Seat Mii 2014 Owner's manual

Manufacturer: SEAT, Model Year: 2014, Model line: Mii, Model: Seat Mii 2014Pages: 219, PDF Size: 4.19 MB

Page 171 of 219

Wheels and tyresTyre code (example)Meaning

TREADWEAR 220Relative service life of the tyre, with respect to specific US standard test.

TRACTION ABraking capacity of tyre on wet surface (AA, A, B or C).

TEMPERATURE ATyre temperature resistance at higher test speeds (A, B or C).

If the tyre has other markings, these are specific tyre manufacturer codes or specific national codes, e.g. for Brazil or China.

a)

The letters TIN refer to the tyre serial number.

Tyres with directional tread pattern

Tyres with directional tread pattern have

been designed to operate best when rotating

in only one direction. An arrow on the tyre

sidewall indicates the direction of rotation on

tyres with directional tread. Always observe

the direction of rotation indicated when

mounting the wheel. This guarantees opti-

mum grip and helps to avoid aquaplaning,

grip, noise and wear.

If the tyre is mounted in the opposite direc-

tion of rotation, drive with extreme caution,

as the tyre is no longer being used correctly.

This is of particular importance when the

road surface is wet. Change the tyre as soon

as possible or remount it with the correct di-

rection of rotation.

Tyre load rating

The load rating code indicates the maximum

load in kilogrammes each wheel can carry

(load capacity). 425 kg

462 kg

487 kg

515 kg

545 kg

615 kg

Speed rating

The speed rating indicates the maximum

speed permitted for the tyres. max. 150 km/h (93 mph)

max. 160 km/h (99 mph)

max. 170 km/h (106 mph)

max. 180 km/h (112 mph)

max. 190 km/h (118 mph)

max. 200 km/h (124 mph)

max. 210 km/h (130 mph)

max. 240 km/h (149 mph)

max. 240 km/h (149 mph)

78

81

83

85

87

91

P

Q

R

S

T

U

H

V

Z max. 270 km/h (168 mph)

max. 300 km/h (186 mph)

Some manufacturers use the letters “ZR” for

tyres with a maximum authorised speed

above 240 km/h.

Snow chains When using snow chains, applicable local

legislation and maximum permitted speed

limits must be observed.

In winter weather, snow chains not only help

to improve grip but also improve the braking

capacity.

The fitting of chains is permitted

only on

front wheels and with the following combi-

nation

s of wheel trims and tyres :

»

W

Y

169

Technical specifications

Advice

Operation

Safety

Page 172 of 219

AdviceTyre sizeWheel rim

165/70 R145 J x 14 offset of 35175/65 R14

SEAT recommends you ask a technical serv-

ice for further information on wheel, tyre and

chain sizes.

Wherever possible use fine-link chains meas-

uring less than 15 mm including the lock.

Remove wheel hub covers and trim rings be-

fore fitting snow chains

››› . The wheel bolts

should be covered with caps for safety rea-

sons. These are available from technical serv-

ices.

Temporary spare wheel

For technical reasons, snow chains must not

be used on the compact temporary spare

wheel ›››

page 165.

If it is necessary to fit chains with the tempo-

rary spare wheel in use, install the wheel on

the rear axle in the event of a fault in a front

wheel. Then, fit the rear wheel that is free, in-

stead of the damaged front wheel. In this sit-

uation, observe the rotating direction of the

wheels. SEAT recommends attaching the

snow chains before fitting the wheel. WARNING

The use of unsuitable or incorrectly fitted

chains could lead to serious accidents and

damage.

● Always the appropriate snow chains.

● Observe the fitting instructions provided by

the snow chain manufacturer.

● Never exceed the maximum permitted

speeds when driving with snow chains. CAUTION

● Remove the snow chains to drive on roads

without snow. Otherwise they will impair ve-

hicle handling, damage the tyres and wear

out very quickly.

