ECU Seat Mii 2013 Service Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2013, Model line: Mii, Model: Seat Mii 2013Pages: 306, PDF Size: 4.3 MB

Page 232 of 306

230Vehicle care and maintenance

Removing and fitting the navigator holder

● Press the holder release button ⇒ Fig. 129 (arrow).

● Remove the holder from the dash panel in an upwards direction.

● If necessary, close the opening with the corresponding cover.

In order to fit the holder, place it on the opening from above and press in a

downwards direction until it engages with a click. ⇒

.

WARNING

Any distraction may lead to an accident, with the risk of injury. Operating

the navigator could distract you from the traffic.

● Always stay alert and drive responsibly.

● Select volume settings that allow you to easily hear signals from out-

side the vehicle at all times (e.g. emergency service sirens).

● Setting the volume too high may cause damage to your hearing. This

also applies if the device is set to high volumes for a short period.

WARNING

Journey instructions and traffic signals shown on the navigation system

may differ to the current traffic situation.

● Traffic signals and driving regulations take precedence over journey

instructions and indications from the navigation system.

● Adjust your speed and driving style to visibility, road, traffic and

weather conditions.

WARNING

If the navigator is not securely fastened in position, it could be sent fly-

ing around the vehicle in the event of sharp braking, sudden manoeuvres

or accident, causing injury.

● Fit the navigator housing safely on the corresponding opening on the

dash panel.

● Always place the navigator securely in its holder or store it safely in

the vehicle.

CAUTION

An unsuitable gradient and angle of vision setting can damage the naviga-

tor.

● When adjusting the navigation device, move it with care and not beyond

its limits.

CAUTION

Excessively high or low outside temperatures can affect the Portable Navi-

gation System operation or damage the device.

● Always take the Portable Navigation System with you when you leave the

vehicle to protect it from excessively high or low temperatures and intense

sunlight.

CAUTION

Humidity can damage the Portable Navigation System connections on the

dash panel.

● Do not clean the holder for the navigation device with moist products.

Use a dry cloth.

Note

SEAT recommends taking the Portable Navigation System with you when

you leave the vehicle to prevent it from being stolen.

Page 243 of 306

241

Practical information

In case of emergency

Introduction

Additional information and warnings:

● Braking, stopping and parking ⇒ page 134

● Emergency locking and unlocking ⇒ page 244

● Vehicle tools ⇒ page 247

● Change wheel ⇒ page 252

WARNING

A faulty vehicle in traffic represents a risk of accident for the driver and

for other road users.

● Stop the vehicle safely as soon as possible. Park the vehicle a safe

distance from surrounding traffic to lock all the doors in case of an emer-

gency. Turn on the hazard warning lights to warn other road users.

● Never leave children or disabled people alone in the vehicle if the

doors are to be locked. In case of an emergency, passengers will be trap-

ped inside the vehicle. Individuals locked in the vehicle can be exposed

to very high or very low temperatures.

