaust tail pipe

It is important to remove road salt and brake

du

s

t

by washing the wheels at regular

234

Page 261 of 308

Wheels

manufacturer. Inadequate tyre clearance can

re

s

ult in damage to the tyres or the vehicle,

causing a serious safety risk. Risk of acci-

dent! It may also invalidate the vehicle's reg-

istration for use on public roads.

● Avoid running the vehicle on tyres that are

more than 6

years old. If you have no alterna-

tive, you should drive slowly and with extra

care at all times.

● If wheel trims are fitted after the car is pur-

cha

sed, ensure that there is an adequate flow

of air for cooling the brake system. For the sake of the environment

Old tyres must be disposed of according to

the la w

s in the country concerned. Note

● Never mou nt

used tyres if you are not sure

of their “previous history”.

● For technical reasons, it is not generally

poss

ible to use the wheels from other vehi-

cles. In some cases, this may also be true for

the same model of wheel. Wheel bolts

The wheel

bolts

ar

e m

atched to the rims.

When installing different wheels (for instance

alloy wheels or wheels with winter tyres) it is

important to use the correct wheel bolts with

the right length and correctly shaped bolt heads. This ensures that wheels are fitted se-

curely

and that the brake system functions

correctly.

The wheel bolts must be clean and turn easi-

ly.

A special adapter is required to turn the anti-

theft wheel bolts* ›››

page 59.

Tyre monitoring systems Introduction WARNING

Unsuitable handling of the wheels and tyres

ma y

lead to sudden tyre pressure losses, to

tread separation or even to a blow-out.

● Check tyre pressures regularly and ensure

they are m

aintained at the pressures indica-

ted. Tyre pressure that is too low could cause

overheating, resulting in tread detachment or

even burst tyres.

● Tyre pressure should be that indicated on

the label when the ty

res are cold at all times

››› page 267.

● Regularly check the cold inflation pressure

of the tyr

es. If necessary, change the tyre

pressure of the vehicle tyres while they are

cold.

● Regularly check your tyres for damage and

wear

. ●

Never e x

ceed the maximum permitted

speed or loads specified for the type of tyre

fitted on your vehicle. For the sake of the environment

Under-inflated tyres lead to increased fuel

c on s

umption and tyre wear. Note

● Drivin g f

or the first time with new tyres at a

high speed can cause them to slightly ex-

pand, which could then produce an air pres-

sure warning.

● Only replace used tyres with those author-

ised by

SEAT for the corresponding type vehi-

cle.

● Do not only rely on the tyre monitoring sys-

tem. Re

gularly check your tyres to ensure

that the tyre pressure is correct and that the

tyres are not damaged due to puncture, cuts,

tears and impacts/dents. Remove objects

from the tyres only when they have not

pierced the tyres. 259

Technical data

Advice

Operation

Emergencies

Safety

Page 269 of 308

Technical specifications

Note

In practice, and considering all the factors

mentioned here, c on

sumption values can dif-

fer from those calculated in the current Euro-

pean regulations. Weights

Kerb weight refers to the basic model with a

fuel

t

ank filled to 90% capacity and without

optional extras. The figure quoted includes

75 kg to allow for the weight of the driver.

Special versions, optional equipment fittings

or retro-fitting accessories will increase the

weight of the vehicle ››› .

WARNING

● Ple a

se note that the centre of gravity may

shift when transporting heavy objects; this

may affect vehicle handling and lead to an ac-

cident. Always adjust your speed and driving

style to suit road conditions and require-

ments.

● Never exceed the gross axle weight rating

or the gros

s vehicle weight rating. If the per-

missible axle load or the permissible total

weight is exceeded, the driving characteris-

tics of the vehicle may change, which could

lead to accidents, injuries and damage to the

vehicle. Driving with a trailer

Tr

ai

ler weights Trailer weight

The trai

l

er weights and drawbar loads ap-

proved are selected in intensive trials accord-

ing to precisely defined criteria. The ap-

proved trailer weights apply to vehicles in the

EU and generally for maximum speeds of 80

km/h (100 km/h in certain circumstances).

The figures may be different in other coun-

tries. All data in the official vehicle documen-

tation takes precedence over these data at all

times ››› .

Dr a

wb

ar loads

The maximum permitted drawbar load on the

ball joint of the towing bracket must not ex-

ceed 80 kg.

In the interest of road safety, we recommend

that you always tow approaching the maxi-

mum drawbar load. The response of the trail-

er on the road will be poor, if the drawbar

load is too small.

If the maximum permissible drawbar load

cannot be met (e.g. with small, empty and

light-weight single axle trailers or tandem

axle trailers with a wheelbase of less than 1

metre), a minimum of 4% of the actual trailer

weight is legally required for the drawbar

load. WARNING

● For s af

ety reasons, do not exceed the 80

km/h (50 mph) limit. This is also valid in

countries where higher speeds are permitted.

● Never exceed the maximum trailer weights

or the drawb

ar load. If the permissible axle

load or the permissible total weight is excee-

ded, the driving characteristics of the vehicle

may change, leading to accidents, injuries

and damage to the vehicle. Wheels

Ty

r

e pressure, snow chains, wheel

bolts Tyre pressures

The s

tic

k

er with the tyre pressure values can

be found on the inside of the fuel tank flap.

The tyre pressure values given there are for

cold tyres. The slightly raised pressures of

warm tyres must not be reduced. ››› The pressure for win

t

er

tyres is 0.2 bar

(2.9 psi / 20 kPa) higher than that of summer

tyres.

Snow chains

Snow chains may be fitted only to the front

wheels, and only for the following tyres: »

267

Technical data

Advice

Operation

Emergencies

Safety

Page 270 of 308

Technical data195/65 R15Chains with links of maximum 15 mm

205/55 R16Chains with links of maximum 15 mm

205/50 R17Chains with links of maximum 15 mm

225/45 R17Chains with links of maximum 9 mm

225/40 R18Chains with links of maximum 9 mm

225/35 R19Chains with links of maximum 7 mm

205/55 R17Snow chains are not permitted

225/45 R18Snow chains are not permitted

Wheel bolts

Af

t

er the wheel

s have been changed, the

tightening torque of the wheel bolts should

be checked as soon as possible with a torque

wrench ››› . The tightening torque for steel

and al lo

y

wheels is 120 Nm. WARNING

● Check the ty

re pressure at least once per

month. Checking the tyre pressure is very im-

portant. If the tyre pressure is too high or too

low, there is an increased danger of accidents

- particularly at high speeds.

● If the tightening torque of the wheel bolts

is t

oo low, they could loosen while the vehi-

cle is in motion. Risk of accident! If the tight-

ening torque is too high, the wheel bolts and

threads can be damaged. Note

We recommend that you ask your Technical

Serv ic

e for information about appropriate

wheel, tyre and snow chain size. 268