● Wheel rims may be damaged or scratched if

the chains come into direct contact with

them. SEAT recommends the use of covered

snow chains. Note

Snow chains are available in different sizes

according to the vehicle type. Emergencies

In case of emergency First aid kit, warning triangle and fire

extinguishers* Fig. 120

In the luggage compartment: stor-

age compartment for the warning triangle Warning triangle

In some vehicle equipment it is possible to

store the warning triangle model shown in a

storage compartment of the luggage com-

partment

››› Fig. 120 .

Fir s

t-aid kit

The first aid kit must comply with legal re-

quirements. Check the expiry date of the con-

tents of the first aid kit.

170

Page 173 of 219

Emergencies

Fire extinguisher

A fire extinguisher can be stored in a holder

in the passenger seat footwell.

The fire extinguisher must conform to legal

requirements, be ready for use and be

checked regularly. Check the certification

seal on the extinguisher. WARNING

Loose objects in the vehicle interior can be vi-

olently thrown in case of a sudden manoeu-

vre or braking and especially in accidents

causing serious injury.

● Secure or store fire extinguishers, first aid

kit, reflective vests and warning triangle se-

curely in the vehicle. Protecting yourself and securing the

vehicle

Fig. 121

Dash panel: Button for switching the

hazard lights warning system on and off. Always fulfil legal requirements for securing a

broken down vehicle. In a number of coun-

tries it is now obligatory, for example, to turn

on the hazard warning lights and use a re-

flective safety vest

››› page 170.

For your own safety and that of other passen-

gers, the following points should be ob-

served in the order given:

Park the vehicle a safe distance from

traffic and on suitable ground ››› .

Turn on the hazard warning lights with

the button

››› Fig. 121.

Apply the handbrake firmly ››› page 89.

Put the gearbox lever in neutral or the

selector lever in position N ››› page 93.

1.

2.

3.

4. Switch off the engine and remove the

key from the ignition.

Have all occupants leave the vehicle and

move to safety, for example behind a

guard rail.

When leaving the vehicle, take all keys

with you.

Place an emergency warning triangle to

indicate the position of your vehicle to

other road users.

Allow the engine to cool and check if a

specialist is required.

When being towed with the hazard warning

lights on, a change in direction or traffic lane

can be indicated as usual using the turn sig-

nal lever. The hazard lights will be interrup-

ted temporarily.

Examples of when to use the hazard warning

lights:

● If the vehicles ahead suddenly slow down

or reach the end of a traffic jam, to warn the

vehicles behind.

● In case of an emergency.

● If the vehicle breaks down.

● When tow-starting or towing.

Always comply with the applicable laws re-

garding the use of hazard warning lights.

If the hazard warning lights are not working,

you must use an alternative method of »

5.

6.

7.

8.

9.

171Technical specifications

Advice

Operation

Safety

Page 174 of 219

Advice

drawing attention to your vehicle. This meth-

od must comply with traffic legislation. WARNING

A faulty vehicle in traffic represents a risk of

accident for the driver and for other road

users.

● Stop the vehicle safely as soon as possible.

Park the vehicle a safe distance from sur-

rounding traffic to lock all the doors in case of

an emergency. Turn on the hazard warning

lights to warn other road users.

● Never leave children or disabled people

alone in the vehicle if the doors are to be

locked. In case of an emergency, passengers

will be trapped inside the vehicle. Individuals

locked in the vehicle can be exposed to very

high or very low temperatures. WARNING

The components of the exhaust system reach

very high temperatures. This could cause a

fire and considerable damage.

● Always park your vehicle so that no part of

the exhaust system can come in contact with

flammable materials (such as dried grass or

fuel). Note

● The vehicle battery will discharge and run

down if the hazard warning lights remain on

for too long (even with the ignition turned

off). ●

For some vehicles, the brake lights will

blink when braking suddenly at speeds of ap-

proximately 80 km/h (50 mph) to alert vehi-

cles to the rear. If braking continues, the haz-

ard warning lights system will automatically

be turned on at a speed of less than approxi-

mately 10 km/h (6 mph). The brake lights re-

main lit. Upon accelerating, the hazard warn-

ing lights will be automatically turned off. Vehicle tool kit*

Introduction When securing the vehicle in case of a break-

down, please note the legal requirements for

each country.