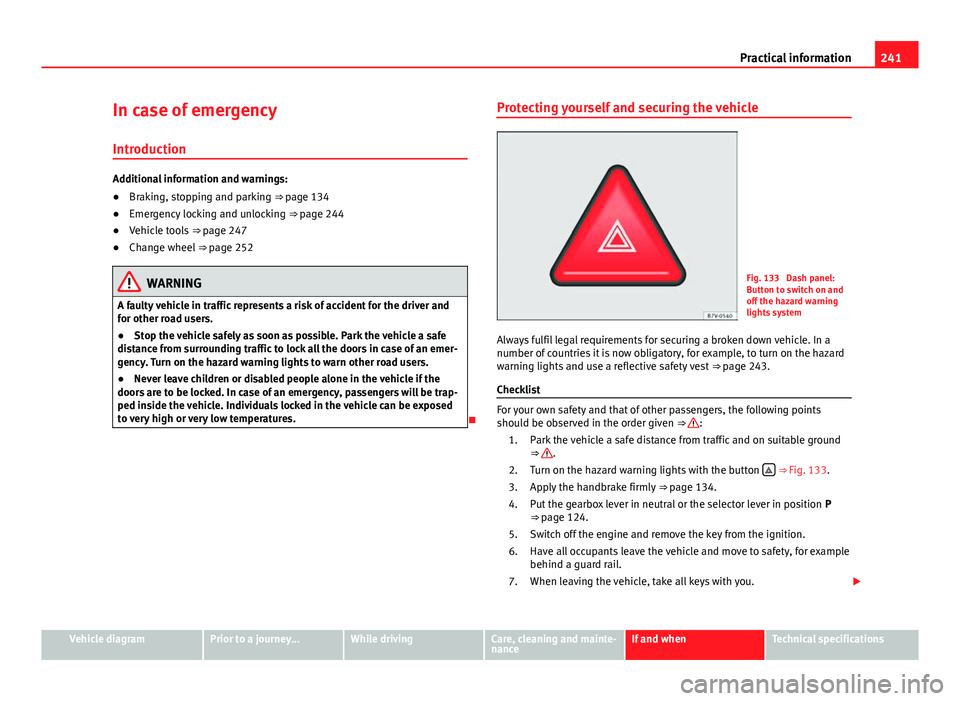

Protecting yourself and securing the vehicle

Fig. 133 Dash panel:

Button to switch on and

off the hazard warning

lights system

Always fulfil legal requirements for securing a broken down vehicle. In a

number of countries it is now obligatory, for example, to turn on the hazard

warning lights and use a reflective safety vest ⇒ page 243.

Checklist

For your own safety and that of other passengers, the following points

should be observed in the order given ⇒

:

1. Park the vehicle a safe distance from traffic and on suitable ground ⇒

.

2. Turn on the hazard warning lights with the button ⇒

Fig. 133.