Vehicle tool kit

For vehicles with a factory-fitted spare wheel

or temporary spare wheel, in addition to win-

ter wheels, the luggage compartment may

contain additional vehicle tools

››› page 172. WARNING

When the vehicle tool kit, tire mobility set

and spare wheel are loose in the interior they

can be violently thrown in case of a sudden

manoeuvre or braking and especially in acci-

dents, causing serious injury.

● Ensure that the vehicle tool kit, the tire mo-

bility set and the spare wheel or temporary spare wheel are safely secured in the luggage

compartment.

WARNING

Unsuitable or damaged vehicle tools can

cause injury or accidents.

● Never work with inappropriate or damaged

tools. Location

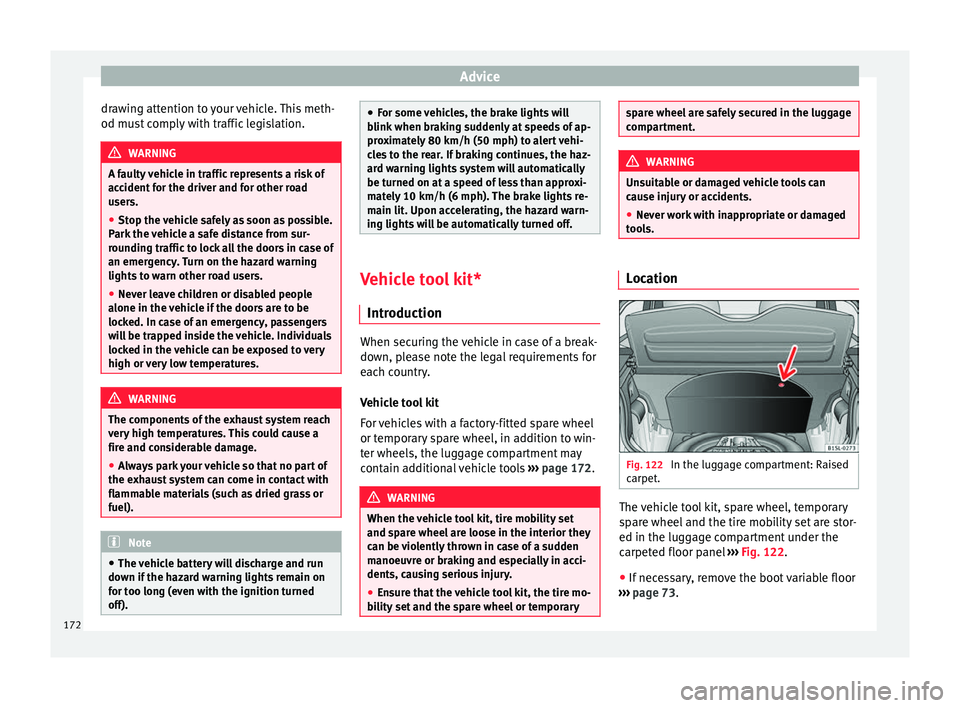

Fig. 122

In the luggage compartment: Raised

carpet. The vehicle tool kit, spare wheel, temporary

spare wheel and the tire mobility set are stor-

ed in the luggage compartment under the

carpeted floor panel

›››

Fig. 122 .

● If nec

essary, remove the boot variable floor

››› page 73.

172

Page 175 of 219

Emergencies

● Raise the carpet at the recess (arrow)

››› Fig. 122 . Note

After use, return the jack to its initial position

using the handle in order to securely store it

in the vehicle. Accessing the vehicle tool kit and tyre

mobility system in vehicles fitted with

the SEAT SOUND 7 speaker system

(with subwoofer)*

●

Open the boot hatch and lift the shelf.

● If necessary, remove the boot variable floor

››› page 76 .

● Lif t

up the carpet from the recess and re-

move it from the luggage compartment.

● Disconnect the subwoofer’s speaker cable.

● Completely remove the hand-controlled

wheel from the centre of the subwoofer

speaker by turning it anti-clockwise.

● Take out the subwoofer, which is on top of

the tools and tyre mobility system.

● When finished, place the tools and system

back in the same way and place as before to

ensure the speaker sits properly in its hous-

ing. ●

Place the subwoofer in the direction of the

arrow and with the word “FRONT” facing for-

ward.

● Reconnect the speaker cable and firmly ro-

tate the securing wheel clockwise so that the

subwoofer is firmly in place.

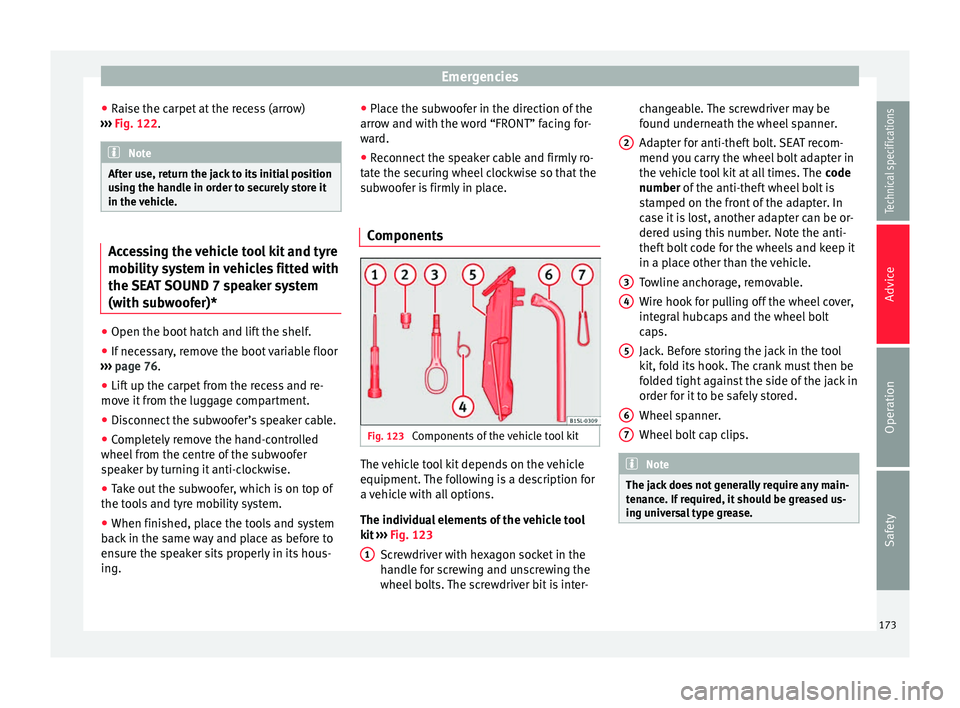

Components Fig. 123

Components of the vehicle tool kit The vehicle tool kit depends on the vehicle

equipment. The following is a description for

a vehicle with all options.

The individual elements of the vehicle tool

kit

›

›› Fig. 123

Sc

rewdriver with hexagon socket in the

handle for screwing and unscrewing the

wheel bolts. The screwdriver bit is inter-

1 changeable. The screwdriver may be

found underneath the wheel spanner.

Adapter for anti-theft bolt. SEAT recom-

mend you carry the wheel bolt adapter in

the vehicle tool kit at all times. The

code

number of the anti-theft wheel bolt is

s t

amped on the front of the adapter. In

case it is lost, another adapter can be or-

dered using this number. Note the anti-

theft bolt code for the wheels and keep it

in a place other than the vehicle.

Towline anchorage, removable.

Wire hook for pulling off the wheel cover,

integral hubcaps and the wheel bolt

caps.