3. Apply the handbrake firmly ⇒ page 134.

4. Put the gearbox lever in neutral or the selector lever in position P ⇒ page 124.

5. Switch off the engine and remove the key from the ignition.

6. Have all occupants leave the vehicle and move to safety, for example behind a guard rail.

7. When leaving the vehicle, take all keys with you.

Vehicle diagramPrior to a journey...While drivingCare, cleaning and mainte-

nanceIf and whenTechnical specifications

Page 245 of 306

243

Practical information

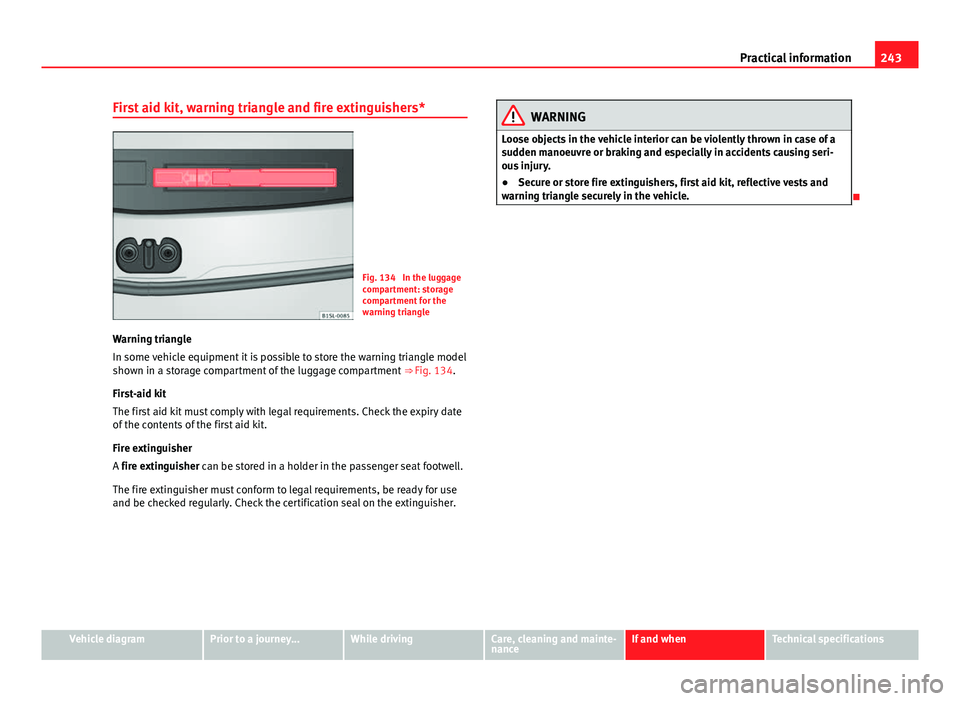

First aid kit, warning triangle and fire extinguishers*

Fig. 134 In the luggage

compartment: storage

compartment for the

warning triangle

Warning triangle

In some vehicle equipment it is possible to store the warning triangle model

shown in a storage compartment of the luggage compartment ⇒ Fig. 134.

First-aid kit

The first aid kit must comply with legal requirements. Check the expiry date

of the contents of the first aid kit.

Fire extinguisher

A fire extinguisher can be stored in a holder in the passenger seat footwell.

The fire extinguisher must conform to legal requirements, be ready for use

and be checked regularly. Check the certification seal on the extinguisher.

WARNING

Loose objects in the vehicle interior can be violently thrown in case of a

sudden manoeuvre or braking and especially in accidents causing seri-

ous injury.

● Secure or store fire extinguishers, first aid kit, reflective vests and

warning triangle securely in the vehicle.

Vehicle diagramPrior to a journey...While drivingCare, cleaning and mainte-

nanceIf and whenTechnical specifications

Page 249 of 306

247

Practical information

Vehicle tool kit*

Introduction

When securing the vehicle in case of a breakdown, please note the legal re-

quirements for each country.

Vehicle tool kit

For vehicles with a factory-fitted spare wheel or temporary spare wheel, in

addition to winter wheels, the luggage compartment may contain additional

vehicle tools ⇒ page 247.

Additional information and warnings:

● Working in the engine compartment ⇒ page 180

● In case of emergency ⇒ page 241

● Change wheel ⇒ page 252

● Tire Mobility Set ⇒ page 258

WARNING

When the vehicle tool kit, tire mobility set and spare wheel are loose in

the interior they can be violently thrown in case of a sudden manoeuvre

or braking and especially in accidents causing serious injury.

● Ensure that the vehicle tool kit, the tire mobility set and the spare

wheel or temporary spare wheel are safely secured in the luggage com-

partment.

WARNING

Unsuitable or damaged vehicle tools can cause injury or accidents.

● Never work with inappropriate or damaged tools.