Jack. Before storing the jack in the tool

kit, fold its hook. The crank must then be

folded tight against the side of the jack in

order for it to be safely stored.

Wheel spanner.

Wheel bolt cap clips. Note

The jack does not generally require any main-

tenance. If required, it should be greased us-

ing universal type grease. 2

3

4

5

6

7

173

Technical specifications

Advice

Operation

Safety

Page 176 of 219

Advice

Changing a wheel Introduction Some vehicle versions and models do not

have a factory-fitted jack or box spanner. In

this case, we recommend consulting a Speci-

alised workshop to change the wheel.

You should only change the wheels yourself if

the vehicle is parked in a safe place, you are

familiar with the procedure and safety stand-

ards and you have all the necessary tools!

Otherwise, you should seek professional as-

sistance.

WARNING

Changing a wheel can be dangerous, espe-

cially on the hard shoulder. Please observe

the following rules to minimise the risk of in-

jury:

● Stop the vehicle safely as soon as possible.

Park at a safe distance from surrounding traf-

fic to change a wheel.

● When changing a wheel, keep all passen-

gers, and particularly children, a safe dis-

tance away from the work area.

● Turn on the hazard warning lights to warn

other road users.

● Ensure the ground on which you park is flat

and solid. If necessary, support the jack on a

wide solid base. ●

If you are changing a wheel yourself, you

should be familiar with the required proce-

dure. Otherwise, you should seek professio-

nal assistance.

● Only use suitable tools that are not dam-

aged when changing a wheel.

● Always stop the engine, apply the hand-

brake lever firmly and place the selector lever

in position P, or engage a gear for a manual

gearbox to reduce the risk of the vehicle mov-

ing accidentally.

● Have the tightening torque of the wheel

bolts checked as soon as possible with a reli-

able torque wrench. WARNING

If the wheel trims are not appropriate or not

fitted correctly, they could cause major acci-

dents or damage.

● Incorrectly mounted wheel trims may come

off while driving and endanger other road

users.

● Damaged trims must never be mounted on

the wheels.

● Always ensure that the brake ventilation

and cooling is not cut off or blocked. This is

also valid if hubcaps are fitted later. If there

is not enough air, you may require signifi-

cantly longer braking distances. CAUTION

Remove and remount wheel trims taking care

to avoid damage to the vehicle. Hubcaps

Fig. 124

Remove the hubcap of the steel

wheel trim In order to access the wheel bolts, first re-

move the hubcap.

Removing and fitting the hubcap

● To remove , take the vehicle tool kit wire

hook and att

ach it to the edge of the wheel

trim ››› Fig. 124

.

● Remove the trim by pulling it in the direc-

tion of the arrow.

● To replace the hubcap , press the hubcap

against the trim until it clicks into place.

174

Page 177 of 219

Emergencies

The caps protect the wheel bolts and should

be remounted after changing the tyre.