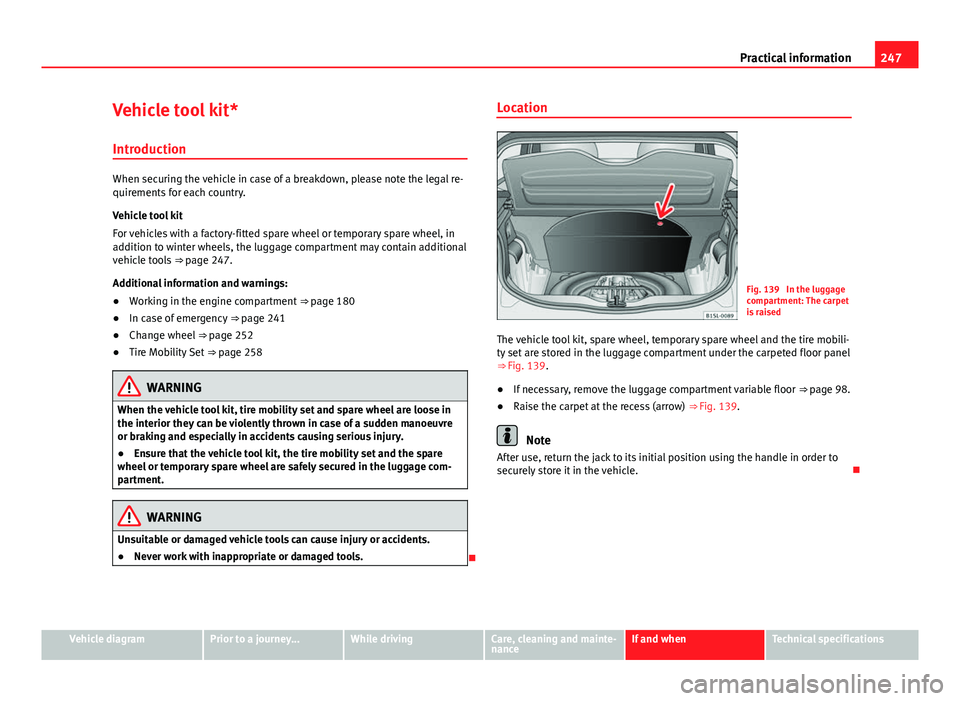

Location

Fig. 139 In the luggage

compartment: The carpet

is raised

The vehicle tool kit, spare wheel, temporary spare wheel and the tire mobili-

ty set are stored in the luggage compartment under the carpeted floor panel

⇒ Fig. 139.

● If necessary, remove the luggage compartment variable floor ⇒ page 98.

● Raise the carpet at the recess (arrow) ⇒ Fig. 139.

Note

After use, return the jack to its initial position using the handle in order to

securely store it in the vehicle.

Vehicle diagramPrior to a journey...While drivingCare, cleaning and mainte-

nanceIf and whenTechnical specifications

Page 250 of 306

248Practical information

Access the tools and anti-puncture kit in vehicles equipped

with SEAT SOUND 7 speakers (with subwoofer)*

●Open the rear lid and lift the shelf.

● If necessary, remove the luggage compartment variable floor

⇒ page 101.

● Lift up the carpet from the recess and remove it from the luggage com-

partment.

● Disconnect the subwoofer’s speaker cable.

● Remove the whole hand wheel located in the centre of the subwoofer by

rotating it anti-clockwise.

● Remove the subwoofer, under which the tools and anti-puncture kit are

stowed.

● After you have used them, put the the tools and anti-puncture kit back

exactly as you found them so that the speaker will sit properly in its hous-

ing.

● Fit the subwoofer in the direction of the arrow, with the “FRONT” indica-

tion facing forwards.

● Reconnect the speaker cable and firmly rotate the securing wheel clock-

wise so that the subwoofer system is firmly in place. Components

Fig. 140 Components of the vehicle tool kit

The vehicle tool kit depends on the vehicle equipment. The following is a

description for a vehicle with all options.

The individual elements of the vehicle tool kit ⇒ Fig. 140

Screwdriver with hexagon socket in the handle for screwing and un-

screwing the wheel bolts once loosened. The screwdriver bit is inter-

changeable. The screwdriver may be found underneath the wheel span-

ner.

Adapter for anti-theft bolt. SEAT recommend you carry the wheel bolt

adapter in the vehicle tool kit at all times. The code number of the anti-

theft wheel bolt is stamped on the front of the adapter. In case it is lost,

another adapter can be ordered using this number. Note the anti-theft

bolt code for the wheels and keep it in a place other than the vehicle.

Towline anchorage, removable.

Wire hook for pulling off the wheel cover, integral hubcaps and the

wheel bolt caps.

1

2

34

Page 256 of 306

254Practical information

If the wheel bolt is very tight, you may be able to loosen it by pushing down

on the end of the wheel brace carefully with your foot. Hold on to the vehicle

for support and take care not to slip.

Loosening wheel bolts

● Fit the wheel brace as far as it will go over the wheel bolt ⇒ Fig. 144.

● Hold the wheel brace at the end and rotate the bolt approximately one

turn anticlockwise ⇒

.

Loosening anti-theft wheel bolts

For wheels with full hubcap, the anti-theft wheel lock must be threaded into

position ⇒ Fig. 145 2

before mounting the hubcap. Otherwise it will not be

possible to mount the full hubcap.

● Take the adapter for anti-theft wheel bolts out of the vehicle tool kit.

● Insert the adapter onto the wheel bolt ⇒ Fig. 145. Push it on as far as it

will go.

● Fit the wheel brace onto the adapter as far as possible.

● Hold the wheel brace at the end and rotate the bolt approximately one

turn anticlockwise ⇒

.

Important information about wheel bolts

The wheel rims and bolts have been designed to be fitted to factory op-

tions. If different rims are fitted, the correct wheel bolts with the right length

and correctly shaped bolt heads must be used. This ensures that wheels are

fitted securely and that the brake system functions correctly.

In some circumstances, wheel bolts from the same model vehicle should

not be used.

Wheel bolt tightening torque

The prescribed tightening torque for wheel bolts for steel and alloy wheels

is 110 Nm. Have the tightening torque of the wheel bolts checked as soon

as possible with a reliable torque wrench. If wheel bolts are rusty and it is difficult to tighten them, the threads should

be replaced and cleaned before checking the tightening torque.

Never grease or lubricate wheel bolts or the wheel hub threads. Although

they have been tightened to the prescribed torque, they could come loose

while driving.

WARNING

If the wheel bolts are not fitted correctly they could be released while

driving leading to loss of vehicle control and serious damage.

● Only use wheel bolts which correspond to the wheel rims in question.

● Never use different wheel bolts.

● The bolts and threads should be clean, free of oil and grease and easy

to thread.

● To loosen and tighten the wheel bolts, always use the wheel brace

supplied with the vehicle.

● Loosen the wheel bolts only about one turn before raising the vehicle

with the jack.

● Never grease or lubricate wheel bolts or the wheel hub threads. Al-

though they have been tightened to the prescribed torque, they could

come loose while driving.

● Never loosen the bolted joints of wheel rims with bolted ring trims.

● If the wheel bolts are not tightened to the correct torque, they may

come loose while driving, and the bolts and rims may come out. If the

tightening torque is too high, the wheel bolts and threads can be dam-

aged.

Page 259 of 306

257

Practical information

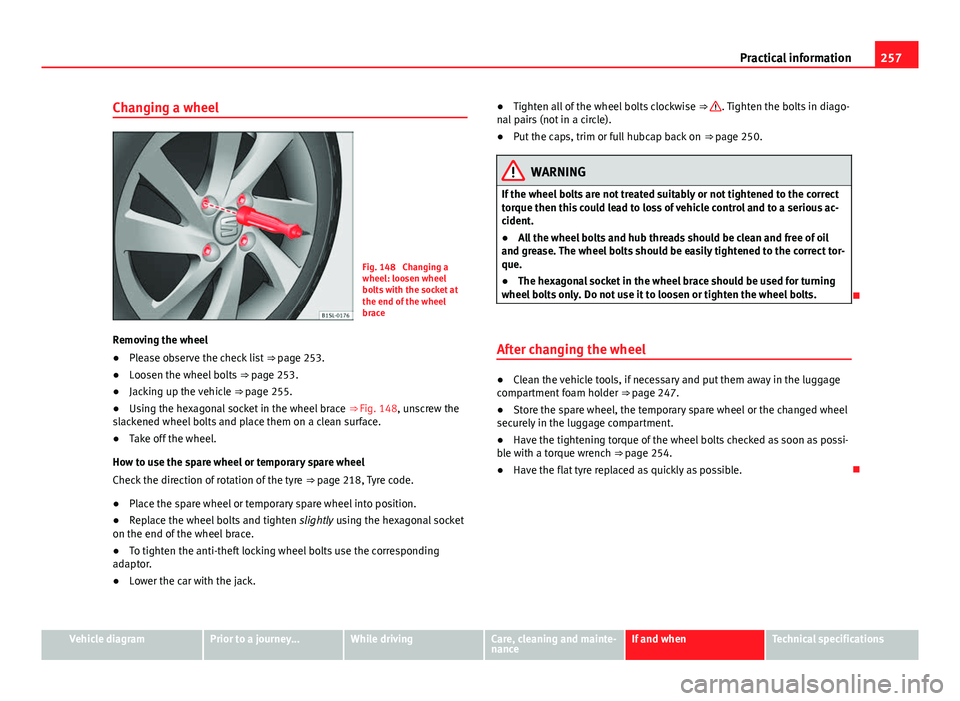

Changing a wheel

Fig. 148 Changing a

wheel: loosen wheel

bolts with the socket at

the end of the wheel

brace

Removing the wheel

● Please observe the check list ⇒ page 253.