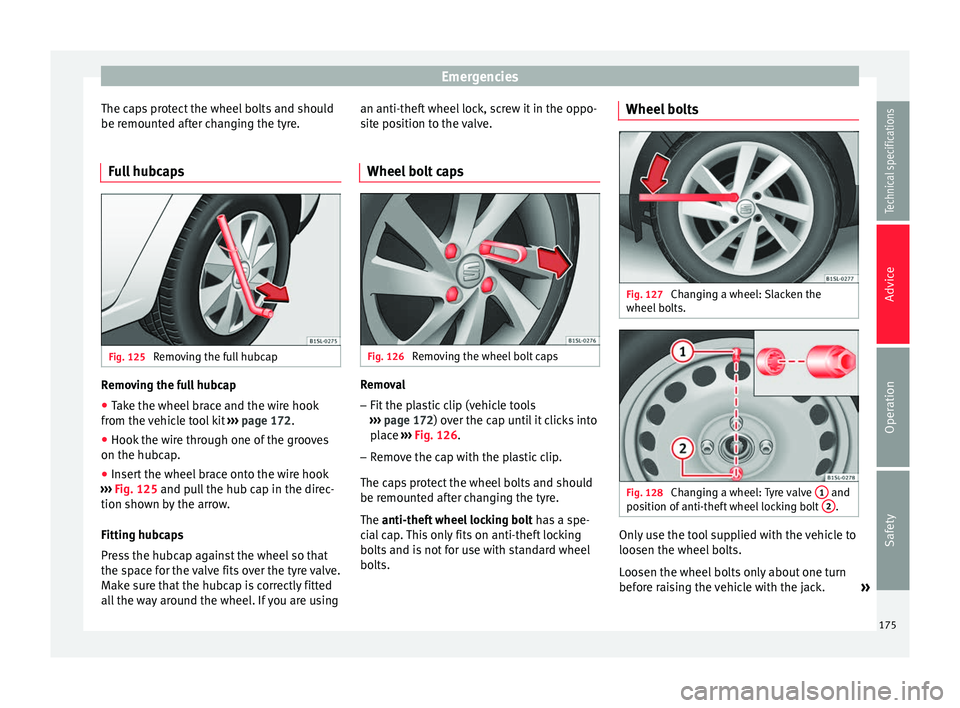

Full hubcaps Fig. 125

Removing the full hubcap Removing the full hubcap

● Take the wheel brace and the wire hook

from the vehicle tool kit ››› page 172.

● Hook the wire through one of the grooves

on the hubcap.

● Insert the wheel brace onto the wire hook

››› Fig. 125 and pull the hub cap in the direc-

tion sho wn b

y the arrow.

Fitting hubcaps

Press the hubcap against the wheel so that

the space for the valve fits over the tyre valve.

Make sure that the hubcap is correctly fitted

all the way around the wheel. If you are using an anti-theft wheel lock, screw it in the oppo-

site position to the valve.

Wheel bolt caps Fig. 126

Removing the wheel bolt caps Removal

– Fit the plastic clip (vehicle tools

››› page 172 ) over the cap until it clicks into

p l

ace ››› Fig. 126.

– Remove the cap with the plastic clip.

The caps protect the wheel bolts and should

be remounted after changing the tyre.

The anti-theft wheel locking bolt ha

s a spe-

cial cap. This only fits on anti-theft locking

bolts and is not for use with standard wheel

bolts. Wheel bolts

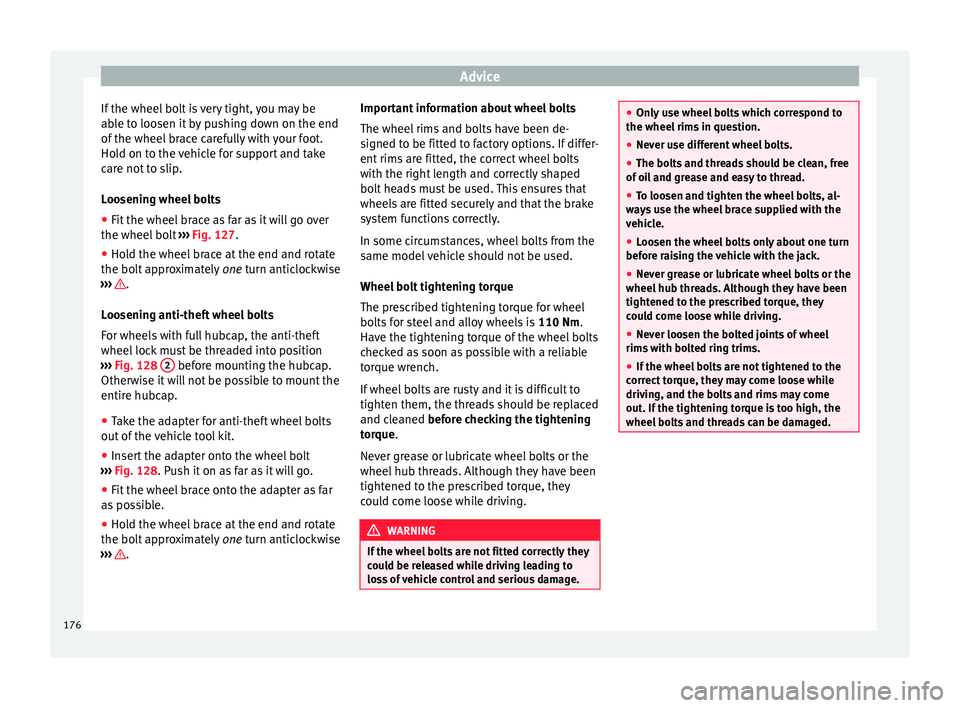

Fig. 127

Changing a wheel: Slacken the

wheel bolts. Fig. 128

Changing a wheel: Tyre valve 1 and

position of anti-theft wheel locking bolt 2 .

Only use the tool supplied with the vehicle to

loosen the wheel bolts.

Loosen the wheel bolts only about one turn

before raising the vehicle with the jack.

»

175

Technical specifications

Advice

Operation

Safety

Page 178 of 219

Advice

If the wheel bolt is very tight, you may be

able to loosen it by pushing down on the end

of the wheel brace carefully with your foot.

Hold on to the vehicle for support and take

care not to slip.

Loosening wheel bolts

● Fit the wheel brace as far as it will go over

the wheel bolt ››› Fig. 127 .

● Ho l

d the wheel brace at the end and rotate

the bolt approximately one turn anticlockwise

››

› .

Loosening anti-theft wheel bolts

For wheels with full hubcap, the anti-theft

wheel lock must be threaded into position

››› Fig. 128 2 before mounting the hubcap.

Otherwise it will not be possible to mount the

entire hubcap.

● Take the adapter for anti-theft wheel bolts

out of the vehicle tool kit.

● Insert the adapter onto the wheel bolt

››› Fig. 128 . Push it on as far as it will go.

● Fit the wheel

brace onto the adapter as far

as possible.

● Hold the wheel brace at the end and rotate

the bolt approximately one turn anticlockwise

››

› . Important information about wheel bolts

The wheel rims and bolts have been de-

signed to be fitted to factory options. If differ-

ent rims are fitted, the correct wheel bolts

with the right length and correctly shaped

bolt heads must be used. This ensures that

wheels are fitted securely and that the brake

system functions correctly.

In some circumstances, wheel bolts from the

same model vehicle should not be used.

Wheel bolt tightening torque

The prescribed tightening torque for wheel

bolts for steel and alloy wheels is

110 Nm

.

Hav e the tight

ening torque of the wheel bolts

checked as soon as possible with a reliable

torque wrench.

If wheel bolts are rusty and it is difficult to

tighten them, the threads should be replaced

and cleaned before checking the tightening

tor

que.

Never grease or lubricate wheel bolts or the

wheel hub threads. Although they have been

tightened to the prescribed torque, they

could come loose while driving. WARNING

If the wheel bolts are not fitted correctly they

could be released while driving leading to

loss of vehicle control and serious damage. ●

Only use wheel bolts which correspond to

the wheel rims in question.

● Never use different wheel bolts.

● The bolts and threads should be clean, free

of oil and grease and easy to thread.

● To loosen and tighten the wheel bolts, al-

ways use the wheel brace supplied with the

vehicle.

● Loosen the wheel bolts only about one turn

before raising the vehicle with the jack.

● Never grease or lubricate wheel bolts or the

wheel hub threads. Although they have been

tightened to the prescribed torque, they

could come loose while driving.

● Never loosen the bolted joints of wheel

rims with bolted ring trims.

● If the wheel bolts are not tightened to the

correct torque, they may come loose while

driving, and the bolts and rims may come

out. If the tightening torque is too high, the

wheel bolts and threads can be damaged. 176

Page 179 of 219

Emergencies

Raising the vehicle with the jack Fig. 129

Jack position points Fig. 130

Jack mounted on the left rear part of

the vehicle The jack may be applied only at the jacking

points shown (marks on chassis)

››› Fig. 129 .