● Loosen the wheel bolts ⇒ page 253.

● Jacking up the vehicle ⇒ page 255.

● Using the hexagonal socket in the wheel brace ⇒ Fig. 148, unscrew the

slackened wheel bolts and place them on a clean surface.

● Take off the wheel.

How to use the spare wheel or temporary spare wheel

Check the direction of rotation of the tyre ⇒ page 218, Tyre code.

● Place the spare wheel or temporary spare wheel into position.

● Replace the wheel bolts and tighten slightly using the hexagonal socket

on the end of the wheel brace.

● To tighten the anti-theft locking wheel bolts use the corresponding

adaptor.

● Lower the car with the jack. ●

Tighten all of the wheel bolts clockwise ⇒

. Tighten the bolts in diago-

nal pairs (not in a circle).

● Put the caps, trim or full hubcap back on ⇒ page 250.

WARNING

If the wheel bolts are not treated suitably or not tightened to the correct

torque then this could lead to loss of vehicle control and to a serious ac-

cident.

● All the wheel bolts and hub threads should be clean and free of oil

and grease. The wheel bolts should be easily tightened to the correct tor-

que.

● The hexagonal socket in the wheel brace should be used for turning

wheel bolts only. Do not use it to loosen or tighten the wheel bolts.

After changing the wheel

● Clean the vehicle tools, if necessary and put them away in the luggage

compartment foam holder ⇒ page 247.

● Store the spare wheel, the temporary spare wheel or the changed wheel

securely in the luggage compartment.

● Have the tightening torque of the wheel bolts checked as soon as possi-

ble with a torque wrench ⇒ page 254.

● Have the flat tyre replaced as quickly as possible.

Vehicle diagramPrior to a journey...While drivingCare, cleaning and mainte-

nanceIf and whenTechnical specifications

Page 262 of 306

260Practical information

Bottle of sealant 1)

Spare tyre valve

The valve insert remover 1

has a gap at the lower end for a valve insert.

The valve insert can only be screwed or unscrewed in this way. This also ap-

plies to its replacement part 11

.

Preparation

Checklist

Before filling a tyre, complete the following operations in the order given

⇒

:

1. In the event of a puncture, park the vehicle as far as possible from traffic and on flat, suitable ground.

2. Apply the handbrake firmly ⇒ page 134.

3. Stop the engine and remove the key from the ignition ⇒ page 119.

4. Manual gearbox: Select a gear ⇒ page 124.

5. Have all vehicle occupants get out of the vehicle and wait in a safe place (for example, behind the safety barrier).

6. Switch on the hazard warning lights and set the warning triangle in position ⇒ page 241. Observe legal requirements.

7. Check whether a repair is possible using the Tyre Mobility Set ⇒ page 258

8. If the luggage compartment is full: take the baggage out of the vehi- cle.

9. Remove the tire mobility set from the luggage compartment.

10. Apply the sticker ⇒ Fig. 149 2

from the tire mobility set to the dash

panel where it can be seen clearly.

11. Do not remove foreign objects, e.g. screws or nails, from the tyre.

1011WARNING

Failure to follow the checklist prepared for your own safety could lead to

accidents and severe injuries.

● Always complete the operations given in the checklist and observe

the general rules of safety.

Sealing and inflating a tyre

Sealing a tyre

● Unscrew the tyre valve cap.

● Use the corresponding enclosed extractor ⇒ Fig. 149 1

to unscrew the

tyre valve insert. Place the valve insert on a clean surface.

● Vigorously shake the sealant bottle ⇒ Fig. 149 10

for several seconds.

● Screw the inflator tube ⇒ Fig. 149 3 securely into the sealant bottle in

a clockwise direction. The seal on the mouth of the bottle moves automati-

cally.

● Remove the lid from the filling tube ⇒ Fig. 149 3

and screw the open

end of the tube into the tyre valve.