A lw

ays the relevant jacking point for the

wheel to be changed ››› .

Raise the vehicle using only the designated

jacking points. WARNING

If the vehicle is not correctly raised, it could

fall off the jack causing serious injury. Please

observe the following rules to minimise the

risk of injury:

● You should only use a jack approved by

SEAT for your vehicle. Other jacks, even those

approved for other SEAT models, might slip

out of place.

● The ground should be firm and flat. If the

ground is sloped or soft then the vehicle

could slip and fall off the jack. If necessary,

support the jack on a wide solid base.

● If the ground is slippery, such as tiles,

place a non-slip surface (a floor mat, for in-

stance) beneath the jack to avoid slipping.

● Only fit the jack at the prescribed jacking

points. The claw of the jack should grip the

reinforcement nerve on the underbody

››› Fig. 130.

● You shou

ld never place a body limb such as

an arm or leg under a raised vehicle that is

solely supported by the jack.

● If you have to work underneath the vehicle,

you must use suitable stands additionally to

support the vehicle, there is a risk of acci-

dent!.

● Never raise the vehicle if it is tilting to one

side or the engine is running.

● Never start the engine when the vehicle is

raised. The vehicle may come loose from the

jack due to the engine vibrations. 177

Technical specifications

Advice

Operation

Safety

Page 180 of 219

Advice

Changing a wheel Fig. 131

Changing a wheel: loosen wheel

bolts with the socket at the end of the wheel

brace Removing the wheel

● Loosen the wheel bolts ››› page 175 .

● Jacking up the vehicle ››› page 177.

● Using the hexagonal socket in the wheel

brace ››› Fig. 131 , unscrew the slackened

wheel bo

lts and place them on a clean sur-

face.

● Take off the wheel.

How to use the spare wheel or temporary

spare wheel

Check the direction of rotation of the tyre

››› page 167, Tyre code.

● Plac

e the spare wheel or temporary spare

wheel into position. ●

Replace the wheel bolts and tighten slight-

ly using the hexagonal socket on the end of the wheel br

ace.

● To tighten the anti-theft locking wheel bolts

use the corresponding adaptor.

● Lower the car with the jack.

● Tighten all of the wheel bolts clockwise

››› . Tighten the bolts in diagonal pairs (not

in a circle).

● Put the caps, trim or full hubcap back on

››› page 174 . WARNING

If the wheel bolts are not treated suitably or

not tightened to the correct torque then this

could lead to loss of vehicle control and to a

serious accident.

● All the wheel bolts and hub threads should

be clean and free of oil and grease. The wheel

bolts should be easily tightened to the cor-

rect torque.

● The hexagonal socket in the wheel brace

should be used for turning wheel bolts only.

Do not use it to loosen or tighten the wheel

bolts. After changing the wheel

●

Clean the vehicle tools, if necessary and

put them away in the luggage compartment

foam holder ›››

page 172 . ●

St or

e the spare wheel, the temporary spare

wheel or the changed wheel securely in the

luggage compartment.

● Have the tightening torque of the wheel

bolts checked as soon as possible with a tor-

que wrench ››› page 176

.

● Have the flat tyre replaced as quickly as

possible.

Tyre repair

TMS (Tyre Mobility System)* The Anti-puncture kit* (Tyre Mobility System)

will reliably seal punctures caused by the

penetration of a foreign body of up to about

4 mm

in diameter.

Do not remove foreign ob-

j

ects, e.g. screws or nails, from the tyre.

After inserting the sealant residue in the tyre,

you must again check the tyre pressure about

10 minutes after starting the engine.

You should only use the tire mobility set if

the vehicle is parked in a safe place, you are

familiar with the procedure and you have the

necessary tire mobility set! Otherwise, you

should seek professional assistance.

The tyre sealant must not be used in the

following cases: ● If the wheel rim has been damaged.

178