● Hold the tyre sealant can upside down and fill the complete contents of

the can into the tyre.

● Remove the tyre sealant bottle from the valve.

● Screw the valve insert again with the corresponding enclosed extractor

⇒ Fig. 149 1

into the tyre valve.

Inflating the tyre

● Securely screw the tyre inflator tube ⇒ Fig. 149 5

of the compressor in-

to the tyre valve.

● Check whether the air bleed screw ⇒ Fig. 149 7

is closed.

1)

A compressor may also be included.

Page 263 of 306

261

Practical information

● Start the vehicle engine and leave it running.

● Attach the connector ⇒ Fig. 149 9

to a 12 volt socket of the vehicle

⇒ page 117.

● Connect the air compressor with the ON/OFF switch ⇒ Fig. 149 8

.

● Keep the air compressor running until it reaches 2.0 to 2.5 bar

(29-36 psi / 200-250 kPa) ⇒

. Maximum operation time 8 minutes ⇒ .

● Disconnect the air compressor.

● If it is not possible to achieve an air pressure of 2.0 to 2.5 bar

(29-36 psi / 200-250 kPa), unscrew the tyre inflator tube from the tyre valve.

● Move the vehicle some 10 metres forwards or backwards so that the

sealant is evenly distributed in the tyre interior.

● Securely screw the compressor tyre inflator tube into the tyre valve and

repeat the inflation process.

● If the indicated pressure can still not be reached, the tyre is too badly

damaged. The tyre cannot be sealed with the anti-puncture kit. Do not con-

tinue driving. You should obtain professional assistance ⇒

.

● Disconnect the air compressor and unscrew the flexible inflator tube

from the tyre valve.

● When the tyre pressure is between 2.5 and 2.0 bars, immediately con-

tinue driving without exceeding 80 km/h (50 mph).

● After 10 minutes, Check the pressure again ⇒ page 261.

WARNING

When inflating the wheel, the air compressor and the inflator tube may

become hot.

● Protect hands and skin from hot parts.

● Do not place the hot flexible inflator tube or hot air compressor on

flammable material.

WARNING (Continued)

● Allow them to cool before storing the device.

● If it is not possible to inflate the tyre to at least 2.0 bars (29 psi /

200 kPa), the tyre is too badly damaged. The sealant is not in a good con-

dition to seal the tyre. Do not continue driving. Seek specialist assis-

tance.

CAUTION

Switch off the air compressor after a maximum of 8 operational minutes to

avoid overheating! Before switching on the air compressor again, let it cool

for several minutes.

Check after 10 minutes of driving

Screw the inflator tube ⇒ Fig. 149 5 again and check the pressure on the

gauge 6.

1.3 bar (19 psi / 130 kPa) and lower:

● Stop the vehicle! The tyre cannot be sealed sufficiently with the tyre mo-

bility set.

● You should obtain professional assistance ⇒

.

1.4 bar (20 psi / 140 kPa) and higher:

● Set the tyre pressure to the correct value again ⇒ page 210.

● Carefully resume your journey until you reach the nearest specialised

workshop without exceeding 80 km/h (50 mph).

● Have the damaged tyre replaced.

Vehicle diagramPrior to a journey...While drivingCare, cleaning and mainte-

nanceIf and whenTechnical specifications

Page 272 of 306

270Practical information

Complete operations only in the sequence given:

6.Turn the bulb holder ⇒ Fig. 155 in the direction of the arrow, in an

anticlockwise direction as far as it will go and remove it, along with

the bulb, pulling backwards.

7.Replace the faulty bulb by a new identical bulb.

8.Insert the bulb holder in the headlight and turn it clockwise as far

as the stop.

9.Plug the connector 1 into the bulb holder. The connector must au-

dibly click into place.

Complete operations only in the sequence given:10.Replace the wheel arch trim into its position.

11.Place the expansive rivet in the wheel arch trim and bumper and

press it completely inwards ⇒ Fig. 154 A.

12.Securely screw the 2 retaining screws

⇒ Fig. 154 (arrows) with a

screwdriver.